A loading ramp dock is the critical bridge connecting your facility to the supply chain. This guide will walk you through everything you need to know, from understanding the different types of equipment to selecting, installing, and maintaining the perfect system for your operations. You’ll learn how to choose between permanent dock levelers and flexible portable ramps, calculate the right weight capacity, and implement essential safety features to keep your team protected and your workflow efficient.

Understanding Your Loading Dock’s Role

The term loading ramp dock often describes the entire system, but it can also refer specifically to the ramp itself—that inclined surface bridging the gap between a truck and your warehouse floor. Think of it as the handshake between your facility and the world of commerce. A well-functioning system is the heart of a productive supply chain, preventing delays, protecting your team, and keeping goods moving.

When this system works correctly, inventory flows smoothly, delivery schedules are met, and operational costs stay in check. Conversely, a poorly designed or malfunctioning dock can cause significant bottlenecks, create serious safety hazards, and negatively impact your bottom line. As your respected partners, we’re committed to delivering reliable service that keeps your operations moving seamlessly.

The Foundation of Facility Throughput

At its core, every component of a loading dock is designed to solve one fundamental challenge: safely bridging the horizontal and vertical space between a building and a vehicle. This gap changes with every truck, depending on its bed height and how the suspension shifts during loading. A reliable loading ramp must accommodate these variables to create a stable, secure path.

For example, a busy distribution centre running 24/7 will almost certainly use permanent dock levelers built directly into the facility. These are designed for high-volume, continuous use where speed and durability are paramount.

In contrast, a business without a raised dock bay might use a portable loading dock ramp. This is a standalone steel structure that a forklift can move into position, creating ground-to-truck access anywhere it’s needed. This flexibility is invaluable for businesses in leased spaces or those that only handle occasional oversized shipments.

A loading dock isn’t just a part of your building; it’s a direct driver of operational efficiency. The right equipment minimizes product damage, reduces labour hours per shipment, and significantly lowers the risk of workplace accidents, which are unfortunately common in these high-traffic areas.

Knowing the condition of your equipment is the first step. Proactive inspections can reveal whether your current setup is a bottleneck or a strength. Regular checks and timely fixes are crucial for safety and efficiency, a topic we cover in our guide to loading dock repairs in Ontario.

Choosing Your Loading-Dock-Ramp Solution

Not all loading docks are created equal, and the same goes for the equipment that makes them run. Selecting the right loading ramp dock solution is a critical decision that directly affects your facility’s efficiency, safety, and daily throughput. It’s more than just bridging a gap; it’s an investment in a system that must align with your daily workflow, the types of vehicles you service, and your business’s future growth.

Let’s break down the most common types of loading dock equipment to help you find the perfect fit. We’ll explore the key differences between permanent, built-in systems and more flexible, standalone options, giving you the confidence to make the right choice.

Think of it this way: the right equipment is the engine that drives uptime and safety, which in turn fuels your profitability.

Alt text: A flowchart showing how uptime and safety lead to profit at a loading ramp dock.

As you can see, investing in reliable and safe loading dock gear isn’t just an expense. It’s a direct route to better financial results by cutting down on costly downtime and preventing accidents.

Permanent Dock Levelers

For high-volume locations like distribution centres and manufacturing plants, permanent dock levelers are the industry standard. They are installed into a concrete “pit” at the dock door, creating a seamless and adjustable bridge from the warehouse floor to the truck bed.

There are two primary types:

- Hydraulic Dock Levelers: The top choice for any busy dock. Powered by hydraulic cylinders and operated with a simple push-button, they offer smooth, precise height adjustments. This makes them exceptionally efficient and safe. If your facility moves hundreds of pallets daily, the speed and reliability of a hydraulic leveler are unmatched.

- Mechanical Dock Levelers: A more traditional and cost-effective option. These levelers use a spring-and-chain system for manual positioning. While they lack the push-button convenience of hydraulic models, they are durable workhorses, perfect for facilities with lower traffic or where electrical access is limited.

Both types are powerful, long-term investments built to handle heavy loads and constant use, making them the clear choice for dedicated, high-traffic shipping and receiving operations.

Edge-of-Dock Levelers

What if you don’t have the space—or budget—for a full pit-style leveler? That’s where an Edge-of-Dock (EOD) leveler comes in. It’s a compact unit that bolts directly to the face of your dock wall. EODs are designed for facilities where incoming trucks have a fairly consistent trailer bed height.

Think of an EOD as a light-duty bridge. It’s perfect for operations handling standard delivery trucks with a consistent dock approach, offering a more budget-friendly and less invasive installation than a pit leveler.

The trade-off is their limited service range, which is typically just a few inches above or below the dock height. This makes them unsuitable for yards that service a wide variety of vehicle heights.

The Versatile Portable Loading Dock Ramp

Now, let’s talk about a real problem-solver: the portable loading dock ramp. Imagine you need to unload a container in the middle of your yard, but you don’t have a built-in dock. This is the exact scenario where a portable ramp excels. A portable loading dock ramp can be a highly effective substitute for a traditional dock leveler in environments lacking a raised dock platform.

A portable ramp is a standalone, heavy-duty steel structure that creates a ground-to-truck loading solution wherever you need it. It can be easily moved with a forklift, providing an inclined path for loading and unloading trailers or containers without any permanent construction.

Here’s why a portable ramp might be your ideal solution:

- No Dock Necessary: It’s the perfect answer for businesses in leased buildings where permanent construction isn’t feasible.

- Flexibility: You can create an extra loading point during peak seasons to handle overflow and eliminate bottlenecks.

- Cost-Effective: Renting or buying a portable ramp is often significantly more affordable than constructing a permanent concrete dock.

For example, a temporary distribution hub for seasonal goods can become fully operational in hours, not weeks, by using a portable ramp. It delivers the full function of a permanent loading ramp dock but with the agility modern logistics demands.

Comparing Common Loading Dock Solutions

Use this table to quickly compare the features and ideal applications of different loading ramp and leveler types, helping you identify the best fit for your facility.

| Ramp Type | Best For | Power Source | Capacity Range | Key Advantage |

|---|---|---|---|---|

| Hydraulic Leveler | High-volume distribution centres, manufacturing plants | Electric/Hydraulic | 25,000–80,000 lbs | Push-button ease, speed, and precision |

| Mechanical Leveler | Low-to-medium traffic docks, budget-conscious facilities | Manual (Springs) | 20,000–50,000 lbs | Durability, no electrical needed |

| Edge-of-Dock Leveler | Facilities with consistent truck heights, light-duty use | Manual or Hydraulic | 20,000–30,000 lbs | Low cost, simple installation |

| Portable Ramp | Facilities without a dock, yard loading, temporary needs | Manual (Hydraulic pump) | 16,000–60,000 lbs | Unbeatable flexibility and mobility |

Ultimately, making the right choice comes down to your specific operational needs. By understanding the core strengths of each system, you can equip your facility for maximum productivity.

Key Factors for Selecting the Right Equipment

Choosing the right loading ramp dock is more than just picking a part from a catalogue. The ideal equipment should feel like a natural extension of your workflow, perfectly matched to the unique demands of your facility. A smart choice involves a deep dive into your daily operations to find a solution that genuinely boosts efficiency and safety.

This practical checklist will help you get started. While a professional assessment is always recommended, these factors will give you a powerful head start.

Calculating Your Weight Capacity Needs

The single most critical factor is weight capacity. Getting this wrong can lead to catastrophic equipment failure and serious accidents. Calculating this isn’t as simple as matching the capacity to your forklift’s lift rating. You need to determine the gross rolling load. In simple terms, this is the total combined weight that the ramp will have to support at any given moment.

This calculation is the sum of three key elements:

- The weight of your heaviest forklift: Remember to include the battery, as electric models can be surprisingly heavy.

- The weight of the forklift operator: A standard estimate usually works.

- The maximum weight of the load it will carry: Think of the heaviest pallet or product you handle.

Crucial Insight: Your required ramp capacity should be at least 2.5 to 3 times your forklift’s lifting capacity. This safety margin accounts for the dynamic forces—the momentum and impact—generated as the forklift accelerates, brakes, and moves up and down the ramp.

Measuring Your Operational Dimensions

Precise measurements are non-negotiable. They ensure a seamless fit between your dock, the ramp, and the vehicles you service. Even a small discrepancy can create a dangerous gap or an overly steep incline, putting your team and equipment at risk.

Start by measuring these key areas:

- Dock Height: The vertical distance from the ground to the warehouse floor.

- Truck Bed Heights: Record the lowest and highest trailer beds that visit your facility. This range determines the necessary “service range” for your leveler or ramp.

- Approach Space: Ensure there’s enough level, clear space for trucks to back in straight and for a portable ramp to be positioned safely.

Knowing the size of the containers your dock will handle is crucial; for instance, understanding the specific dimensions of 40HQ containers is paramount for ensuring equipment compatibility. For a more detailed walkthrough, you might find our guide on how to choose the right dock leveler helpful.

Evaluating Workflow and Environment

Finally, consider the real-world conditions where the equipment will be used. Your operational frequency and physical environment play a huge role in determining the right materials, power source, and design.

Ask yourself these questions:

- How often will it be used? A dock handling 50 trucks a day needs a heavy-duty hydraulic leveler. In contrast, a facility unloading one truck a week might be perfectly served by a durable mechanical leveler or a portable ramp.

- What are the environmental conditions? Equipment used outdoors needs a galvanized or painted finish to resist rust. In a refrigerated or wash-down facility, you might need stainless steel components or special hydraulic fluids to handle moisture and extreme temperatures.

The sheer volume of goods moving through major hubs underscores the need for robust equipment. The Port of Los Angeles, for example, remains a dominant force, processing a staggering 504,514 loaded import TEUs in August 2025 alone. That level of traffic relies on highly functional loading ramp docks built for constant use.

By carefully analyzing your capacity, dimensions, and workflow, you can select equipment that actively enhances your facility’s productivity. We’re here to provide reliable service and expert guidance to help you make the most informed decision possible.

Integrating Your New Loading Dock System

Getting your new loading ramp dock installed and operational is where theory becomes reality. Proper installation is the foundation for a safe, efficient, and reliable system that will perform for years. Whether you’re building a new facility or upgrading an existing one, this process turns a piece of equipment into a fully integrated part of your workflow.

Think of professional installation as an insurance policy for safety, compliance, and the long-term health of your logistics operation.

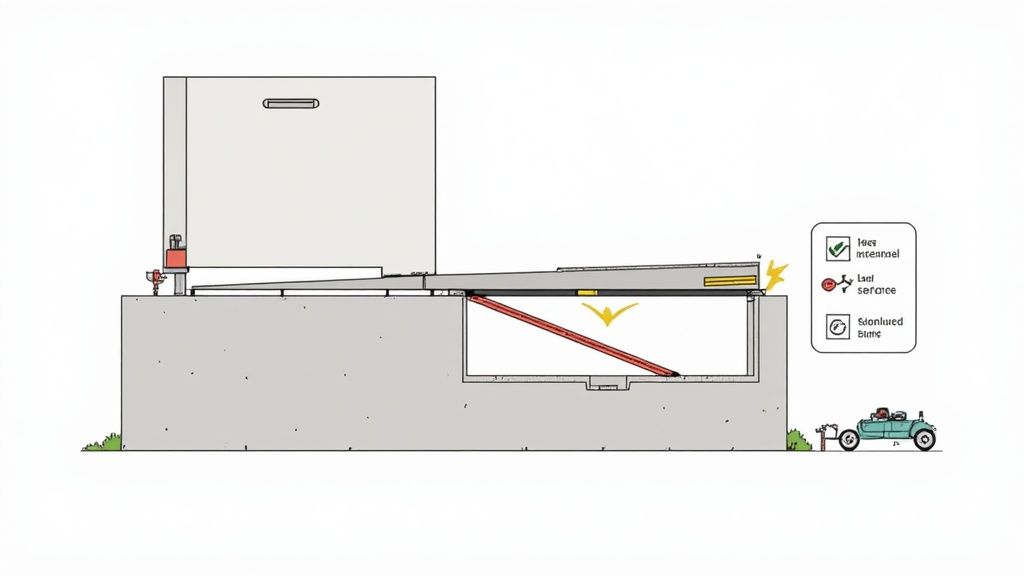

Alt text: A diagram of a loading ramp dock with an adjustable leveler and support mechanism.

Site Preparation for Different Systems

The required prep work depends entirely on the type of system you’ve chosen. A permanent dock leveler has vastly different requirements than a flexible portable ramp.

- Recessed Dock Levelers (Hydraulic/Mechanical): These require a pre-formed concrete pit built into your loading dock floor. This pit houses the leveler, allowing it to sit flush when not in use. This job involves precise concrete work, steel reinforcements, and often, running electrical conduits for powered models.

- Edge-of-Dock Levelers: As surface-mounted units, these are far less invasive. The main requirement is a solid, structurally sound dock face where the unit can be securely bolted.

- Portable Loading Ramps: These are the easiest to accommodate. All you need is a firm, level, and clear surface—like a concrete pad or sturdy asphalt yard—where the ramp can be positioned and operated safely.

Structural and Electrical Requirements

If your system needs power, like a hydraulic dock leveler, the infrastructure must be in place. This means having the correct electrical service run to the dock bay by a licensed electrician to ensure the power supply, voltage, and amperage match the equipment’s specifications.

Structurally, the dock edge and foundation must be strong enough to handle not just the equipment’s weight, but also the dynamic forces of a fully loaded forklift. Any cracks or weak spots in the concrete must be repaired before installation. A smooth, clear approach isn’t just a convenience—it’s essential for safe operation.

Key Takeaway: Retrofitting an existing facility often presents challenges, such as non-standard dock heights or tight maneuvering space. An experienced installation partner can devise creative solutions, like custom steel fabrications, to overcome these obstacles and ensure a seamless fit.

The Value of Professional Installation

Choosing an installation partner with a proven track record is critical. A professional crew ensures the equipment is set up correctly and complies with all safety standards and manufacturer guidelines. This expertise is your best defense against premature wear, operational failures, and potential safety incidents.

As your respected partners in reliable service, we know that a proper installation is the first step in a long-lasting loading dock solution. To discuss your project’s needs, feel free to explore our range of commercial and industrial door solutions or learn more about our expert services.

Creating a Safer Loading Dock Environment

The loading dock is the busiest intersection in any facility—a hub of constant activity where a small misstep can have major consequences. Transforming this high-risk area into a controlled, safe environment is fundamental to running a reliable and productive operation.

Let’s walk through the most common dangers and the modern safety equipment designed to mitigate them, turning your dock from a hazard zone into a secure asset.

Alt text: A worker supervises a truck on a scale at a commercial loading ramp dock.

Identifying and Mitigating Common Dangers

The greatest risks often exist in the gap between the trailer and the building. An unsecured trailer can slowly inch away from the dock, a dangerous phenomenon known as trailer creep. This creates a gap wide enough for a forklift and its operator to fall through.

Another major hazard is a truck driver accidentally pulling away while loading is still in progress. These aren’t just hypothetical scenarios; they are leading causes of severe injuries. The solution is to create a secure, locked connection between the trailer and the building before any activity begins.

Essential Safety Systems for the Modern Dock

To combat these risks, a suite of integrated safety equipment has become the industry standard. These systems work together to form a protective shield around your loading and unloading activities.

Here are the core components of a safe loading ramp dock environment:

- Vehicle Restraints: Also known as truck restraints or dock locks, these devices physically latch onto a trailer’s rear impact guard (the metal bar under the back). This simple action prevents both trailer creep and premature departure, creating a strong anchor.

- Integrated Communication Lights: A simple but brilliant system. Red and green lights are installed both inside and outside the dock door. A green light inside signals to the forklift operator that it’s safe to proceed, while a red light outside tells the truck driver to remain parked.

- Safety Barriers and Gates: For any dock with an open drop-off, powered or manual safety gates are a must. To see these in action, learn how dock lip safety barriers prevent forklift falls when no trailer is present.

An investment in modern dock safety equipment is an investment in your people and your uptime. It’s about preventing avoidable accidents and ensuring every shift ends safely, reinforcing your commitment as a reliable partner.

Beyond Equipment: Reinforcing Safe Practices

While having the right equipment is critical, it’s only half the battle. A true culture of safety is built on clear procedures and consistent training. Your team must understand how the safety systems work and why using them is non-negotiable.

Regular training should cover proper docking procedures, how to operate vehicle restraints, and what the light signals mean. When you combine top-tier equipment with a well-trained team, you create a model of safety and efficiency. A 2025 industry report found that roughly 25% of all industrial accidents happen at the loading dock, highlighting the serious risks. As a result, innovations like vehicle restraints and connected dock technologies are being widely adopted. You can explore more insights from the full 2025 loading dock trends report.

Your Guide to Proactive Maintenance and Care

A loading ramp dock that’s out of service isn’t just an inconvenience—it’s a bottleneck that can halt your entire operation. The key to avoiding unexpected downtime is consistent, proactive maintenance. Just like any heavy-duty machinery, your dock equipment requires regular attention to perform safely and reliably.

Think of it this way: proactive care helps you catch small problems before they become major failures. This section provides a practical plan to keep your equipment in top condition, turning maintenance into a smart operational investment.

Creating an In-House Inspection Routine

Your on-site team is your first line of defense. A simple, routine checklist can help them catch common issues early. These daily, weekly, and monthly checks are critical for spotting early warning signs.

Here’s a simple framework to get you started:

- Daily Visual Checks: Before each shift, walk the area to clear any debris from the ramp and pit, look for obvious damage like cracked welds, and ensure all safety guards are in place.

- Weekly Functional Tests: Once a week, operate the equipment. For a mechanical leveler, ensure the pull-chain works smoothly. For a hydraulic system, listen for unusual noises and watch for steady movement.

- Monthly Structural Inspections: Take a closer look at all moving parts. Check for loose bolts, signs of wear on hinges, and the condition of dock bumpers. Ensure all safety labels are clean and legible.

Expert Insight: Debris, dirt, and ice buildup in the dock pit are leading causes of mechanical failures. Simple housekeeping prevents levelers from operating correctly and accelerates wear on moving parts.

The Importance of a Professional Maintenance Plan

While daily checks are vital, they can’t replace the expertise of a professional technician. A scheduled preventative maintenance plan is a must for complex hydraulic and electrical systems.

A professional service typically covers:

- Hydraulic System Analysis: Checking fluid levels, inspecting hoses for leaks, and testing system pressure.

- Structural Integrity Assessment: Examining welds and key components for stress fractures invisible to the untrained eye.

- Load Capacity Verification: Ensuring the equipment still meets its original safety and compliance rating.

- Lubrication and Adjustments: Greasing all pivot points and making minor adjustments for peak performance.

Think of professional maintenance as a regular health check-up for one of your most critical assets. It ensures your loading ramp dock is working safely and according to manufacturer specifications. This expert care is a cornerstone of our “Respected Partners, Reliable Service” promise.

Loading Dock Maintenance Schedule

| Frequency | Inspection/Task | Performed By | Notes |

|---|---|---|---|

| Daily | Visual inspection of ramp, pit, and surrounding area for debris. | On-Site Staff | Clear any obstructions before the first shift begins. |

| Daily | Check for visible damage (bent steel, cracked welds). | On-Site Staff | Report any significant damage immediately for assessment. |

| Weekly | Test basic operation (e.g., pull-chain, hydraulic lift/lower). | On-Site Staff | Listen for unusual noises or jerky movements. |

| Weekly | Check dock bumpers for secure attachment and excessive wear. | On-Site Staff | Loose or damaged bumpers can lead to bigger problems. |

| Monthly | Inspect all moving parts (hinges, pivot points) for wear. | On-Site Staff | Note any areas that seem to be wearing down quickly. |

| Monthly | Tighten any loose nuts and bolts. | On-Site Staff | A simple task that prevents major mechanical stress. |

| Quarterly/Bi-Annually | Professional lubrication of all pivot points and moving parts. | Certified Technician | Use manufacturer-recommended lubricants. |

| Quarterly/Bi-Annually | Hydraulic system check (fluid level, hoses, pressure). | Certified Technician | Essential for preventing hydraulic failures. |

| Annually | Full structural inspection and load capacity verification. | Certified Technician | Ensures compliance and identifies hidden stress fractures. |

| Annually | Electrical system and safety interlock testing. | Certified Technician | Confirms all safety features are functioning correctly. |

This checklist is a great starting point, but always consult your equipment’s manual for manufacturer-specific recommendations. A well-maintained log demonstrates a commitment to safety and compliance.

Frequently Asked Questions About Loading Ramps

We’ve covered the main types of loading ramps and how to choose the right one, but facility managers often have more specific questions. Getting clear, straightforward answers is the best way to make a confident decision for your operations.

Here are some of the most common questions we hear about the modern loading ramp dock.

What Is The Difference Between A Loading Ramp And A Dock Leveler?

This is an excellent question. The answer comes down to whether the equipment is part of the building or a standalone tool.

- A dock leveler is a permanent, hinged ‘bridge’ built into a pit in your loading dock. Its purpose is to move up or down slightly to perfectly match the height of a truck bed, making it an integrated part of your facility.

- A portable loading ramp, on the other hand, is a separate, mobile inclined structure. You use it to create a path from the ground up to a trailer when you don’t have a raised dock.

In short, a leveler fine-tunes an existing dock, while a portable ramp creates a dock-like function anywhere you need one.

How Do I Determine The Right Weight Capacity?

Figuring out the right capacity is about calculating the total rolling load—not just your forklift’s lifting capacity. This means adding together the weight of your heaviest forklift, its operator, and the maximum load it will ever carry.

As a solid rule of thumb, choose a ramp with a capacity that’s at least 2.5 to 3 times your forklift’s lifting capacity. This is a crucial safety margin that accounts for the dynamic forces created as a heavy forklift moves on an incline. When in doubt, always have an expert verify your calculations.

Can I Use A Portable Ramp Instead Of A Permanent Dock?

Yes, absolutely. For many businesses, a portable loading ramp is a fantastic and highly flexible alternative, especially for facilities that don’t have built-in docks.

They are perfect for unloading shipping containers at ground level or for businesses in leased spaces where constructing a dock pit isn’t an option. They provide an operational adaptability that a permanent, fixed dock simply can’t match.

How Often Should My Loading Dock Equipment Be Serviced?

For most operations, we strongly recommend a professional preventative maintenance inspection at least once a year.

However, if your docks see heavy use or operate in a harsh environment (like cold storage or outdoors), scheduling quarterly or semi-annual service is a smart investment. It’s the best way to ensure safety, minimize downtime, and keep your equipment compliant with manufacturer guidelines.

Your loading dock is the heart of your operation, and keeping it running smoothly is our top priority. As Wilcox Door Service, we are your respected partners for reliable service. To keep your operations running smoothly and safely, contact our team today to schedule a professional consultation or service inspection.