This guide explains everything facility and property managers need to know about a fire rated door. You will learn why these doors are critical life-saving systems, how to understand their ratings and components, and the non-negotiable importance of annual inspections and drop testing. We’ll cover how proper maintenance protects you from liability and ensures the safety of your occupants, reinforcing our commitment as Respected Partners delivering Reliable Service.

Why Your Fire Rated Door Is a Critical Safety System

Think of a fire rated door as an active defender in your building’s life safety plan, not just a passive barrier. Its main purpose is to contain fire, smoke, and deadly heat, buying precious time for people to evacuate safely and for first responders to arrive. It’s not just the door slab itself, but a complete assembly—including the door, frame, and hardware—that all work in unison to compartmentalize a building during a fire. This is what stops a small incident from turning into a full-blown disaster.

A properly working system also limits property damage by keeping the fire contained where it started. For any facility manager, property manager, or building owner, that’s a huge deal, because the financial fallout from a widespread fire can be devastating.

Alt text: Silhouettes escaping a fire through a fire rated door, illustrating the door’s role in safety and protection.

Beyond Compliance: Liability, Safety, and Security

While meeting building codes is a legal must, the true value of these doors is measured in human safety, business continuity, and liability protection. A failed door assembly puts lives on the line and opens your organization up to serious legal and financial consequences.

The stakes are getting higher all the time. In January 2021 alone, California saw 297 fires burn over 1,171 acres—a figure 20 times the historical average. The nationwide economic toll is just as shocking, with property damage from fires hitting $21.9 billion in 2020. These numbers have pushed regulators to double down on mandating fire-rated doors as a core part of any fire prevention strategy. You can dig deeper into the data in a report from the Door & Access Systems Manufacturers Association.

Understanding Your Responsibility as a Property Owner or Manager

For property managers, facility owners, and organizations, the responsibility for maintaining these systems is clear and non-negotiable. Negligence in this area can lead to catastrophic outcomes. Your duty of care comes down to three key areas:

- Safety and Proper Function: The entire assembly, from the self-closing mechanism to the latching hardware, must work perfectly. A failure here directly endangers occupants.

- Liability and Compliance: Annual inspections and testing by a qualified professional are required by standards like NFPA 80. Documented proof of these inspections is your primary defense against claims of negligence should an incident occur.

- Security: In many commercial settings, a fire door is also a security barrier. Ensuring it closes and latches correctly prevents unauthorized access, protecting your assets and people.

A well-maintained fire rated door is a testament to your commitment to safety. It tells your tenants, employees, and inspectors that you put their well-being first.

Making Sense of Fire Ratings and Building Codes

Navigating the world of fire safety regulations can feel complex, but understanding the basics is essential for any property manager. When it comes to your facility’s fire rated doors, mastering the key standards isn’t just about compliance—it’s about ensuring your safety systems will actually perform in a crisis.

The good news? These codes and ratings are built on a foundation of common sense, all with one goal in mind: saving lives.

The Key Players in Fire Safety

In North America, two main organizations are the authority on fire door safety. Think of them as the rule-makers and the referees.

- The National Fire Protection Association (NFPA): This is the group that writes the rulebook. For fire doors, their most important document is NFPA 80, which is a technical standard that lays out the requirements for everything from installation and inspection to annual testing and maintenance.

- Underwriters Laboratories (UL): UL is the independent referee. They’re a global safety company that puts products through rigorous testing to certify they meet specific performance standards. When you see a UL label on a fire door assembly, it’s your proof that it has been tested and proven to withstand fire for a set amount of time.

Together, the NFPA’s codes and UL’s testing create a reliable system that ensures fire doors perform as expected when you need them most.

Decoding Fire Door Ratings

So, what exactly is a “fire rating”? In simple terms, it’s a measurement of time. The rating tells you precisely how long a door assembly—that’s the door, frame, and hardware together—can hold back a fire and stop it from spreading.

These ratings aren’t just arbitrary numbers. They are earned through intense, real-world testing where a complete door assembly is installed in a massive furnace and subjected to a controlled fire. Ratings like 20, 45, 60, 90, and 180 minutes are only given after the door successfully passes punishing tests like UL 10B and UL 10C.

At its core, the principle is straightforward: the door’s rating needs to be appropriate for the wall it’s sitting in.

Matching Door Ratings to Wall Requirements

You can’t just put any fire door in any wall. Building codes are very specific about this, requiring the door’s fire rating to be proportional to the wall’s fire-resistance rating. The door is essentially a planned opening in a fire-resistant barrier, so it has to be strong enough to maintain the integrity of that wall for a specific duration.

A great rule of thumb is that a fire door should have a rating that is 75% of the wall’s fire-resistance rating. This ensures the entire assembly—wall and door—works as a single, effective system to contain a fire.

Let’s look at a practical, real-world example. A stairwell in a commercial building is a critical escape route, so it’s often enclosed by walls built to withstand fire for 2 hours (120 minutes). Applying our rule of thumb, the code would require a 90-minute fire rated door (120 minutes x 0.75 = 90 minutes) for that opening.

This quick reference table can help you visualize how these pairings typically work in a commercial building.

Matching Fire Doors to Wall Ratings

| Door Fire Rating | Required Wall Rating | Typical Application Location |

|---|---|---|

| 20 Minutes | 1 Hour | Corridor doors, office doors opening into corridors |

| 45-60 Minutes | 1 Hour | Room enclosures, some corridor separations |

| 90 Minutes (1.5 Hours) | 2 Hours | Stairwell enclosures, openings between buildings |

| 180 Minutes (3 Hours) | 3-4 Hours | Walls separating major building sections or different occupancies |

Knowing which door goes where is absolutely essential for both safety and passing inspections. For a deeper dive into specific options, you can explore some of the best interior fire rated door choices available for different commercial needs.

Understanding these codes doesn’t just keep the fire marshal happy. It empowers you to make smart, informed decisions that truly protect your building and the people inside it.

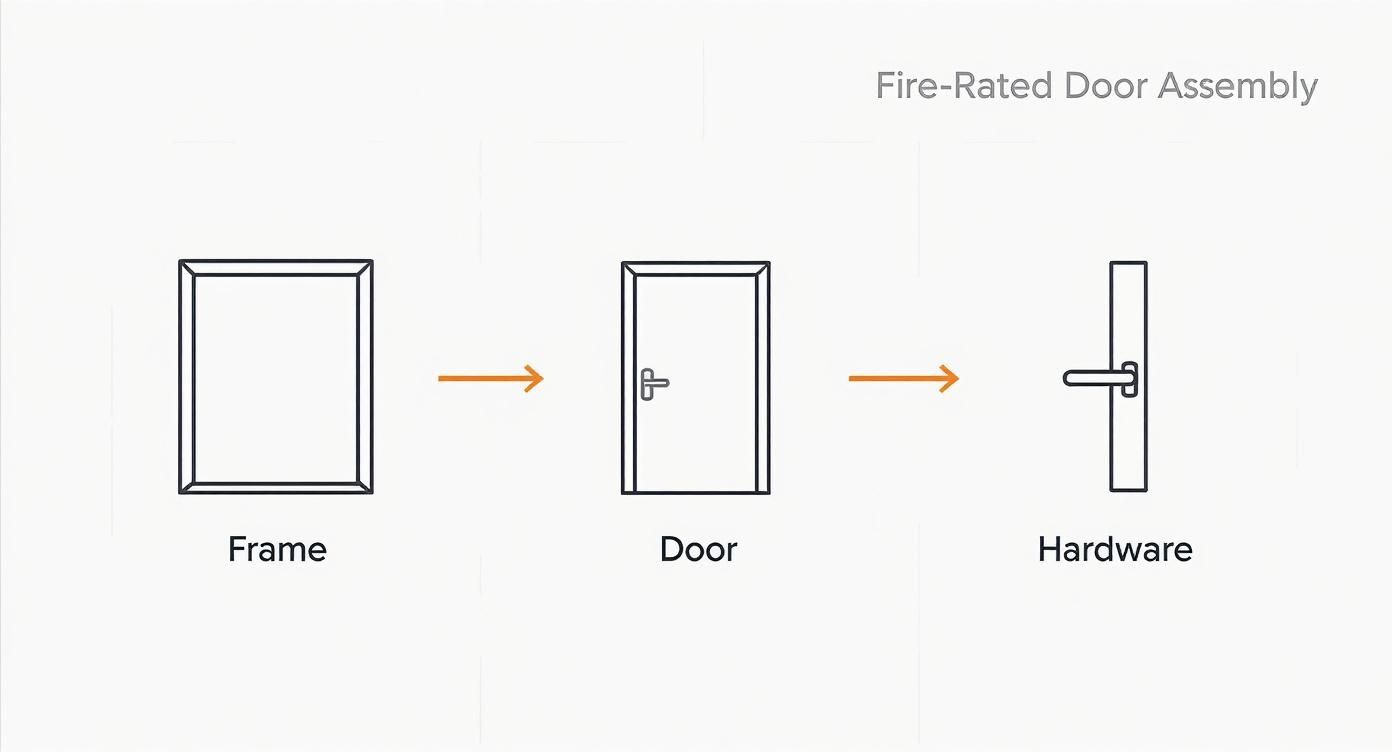

Understanding the Fire Rated Door Assembly

A compliant fire rated door isn’t just a heavy slab of steel—it’s a complete, engineered system. Every single component must work in perfect harmony to contain a fire. To grasp its life-saving role, you have to look past the door itself and see the entire assembly. The whole system is only as strong as its weakest link.

Think of it like a chain. One weak link—a non-rated hinge, a damaged frame, or a latch that doesn’t quite catch—and the whole thing fails under pressure. Every part, from the smallest screw to the heavy-duty frame, is tested and certified to perform as one cohesive unit. Getting this concept right is the first step to making sure your facility’s doors are truly ready to do their job.

The Core Components of a Fire Door System

A true fire rated door assembly breaks down into three essential parts. Each one has a specific job, and all of them must be rated and compatible to keep the system’s integrity intact.

- The Door Leaf (The Door Itself): This is your main barrier, usually built from steel, wood, or composites with a special fire-resistant core. Its whole purpose is to block flames and intense heat for its specific time rating.

- The Door Frame: The frame is what holds the door leaf in place within the wall. It must have a fire rating equal to or greater than the door it’s holding and be anchored securely to the wall so it doesn’t buckle or collapse in the fire.

- The Hardware: This is often the most complex part of the puzzle, covering all the moving bits. Every single piece of hardware—hinges, locks, latches, and closing devices—must be fire-rated and officially listed for use with that specific door and frame combination.

To get a better sense of how these pieces all come together in a professional installation, you can see the process of a sectional and fire door installation.

Why Self-Closing and Positive Latching Are Non-Negotiable

For any fire door to be compliant and effective, two functions are absolutely critical: it must be self-closing, and it must have a positive latch. Let’s unpack what these technical terms mean in the real world.

Self-Closing: A fire door has to swing shut on its own, without anyone needing to pull it. This is typically handled by a door closer, an arm-like mechanism at the top of the door. During a fire, people are focused on evacuating—they aren’t going to stop to close doors behind them. The self-closing mechanism guarantees the fire barrier is put back in place automatically.

Positive Latching: Just closing isn’t enough; the door must also lock itself into the frame. Positive latching means that as the door closes, a latch bolt engages with the frame, securing it. This is what prevents the immense pressure from a fire from simply blowing the door back open, which would make it completely useless.

One of the most common—and dangerous—code violations we see is a fire rated door propped open with a wedge or fire extinguisher. An open fire door is nothing more than a hole in a wall, offering zero protection.

The Role of Fire Rated Glazing

Some fire doors feature windows, which are known as glazing or vision lites, to provide visibility in hallways or stairwells. You can’t just put any old piece of glass in there. This is highly specialized glazing that is also fire-rated and tested to handle the same extreme conditions as the rest of the door.

There are strict rules under NFPA 80 that dictate the size and placement of this glass. How much glazing you’re allowed depends on the door’s overall fire rating. For example, a 90-minute door has much tighter limits on glass size than a 20-minute door does. This ensures the window doesn’t become the first point of failure. Every piece of rated glass will have a permanent marking etched on it, often called a “bug,” that shows its specific fire rating.

Why Annual Drop Testing Is Non-Negotiable for Liability and Safety

If your facility has rolling or sliding fire doors—common at loading docks or as large-scale dividers—there’s one maintenance task that is absolutely critical: the annual fire door drop test. This isn’t just a best practice; it’s a mandatory safety protocol spelled out in the NFPA 80 standard. Skipping this test isn’t just cutting a corner; it’s creating a massive liability for your organization and putting people and property at serious risk.

A drop test is simply a controlled, simulated emergency that confirms the door’s automatic closing system is ready to do its life-saving job without a hitch.

Simulating a Real-World Emergency

During a drop test, a certified technician will manually trigger the door’s release mechanism. This action mimics what would happen in a real fire, whether it’s a fusible link melting from the intense heat or an electronic signal coming from your building’s alarm system. A fusible link is a small, heat-sensitive device designed to melt at a specific temperature, releasing the door.

A successful test is one where the fire rated door closes completely on its own, descending at a safe, controlled speed until it seats firmly in the frame. This creates the solid barrier needed to stop fire and smoke in their tracks.

The Critical Role of a Documented Pass for Liability Protection

A properly documented, successful drop test is your best defence against hefty compliance fines and, more importantly, claims of negligence. It’s tangible proof you can show to a fire marshal or insurance inspector that you’re doing your due diligence to maintain your building’s life safety systems.

This record is more than just paperwork. It’s a clear statement that you are committed to safety and have taken the right steps to protect everyone and everything inside your facility. To dig deeper into this, you can learn more about why drop testing is critical for safety and compliance in industrial environments.

Understanding a Failed Test

But what happens if the door doesn’t close properly? A failed drop test is a major red flag. It means a critical safety system has failed, and the door is immediately considered non-compliant and out of service until it’s properly repaired and can pass a re-test.

Common culprits behind a failed test include:

- Obstructions: Debris, clutter, or even improperly stored equipment blocking the door’s path. For example, pallets or machinery left too close to a loading dock fire door.

- Mechanical Issues: Things like damaged tracks, incorrect spring tension, or frayed release cables.

- Release Mechanism Failure: A fusible link that’s painted over and won’t melt, or a faulty connection to the fire alarm system.

A failed drop test is an urgent call to action. The door offers zero fire protection until a qualified technician can diagnose the problem, make the necessary repairs using manufacturer-approved parts, and officially document a successful re-test.

Ignoring a failed test is a gamble you can’t afford to take. In a real fire, a door that fails to close could mean the difference between a small, contained incident and a devastating loss of life and property.

This whole process really shows how a fire door assembly is a system where every single component has to work together perfectly. As the diagram below illustrates, the frame, the door, and the hardware are all interconnected. If one part fails, the whole system fails.

Alt text: Diagram of a fire rated door assembly showing how the door, frame, and hardware work together for compliance.

The drop test isn’t just about checking the door slab; it’s about verifying the entire system’s ability to activate and seal an opening just as it was designed to.

Implementing a Maintenance and Recordkeeping Plan

True compliance for your fire rated door systems is about more than just a single annual test. To keep these life-saving assemblies ready for action and to prove your due diligence to inspectors, you need a consistent maintenance and recordkeeping plan. Think of it as your operational guide and your legal shield, all in one.

A solid plan doesn’t need to be complex. It starts with simple, regular visual checks that anyone on your facility maintenance team can perform. Catching minor issues early through these routine inspections can prevent them from becoming major liabilities down the road.

Alt text: A workspace illustration showing a checklist and calendar, representing a fire rated door maintenance plan.

Your Regular Visual Checklist

Making these simple checks a part of your team’s weekly or monthly walkthroughs can make a huge difference. Here are the most critical items to keep an eye on:

- Clear Path: Is the door’s swing path completely free of obstructions? Nothing—not a garbage bin, a stack of boxes, or even a doorstop—should ever block a fire door from closing and latching. This is especially important around loading docks.

- Intact Hardware: Give all the hardware a quick visual scan. Check that the closing device is attached, the latch bolts are present, and the hinges look secure. Any loose or missing parts are an immediate red flag.

- Door and Frame Condition: Look for obvious signs of damage, like deep dents in a steel door or splintering on a wood one that could compromise its integrity. The frame should also be secure and free from damage.

- Legible Labels: The certification labels on both the door and the frame must be visible and easy to read. These labels are the only official proof of the component’s fire rating. Never, ever paint over them.

Creating an Ironclad Documentation Trail

The paperwork is just as important as the physical maintenance. Your fire door logbook is your compliance shield—it’s the first thing a fire marshal or insurance investigator will ask to see after an incident. Meticulous records are your proof of a commitment to safety and adherence to NFPA 80 standards.

To streamline this process, many facilities are now using modern solutions like property management apps for compliance to keep everything organized and accessible.

For every single fire rated door in your facility, your log should include:

- A unique identifier for the door (e.g., “Loading Dock 3 North Wall”).

- The date of every inspection and test performed.

- The name and company of the certified technician who did the work.

- Detailed results of the test (Pass/Fail).

- A full description of any problems found and the corrective actions taken.

- The date the repairs were finished and the results of the successful re-test.

This level of detail creates an undeniable history of responsible management. It shows that you not only find issues but also fix them promptly and professionally.

“Your fire door logbook is more than a record; it’s a verifiable account of your commitment to life safety. In the eyes of an inspector or insurer, if it isn’t documented, it didn’t happen.”

By pairing routine visual checks with diligent, detailed recordkeeping, you build a powerful program that protects your people, your property, and your organization’s reputation.

Frequently Asked Questions About Fire Rated Doors

When you’re responsible for a facility’s safety and compliance, fire rated doors are a hot topic. As your trusted partner, our job is to give you clear, straight answers to the questions we hear most often from property managers and business owners. Let’s tackle some of the big ones.

Can I Modify or Paint Over a Fire Rated Door?

This is a big one, and the answer is a hard no. A fire rated door is a complete, certified assembly. Any field modification that isn’t explicitly approved—like drilling holes for a new sign, adding a non-rated kick plate, or painting over the certification label—instantly voids its fire rating.

Think of that label as the door’s birth certificate. It’s the only official proof that the entire assembly meets critical safety standards. If an inspector can’t read that label, the door is non-compliant. Period. Any changes have to be done by a qualified pro using approved, fire-rated parts to keep the system working as designed. Unauthorized tweaks don’t just create a compliance headache; they create a serious safety hazard and a massive liability.

What Happens If a Fire Door Fails Its Drop Test?

A failed drop test is a red flag that demands immediate action. It officially means the door is non-compliant and must be taken out of service until it’s professionally repaired. This isn’t just a suggestion; NFPA 80 is very clear that the door cannot be considered operational until it passes a documented retest.

A qualified technician needs to find the root cause of the failure. It could be anything from a blocked track or a faulty release mechanism to incorrect spring tension or even a painted-over fusible link. Once the problem is pinpointed, the technician must fix it using only manufacturer-approved components. The whole event—the initial failure, the diagnosis, the repair, and the successful retest—needs to be carefully documented in your fire door logbook to prove you’ve taken corrective action.

How Do I Know Which Fire Rating My Door Needs?

Figuring out the right fire rating for a door isn’t a guessing game. It’s dictated by the fire-resistance rating of the wall it’s installed in, as laid out by national and local building codes. A good rule of thumb is that the door needs a rating that is 75% of the wall’s rating.

For example, stairwells are critical escape routes and are often built inside 2-hour fire-rated walls. To maintain that protective barrier, the opening would typically need a 90-minute fire rated door. While this guideline is helpful, the only way to know for sure is to consult your building’s life safety plans or have a professional fire door inspector assess the location.

Is There a Difference Between a Fire Door and a Smoke Door?

Yes, and it’s a critical distinction. They are engineered to fight two different, but equally dangerous, threats.

A fire rated door is built and tested to block intense flames and radiant heat for a set amount of time. Its main job is structural containment—stopping the fire itself from spreading.

A smoke door, on the other hand, is all about stopping the spread of smoke and toxic gases, which are often the deadliest part of a fire. These doors use special seals or gaskets around the edges to block the gaps that smoke would otherwise pour through. While many modern fire doors now include smoke seals (making them a fire and smoke assembly), not all smoke doors are rated to stop a fire. Both are essential parts of a complete life safety system.

Your facility’s safety, security, and liability protection hinge on every component working exactly as it should. If you need to schedule a professional inspection, repair, or drop test for your fire doors, trust the experts. As Wilcox Door Service Inc., we are your Respected Partners in ensuring reliable, code-compliant service. Contact us today to ensure your fire doors are ready to protect what matters most.