As a facility manager, you’re constantly balancing operational efficiency with the budget. The performance of your garage and loading dock doors has a direct impact on both. This guide will show you how investing in the right side seals for garage doors delivers a significant return by boosting your facility’s energy efficiency, safety, and cleanliness. We’ll explain the different types of seals, their best uses in commercial settings like warehouses and loading docks, and the real-world benefits you can expect.

Think of side seals as more than just rubber strips; they are a critical part of creating an efficient, secure, and clean facility. These seals run along the vertical edges of your overhead door, closing the gap between the door and the frame. They are the final piece of the puzzle, creating an essential barrier against the elements, pests, and costly energy loss.

What You Will Learn About Commercial Door Seals

For any facility in Canada, especially with our harsh winters, proper sealing isn’t just a nice-to-have—it’s a necessity. Natural Resources Canada data shows that buildings are responsible for 18% of the country’s energy consumption. Worse, industrial sites can lose up to 25% of their heated air through unsealed doors alone. A set of high-quality side seals, installed correctly, can slash this waste and lead to some serious savings on your utility bills. You can learn more about how the right materials make all the difference in our guide to garage door weatherstripping.

Here’s what we’ll cover in this article:

- Types of Side Seals: We’ll break down the best options for different environments, from durable rubber and vinyl to versatile brush seals. What works for a high-traffic warehouse might not be right for a food-grade processing plant.

- Key Performance Benefits: We’ll go beyond the basics to see how seals impact energy savings, pest and dust control, and overall facility safety.

- The Importance of Loading Dock Seals: We’ll discuss how sealing the loading dock area is crucial for warehouse energy savings and maintaining a stable internal environment.

- Installation and Maintenance: You’ll understand why professional installation is so important and learn how to do routine checks to make sure your seals are still doing their job.

- Calculating Your ROI: We’ll help you figure out how to quantify the financial benefits of upgrading your door seals, making it much easier to justify the investment.

By the end, you’ll have a clear roadmap for selecting, maintaining, and getting the most value out of your commercial garage door seals.

Choosing the Right Type of Commercial Door Side Seal

Picking the right side seals for garage doors isn’t a one-size-fits-all job. The best choice is always dictated by what your facility really needs day-to-day. Think of it like buying a jacket: a light windbreaker works for a mild spring afternoon, but you’d be in real trouble without a high-performance parka during a Canadian winter. The same logic holds true for sealing up your commercial doors.

Each seal material brings something different to the table, designed for specific work environments. Nailing this choice means you’ll get the best possible return on your investment through better energy efficiency and smoother operations.

Common Materials and Their Best Uses

Let’s walk through the most common options you’ll come across for your facility’s exterior doors. Getting a handle on these differences is the first step. For a deeper dive, check out our comprehensive guide on the types of exterior door weatherstripping.

- Vinyl Seals: These are the versatile workhorses of the industry. Vinyl is a reliable and cost-effective material that creates a solid barrier against drafts and light moisture. This makes it a great all-around choice for standard warehouses and manufacturing plants with moderate traffic.

- Rubber Seals (EPDM): When durability is the top priority, rubber is the only answer. EPDM (which stands for Ethylene Propylene Diene Monomer) is a tough synthetic material famous for its incredible resistance to extreme temperatures, UV damage, and physical abuse. It’s perfect for high-traffic loading docks in places like Calgary, where the seal has to handle constant compression from trucks and brutal weather without cracking.

Before we get into specialized seals, let’s compare these materials side-by-side to make the decision clearer.

Comparison of Commercial Side Seal Materials

This table breaks down the most common materials used for side seals. We’ve highlighted their key features, best use cases, and typical lifespan to help facility managers make a smart, informed decision.

| Seal Material | Key Benefit | Ideal Environment | Durability Rating |

|---|---|---|---|

| Vinyl | Cost-effective and versatile | General warehouses, light manufacturing, low-to-moderate traffic areas. | Good |

| Rubber (EPDM) | Extreme weather & UV resistance | High-traffic loading docks, facilities in harsh climates. | Excellent |

| Brush | Pest and debris control | Food processing, dusty environments, uneven floors. | Very Good |

| Inflatable | Airtight and contamination control | Clean rooms, cold storage, pharmaceutical facilities. | Excellent |

As you can see, the right material directly aligns with your operational priorities, whether that’s budget, durability, or environmental control.

Specialized Seals for Unique Environments

Moving beyond the standard choices, some facilities have needs that require a more specialized solution to maintain a tightly controlled environment.

For facilities in the food and beverage or pharmaceutical industries, contamination control is non-negotiable. The right seal is not just about saving energy; it’s a critical component of your quality control and compliance strategy.

This is where advanced seals really shine.

- Brush Seals: These are your number one defence against dust, debris, and pests. The dense bristles form a flexible but solid barrier that conforms perfectly to uneven surfaces. A food processing facility in Manitoba, for instance, would get huge benefits from brush seals to keep contaminants and rodents out while still letting the door run smoothly.

- Inflatable Seals: For places that need a nearly perfect airtight seal, like cold storage facilities or clean rooms, inflatable seals are the top-tier solution. When the door closes, these seals fill with low-pressure air, expanding to plug every last gap. This creates a hermetic seal—meaning it’s completely airtight—that stops temperature exchange and contamination cold. They are the true “arctic parka” of door seals, giving maximum protection for the most sensitive operations.

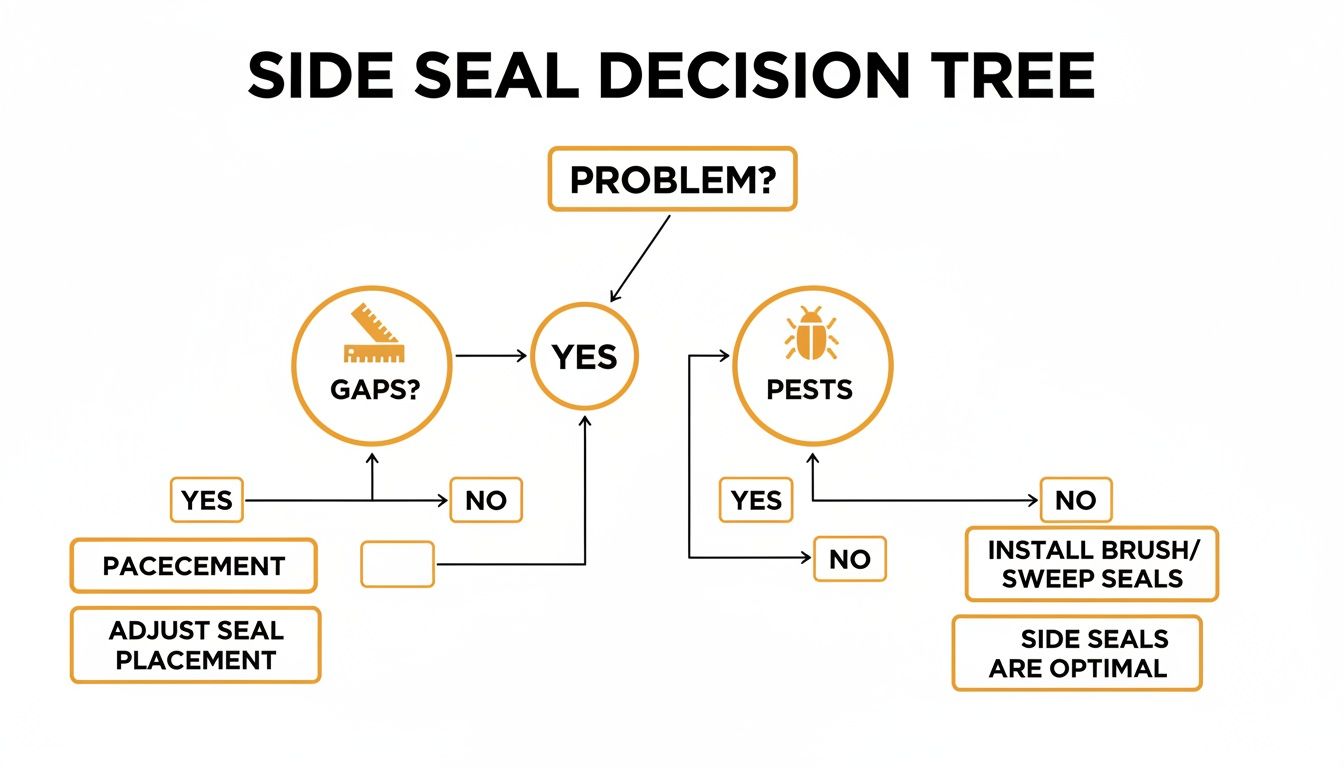

This infographic lays out a simple decision tree to help you figure out which side seal might solve your most common problems.

Alt text: A decision tree flowchart to help select the right side seals for garage doors based on problems like gaps, pests, or energy loss.

The visual walks you through identifying an issue, like visible gaps or pest problems, and points you toward the most effective type of seal for that specific challenge.

The Unseen Benefits of Sealing Your Loading Docks and Doors

Beyond just filling a gap, properly installed side seals for garage doors deliver a powerful range of operational benefits that directly impact your bottom line. It helps to think of your facility as an ‘energy envelope’—a sealed container designed to maintain a consistent internal environment. Every unsealed gap around a door is a tear in that envelope, leading to significant and often unseen costs.

These gaps are especially problematic at the loading dock, where the constant flow of goods creates a major point of energy exchange. A huge part of unlocking commercial building energy efficiency lies in effectively sealing all openings, and your industrial doors are the largest and most dynamic of them all. When left unaddressed, these small openings can collectively add up to massive energy waste.

Alt text: An illustration of a commercial garage door with side seals, showing icons for energy savings, pest control, dust prevention, and noise reduction benefits.

Driving Down Energy Costs with Loading Dock Seals

The most significant benefit is the reduction in energy consumption. During a harsh Canadian winter, every gap around your loading dock doors allows heated air to pour out and cold air to rush in. This forces your HVAC system to work overtime just to maintain the set temperature, driving up your utility bills month after month.

This is where dedicated Loading Dock Seals become essential. While side seals close the gap between the door and its frame, dock seals create a barrier between the building and the back of a parked trailer. This complete seal prevents massive energy loss during loading and unloading. For instance, a warehouse in Toronto we worked with was struggling with high heating costs. Their existing dock seals were worn and compressed, creating noticeable gaps. After retrofitting their bays with high-quality, durable dock seals, they reported a tangible drop in their natural gas consumption the following winter. It wasn’t just about comfort; it was a measurable financial return.

A properly sealed loading dock door isn’t just an operational component; it’s an investment in your facility’s energy efficiency. The payback often comes much faster than facility managers expect, directly contributing to a healthier operating budget.

Creating a Cleaner and More Secure Environment

Beyond energy savings, effective seals are your first line of defence against a host of external contaminants and nuisances. They create a formidable barrier that delivers several key advantages.

- Pest and Rodent Control: For facilities in the food, beverage, or pharmaceutical sectors, preventing pest entry is a matter of compliance and product safety. Even a small gap is an open invitation for rodents and insects seeking shelter and food. A properly fitted brush or rubber seal closes these entry points securely.

- Dust and Debris Management: In manufacturing environments or facilities located near busy roads, dust and debris can compromise product quality and create an unpleasant work environment. Side seals effectively block airborne particles, helping you maintain a cleaner, more controlled workspace.

- Noise Reduction: For facilities located in dense urban industrial parks, noise complaints can be a serious issue. Well-maintained seals help dampen sound transmission from inside and outside the building, contributing to a better relationship with neighbouring businesses and a more comfortable environment for your team.

By addressing these seemingly minor issues, you elevate your facility’s overall performance, safety, and compliance. Partnering with Wilcox means turning a simple component like a door seal into a tool for achieving significant operational improvements.

A facility manager’s job is a balancing act between operational efficiency and the bottom line. But when it comes to safety and regulatory compliance, there are no compromises. High-quality side seals for garage doors play a surprisingly big role in a facility’s overall safety program, going far beyond just saving on the energy bill to protect your people and your compliance record.

One of their most crucial safety functions is preventing hazards right where the action is: at high-traffic entry points like loading docks. During a Canadian winter, vehicles inevitably track in snow, slush, and ice. This can quickly turn a busy dock area into a dangerous slip-and-fall zone. Properly installed side seals create a tight barrier that dramatically cuts down on the amount of precipitation getting inside, keeping your floors drier and safer for the team.

This simple function has a massive impact. A report from the Canada Safety Council found that gaps in garage door side seals are a contributing factor in 22% of warehouse slip-and-fall incidents caused by tracked-in snow and ice—a huge concern in places like Manitoba and Saskatchewan during the winter. The data also showed that installing robust side seals slashed these specific hazards by 40% across a sample of 500 sites in Alberta. You can get more insights on how the right seals prevent these common hazards at SnirtStopper.

Maintaining Controlled Environments

Beyond just stopping slips and falls, side seals are absolutely essential for any facility that needs precise environmental controls. In some specialized applications, maintaining a specific air pressure isn’t just about efficiency; it’s critical for safety and operational integrity.

- Positive/Negative Air Pressure: Think about clean rooms, paint booths, or pharmaceutical labs. These environments need to maintain either positive or negative air pressure to stop contamination in its tracks. Side seals are a vital part of creating the airtight envelope required to control that airflow, ensuring contaminants don’t get in—or out.

- Fume and Dust Containment: For manufacturing plants that generate dust, fumes, or other airborne particles, effective seals are your first line of defence. They help contain these particles within designated work areas, which improves the air quality across the rest of the facility and protects your workers’ health.

Meeting Fire Code and Safety Standards

In many commercial and industrial buildings, certain overhead doors are designated as part of a fire-rated assembly. Their job is to slow the spread of a fire, but their effectiveness depends entirely on their ability to block not just the flames, but also the smoke.

A fire door is only as effective as its seal. Gaps around the door can allow smoke—the most dangerous element in a fire—to spread rapidly, compromising evacuation routes and endangering lives.

Properly specified and installed side seals are what ensure a fire door assembly actually performs as designed in an emergency. This isn’t just a “nice-to-have”; it’s a key part of meeting Canadian building codes and fire safety regulations. At Wilcox, our union-certified technicians live and breathe these requirements, making sure your facility is not just efficient, but fully compliant and safe. For more guidance on meeting these critical standards, feel free to explore our commercial door solutions.

Installation And Maintenance Best Practices For Side Seals

Even the best side seals for garage doors are only as good as their installation. To create that airtight barrier we’re all after, a perfect fit isn’t just a nice-to-have—it’s non-negotiable. That’s why professional installation by union-certified technicians is such a crucial step. A DIY job might look like it’s saving you money upfront, but one small mistake can render the entire seal useless.

The real art is in the compression. That’s the amount of pressure the seal exerts against the door. Too little, and you’ve still got gaps. Too much, and you’re creating friction that puts a serious strain on your door operator, leading to premature wear and tear. A pro also ensures the door tracks are perfectly aligned, so the seal glides smoothly without snagging or getting chewed up over time.

While our focus here is on heavy-duty commercial doors, the fundamental principles of sealing garage door gaps apply across the board, and resources like this guide can offer some great general insights.

Your Regular Inspection Checklist

Once your seals are in place, a little preventative maintenance goes a long way in extending their life and keeping your facility protected. Facility managers can easily work these quick visual checks into their routine walkthroughs.

Alt text: A technician inspects a checklist during garage door side seal maintenance, showing a close-up of worn seals.

Use this simple checklist to catch problems early:

- Look for Cracks and Brittleness: Over time, the sun’s UV rays and wild temperature swings can turn flexible rubber and vinyl seals into something hard and brittle. Cracks are a dead giveaway that the material has lost its mojo and needs to be replaced.

- Check for Gaps or Tears: Run your eyes along the entire length of the seal. Pay close attention to the bottom, where it sees the most action from traffic and weather. Even a tiny tear is an open invitation for pests and drafts.

- Assess Compression Set: “Compression set” is the industry term for a seal that’s been squashed flat for so long it’s forgotten how to spring back. If the seal looks permanently flattened against the frame, it’s not doing its job anymore.

Troubleshooting Common Side Seal Issues

Certain day-to-day operational hiccups can really speed up the wear and tear on your seals. Knowing what to look for helps you get ahead of the problem.

Proactive maintenance is always cheaper than a reactive repair. Catching and fixing small seal issues early stops them from snowballing into bigger problems that can compromise your entire door system or the building’s environment.

A classic issue in our Canadian winters is a seal freezing solid to the concrete floor or the door frame. When the door tries to open, the seal rips right off. This is usually a symptom of a bigger problem, like poor drainage or a worn-out bottom seal that’s letting moisture pool up.

Another common headache, especially at busy loading docks, is damage from forklifts or other equipment. One clumsy turn can tear a seal or knock it completely out of alignment. A simple fix? Installing some protective bollards or guide rails can dramatically cut down on this kind of accidental damage.

If you spot any of these issues during your inspection, it’s time to call in the pros. The team at Wilcox provides reliable repair services to get seal damage sorted out quickly, minimizing your facility’s exposure and buttoning up its protective envelope. For the ultimate peace of mind, consider a planned maintenance program to keep all your door components—seals included—in peak condition.

Calculating the Return on Investment for Your Facility

Putting new side seals for garage doors on the budget isn’t just another maintenance expense. Think of it as a strategic investment—one that actually pays for itself. For any facility manager who needs to justify every dollar spent, understanding the return on investment (ROI) is everything. Good seals aren’t a cost; they’re an upgrade with a surprisingly fast payback.

The business case here is pretty straightforward. It’s built on real, quantifiable savings in a few key areas, from direct energy cost reductions and less wear-and-tear on your HVAC systems to the financial upside of better safety and compliance.

A Simple Framework for Estimating ROI

Let’s make this tangible. Imagine you’re running a 10-door warehouse somewhere in Ontario, where the winters don’t mess around.

- Calculate Energy Savings: First, look at the gaps around your doors. It doesn’t take much. A continuous 1/4-inch gap around ten standard 8’x10′ doors adds up to over 6 square feet of open space. That’s a massive hole constantly bleeding out expensive heated or cooled air. Sealing those gaps is the quickest way to slash energy waste.

- Factor in Reduced HVAC Maintenance: When air is leaking out, your heating and cooling systems have to work overtime just to keep up. That extra strain means more frequent service calls and a shorter lifespan for very expensive equipment. When you properly seal the building envelope, you ease that workload, which means fewer repair bills and longer life for your assets.

- Quantify Safety and Compliance Gains: A dry floor is a safe floor. Fewer puddles from tracked-in snow or ice means a lower risk of slip-and-fall incidents, which in turn reduces the chance of liability claims and costly downtime. On top of that, avoiding fines for not meeting environmental or safety regulations goes straight to your bottom line.

The economic impact here is huge. A recent analysis found that inefficient door seals can drive up a warehouse’s operating costs by as much as 15-20%. In Ontario alone, that adds up to an estimated $450 million in preventable heat loss every year. You can find more details on these critical industry findings on us.garadry.com.

With some facilities seeing a full payback in under 18 months, upgrading your door seals is one of the fastest ways to improve your facility’s financial performance. This isn’t just an operational fix; it’s a powerful cost-control measure.

This simple calculation completely changes the conversation. It’s no longer about “How much will new seals cost?” but “How much will we start saving?” When you frame it that way, the decision to invest in proper sealing becomes obvious.

Ready to Enhance Your Facility’s Efficiency and Safety?

Choosing the right side seals for your garage doors might seem like a small detail, but as we’ve seen, it has a massive impact on your facility’s energy bills, safety, and overall bottom line. These aren’t just strips of rubber; they’re the first line of defence in controlling your environment and protecting your assets. With over 100 years of hands-on experience, Wilcox Door Service isn’t just a vendor—we’re Canada’s trusted partner for industrial door solutions.

Our coast-to-coast team of union-certified technicians lives by our promise of “Respected Partners, Reliable Service.” We make sure every job, whether it’s a simple seal replacement or a complex commercial door system installation, is done right the first time.

Don’t let worn-out, inefficient seals undermine your facility’s performance. Contact Wilcox Door Service today to schedule a professional inspection or explore how a planned maintenance program can secure your facility and start cutting down those operating costs.