In any commercial facility, from a bustling warehouse to a high-traffic loading dock, maximizing operational space and ensuring reliability are top priorities. Traditional overhead garage door openers, with their ceiling-mounted rails, often hinder high-stack storage and complicate infrastructure like vehicle lifts or fire sprinklers. This guide explains how a jackshaft garage door opener offers a superior solution for commercial applications. You will learn what a jackshaft opener is, its key benefits for your facility, what is required for installation, and how it delivers long-term value. As your respected partners in reliable service, Wilcox Door Service is committed to providing expert guidance to enhance your facility’s efficiency and security.

Understanding the Jackshaft Garage Door Opener

So, what makes a jackshaft opener different from the trolley systems you’re used to seeing?

Think of it this way: a traditional opener pulls your door along a ceiling track. A jackshaft opener, on the other hand, mounts neatly on the wall beside the door and applies rotational force directly to the door’s torsion bar—the spring-loaded rod that does the heavy lifting. This direct-drive mechanism is the key to its space-saving and powerful design, making it an ideal choice for commercial and industrial doors.

By moving the entire operator to the wall, this system instantly frees up overhead real estate. This isn’t just a small adjustment; it’s a fundamental change that can redefine how you utilize your facility’s vertical space, particularly in environments like distribution centers or automotive service bays where every inch counts.

Key Benefits for Commercial Facilities

For a busy loading dock or a packed maintenance bay, the practical advantages are immediate and significant. Switching to a jackshaft system unlocks several key operational benefits:

- Optimized Overhead Space: Removing the central rail allows you to install taller shelving, operate vehicle lifts without obstruction, and more easily route essential ceiling infrastructure like HVAC or sprinkler systems.

- Enhanced Safety and Security: Many commercial models are equipped with an automatic deadbolt that locks the door every time it closes. This provides an essential layer of physical security to prevent forced entry, a critical concern for any commercial property.

- Simplified Maintenance Access: With the motor mounted on the wall at a reachable height, technicians can perform service without needing a scissor lift, reducing both maintenance costs and operational downtime.

- Reduced Noise and Vibration: The direct-drive system has fewer moving parts than a chain-driven trolley. This results in noticeably quieter and smoother operation—a significant advantage in any work environment.

How Jackshaft Openers Transform Commercial Door Systems

To truly appreciate why a jackshaft garage door opener is a game-changer for commercial facilities, it’s important to understand its mechanics. The design eliminates the long rail and trolley system, mounting cleanly on the wall adjacent to the door.

This wall-mounted position is the secret to its simple and powerful operation. The opener connects directly to the door’s torsion bar and turns it, providing controlled, steady force to lift and lower even the heaviest commercial doors. For a real-world example, imagine a large, insulated sectional door at a cold storage facility. A jackshaft opener provides the consistent torque needed to operate that heavy door hundreds of times a day without the wear and tear a chain-driven system would experience.

By eliminating the overhead rail, the jackshaft opener frees up the entire ceiling area. This is a critical advantage for facilities with high-stack shelving, vehicle lifts, or complex overhead mechanicals.

Unpacking the Core Components

The reliability and strength of a commercial jackshaft opener come from its robust, purpose-built components.

- High-Efficiency Motor: Most modern jackshafts use a DC motor, known for quiet operation and a soft-start/soft-stop feature. This function gently accelerates and decelerates the door, drastically reducing the jarring that wears out hardware over time.

- Robust Gearbox: The motor’s power is channelled through a heavy-duty gearbox. This component converts the motor’s speed into the high-torque force required to turn the torsion bar smoothly and reliably.

- Direct-Drive Mechanism: This is the heart of the system. By connecting directly to the torsion bar, the design eliminates chains and belts, significantly reducing the number of moving parts and points of failure.

Fewer moving parts mean greater reliability, less vibration, and reduced noise—all adding up to a system you can count on in a demanding commercial environment.

The Power of Direct-Drive Operation

Consider a busy distribution center where a loading dock door may cycle hundreds of times daily. The direct-drive power of a jackshaft garage door opener is engineered for these high-cycle demands. It applies force evenly, avoiding the wear that can quickly destroy a trolley-based system under constant use.

This direct application of torque also ensures the door moves smoothly, without the shuddering common in older chain-driven units. This level of control is essential for managing massive, heavy industrial doors safely and efficiently.

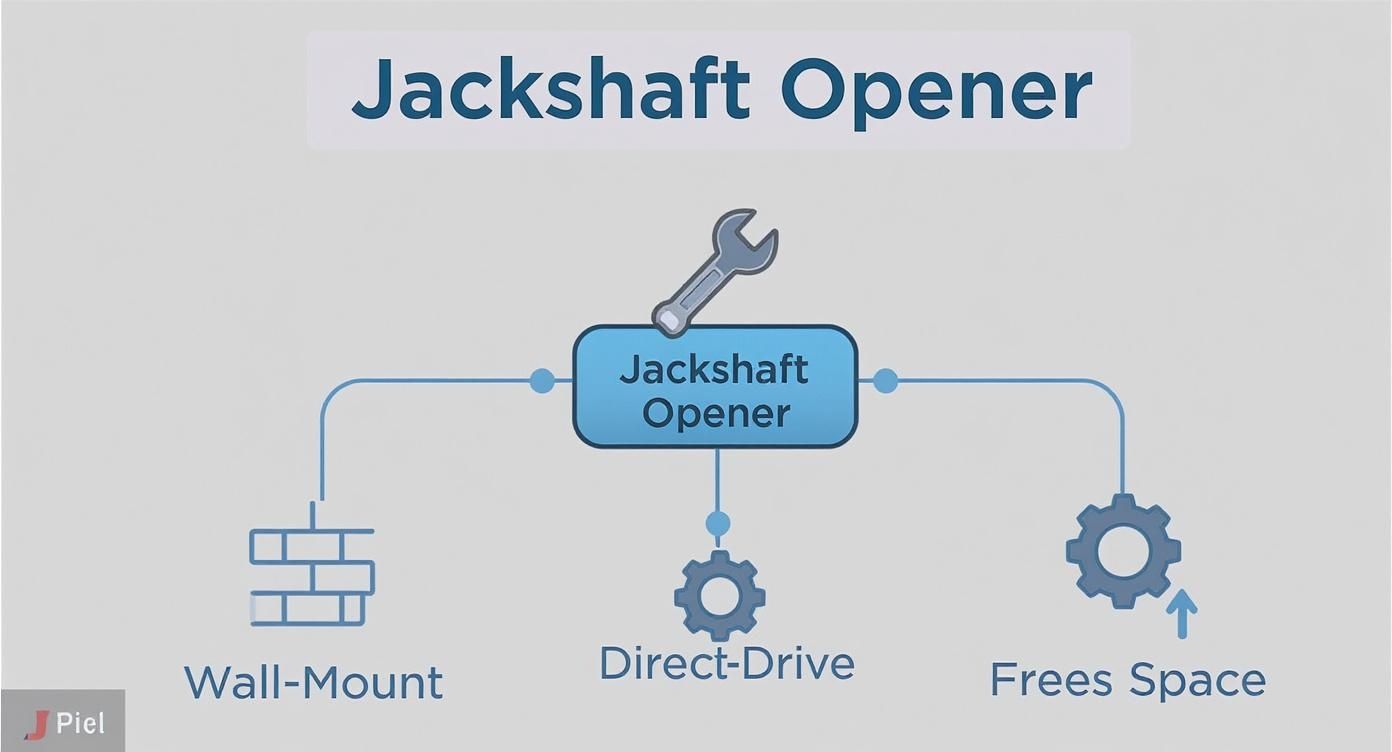

This infographic breaks down the principles that make the jackshaft opener so effective in a commercial setting.

Alt text: Infographic illustrating the benefits of a commercial jackshaft garage door opener, showing its wall-mount design and freed overhead space.

The wall-mount design, direct-drive mechanics, and clear ceiling space are interconnected advantages. Industry data shows that while jackshaft openers currently make up about 9% of the North American market, their adoption rate is climbing, particularly in commercial sectors where space optimization and reliability are paramount.

The smart mechanical design of a jackshaft system translates into real-world operational benefits that facility managers value. As your partners in reliable service, Wilcox Door Service can help you determine if this technology is the right solution for your facility.

Key Advantages for Your Commercial Facility

Choosing a jackshaft garage door opener over a traditional trolley system is a strategic decision that delivers tangible benefits to your daily operations. The true value lies in how it optimizes your facility’s space, enhances security, and simplifies your maintenance workflow.

By shifting the entire operator mechanism to the wall, you immediately reclaim valuable overhead real estate. For warehouses, distribution centers, and vehicle service bays, this is a game-changer.

Maximize Your Vertical Space

The most significant benefit is the elimination of the bulky central rail and motor hanging from the ceiling. This opens up numerous possibilities for using your vertical space more effectively.

- Taller Vehicle Access: Without a low-hanging operator, you can accommodate taller trucks and specialized equipment like forklifts with high masts, making loading docks more efficient and reducing accidental collisions.

- Unobstructed Storage: You gain the freedom to install high-stack shelving or pallet racking closer to the ceiling, maximizing every cubic foot of storage capacity.

- Simplified Infrastructure: It becomes far easier to install or service other overhead systems like fire sprinklers, HVAC ductwork, or lighting without a cumbersome garage door opener in the way.

Real-World Example: A distribution center that switched to jackshaft openers was able to increase its pallet racking height by an entire level, adding 15% more storage capacity in the same footprint. This simple change delayed the need for a costly facility expansion.

Simplify Maintenance and Reduce Downtime

In any commercial facility, uptime is critical. The wall-mounted design of a jackshaft opener makes routine service faster, safer, and less disruptive to your operations.

Technicians can access the motor and controls from the floor without requiring a scissor lift. This reduces service time, labor costs, and safety risks. Since the system has fewer moving parts—no long chain or belt to adjust—preventative maintenance is simpler and less frequent, meaning more uptime for your most critical doorways.

Jackshaft vs. Traditional Trolley Openers for Commercial Use

This table highlights the key differences between the two systems for commercial applications.

| Feature | Jackshaft Opener | Traditional Trolley Opener |

|---|---|---|

| Mounting Location | Wall-mounted next to the door. | Ceiling-mounted in the centre of the door. |

| Overhead Space | Frees up all overhead space, allowing for high-lift tracks, tall vehicles, and overhead storage. | Occupies significant overhead space, limiting vertical clearance and storage options. |

| Maintenance Access | Easily accessible from the floor for faster, safer servicing without specialized lifts. | Requires a ladder or lift for access, increasing service time and potential safety risks. |

| Mechanical Complexity | Simpler design with direct drive to the torsion bar; fewer moving parts like long chains or belts. | More complex system with a long rail, chain/belt, and trolley that can wear, stretch, or require frequent tensioning. |

| Security Features | Often includes an automatic deadbolt that physically locks the door, offering superior forced-entry protection. | Relies on the motor to keep the door closed; lacks a physical locking mechanism. |

| Ideal Use Cases | High-ceiling warehouses, auto service bays, facilities with overhead cranes, or any space needing maximum height. | Standard-height applications and facilities where overhead space is not a critical factor. |

| Installation Requirements | Requires adequate side room (approx. 8 inches) and a solid mounting surface next to the door. | Requires sufficient ceiling height and structural support for the motor and rail. |

For most commercial and industrial settings, the operational advantages of a jackshaft opener are clear.

Enhance Security and Safety

Jackshaft openers are engineered with the security of a commercial environment in mind.

- Automatic Deadbolt: Many commercial models feature a heavy-duty deadbolt that automatically engages every time the door closes. This physical lock is a powerful deterrent against forced entry, adding a critical layer of security.

- Cable Tension Monitor: This safety feature constantly monitors the door’s lifting cables. If it senses slack—a sign that a cable may have snapped—it instantly stops the door from moving, preventing a dangerous free-fall.

These features are a key reason jackshaft openers are integral to comprehensive strategies for access control for business security.

Alt text: A commercial jackshaft garage door opener installed on a wall next to a large warehouse door, highlighting its space-saving and secure design.

Market data reflects this shift toward more efficient and secure systems. Statistical analysis shows a clear trend toward energy-efficient solutions like jackshafts, with sales growth outpacing traditional openers in the commercial sector. This is largely due to their proven reliability and ability to meet modern energy efficiency mandates.

Preparing Your Site For a Jackshaft Opener Installation

A successful upgrade to a jackshaft garage door opener begins with a thorough site assessment. Before scheduling an installation, you must ensure your loading docks or service bays meet the unique structural and spatial requirements of these wall-mounted systems.

Unlike traditional overhead units, a jackshaft opener has specific needs. Confirming your site is ready beforehand prevents costly surprises and ensures a smooth transition. This preparation also allows for a more productive conversation with your service provider, ensuring all technical requirements are addressed from the start.

The Essential Site Readiness Checklist

Before a technician arrives, you can perform a quick preliminary check to determine if your door system is a good candidate for a jackshaft opener.

Here are the critical factors to assess:

- Torsion Bar System: This is the most important requirement. A jackshaft opener works by turning the door’s torsion bar directly. It is not compatible with doors that use an extension spring system (long springs running parallel to the horizontal tracks).

- Adequate Side-Room Clearance: The unit mounts on the wall next to the door, so it requires clear space. You will typically need 8 to 12 inches of unobstructed wall space on one side of the door.

- Nearby Power Source: The opener needs a dedicated electrical outlet. A professional installer will confirm the specific voltage requirements (e.g., 120V, 240V, or 480V for heavy-duty models), but a power source must be accessible near the mounting location.

Expert Insight: The wall structure is a crucial and often overlooked factor. The mounting point must be solid enough to handle the rotational force, or torque, generated by the motor. A weak wall surface can lead to vibration, equipment failure, or unsafe operation.

Alt text: Technician lubricating door, in this image you can see a jackshaft operator with ample side-room next to the stricture of the Commercial overhead door.

Structural and Door Compatibility

The type of door and wall construction play a significant role. The best-fit commercial doors for a jackshaft opener are vertical-lift and high-lift sectional doors, which are common in warehouses and distribution centers. These doors travel straight up the wall, providing the ideal mechanical setup for a direct-drive system. Standard lift doors may also be compatible, but a professional evaluation is required.

As you prepare your site, it is always wise to review general commercial safety guidelines to maintain a secure work environment.

Code Compliance and System Integration

For any commercial property, installation preparation goes beyond physical space. The new opener must integrate with your existing building systems and comply with local regulations.

- Fire Safety Integration: In many facilities, commercial doors are tied to the fire alarm system. Your new jackshaft opener must be compatible with these life-safety protocols.

- Building Codes: Local codes may have specific requirements for commercial door operators, covering safety sensors and emergency egress. Ensuring compliance is a key part of any professional installation.

This diligence is essential for any heavy equipment upgrade. For more detailed guidance, our article on heavy equipment installation safety tips provides valuable context.

As your respected partners, Wilcox Door can perform a comprehensive site assessment to confirm your facility is ready for a jackshaft upgrade.

Analyzing the Long-Term Cost and Maintenance

When evaluating a jackshaft garage door opener, looking beyond the initial purchase price is essential. For any commercial facility, the total cost of ownership tells the real story. From this perspective, a jackshaft system is a smart investment in operational efficiency that delivers returns for years.

A significant part of that return is the lighter maintenance load. Unlike trolley systems with chains or belts that stretch and require frequent tensioning, a jackshaft’s direct-drive design has fewer moving parts. This simpler, more robust mechanism naturally leads to fewer service calls and less downtime.

Building a Simple Preventative Maintenance Schedule

Thanks to its streamlined design, the preventative maintenance schedule for a jackshaft opener is less demanding than for trolley-based systems. The focus is on simple, routine health checks.

- Routine Lubrication: The main moving components, like the drive gear, require periodic lubrication to ensure smooth operation.

- Safety System Checks: Regularly testing the photo-eye sensors and the cable tension monitor is crucial to keep your personnel and property safe.

- Component Inspection: A quick visual inspection of the mounting hardware, motor housing, and electrical connections can help identify potential issues before they become problems.

This simplified upkeep means your maintenance team spends less time on doors and more time on other critical facility tasks. To learn more about maximizing equipment life, explore the benefits of a planned garage door maintenance program in our detailed guide.

Calculating the Long-Term Financial Benefits

The financial upside of a jackshaft opener becomes clear when you analyze lifecycle savings. These benefits contribute directly to your bottom line.

Real-World Example: A jackshaft opener’s value is measured in uptime. For a busy loading dock where a single hour of downtime can cost thousands in delayed shipments and idle labor, the reliability of a direct-drive system offers an immense return on investment.

Consider how the savings accumulate over time:

- Lower Energy Consumption: Many modern jackshaft openers use high-efficiency DC motors with soft-start/soft-stop technology. This reduces mechanical strain and draws less power, leading to savings on your facility’s energy bills.

- Fewer Repair Costs: With no chains to snap or trolleys to misalign, the most common failures of traditional systems are eliminated, saving on parts and emergency labor.

- Reduced Operational Downtime: In a commercial setting, a non-functioning door can halt operations. The superior reliability of a jackshaft garage door opener ensures your access points remain operational, protecting your workflow and revenue.

When you add it all up—lower energy use, fewer repairs, and maximized uptime—the higher initial cost is quickly justified as a cost-effective solution for any facility focused on long-term performance.

How to Choose the Right Commercial Jackshaft Opener

Selecting the right commercial jackshaft garage door opener involves matching the hardware to the unique demands of your facility. When this is done correctly, you are investing in reliability, safety, and long-term value. This checklist will guide you through what to look for.

Start by evaluating the door itself. A heavy, insulated industrial door that cycles hundreds of times a day requires a different class of operator than a lightweight door used infrequently. Understanding these operational demands is the most crucial first step.

Key Specifications to Evaluate

When comparing models, a few technical specifications are non-negotiable. These details determine if an opener can handle the daily workload and integrate with your building’s systems.

- Duty Cycle Rating: This specifies how many times a door can open and close per hour or day without overheating. A busy loading dock requires a continuous-duty operator, while a less-used storage bay may only need a standard-duty model.

- Required Horsepower: The horsepower (HP) must be sufficient to lift your door’s weight without strain. An undersized motor will fail prematurely and can create safety hazards.

- Voltage Compatibility: Commercial buildings have various power setups. Confirm whether you need a 120V, 240V, or 480V operator to match your facility’s electrical supply.

- Essential Features: Consider your daily workflow. Would a battery backup be critical during a power outage? Do you require smart controls for remote access or integration with your facility management software?

Critical Questions for Your Service Provider

Once you have a handle on your specifications, it’s time to consult an expert. A reliable service partner will help you navigate the options and ensure a successful installation. Be prepared with these questions:

Expert Insight: A partnership built on transparency is key. As your trusted advisors, we believe asking the right questions upfront is the foundation of a successful, long-term solution.

- What are the full warranty details? You need to understand what is covered and for how long. Knowing how to protect your investment can save you from unexpected costs. We cover this topic in our guide on how to protect your equipment warranty.

- How will this opener integrate with our current systems? Ask about compatibility with your existing access controls, security systems, or fire alarms to ensure seamless operation.

- What is the expected maintenance schedule? Understanding the ongoing service needs helps you budget for the total cost of ownership, not just the upfront price.

At Wilcox Door Service, we embody our message of “Respected Partners, Reliable Service.” Our team is ready to perform a professional site assessment to help you select the ideal jackshaft opener for your facility.

Got Questions? We’ve Got Answers.

When facility managers consider a jackshaft garage door opener, several key questions typically arise. It’s wise to understand the details of compatibility, cost, and safety before making a decision. Here are straightforward answers to common inquiries.

Can a Jackshaft Opener Be Installed on Any Commercial Garage Door?

Not on every door. The one non-negotiable requirement for a jackshaft opener is that the door must have a torsion bar system—the large spring-loaded bar running across the top of the door opening. This means they are not compatible with doors using side-mounted extension springs.

Additionally, the physical space must be suitable:

- Sufficient side room is needed to mount the unit, typically 8-12 inches of clear space.

- A solid wall structure is required to handle the motor’s rotational force (torque).

- They are most compatible with high-lift and full vertical-lift sectional doors, which are common in commercial buildings.

A professional site evaluation is the best way to confirm if your facility’s doors are ready for a jackshaft system.

Are Jackshaft Openers More Expensive Than Traditional Openers?

Initially, yes. The upfront purchase price of a commercial jackshaft opener is typically higher than a standard trolley system. However, the real value becomes apparent when you consider the total cost of ownership.

The sticker price is just the beginning. The true cost is measured in reliability, less downtime, and day-to-day efficiency—and that’s where a jackshaft opener really shines.

Over the long term, jackshaft openers often save money through lower energy consumption, reduced maintenance needs due to fewer moving parts, and superior durability in high-cycle environments. Furthermore, the value of the reclaimed overhead space for storage or equipment is a significant, often overlooked, financial benefit.

What Safety Features Are Standard on Jackshaft Openers?

Commercial jackshaft openers are equipped with safety features designed for demanding industrial settings. A key feature on many models is the automatic deadbolt lock, which physically secures the door every time it closes, providing a strong deterrent against forced entry.

They also typically include a cable tension monitor. This device detects any slack in the lifting cables and stops the door immediately to prevent it from falling. These features work in conjunction with industry-standard photo-eye sensors and auto-reverse functions, making them a top choice for both safety and security.

How Does a Jackshaft Opener Work During a Power Outage?

Maintaining operations during a power outage is critical for any business. Many commercial jackshaft models can be equipped with an integrated battery backup system, allowing the door to remain fully functional for several open-and-close cycles.

For units without a battery backup, a manual release mechanism is standard. This allows your team to safely open and close the door by hand, ensuring a power outage never brings your workflow to a complete halt.

At Wilcox Door Service, our experts are here to answer any other questions you have about whether a jackshaft garage door opener is the right choice for your facility. We are your trusted partner, providing reliable service and smart solutions to keep your operations running smoothly.

For a professional site assessment and a comprehensive quote, contact our team today.