As a facility manager, you're responsible for keeping your building secure, efficient, and comfortable. This guide will walk you through everything you need to know about door sweeps for commercial doors, from selecting the right type for your needs to understanding their return on investment. You will learn how this small component can significantly lower energy costs, prevent pests, and improve overall facility operations, empowering you to make informed, cost-effective decisions for your building.

Why a Small Seal Makes a Huge Difference

It’s easy to overlook the simple strip of rubber or bristles at the bottom of a door. But in a commercial setting, that door sweep is a silent guardian of your facility's efficiency and security. A properly chosen and installed door sweep is a critical component for controlling energy costs, preventing pest infiltration, and maintaining a safe, compliant building. Ignoring the gap between the door and the floor can lead to surprisingly high operational costs and risks.

For facility managers, understanding the impact of this small component is crucial. A failing or non-existent sweep directly hits your budget and your team's comfort, and can even affect your building's structural integrity. For example, a worn-out sweep on a loading dock door not only drives up heating bills in winter but also lets in rainwater that can create slip hazards. Addressing this gap is one of the most practical and high-return investments you can make in your facility’s upkeep.

Alt text: An illustration of a man inspecting a door with a door sweep, highlighting benefits like energy saving, pest control, and weather protection for commercial doors.

The Role of Door Sweeps in Facility Management

Here in Canada, where weather extremes can strain any building's envelope, effective door sealing is non-negotiable. The industry that produces door sweeps for commercial doors has seen steady growth, largely driven by the increasing focus on energy efficiency. These simple seals stop significant air infiltration—a technical term for drafts—which is a key factor in heat loss, especially in large industrial spaces.

Effectively managing these components is a key part of a larger strategy. For a more holistic view, facility managers should also look into essential facilities management best practices, which cover maintaining all the functional elements of a building, like door sweeps.

Core Benefits for Your Building

A high-quality door sweep delivers several key advantages that contribute directly to a well-run facility:

- Energy Efficiency: It blocks drafts, keeping your heated or cooled air from escaping and reducing the load on your HVAC system. That translates directly to lower utility bills.

- Pest and Debris Control: The seal acts as a physical barrier against rodents, insects, dust, and outdoor contaminants. This is absolutely vital for food processing, pharmaceutical, and clean-room environments.

- Improved Environmental Comfort: By eliminating drafts and helping maintain consistent indoor temperatures, sweeps create a more comfortable and productive environment for employees and visitors.

Exploring the Main Types of Commercial Door Sweeps

Choosing the right door sweeps for commercial doors is like picking the right tool for a job—the best one depends entirely on the situation. Not all sweeps are built the same, and understanding their unique designs and materials is the first step toward a more efficient and secure facility. We'll break down the three main categories you'll encounter: brush sweeps, blade sweeps (like vinyl and neoprene), and automatic door bottoms.

Each type is tailored for specific environments and challenges. For instance, a sweep that’s perfect for the front entrance of an office building would fail quickly on a busy loading dock door exposed to the elements. Matching the sweep to your door’s location, traffic level, and the condition of the floor is key.

Brush Sweeps for Durability and Uneven Surfaces

Picture a very dense, stiff broom running along the bottom of your door. That’s essentially how a brush sweep works. Made of thousands of tightly packed nylon or polypropylene bristles, these sweeps are the workhorses of the commercial door world.

Their biggest advantage is flexibility. The bristles easily conform to irregular surfaces, which makes them perfect for spots with worn thresholds, rough concrete floors, or ramps—common conditions at loading docks or industrial service entrances.

- Best Use Case: High-traffic service corridors, loading dock pedestrian doors, and back-of-house entries where floors might not be perfectly level.

- Primary Benefit: They are incredibly durable and can withstand constant impact from carts, pallet jacks, and heavy foot traffic without tearing or breaking.

- Sealing Focus: Excellent for blocking dust, debris, and pests like rodents and insects, as the dense bristles create a surprisingly tough barrier.

While they are champions of durability, traditional brush sweeps don't offer the same level of thermal and moisture control as solid seals, making them a practical choice when toughness is more important than perfect weatherproofing.

Vinyl and Neoprene Sweeps for a Tight Weather Seal

If a brush sweep is like a broom, then a vinyl or neoprene blade sweep is like a high-quality squeegee. These sweeps have a solid, flexible blade—or sometimes several blades—that compresses against the threshold to create a tight, continuous seal.

This compression is what makes them so effective for weather and energy control. Neoprene, a type of synthetic rubber, is especially effective in tough environments. It withstands exposure to oils and chemicals and stays flexible across a wider range of temperatures than standard vinyl, so it won’t get brittle and crack in the cold.

Expert Insight: For any exterior door that faces direct rain, snow, or significant temperature swings, a heavy-duty neoprene blade sweep is almost always the most reliable choice. Its ability to maintain a firm, compressed seal is key to preventing water intrusion and stopping energy loss, which directly impacts your HVAC costs.

That tight seal also makes them a great option for reducing noise transmission between different areas. For a deeper look at sealing your entire door opening, you can learn more about the different types of weatherstripping for exterior doors and how they work together with a quality door sweep.

Automatic Door Bottoms: The Premium Sealing Solution

Automatic door bottoms are the most advanced sealing technology available. Unlike fixed sweeps, these are mechanical devices mounted on or mortised (recessed) into the door. They operate on a simple but brilliant principle: as the door closes, a plunger on the hinge side contacts the frame, which triggers a mechanism that smoothly drops a sealed bar down to the floor. When the door opens, the seal automatically lifts back up.

Why is this so beneficial?

- Zero Drag: Because the seal lifts completely off the floor, there’s no friction while the door is swinging. This prevents wear and tear on both the sweep and your flooring and allows the door to close smoothly without extra force, which is critical for meeting accessibility compliance.

- Perfect Seal on Demand: It provides an even seal only when needed, easily handling larger gaps under the door without creating a permanent tripping hazard.

- Superior Performance: They deliver the best results for soundproofing and creating a complete barrier against light, drafts, and smoke. This makes them essential for offices, conference rooms, healthcare facilities, and any space where environmental control is a top priority.

While they have a higher upfront cost and require precise installation, their longevity and superior performance provide tremendous value where performance truly matters. Partnering with a professional for installation ensures these mechanisms will work flawlessly for years to come.

Comparing Common Commercial Door Sweep Types

| Sweep Type | Material | Ideal Application | Sealing Performance | Durability |

|---|---|---|---|---|

| Brush Sweep | Nylon or Polypropylene bristles | High-traffic areas, uneven floors, pest control | Good for dust & pests; fair for drafts & water | Excellent |

| Vinyl Blade Sweep | Flexible Vinyl | Exterior doors in moderate climates, interior doors | Good for weather, air, and sound | Good |

| Neoprene Blade Sweep | Synthetic Rubber (Neoprene) | Exterior doors in harsh climates, chemical exposure | Excellent for weather, water, air, and sound | Very Good |

| Automatic Door Bottom | Aluminum housing with a variety of seal materials | Soundproof rooms, clean environments, accessible routes | Superior for air, sound, light, smoke | Excellent |

Each of these options has a clear place and purpose. The key is to match them correctly to your facility's specific needs.

How to Select the Right Door Sweep for Your Facility

Choosing the right door sweeps for commercial doors is more than a simple purchase—it’s a strategic decision that impacts your facility's efficiency, security, and stability. The best choice comes from a clear-eyed look at your specific operational needs.

This isn't about finding a single "best" solution. It's about matching the right hardware to the unique job each doorway performs. A sweep that’s perfect for a climate-controlled office entrance will be destroyed on a busy loading dock door facing a harsh Canadian winter.

Start with a Thorough Needs Assessment

Before you look at a product catalog, walk through your facility. Observe each door not just as an opening, but as a system with its own context. This methodical approach will save you headaches by ensuring you don't miss the small details that make a big difference.

For every door you evaluate, ask yourself these key questions:

- What is this door’s main job? Is it a high-traffic entrance for people, a massive rolling steel door for trucks, or a fire-rated door in a critical hallway?

- What is the floor condition? Are you dealing with a smooth, even threshold, or is it rough, cracked concrete with a ramp?

- What kind of weather does it face? Consider its exposure to driving rain, snow drifts, extreme cold, or intense sun.

- What is our number one goal? Are we trying to stop pests, slash energy bills, reduce noise, or just keep dust out?

The answers will build a clear profile for each door, pointing you directly toward the most effective type of sweep.

Matching the Sweep to the Door Type and Environment

Once your assessment is complete, you can start pairing specific sweeps with your facility's conditions. The goal is a perfect match between what the hardware does best and what the door needs to accomplish.

For example, a food processing plant is focused on preventing pests to meet sanitation standards. For their loading dock doors, a dense nylon brush sweep is an excellent choice. It forms a tough barrier against rodents and insects but is flexible enough to handle the uneven concrete floors common in those areas.

Conversely, a cold storage warehouse has a different priority: keeping the cold in. For their massive overhead doors, a heavy-duty neoprene blade sweep is non-negotiable. This material stays flexible in sub-zero temperatures, preventing ice buildup and ensuring a tight seal to stop expensive energy from escaping.

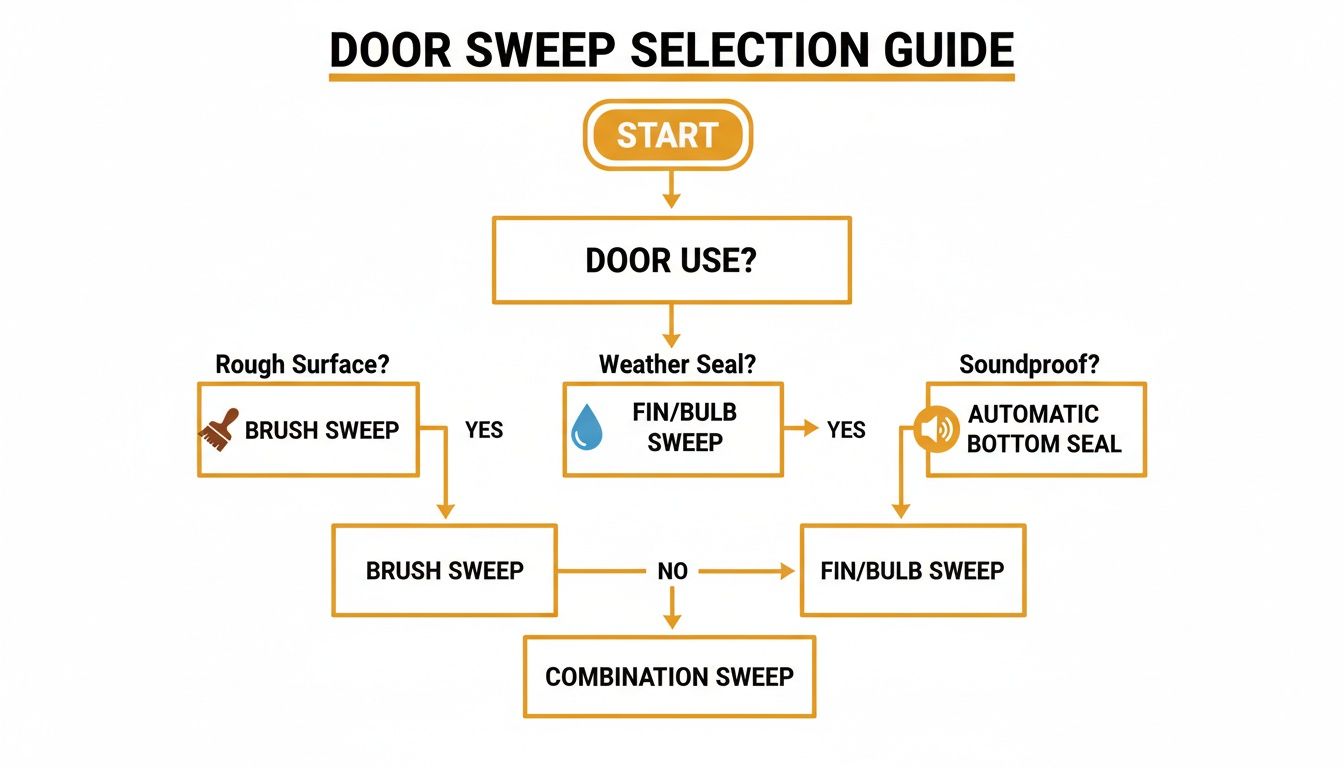

This flowchart helps visualize how your operational needs point to specific door sweep solutions.

Alt text: A flowchart titled “Door Sweep Selection Guide” for commercial doors, illustrating how to choose a sweep based on priorities like energy savings, pest control, or soundproofing.

The key takeaway is this: always start with the problem you're trying to solve—whether it’s drafts, pests, or noise—before you decide on a product.

Considering Compliance and Long-Term Value

The world of commercial doors is constantly evolving, especially with stricter safety regulations and a focus on energy efficiency. An improper sweep can increase the strain on your HVAC system by 10-15%. Getting it right is crucial for both safety and your bottom line.

Your choice of a door sweep isn't just about what works today. It's about meeting long-term safety standards and building code requirements. For fire-rated doors, you must use a sweep that is specifically listed for that purpose to maintain the door's fire-resistance rating. No exceptions.

A good seal is also a big deal for safety. It helps prevent slip-and-fall incidents caused by moisture being tracked inside—a major source of workplace injuries. Remember, while the bottom seal is key, you need to think about the whole opening. You can check out our guide on garage door seals for the top and sides to learn how to create a complete weather barrier.

Ultimately, picking the right door sweeps for commercial doors requires balancing the door type, its environment, and your facility's goals. By taking a thoughtful, systematic approach, you can ensure your investment delivers real value and contributes to a safer, more efficient facility.

Mastering Installation and Maintenance Best Practices

Even the best door sweeps for commercial doors are only as good as their installation and upkeep. A premium sweep that's poorly fitted or neglected won't do its job. Getting a few key practices right will dramatically extend its life and keep your facility sealed tight, highlighting the difference between a temporary fix and a professional solution.

Proper installation is all about precision. The goal is a perfect seal without making the door hard to operate. A sweep installed too tightly creates drag, putting a huge strain on your door operator and leading to burnout and expensive repairs. On the other hand, a sweep cut just a few millimeters too short creates a gap that lets in everything you’re trying to block.

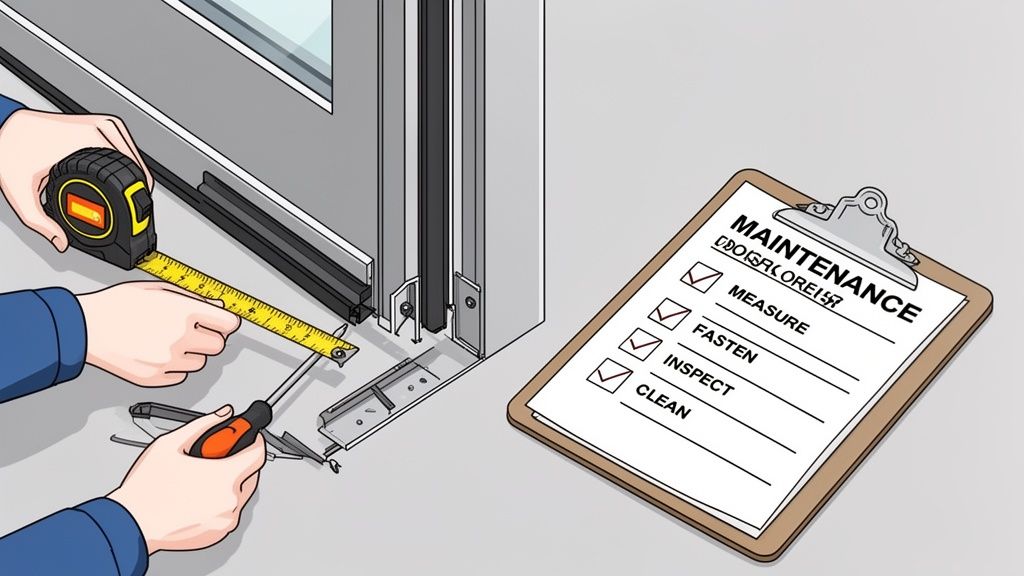

Alt text: A person measures the bottom of a commercial door as part of a door sweep maintenance checklist, emphasizing precision for proper sealing.

Common Installation Mistakes to Avoid

What seems like a simple task can go wrong quickly, leading to poor performance or even damage. Every facility manager should be aware of these common pitfalls—they highlight why calling in an expert is often the best move, especially for specialized systems like rolling fire doors.

- Improper Measurements: This is the number one culprit. Failing to measure the door width and the gap at multiple points can result in a sweep that's too short (leaving gaps) or too long (binding against the frame).

- Using the Wrong Fasteners: A hollow metal door requires different screws than an aluminum storefront or solid wood door. The wrong fasteners will loosen over time or damage the door itself.

- Creating an Overly Tight Seal: The goal is to eliminate gaps, but a seal that’s mashed against the threshold creates serious drag. This forces automatic operators to work overtime, leading to mechanical failure. For manual doors, it can create an accessibility issue.

- Ignoring the Threshold Condition: You can't get a good seal on a bad surface. If the threshold is damaged, cracked, or uneven, the sweep will never make proper contact. The threshold must be in good shape first.

Respected Partners, Reliable Service: For specialized doors, like anything fire-rated, professional installation isn't just a good idea—it's mandatory. An incorrect installation can void the door's fire rating, creating a massive compliance and safety liability for your facility.

Your Essential Maintenance Checklist

Regular upkeep is straightforward but absolutely critical for getting the most from your investment. By incorporating these checks into your routine facility inspections, you can spot trouble early and prevent bigger headaches. For more on general door care, our guide on comprehensive garage door maintenance has valuable tips that apply across many commercial systems.

A proactive maintenance schedule prevents failures before they happen, ensuring your doors stay sealed, secure, and efficient.

Monthly Visual Inspection:

- Check for Visible Gaps: Close the door and look for any light bleeding through underneath. It’s the clearest sign your sweep isn’t making contact anymore.

- Examine the Material: Look for cracks, brittleness, or tearing on vinyl and neoprene sweeps. For brush styles, check for flattened or missing bristles.

- Inspect Fasteners: Make sure all the screws are tight and the sweep housing is firmly attached to the door. Give it a gentle wiggle; it shouldn't move.

Quarterly Functional Check:

- Listen for Dragging: As you open and close the door, listen for any scraping or grinding. That's the sound of a sweep dragging too hard and wearing itself out.

- Clean the Sweep: Wipe down the seal with a damp cloth. Dirt and grime buildup can accelerate wear and compromise the seal's effectiveness.

- Confirm Alignment: Eyeball the sweep to ensure it's still level and making even contact all the way across the threshold.

By following these best practices, you ensure every door sweep for your commercial doors delivers the performance you paid for, protecting your facility and your bottom line.

Calculating the ROI of Quality Door Sweeps

Let's translate the physical benefits of a good seal into what matters most—your bottom line. While a new set of door sweeps for commercial doors may appear as a maintenance expense, it's more accurate to view it as an investment with a real, tangible financial return. Calculating this return on investment (ROI) is key to justifying the upfront cost because it highlights the significant, long-term savings you'll achieve.

This isn’t just about a single number; it's about understanding the cumulative effect of what seems like a small upgrade. For a facility manager, that means looking at direct energy savings, reduced strain on your expensive HVAC equipment, and the costs you avoid—like pest control services, spoiled products, or compliance fines.

Alt text: An illustration showing the ROI of a commercial door sweep, with a bar chart indicating increasing energy savings over time.

Analyzing Your Energy Savings

The most direct way a quality door sweep pays for itself is through lower energy bills. It's simple physics. Gaps under your doors create a constant exchange of air, forcing your heating and cooling systems to work overtime to maintain a stable indoor temperature. This is especially true for large facilities like warehouses or manufacturing plants.

Consider a 100,000 sq. ft. facility with just a couple of poorly sealed loading dock doors. Over a harsh Canadian winter, those small gaps can easily translate into thousands of dollars in wasted heating costs. Sealing them properly creates an immediate and measurable drop in your utility bills.

Poor door sealing is a massive culprit in commercial facilities, causing an estimated 20-30% of all energy waste. Our hands-on experience shows that proper sweeps can deliver significant energy reductions, often with a payback period of under 18 months through lower bills and fewer repairs. It’s a clear ROI that also aligns with national green mandates. To learn more, you can discover insights on the North American doors market.

The Hidden Costs You Avoid

Beyond the energy bill, a failing door sweep leads to a host of other expenses that can quickly add up. These "avoided costs" are a critical part of your ROI calculation.

- Pest Control Services: An unsealed door is an open invitation for rodents and insects. A durable brush sweep is far cheaper than repeated calls to professional pest control services.

- Product Spoilage: In temperature-sensitive environments like food processing or pharmaceutical storage, a stable climate is non-negotiable. A failing seal can lead to thousands in lost product.

- HVAC Maintenance and Replacement: By easing the workload on your HVAC units, you extend their lifespan and reduce the frequency of service calls, delaying major capital expenditures for years.

The Bottom Line: A high-quality door sweep isn't a simple purchase; it's a strategic tool for cost containment. The upfront investment is quickly recovered by direct energy savings and, just as importantly, by preventing much larger, more disruptive expenses down the road.

Putting It All Together

To get a rough ROI estimate, start by adding up the annual costs you can link to a poorly sealed door. Tally your estimated energy waste with what you spend on related issues like pest control or extra maintenance calls.

Now, compare that total to the cost of having new, high-performance door sweeps for commercial doors professionally installed. In most facilities we service, the investment pays for itself in less than two years and continues to deliver savings long after.

This simple calculation shows how a proactive approach to facility maintenance delivers real, measurable financial benefits. For help selecting the right products to maximize your ROI, exploring our door and dock services can provide the expert guidance you need.

Why Partner with a Commercial Door Expert?

While it may be tempting to handle some maintenance tasks in-house, the performance and compliance of your facility's doors often hinge on deep expertise. When dealing with specialized systems like fire-rated doors, planning large-scale retrofits, or managing a facility with strict sanitation requirements, calling in a professional for your door sweeps for commercial doors isn't just a good idea—it's essential. The stakes are simply too high for guesswork.

Choosing to partner with a commercial door expert is a strategic move that protects your assets, ensures safety, and keeps your operations running smoothly. It’s the difference between a quick patch and a lasting solution.

The Value of Certified Expertise

A professional installation is all about precision. Our union-certified technicians bring decades of hands-on experience to every job, ensuring each sweep is measured, cut, and fastened perfectly. This guarantees optimal performance without putting premature wear on your door operators—a level of detail that is absolutely critical for complex applications.

Consider these scenarios where an expert is non-negotiable:

- Specialized Door Systems: Installing sweeps on rolling steel fire doors or high-traffic cold storage doors requires specific know-how to maintain both functionality and compliance.

- Large-Scale Retrofits: Upgrading an entire building means navigating dozens of different door types and conditions. An expert ensures consistency and correct application across the board.

- Strict Compliance Requirements: In industries like food processing or pharmaceuticals, a perfect seal isn't a "nice-to-have"—it's mandatory for sanitation and quality control.

When looking at the bigger picture of your commercial door's security and function, making sure every component works together is key. That's where broader expertise from providers of commercial locksmith services can be invaluable in maintaining peak performance and security.

Respected Partners, Reliable Service

Our goal isn't just to complete a single service call. We aim to be your long-term partner in facility safety and efficiency, delivering on a promise of reliable service you can count on for years to come.

Your Next Step Toward a Sealed Facility

From understanding why a good seal is so important to calculating its return on investment, it's clear that door sweeps for commercial doors are a small part with a massive impact. They protect your budget, your people, and your products. By working with Wilcox Door Service, you’re not just getting a part installed; you're gaining access to the expertise needed to keep your facility sealed, secure, and efficient.

Ready to ensure your doors are performing at their best? Contact our team today to schedule a comprehensive facility assessment.

Your Questions About Commercial Door Sweeps, Answered

As a facility manager, you're always looking for practical solutions. When it comes to door sweeps for commercial doors, a few key questions come up time and again. Here are clear, straightforward answers based on our experience in the field.

How Often Should We Be Replacing Our Door Sweeps?

There’s no single answer here. The lifespan of a door sweep depends on its material, the door's traffic volume, and the environment. A heavy-duty neoprene sweep on a busy loading dock might last 2-4 years, while a tough brush sweep in a quiet office hallway could perform well for much longer.

The key is to inspect them regularly rather than sticking to a rigid schedule. Catching the warning signs early prevents bigger problems like energy loss and security gaps.

Here’s what to look for:

- You Can See Daylight: This is the most obvious red flag. If light is getting under the door, so are drafts, pests, and noise.

- The Material is Breaking Down: Check for cracking, brittleness, or tears on vinyl and neoprene sweeps. Once the material loses its flexibility, the seal is compromised.

- The Bristles are Flat: For brush sweeps, the bristles need to be stiff to work. If they’re bent, matted down, or flattened, they are no longer creating a proper barrier.

Can a Door Sweep Actually Help with Noise Reduction?

Absolutely. While we usually think of sweeps for blocking drafts, the right one can make a noticeable difference in soundproofing. It all comes down to creating a solid, uninterrupted seal against the threshold.

Heavy-duty neoprene or solid vinyl sweeps that press firmly against the floor are great for dampening sound. But if you’re serious about acoustic control—for an office, boardroom, or healthcare setting—the best-in-class solution is an automatic door bottom. These devices drop down to create a perfect, tight seal only when the door is closed, offering superior noise reduction.

Do Fire-Rated Doors Need Special Sweeps?

Yes, and this is a non-negotiable point for safety and compliance. A fire-rated door is a critical part of a building’s life-safety system, and every single component on that door must be tested and listed for that specific use.

Slapping a standard, non-rated sweep on a fire-rated door assembly instantly voids the door's fire rating. This creates a massive liability and puts people at risk.

These specialized sweeps are often called smoke seals or intumescent seals. An intumescent material is designed to swell up when exposed to heat from a fire, completely blocking the gap and stopping smoke from spreading. You must always work with a certified door technician to ensure your hardware meets the strict fire safety requirements of the National Building Code.

For expert guidance on selecting the right hardware or to schedule a professional installation, trust the team at Wilcox Door Service Inc. Our certified technicians ensure your facility’s doors are sealed, secure, and fully compliant. Learn more by visiting us at https://www.wilcoxdoor.com.