If you manage a commercial or industrial facility, understanding the door fire rating system isn’t just a good idea—it’s a critical part of your life safety plan. A fire rating is a certified promise of how long a door assembly can contain fire and smoke, protecting both people and property. This guide will break down what those ratings mean, what codes you need to follow, and why professional installation and maintenance are essential for keeping your facility safe and compliant.

What a Door Fire Rating Actually Means

Let’s get straight to it: what does a door fire rating really mean for your facility? It’s not just some technical label slapped on the side of a door. It’s a measure of time—specifically, how long a complete door assembly can stand its ground against a fire, holding back flames and smoke.

Think of a fire-rated door as a critical part of a dam system inside your building. This strategy is called compartmentalization, and it’s a cornerstone of any good passive fire protection plan. By dividing a building into fire-resistant zones, you can effectively contain a fire to one area, slowing its spread and buying precious time for people to evacuate safely. For example, a properly rated fire door between a warehouse and an office block is designed to stop a fire that starts near inventory from spreading to administrative areas.

Alt text: Illustration showing a fire-rated door with a timer successfully containing fire and smoke, demonstrating the importance of a door fire rating.

How Ratings Are Earned Through Intense Testing

A door doesn’t just get a fire rating; it earns it through some seriously tough, standardized testing. Independent organizations like Underwriters Laboratories (UL) and Intertek (ETL) put door assemblies through conditions that mimic a real, intense building fire.

Governed by standards like UL 10C, the entire assembly—door, frame, and all hardware—is mounted in a test wall and blasted with extreme heat inside a specialized furnace. The test is designed to see how long the door can successfully:

- Stop flames from passing from one side to the other.

- Keep its structural integrity without collapsing or forming major gaps.

But it doesn’t stop there. After cooking for its designated time, the glowing red-hot door is immediately hammered with a high-pressure fire hose. This simulates the thermal shock and force from firefighting efforts. Only if the door assembly holds together after both the fire and the hose stream does it earn its official label.

Understanding the Numbers: Hourly Ratings Explained

When you see a fire rating, it’s usually in minutes or hours (20-minute, 45-minute, 90-minute, 3-hour). This number isn’t arbitrary; it tells you exactly how long the door assembly survived those harsh test conditions. These ratings are designed to correspond with the fire-resistance rating of the walls they’re installed in.

Key Takeaway: A fire rating is a performance guarantee under extreme conditions. It certifies that a door, when installed correctly as a complete assembly, will perform its life-saving duty of containing a fire for a specific period.

For example, California’s commercial building codes have become much stricter over the decades, especially for industrial access points. The state’s devastating history with wildfires, which destroyed 3,629 structures in 2021 alone, has pushed this evolution. Facility managers in distribution centres now have to prioritize robust solutions, like 3-hour rated fire doors for commercial and industrial use, that are proven to endure intense heat and control smoke. This really highlights the real-world stakes of getting compliance right.

What Is a Labeled Fire Door Assembly?

You’ll hear the term “labeled” a lot when talking about fire doors. A labeled fire door assembly means every single component has been tested and certified by an approved agency. We’re talking about the whole package:

- The door slab itself

- The frame

- The hinges

- The latching hardware

- The closing device

This is an absolutely critical detail. You can’t just mix and match parts from different manufacturers or throw non-rated hardware on a rated door and hope for the best. If even one component—say, a single hinge—isn’t part of that certified assembly, the entire door’s fire rating is void. It’s all or nothing.

This is exactly why professional installation from technicians who live and breathe these strict requirements is non-negotiable. It’s about safety, but it’s also about legal compliance. Partnering with experts ensures every door in your facility isn’t just a door, but a complete, compliant life-safety system—a silent guardian, ready to do its job when it matters most.

Navigating Critical Fire Door Codes and Standards

When it comes to fire doors, understanding the rules is just as critical as understanding the hardware itself. For facility managers, compliance isn’t just about ticking a box to avoid a fine; it’s about making absolutely sure your life safety systems will perform when the worst happens. Think of fire door codes and standards as the official, life-saving instruction manual for everything from installation to long-term maintenance.

The cornerstone of this regulatory world is the National Fire Protection Association (NFPA), specifically their benchmark document, NFPA 80, Standard for Fire Doors and Other Opening Protectives. This is the bible for the entire lifecycle of a fire door assembly. It gets into the nitty-gritty of how a door must be installed and lays out the exact requirements for its annual inspection.

The Role of NFPA 80

NFPA 80 is the foundation of fire door safety, plain and simple. It mandates that every single fire door assembly has to be inspected and tested at least once a year by a qualified professional. And this isn’t just a quick once-over. We’re talking about a detailed, 13-point inspection that confirms every single component is present and working correctly.

For rolling steel fire doors—the kind you see all the time in warehouses and loading docks—this annual check includes a vital fire door drop testing. This test verifies that the door’s automatic closing mechanism is working perfectly, ensuring it will reliably seal the opening in an emergency. Failing to perform and document these annual inspections is a serious compliance issue.

Crucial Insight: An uninspected fire door is a liability waiting to happen. NFPA 80 demands documented annual inspections to prove your doors aren’t just installed correctly, but remain ready to do their life-saving job year after year.

Local Building Codes Determine What You Need

While NFPA 80 tells you how a fire door needs to be cared for, it’s your local building codes that tell you where you need fire-rated doors and what specific door fire rating they must have. These local codes directly tie the door’s rating to the fire-resistance rating of the wall it’s sitting in.

For instance, a wall built to hold back a fire for two hours will almost always require a door with a 90-minute (1.5-hour) rating. A four-hour fire wall, which might be used to separate massive sections of a manufacturing plant into distinct fire areas, demands a door with a 3-hour rating. For any safety-critical building component, a deep dive into specific building codes is essential. Similar to fire doors, this includes understanding glass balustrade regulations, including Approved Document K and BS 6180. The goal is always to create a complete, unbroken fire-resistant barrier.

This is where having a professional partner in your corner is invaluable. Experts who live and breathe both national standards and the nuances of local codes make sure you get the right door for the right opening, achieving full compliance without any costly guesswork.

Understanding Certification Labels

So, how do you know for sure that a door actually meets its claimed rating? The proof is on the certification label. This small but mighty tag, attached to both the door and the frame, is your guarantee that the entire assembly has been tested and passed by an independent, third-party organization like Underwriters Laboratories (UL) or Intertek (ETL).

These labels give you critical info at a glance:

- The manufacturer’s name.

- The name of the third-party testing agency.

- The specific hourly fire rating (e.g., 90-minute, 3-hour).

- Confirmation that it’s part of a complete, tested assembly.

California’s strict fire safety evolution, spearheaded by the Office of State Fire Marshal (OSFM), really drives home why these standards matter. Tragic events like the 2003 Cedar Fire pushed legislative action, leading to precise door fire rating mandates for industrial settings, where 3-hour ratings are now common for separating large warehouse fire areas. These state-level codes require doors with specific hourly ratings, all verified through hose stream tests and temperature limits, proving the real-world importance of these certified labels. You can learn more about the history of California’s fire safety regulations.

Ultimately, these codes, standards, and labels all work together to create a robust system of accountability. They ensure that from the day they’re installed through decades of service, your fire doors provide proven, reliable protection. It’s a complex landscape, but partnering with a service provider who knows the ins and outs is the surest way to achieve compliance and peace of mind.

Choosing the Right Fire-Rated Door for Your Facility

Picking the right fire-rated door isn’t just about grabbing the one with the highest hourly rating. You have to strike a balance between what the building code demands and how your facility actually operates day-to-day. A door that’s perfectly compliant but gums up your workflow is a bad investment. So is a convenient door that doesn’t meet code—that’s a serious liability waiting to happen.

The real goal is to find a solution that fits seamlessly into your environment while delivering the life-saving protection it was designed for. This means thinking about the door’s type, its material, and how it will be used in its specific location, whether that’s a hectic loading dock or a quiet emergency stairwell.

Matching Door Type to Application

The physical design of the door is the first thing to consider, as different types are built for very specific jobs. Each one has its own strengths depending on the size of the opening and the kind of work happening around it.

In most commercial or industrial buildings, you’ll run into a few common types:

- Rolling Steel Fire Doors: These are the heavy-duty workhorses for large openings. You’ll see them in warehouses, on loading docks, and in manufacturing plants. Their interlocking steel slats coil up neatly above the opening, which is a huge plus for saving precious floor and wall space. They’re built tough and provide top-notch security on top of their fire protection.

- Sectional Fire Doors: Made of several hinged panels, these doors slide up and back along tracks, much like a typical garage door. They offer more flexibility for custom features, like adding insulation to boost energy efficiency—a big deal for any climate-controlled facility. They’re a common sight in service bays, fire stations, and commercial garages.

- Swinging Fire Doors: These are what most people picture when they think of a door. They’re the go-to for personnel use in places like stairwells, hallways, and doorways separating office areas from the plant floor. They look and feel like standard doors but are constructed with fire-resistant cores and special hardware that makes them automatically close and latch when a fire alarm goes off. If you’re looking at options for these areas, our guide covers some of the best interior fire-rated door options out there.

Considering Materials and Operational Needs

Once you’ve settled on a door type, you need to think about materials and daily operation. Steel is the most popular choice because of its sheer strength and high melting point, making it perfect for tough 3-hour ratings. However, fire-rated wood doors are also an option for spots where aesthetics matter, though they typically come with lower hourly ratings.

How the door will be used is just as critical. Is it going to be opened and closed constantly all day, or is it a pass-through that’s rarely touched?

- Manual Operation: This works best for doors that aren’t used very often.

- Motorized Operation: This is a must-have for large, heavy doors or any door in a high-traffic area. It improves efficiency and saves your employees from physical strain.

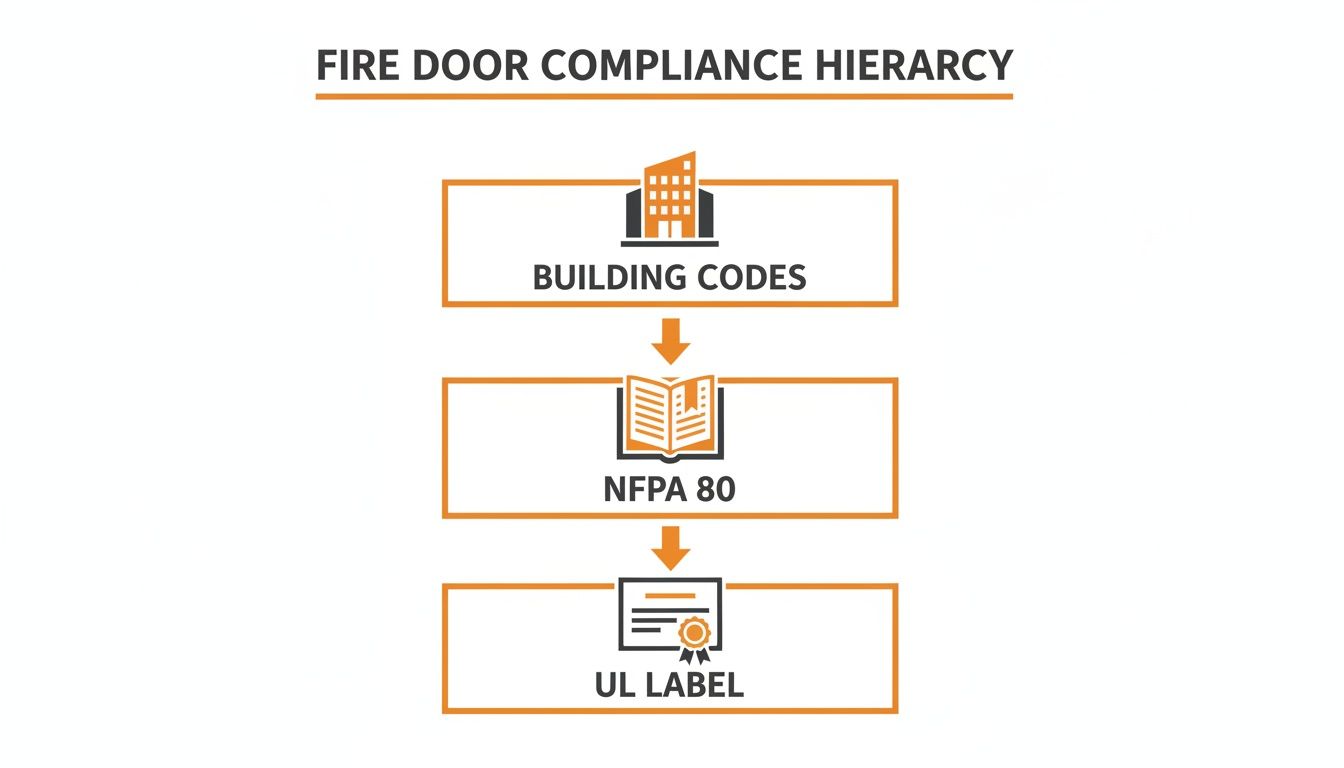

This infographic neatly sums up the compliance chain of command, from the high-level building codes down to the specific label on the door itself.

Alt text: A compliance hierarchy diagram for door fire ratings showing that Building Codes mandate use, NFPA 80 sets standards, and a UL Label provides certification.

It’s a great visual reminder that local building codes tell you why you need a fire door, NFPA 80 gives you the rules for how it must perform, and the UL label is the final proof that it meets those rules.

Ensuring a Complete and Compliant Assembly

If you take away only one thing, let it be this: a door fire rating applies to the entire opening protective assembly—not just the door panel. Every single component has to be tested, listed, and labelled to work together as a single, fire-stopping unit.

Crucial Reminder: A fire-rated door is only compliant if installed as a complete, certified assembly. Using a non-rated frame, incorrect hinges, or the wrong latching hardware will completely void the door’s fire rating and compromise its ability to function in an emergency.

This is exactly why working with a professional partner is so non-negotiable. Experts who live and breathe the intricate rules of NFPA 80 make sure every piece—from the frame and seals to the closers and latches—is correctly specified and installed. That’s how you guarantee your door will not only pass inspection but will actually perform its life-saving job when everything is on the line.

Why Professional Installation and Maintenance Are Non-Negotiable

A top-tier fire door is only as good as its installation. You can have the most robust, highly-rated door on the market, but if it’s installed or maintained improperly, it’s completely useless. Proper commercial door installation isn’t just a suggestion—it’s a legal and functional requirement for the door’s fire rating to be valid, and it’s the only way to ensure it will actually perform its life-saving duty.

This is where the expertise of certified professionals becomes absolutely essential. They understand that a fire door isn’t just a slab of steel; it’s a complete, engineered assembly where every single component must work in perfect harmony.

Alt text: A certified technician conducting a professional fire door inspection to ensure door fire rating compliance.

Common Mistakes That Void a Fire Rating

Even a small mistake during installation can have catastrophic consequences, instantly voiding the door fire rating and creating a massive liability for your business. These aren’t minor details; they are critical failures that stop the door from doing its one job: containing a fire.

Some of the most common—and dangerous—mistakes include:

- Using Non-Compliant Hardware: Every piece of hardware, from the hinges and closers to the latches and locks, must be fire-rated and listed for use with that specific door assembly. Swapping in a non-rated hinge might seem trivial, but it will fail under extreme heat, causing the entire door to collapse.

- Incorrect Clearances: NFPA 80 specifies exact gap measurements around the door’s perimeter. If the gaps are too large, smoke and flames can easily slip through. If they’re too small, the door might not close and latch properly, especially as materials expand in the heat.

- Unauthorized On-Site Modifications: Drilling extra holes for new hardware, adding a non-rated vision panel, or altering the door in any way not approved by the manufacturer immediately nullifies its certification. A fire door is a tested system, and any change compromises its integrity.

These are exactly the kinds of issues that demand a professional touch. It’s not just about hanging a door; it’s about building a proven life-safety barrier. This is why trusting professionals who know how to help you succeed in compliance is paramount.

Your Ongoing Responsibilities Under NFPA 80

Once a fire door is correctly installed, your responsibility doesn’t end. NFPA 80 mandates that all fire door assemblies must be inspected and tested annually by a qualified person. This isn’t a simple visual check; it’s a detailed, documented process to ensure the door remains in perfect operational condition. Through regular checks and our planned maintenance programs, we ensure your doors stay compliant year after year.

The Bottom Line: An uninspected fire door is a non-compliant fire door. That annual inspection is your documented proof that the assembly is ready to protect your people and property, year after year.

The Annual Inspection Checklist: What Inspectors Look For

During an annual inspection, technicians methodically check every single aspect of the door assembly. It’s a comprehensive process.

They’ll be looking for things like:

- Labels and Markings: They verify that the labels on the door and frame are present, legible, and match the requirements for that specific opening.

- Structural Integrity: They’re looking for any damage to the door, frame, or hardware that could compromise its function in a fire.

- Self-Closing and Latching: This is a hands-on test. They’ll confirm the door closes completely and latches securely on its own from any open position. No exceptions.

- Hardware Functionality: Technicians inspect all components, especially hinges and closers, to make sure they’re in good working order and show no signs of excessive wear.

- Gaps and Clearances: Out come the measuring tools. They measure the gaps between the door and frame to confirm they are within the strict tolerances set by NFPA 80.

For rolling steel fire doors, this annual service also includes a fire door drop test. This is a crucial functional check that verifies the automatic closing mechanism will work flawlessly when triggered by a fire alarm. You can learn more about this mandatory procedure by reading our in-depth guide to understanding fire door drop testing.

Trusting certified professionals for installation and planned maintenance isn’t just a best practice; it’s a fundamental part of risk management. It ensures life safety, mitigates liability, and guarantees that your investment in fire protection will actually work when it matters most.

Achieve Full Compliance with a Trusted Partner

We’ve covered a lot of ground, and it’s clear that a compliant door fire rating is one of the most critical parts of your building’s passive fire protection system. The big takeaways are simple: you need to understand the ratings, stick to codes like NFPA 80, and commit to professional installation and maintenance. After all, a fire door is only as reliable as its weakest component.

Now, it’s time to put that knowledge into practice. Making sure your fire doors are fully compliant is about more than just checking a box—it’s about protecting your people, your property, and your business’s future. This isn’t just about passing an inspection; it’s about having a life safety system you know will work when everything is on the line.

From Knowledge to Actionable Steps

Taking that next step is straightforward. It doesn’t matter if you’re managing a single warehouse or a whole portfolio of commercial properties, the path to compliance always starts with a professional assessment and service. This is where bringing in an expert team makes a world of difference, taking the guesswork out of the equation and making sure every last detail is handled correctly.

A fire door is more than just hardware; it is a complete life safety system. Trusting its installation and maintenance to certified professionals is the only way to guarantee it will perform as intended during an emergency, providing peace of mind and protecting what’s most important.

For example, different door types have their own specific requirements, and knowing those details is crucial. You can see how these complexities are managed in the real world by looking at a sectional door and fire door installation. That kind of hands-on expertise is what turns a good safety plan into a great one.

Whether you need to schedule a compliance inspection for your existing doors, get a quote for a new fire-rated installation, or set up a planned maintenance program, our team is ready to help. Partner with Wilcox Door Service and get the confidence that comes from knowing your facility is safe, compliant, and protected by “Respected Partners, Reliable Service.”

Got Questions About Fire Door Ratings? We’ve Got Answers.

We’ve covered a lot of ground on fire door compliance, but you probably still have a few specific things on your mind. Here are some straightforward answers to the questions we hear most often from facility managers trying to navigate the door fire rating system.

How Do I Figure Out the Right Fire Rating for a Door?

This is a great question, and the answer always starts with the wall. The required door fire rating is directly tied to the fire-resistance rating of the wall where it’s being installed. Think of it as a simple matching rule: the door has to be strong enough for the wall it’s in.

As a general guide, building codes typically follow this logic:

- A wall rated for 4 hours of fire resistance will require a door rated for 3 hours. You’ll often find these in walls that separate massive fire areas, like in a large warehouse.

- A 2-hour rated wall calls for a 1.5-hour (90-minute) door. These are common in critical exit paths like stairwells and elevator shafts.

- A 1-hour rated wall usually needs a 45-minute or 20-minute door. This is what you’d typically see in corridor walls or separating an office area from the plant floor.

But here’s the catch: local codes can have their own specific requirements. It’s always best to consult your local building code and a certified professional to be absolutely sure you’re meeting the exact standard for your facility.

Can My In-House Maintenance Crew Install a Fire-Rated Door?

While it might seem like a good way to save some money, this is a path you really want to avoid. In fact, it’s often a direct violation of compliance standards. Installing a fire door is a precise process, strictly governed by NFPA 80. The entire assembly—the door, frame, hardware, and closer—has to be put together exactly as the manufacturer specified in their testing.

Even a tiny mistake, like using the wrong screws, leaving a gap that’s a millimetre too wide, or drilling a small hole where one doesn’t belong, can instantly void the door’s fire rating. If that door fails during a fire, the consequences could be catastrophic, not to mention the massive legal liability that would follow.

To protect your people and your business, always bring in a qualified technician who is specifically trained and certified in fire door installation. It’s the only way to guarantee safety and compliance.

What Happens If a Fire Door Fails Its Annual Inspection?

According to NFPA 80, a failed inspection means you have to act immediately. The standard states that any deficiencies must be repaired “without delay.” Your inspection report will give you a detailed list of what’s wrong, which could be anything from a worn-out seal or a malfunctioning closer to a damaged frame.

You are legally required to document every corrective action you take to bring that door back up to code. Ignoring a failed inspection is a serious gamble that can lead to heavy fines, denied insurance claims, and unimaginable liability if a fire breaks out. The moment you get that report, your first call should be to a professional service provider to handle the repairs and get the door re-certified.

Staying on top of fire door ratings and compliance is a heavy but essential responsibility. The experts at Wilcox Door Service Inc. are here to make sure your facility is safe, compliant, and always prepared.

Schedule a professional fire door inspection or get a quote for a new installation today.