This guide provides facility and operations managers in Hamilton with the essential knowledge needed for effective commercial garage door repair. You will learn how to identify common door failures before they escalate, understand the unique demands of industrial overhead doors, and see the value of proactive maintenance in preventing costly downtime. We'll explore the specific challenges faced by Hamilton's manufacturing plants and distribution centres, offering practical insights to keep your operations running safely and efficiently.

Keeping Your Hamilton Business Running Smoothly

In Hamilton’s bustling industrial hubs, from manufacturing plants along the QEW to massive distribution centres, a commercial overhead door is more than just an entry point—it's a critical piece of operational machinery. Unlike a simple residential door, these systems are the gatekeepers to your business's productivity and security. When one fails, the consequences can ripple through your entire operation, halting production and delaying shipments.

This guide is for the facility and operations managers on the front lines, keeping Hamilton’s industries moving. We understand that a stuck loading dock door isn't just another repair ticket; it's a logistical nightmare that can delay shipments from a manufacturing plant, expose valuable inventory in a warehouse, and create genuine safety hazards for your team.

alt=A facility manager inspects a warehouse in Hamilton, highlighting the need for reliable commercial garage door repair.

Why This Guide Is for You

Your job is to solve problems quickly and effectively. You can't afford to wait for a technician who doesn’t grasp the urgency or the high-cycle demands of an industrial environment. You need a partner who understands the complex mechanics of your facility's access points and provides reliable service.

As Respected Partners, Reliable Service providers to Hamilton businesses for decades, we’ve seen firsthand how a single door failure can throw an entire production schedule into chaos. Our focus is on getting you back to work safely and swiftly.

Throughout this guide, we’ll break down complicated topics into clear, actionable insights, helping you make informed decisions that protect both your assets and your people.

Here's what you'll learn:

- The unique mechanics of industrial overhead doors and why they demand specialized care.

- How to spot the early warning signs of common failures before they become emergencies.

- What to expect from a professional emergency repair service built for commercial clients.

- The value of proactive maintenance programs in preventing downtime and ensuring safety.

Our goal is to arm you with the knowledge to keep your facility’s access points secure, efficient, and reliable.

Why Industrial Doors Demand Specialized Expertise

It’s a common mistake to think a garage door is just a garage door. But the massive overhead door at a Hamilton manufacturing plant is a completely different class of machinery compared to one on a home. It’s less of a simple door and more like a critical piece of your production line. When you need garage door repair in Hamilton for your facility, understanding these differences is key to choosing the right service partner. This isn't a job for a handyman; it’s a task for certified industrial technicians.

The Anatomy of a Commercial Overhead Door

The real contrast between residential and industrial doors is in their components. A residential door might cycle a few times a day, but a commercial door at a busy loading dock could open and close hundreds of times in the same period. This high-cycle demand requires parts built for intense, repetitive stress.

- Heavy-Gauge Steel Tracks: Commercial tracks are made from much thicker steel to guide and support doors weighing thousands of pounds, preventing damage from accidental forklift impacts.

- High-Tension Torsion Springs: These massive springs are the real muscle, engineered based on the door’s weight, height, and expected daily cycles—often rated for 50,000, 75,000, or even 100,000 cycles. A cycle is one full opening and closing motion.

- Powerful Commercial Operators: The motor, or operator, is the powerhouse. Industrial operators deliver the immense torque needed to lift heavy, insulated, or oversized doors smoothly and safely, day in and day out.

Think of it this way: a residential door is like a family car, reliable for daily errands. An industrial door is a transport truck, built to haul heavy loads non-stop. You wouldn't use a car's engine in a transport truck, and the same logic applies here.

Safety and Compliance Are Non-Negotiable

Beyond the heavy-duty hardware, specialized expertise is critical for safety. The immense weight and powerful spring tension make industrial doors incredibly dangerous to work on without proper training and tools. An improperly handled torsion spring can release its energy with explosive force.

Furthermore, industrial facilities in Hamilton are subject to strict workplace safety regulations. A qualified commercial door technician understands these requirements, ensuring repairs are not just functional but also fully compliant. This includes verifying that crucial safety features like photo-eye sensors (electric eyes that detect obstructions) and reversing mechanisms are working perfectly to protect your staff. Choosing a certified specialist is an investment in your facility's uptime and safety, especially when dealing with complex commercial door operators.

Need an expert assessment of your commercial doors? Schedule a service inspection with our certified technicians today.

Identifying Common Commercial Door Failures

In a busy Hamilton facility, a surprise door failure is a direct hit to your bottom line. Catching the symptoms early means you can get professional garage door repair in Hamilton before a small problem spirals into a crisis.

Torsion Springs: The Heart of the Lifting System

The torsion springs are the most crucial—and dangerous—part of your overhead door. These massive, tightly wound springs do the heavy lifting; the electric operator simply guides the movement. The primary reason they fail is metal fatigue—the weakening of steel from repeated twisting—until it snaps with a loud bang.

- Symptom: An incredibly loud noise, like a gunshot. The door will refuse to open or feel impossibly heavy, as the operator cannot lift the door's full weight alone.

- Business Risk: For a manufacturing plant, this means a complete halt at a critical loading bay. Trying to force the door open with the operator will likely burn out the motor, turning a standard repair into a much more expensive one.

Damaged Tracks and Rollers: Signs of Impact

In the fast-paced world of a loading dock, it’s common for forklifts or trucks to hit the metal tracks that guide the door. Even a minor dent can throw the door off its path, creating massive friction and straining the entire system.

Real-World Example: At a Hamilton steel processing facility, a forklift accidentally clipped a track. The door began to operate with a jerky, grinding motion. This put uneven stress on the lifting cables and operator, accelerating wear and risking a more catastrophic failure. A prompt track repair prevented a full door collapse.

Frayed Lifting Cables and Worn Drums

Working with the springs are the lifting cables, high-tension steel wires that pull the door's weight. Constant friction can cause them to fray, rust, or stretch. If you're facing this, learn more in our guide on what to do when you have a broken garage door cable.

- Symptom: Visible fraying along the cable or a door that hangs crooked. If a cable snaps, one side of the door will likely slam shut.

- Business Risk: A snapped cable is a major safety hazard. The uncontrolled drop of a heavy door can cause catastrophic damage to equipment and poses a serious threat of injury.

Commercial Door Problem Identification Guide

| Common Fault | Observable Symptom | Primary Business Risk |

|---|---|---|

| Broken Torsion Spring | Loud bang, door won't open or is extremely heavy. | Complete operational halt, potential for motor burnout if operated. |

| Damaged Tracks | Grinding noises, jerky or stalled door movement. | Accelerated wear on other parts, potential for the door to come off its tracks. |

| Frayed/Broken Cables | Door hangs crooked, visible fraying on cables, or sudden drop. | Severe safety hazard from falling door, catastrophic equipment damage. |

| Operator Malfunction | Door opens/closes partially, won't respond to controls. | Security vulnerability, operational bottleneck, potential electrical hazard. |

The Professional Diagnostic Approach

While a facility manager is often first to spot symptoms, finding the why requires a trained eye. While you can find lists of local service providers on the BBB website, these directories don’t guarantee industry-specific expertise.

A certified technician from Wilcox Door Service follows a systematic process:

- Safety First: The first step is securing the site, disengaging the operator, and ensuring the door cannot move unexpectedly.

- Root Cause Analysis: We don't just replace the broken part. We investigate why it failed. Was the spring undersized for the door's weight? Did a misaligned track cause a cable to wear out?

- Comprehensive Inspection: Our check covers all related components—rollers, hinges, bearings—to spot underlying issues that could cause another failure.

This expert approach ensures your door isn't just working again; it's safe, reliable, and ready for the demands of your Hamilton facility.

If you’re seeing any of these warning signs, don’t wait. Contact us to schedule a professional inspection.

What to Expect from Our Emergency Repair Process

When a critical overhead door fails at your Hamilton facility, the clock starts ticking. A stuck loading dock door is a direct threat to your productivity, security, and safety. Knowing what to expect when you call for an emergency garage door repair in Hamilton provides clarity and peace of mind. Our process is built to get your operations back online safely and quickly, minimizing downtime with a transparent, professional response.

Your First Call Kicks Off an Immediate Response

The moment you contact our 24/7 dispatch, our emergency protocol activates. We gather critical information—the door's behavior, its location, and any safety concerns—to ensure our technician arrives prepared. This initial conversation helps us understand if we're dealing with a high-speed door in a food processing area or a large sectional door at a main shipping bay, allowing us to dispatch a union-certified technician in a fully-stocked service vehicle.

On-Site Safety and Diagnostics

Upon arrival, our technician's first priority is to secure the area by assessing risks and ensuring the door is stable. Safety for your team and ours is non-negotiable. Once the site is secure, methodical diagnostic work begins to find the root cause of the failure.

- Visual Inspection: The technician examines the entire door system for visible signs of damage like metal fatigue or frayed cables.

- Operational Testing: If safe, they test the operator, sensors, and controls for electrical or mechanical malfunctions.

- Root Cause Analysis: A snapped cable is the problem, but why did it snap? Our technicians dig deeper to find underlying issues, like a misaligned track, that caused the failure.

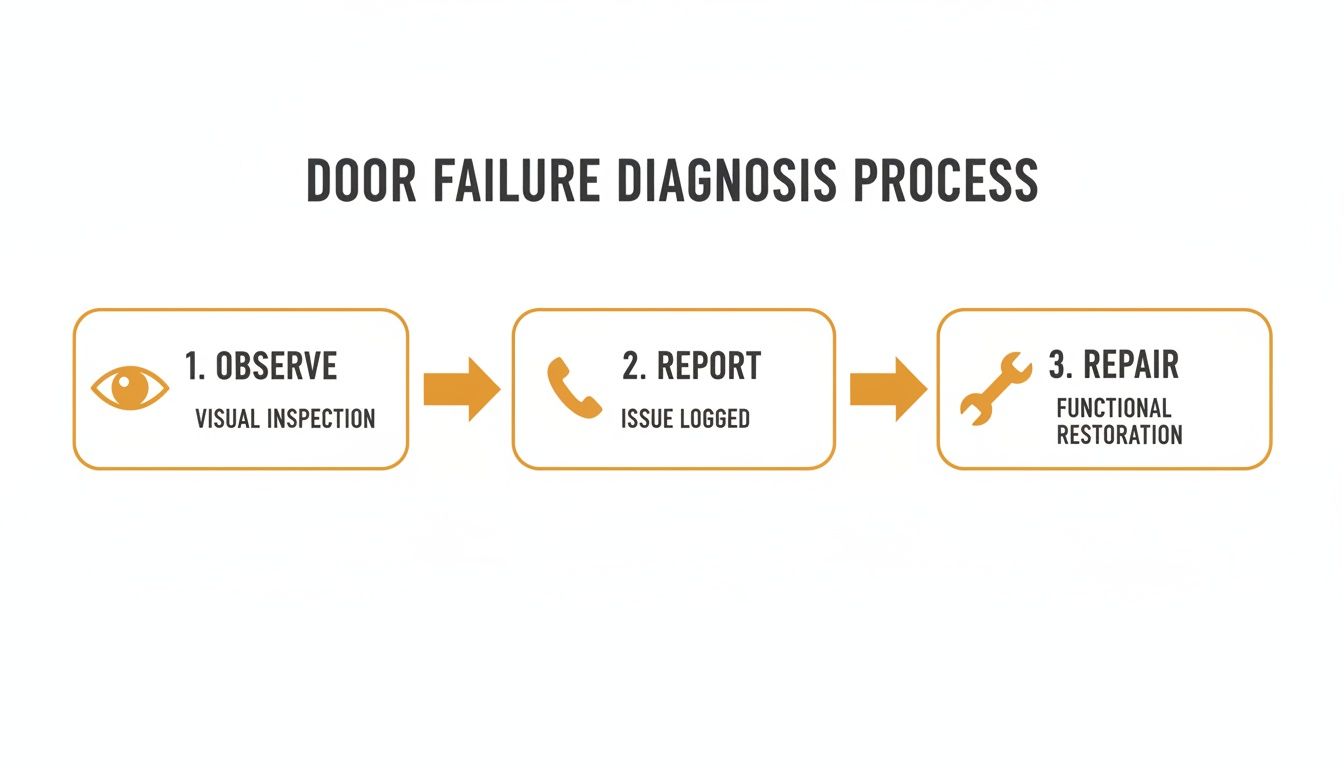

alt=A flowchart of the Wilcox Door Service diagnostic process for commercial door repair in Hamilton, showing the Observe, Report, and Repair steps.

This simple three-step process—Observe, Report, Repair—ensures we address the core problem for a permanent solution.

Clear Communication and On-the-Spot Repairs

After diagnosis, our technician will explain the findings in clear, simple terms, providing a detailed breakdown of the issue and an upfront quote. We believe in total transparency so you can make an informed decision.

Our commitment is to get you operational on the first visit. With service vehicles stocked with a wide inventory of commercial parts, our technicians complete most repairs on the spot.

Real-World Example: A loading dock door at a Hamilton logistics company is stuck halfway, preventing a truck from unloading critical supplies. Our technician arrives, identifies a failed bearing in the spring assembly, and replaces it from their vehicle's stock. The door is tested, re-balanced, and back in service within hours, preventing a major supply chain disruption. Learn more about our emergency door fixer process.

From call to completion, our process is efficient, professional, and reliable—reflecting our promise as your trusted partner.

If you have a door down, call our 24/7 emergency service line now for a rapid response.

Moving Beyond Repairs with Proactive Maintenance

The best way to handle garage door repair in Hamilton is to prevent it from happening in the first place. A reactive approach means you’re constantly one breakdown away from a crisis. Proactive maintenance is a smart business decision that protects uptime, keeps people safe, and saves you money. A Planned Maintenance Program (PMP) applies the same logic as scheduled vehicle service to your facility's most critical access points.

alt=A Wilcox technician performing preventative maintenance on a commercial overhead door in Hamilton.

What a Comprehensive Maintenance Visit Includes

A PMP visit is a thorough, systematic inspection designed to find small problems before they become major failures. Our technicians work through a detailed checklist:

- Lubrication of All Moving Parts: We lubricate every roller, hinge, and bearing to reduce friction—a major cause of premature wear.

- Spring Tension Adjustment: We check and adjust torsion springs to ensure the door is perfectly balanced. An unbalanced door puts massive strain on the operator, risking a burnt-out motor.

- Hardware Inspection and Tightening: We tighten all nuts and bolts loosened by daily vibrations to prevent misalignments.

- Safety Feature Testing: We run full diagnostics on safety mechanisms like photo-eye sensors and reversing edges to confirm they work perfectly.

The Financial Case for Proactive Maintenance

A PMP gives you control over your budget. Emergency repairs are always more expensive, but the real cost is downtime—lost production and delayed shipments can easily cost more than the repair itself.

Real-World Example: During a PMP visit at a Hamilton food distribution facility, a technician noticed advanced wear on a loading dock leveller's hydraulic hose. Replacing the hose was a quick, low-cost preventative repair. Had it failed during a busy loading cycle, it would have trapped a truck, spoiled perishable goods, and required a costly emergency cleanup and repair.

Proactive maintenance turns your repair budget from a volatile expense into a manageable operational cost. Our guide on garage door maintenance digs deeper into how these small steps prevent large-scale disasters.

Ensuring Safety and Compliance

Proactive maintenance is essential for meeting legal and safety obligations. Many Hamilton facilities must comply with strict fire codes. A key part of our PMP is performing and documenting mandatory annual fire door drop tests. These legally required tests prove your fire-rated doors will close and latch properly in an emergency, protecting your people and containing potential damage.

To build a proactive strategy for your facility, explore our planned maintenance programs.

Choosing the Right Repair Partner in Hamilton

Picking a service provider for commercial garage door repair in Hamilton is a decision that directly impacts your operational uptime, team safety, and bottom line. You aren't just looking for a quick fix—you're looking for a genuine partner who understands the pressures of an industrial environment and delivers lasting solutions. This comes down to a proven track record and union-certified technicians who master their craft, ensuring every job meets the highest safety and quality standards.

What Defines a True Partner

A reliable service partner offers a full spectrum of solutions to keep your facility running smoothly. This includes managing your entire access point ecosystem:

- New Installations: Expert guidance on selecting and installing the right door for your needs, from insulated sectional doors to high-speed models.

- Energy-Efficient Upgrades: Solutions that reduce energy bills, like high-performance doors and effective loading dock seals and shelters.

- Integrated Systems: Deep knowledge of how doors, docks, and commercial door operators work together.

At its core, a great partnership is built on trust. It’s knowing the team you call is as committed to your success as you are—a team that lives by the principle of “Respected Partners, Reliable Service.”

The Wilcox Advantage

Choosing Wilcox is a deliberate choice for safety, reliability, and long-term value. Our union-certified technicians ensure every job is done right the first time. We don't just fix what’s broken; we provide strategic advice to improve your facility's safety and efficiency. We know the unique demands of Hamilton's manufacturing plants, warehouses, and distribution centres inside and out. From routine maintenance to complex installations, we've got you covered.

Ready to see what a true partnership looks like? Contact our expert team today to discuss your needs and get a comprehensive quote.

Frequently Asked Questions

When it comes to commercial garage door repair in Hamilton, facility managers often have the same core questions. Here are some straight answers based on our decades of experience keeping local businesses running.

How Quickly Can You Respond to an Emergency Call?

When a critical door fails, every minute of downtime costs you money. That's why we offer 24/7 emergency service for garage door repair across Hamilton and the surrounding area.

The moment your call comes in, we dispatch a union-certified technician. Our goal is always to get on-site as fast as humanly possible to get you operational again. While exact timing depends on your specific location and traffic, our dispatch system is built to prioritize emergencies and minimize the disruption to your business.

Is It Better to Repair or Replace an Old Commercial Door?

That's the million-dollar question, and the honest answer is: it depends. We look at three things to help you make the right call: the severity of the damage, the door's age, and whether a repair is truly cost-effective.

A simple fix, like replacing a faulty sensor on a relatively new door, is a clear-cut repair. But if you have an older door with structural damage or one that needs constant, expensive attention, replacement often becomes the smarter long-term investment.

A new, modern door can deliver a significant return on investment through better energy efficiency and enhanced security—benefits that go far beyond just fixing the immediate issue. We'll always give you a straightforward assessment to help you weigh the costs and benefits for your facility.

What Is a Fire Door Drop Test and Is It Mandatory?

Yes, it's absolutely mandatory. A fire door drop test is an annual inspection required by the Ontario Fire Code for any facility with fire-rated rolling or sliding doors.

During the test, one of our certified technicians simulates an emergency to verify the door's automatic closing mechanism works perfectly, closing completely and latching securely. This isn't just about compliance; it's about ensuring that door will do its job in a fire, protecting your people and your property. After every test, we provide official documentation for your records. To see how this fits into a broader safety plan, check out our guide on planned maintenance programs.

For a complete assessment of your facility's door and dock needs or for immediate emergency service, partner with the team that has served Hamilton's industries with reliability and expertise. Contact Wilcox Door Service today to schedule an inspection or request a quote.