Choosing the right commercial door glass is a critical decision that impacts your facility's security, energy efficiency, and daily operations. This guide is designed to give facility managers and business owners clear, practical insights into making an informed choice. You will learn about the different types of commercial glass, what key performance ratings actually mean, and how professional installation and maintenance can protect your investment and ensure a safe, compliant environment.

What Is Commercial Door Glass

At its core, commercial door glass is any glazing—an industry term for the glass system installed in a door—that is specifically engineered to withstand the rigorous demands of business environments. Unlike residential glass, it must handle high foot traffic, significant security risks, and strict building safety codes. You'll find it in everything from a retail storefront's inviting entryway to the massive overhead doors of a busy loading dock.

The importance of these components cannot be overstated. In Canada, the doors segment of the windows and doors market holds a massive 54.02% revenue share, translating to approximately USD 7 billion. This highlights the vital role that high-quality commercial door systems, including their glass, play in facilities like warehouses, manufacturing plants, and public buildings.

More Than Just a Window

Thinking of commercial door glass as a simple pane is missing the bigger picture. It's an engineered system designed to perform multiple functions that keep a facility running smoothly and safely. For any facility manager, understanding these functions is the first step toward making a sound investment.

A well-chosen glass solution can:

- Enhance Natural Light: Brighten workspaces and retail floors, improving employee morale and creating a more welcoming atmosphere for customers.

- Improve Security: Serve as the first line of defense against break-ins, with specialized options designed to resist impact and forced entry.

- Increase Energy Efficiency: Help regulate indoor temperatures by preventing heat loss in the winter and heat gain in the summer, leading to tangible savings on energy bills.

- Ensure Safety and Compliance: Meet strict building codes for hazardous locations, such as fire exits and busy corridors, protecting occupants and helping you avoid costly fines.

Real-World Applications

To put it in practical terms, the glass needed for a storefront in a high-traffic mall is fundamentally different from the glass required for a door in a pharmaceutical cleanroom. The storefront needs maximum visibility and impact resistance. The cleanroom door, however, demands specific seals and durability to withstand harsh cleaning agents.

Similarly, glass used in exterior doors must deliver exceptional thermal performance to combat Canada's weather extremes. You can learn more about this in our guide to commercial glass entry doors.

Ultimately, selecting the right commercial door glass is a strategic decision. As "Respected Partners, Reliable Service," we at Wilcox Door know that an informed choice leads to superior performance, lower operational costs, and a safer environment for everyone.

Decoding the Main Types of Commercial Door Glass

Choosing the right commercial door glass is far more complex than picking out a window for your home. Each type is specifically engineered to balance safety, security, and day-to-day performance. Getting this choice right is a smart investment that protects your facility, your people, and your bottom line.

Think of it like choosing tires for a vehicle. You wouldn’t put racing slicks on a heavy-duty transport truck, and you wouldn't use standard glass where high security is a must. Let’s break down the main players in the world of commercial glass.

Tempered Glass The Safety Standard

Tempered glass is the workhorse of commercial doors, especially in areas with high foot traffic. It undergoes a process of intense heating and rapid cooling that makes it about four times stronger than standard annealed glass.

But its key safety feature isn't just its strength—it’s how it breaks. Instead of shattering into large, dangerous shards, tempered glass crumbles into small, pebble-like pieces that are far less likely to cause serious injury. This is precisely why it is mandated for storefronts, office entryways, and any pedestrian door where public safety is the top priority.

Laminated Glass The Security Specialist

If tempered glass is about breaking safely, laminated glass is engineered to not break apart at all. It's essentially a glass sandwich: two or more layers of glass are bonded together with a tough, clear vinyl interlayer, typically polyvinyl butyral (PVB).

When laminated glass is struck, the glass layers may crack, but the vinyl interlayer holds the pieces firmly in place. This feature is a game-changer for security. It effectively stops "smash-and-grab" burglaries and creates a formidable barrier against forced entry, making it ideal for facilities that store valuable assets. For a deeper dive into these materials, this guide on laminated and toughened glass is an excellent resource.

Insulated Glass Units The Energy Saver

Energy costs are a major operational expense for any facility. Insulated Glass Units (IGUs) are designed to tackle this problem head-on. An IGU consists of two or more panes of glass separated by a spacer and hermetically sealed, creating a gap filled with air or an inert gas like argon.

This sealed gap acts as a thermal barrier. It dramatically reduces heat transfer, keeping your building warmer in the winter and cooler in the summer. For a refrigerated warehouse or a climate-controlled manufacturing facility, IGUs are not just a nice-to-have—they are essential for operational efficiency and cost control.

This flowchart illustrates how the key factors of security, energy, and safety influence your glass selection.

Alt text: Flowchart illustrating three interconnected factors for selecting commercial door glass: security, energy efficiency, and safety compliance.

As you can see, these three pillars are interconnected. The best glass choice often comes down to finding the right balance for your facility's unique needs.

Specialized Glass for Unique Demands

Beyond the big three, several specialized types of commercial door glass are engineered for specific, high-stakes applications.

- Fire-Rated Glass: This is a critical life-safety product. It is constructed with materials like ceramic glass or intumescent interlayers that can withstand extreme heat, containing fire and smoke for a specified period (e.g., 20, 45, or 90 minutes). It is legally required in fire-rated door assemblies, particularly in exit corridors and stairwells.

- Security Glass (Polycarbonate & Acrylic): When maximum impact resistance is needed, materials like polycarbonate are the solution. Often used in high-security government buildings or industrial sites, polycarbonate is virtually unbreakable and offers premier protection against vandalism and forced entry.

- Vision Lites: These are the small windows, or "lites," you see in otherwise solid doors, such as those in warehouses or staff entrances. Typically made from tempered or laminated glass, they provide just enough visibility to prevent collisions and improve workplace safety without compromising the door's structural integrity.

To help clarify how these types compare, here is a quick reference guide.

Commercial Door Glass Types at a Glance

| Glass Type | Key Feature | Primary Benefit | Common Application |

|---|---|---|---|

| Tempered | Shatters into small, dull pieces | Reduces risk of injury | Storefronts, office entries, high-traffic areas |

| Laminated | Interlayer holds glass together | Prevents forced entry | Retail, high-value storage, government buildings |

| Insulated (IGU) | Gas-filled gap between panes | Improves thermal efficiency | Climate-controlled warehouses, exterior doors |

| Fire-Rated | Withstands extreme heat | Contains fire and smoke | Stairwells, exit corridors, fire separation walls |

| Security | Polycarbonate or acrylic | Extreme impact resistance | High-security facilities, correctional institutions |

| Vision Lite | Small window in a solid door | Provides visibility for safety | Warehouses, back-of-house, staff entrances |

This table provides a clear overview of which glass type is engineered for which task. Matching the glass to the application is the key to achieving the performance, safety, and security your facility demands.

Understanding Key Performance and Safety Ratings

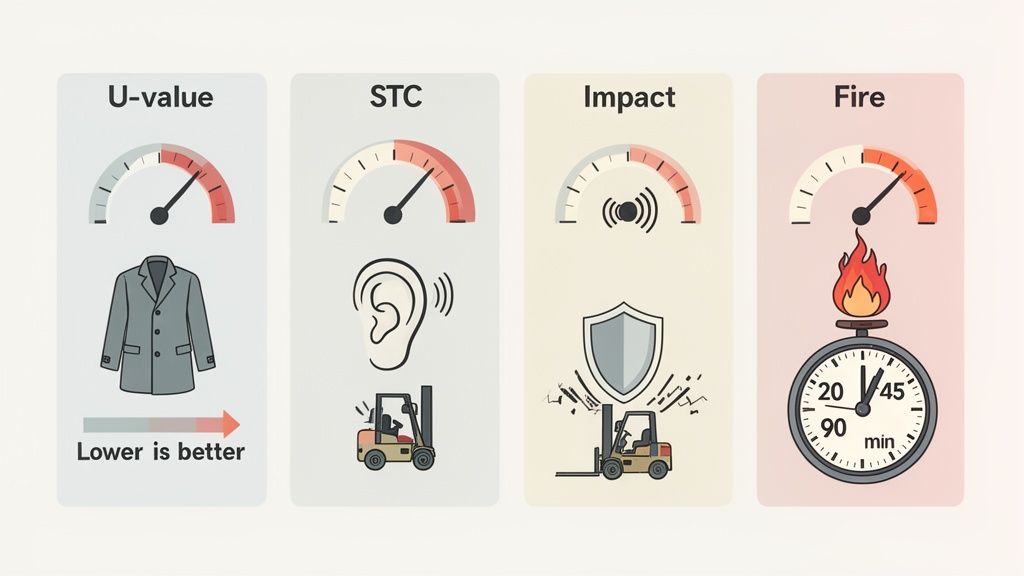

When reviewing specifications for commercial door glass, the acronyms and numbers—U-value, STC, fire ratings—can seem intimidating. However, these ratings are your best tools for ensuring you get real value in safety and energy savings.

Think of these ratings not as technical jargon, but as a performance report card. They tell you precisely how the glass will function, from insulating your building to providing critical time in an emergency. Understanding these metrics is key to making a smart decision that balances cost, performance, and compliance.

Alt text: Infographic icons for commercial glass performance metrics: U-value (thermometer), STC (sound waves), impact resistance (shattered shield), and fire resistance (flame).

U-Value: Your Defence Against Energy Loss

The U-value measures insulation. Put simply, it tells you how well the glass prevents heat from passing through it. The lower the U-value, the better the insulation.

In a real-world scenario like a Canadian winter, a door with a low U-value keeps heated air inside and cold air out. This directly reduces the workload on your HVAC system, leading to lower energy bills and operational costs. For insulated units, it's also helpful to understand issues like why double pane windows fog up, as this indicates a failure in their insulating properties.

Sound Transmission Class: Quieting the Noise

The Sound Transmission Class (STC) rating measures how effectively the glass blocks sound. A higher STC rating means less noise gets through. This can be a game-changer in certain commercial environments.

For example, in a manufacturing facility, installing a high STC-rated glass door between the noisy production floor and the main office can transform the workspace from chaotic to quiet and focused. This single feature can significantly boost productivity and employee well-being.

Impact Resistance: Guarding Against Threats

Impact resistance levels indicate how well the glass can withstand being struck. These ratings are crucial for both security and safety, protecting against everything from an accidental bump with a forklift to a deliberate break-in attempt.

- Low-Level Impact: Suitable for areas where accidental contact is possible but forced entry is not a major concern.

- Forced-Entry Resistance: This calls for laminated glass or polycarbonate. These materials are designed to withstand repeated blows, delaying or preventing unauthorized entry. Such features often work in tandem with access control systems, which you can learn about in our article on magnetic locks for doors.

- Ballistic Ratings: For high-security facilities like government buildings or banks, ballistic-rated glass is engineered to stop projectiles from specific firearms.

Choosing the right level depends on a realistic assessment of your facility's security risks.

Fire-Resistance Ratings: A Matter of Life Safety

This is arguably the most critical rating. The fire-resistance rating on commercial door glass, measured in minutes (e.g., 20, 45, 60, or 90 minutes), tells you precisely how long the glass can maintain its integrity when exposed to fire. It is designed to contain flames and smoke, preventing them from spreading.

This isn't just a feature; it's a non-negotiable life-safety requirement mandated by building codes for locations like stairwells and fire-rated corridors. Every minute of resistance buys precious time for occupants to evacuate and for first responders to arrive. It is no surprise that Canada's fire-rated glass market, valued at USD 284.4 million, is growing, with the commercial segment holding a 63% market share as businesses upgrade to meet modern safety standards.

By understanding these performance metrics, you are empowered to choose a solution that genuinely enhances your facility’s safety, security, and efficiency.

Navigating Building Codes and Professional Installation

Selecting the right commercial door glass is only half the battle. Ensuring it is installed correctly and meets all legal requirements is equally critical. Adhering to building codes isn't just about avoiding fines—it's about ensuring the safety of every person who enters your facility. A professional installation guarantees that your investment performs exactly as intended.

This section will explain the key Canadian National Building Code (NBC) requirements for commercial door glass and break down why a professional installation process is essential for protecting your property and people.

Why Building Codes Matter for Glass

At their heart, building codes exist for one primary reason: life safety. For commercial door glass, these rules are focused on preventing injuries and ensuring safe egress, especially during an emergency. The National Building Code of Canada (NBC) identifies specific "hazardous locations" where safety glazing is not just recommended, but mandatory.

Think of these codes as a safety blueprint. They dictate where you must use tougher glass—like tempered or laminated options—to mitigate risk.

Key areas where the NBC requires safety glass include:

- Glazing in All Doors: Any glass panel within a swinging, sliding, or bifold door is considered a hazardous location and requires safety glazing.

- Glazing Near Doors: Glass panels located close to a doorway (typically within 24 inches horizontally) are subject to the same strict rules. This is to prevent someone from accidentally putting a hand through a standard glass pane when reaching for the door handle.

- Large Glass Panels Near the Floor: Large windows or glass walls near pedestrian traffic areas must be safety glass to prevent severe injuries from a trip or fall.

- Glass in Fire-Rated Assemblies: Any glass installed in a fire door or a fire-rated wall must be a specialized, fire-rated product that has been tested to contain smoke and flames for a specified duration.

These regulations ensure that in high-traffic or high-risk zones, the glass is either strong enough to withstand impact or will break in a much safer manner.

The Professional Installation Process: A Step-by-Step Look

A professional installation is a precise, meticulous process that guarantees security, energy efficiency, and long-term durability. Attempting a DIY installation or hiring a non-specialist can easily result in air leaks, security vulnerabilities, and non-compliance with building codes.

The process follows several critical steps:

- Thorough Site Assessment: A certified technician begins by evaluating the existing door, frame, and surrounding structure. They assess usage patterns—such as traffic flow and security risks—to confirm that the selected glass is the right fit for the application.

- Precise Measurement and Fabrication: Measurements must be exact. An error of even a few millimetres can compromise the seal and structural integrity of the door. These precise specifications are then used to custom-fabricate the glass unit.

- Expert Installation and Sealing: The technician carefully removes the old glass and installs the new unit using the correct glazing compounds and seals for that specific door and glass type. A proper seal is absolutely essential for preventing drafts and moisture intrusion, which is critical for insulated glass performance.

A professional installation is not an expense; it's an investment in performance. It ensures that the U-values, STC ratings, and security features you paid for are actually realized, preventing costly issues like energy loss or premature failure down the road.

Imagine retrofitting a warehouse's overhead doors with new insulated glass units. A professional will ensure the new panels integrate perfectly with the existing door system and operator. They will verify that the added weight won’t strain the motor and that the seals are completely airtight. The result is immediate energy savings, reduced noise for your staff, and full compliance with safety standards—benefits that a rushed job simply cannot provide. As your "Respected Partners, Reliable Service" provider, we ensure every installation meets the highest industry standards.

To ensure your facility is safe, compliant, and efficient, it's always best to work with experts. Schedule a service inspection with our union-certified technicians to assess your current door glass and identify opportunities for upgrades.

Essential Maintenance and Repair Strategies

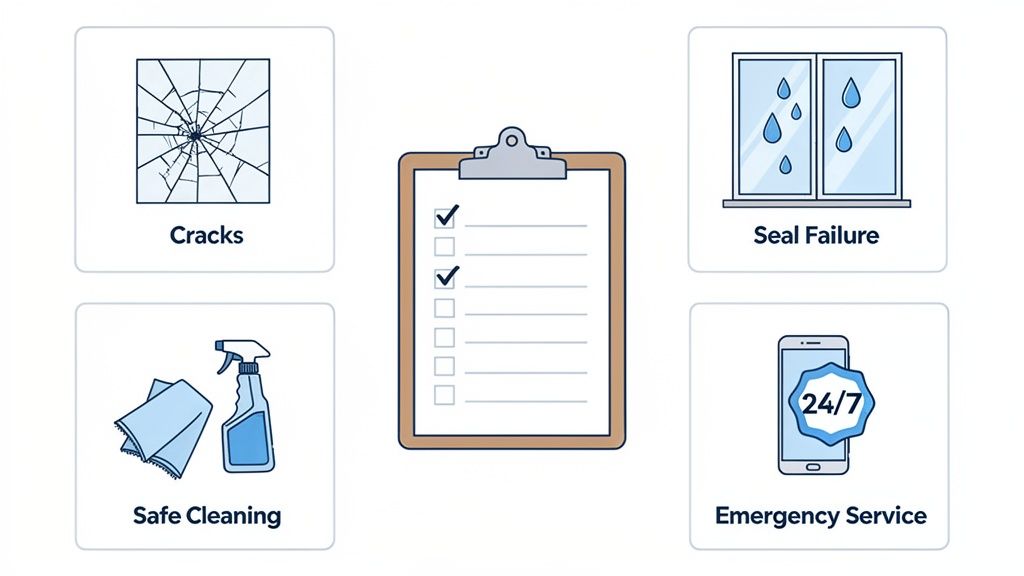

Your commercial door glass is a significant investment in your building's safety, security, and aesthetic appeal. Like any other critical facility component, it requires regular attention to maintain peak performance and prevent minor issues from escalating into costly emergencies. A proactive maintenance plan is the best way to ensure your glass protects your property and people for years to come, minimizing unexpected downtime.

This section provides a practical playbook for maintaining your commercial door glass. We will cover a straightforward inspection checklist, share tips for safe cleaning, and help you determine when a repair is sufficient versus when a full replacement is necessary.

Alt text: Infographic of common commercial glass issues and services: cracks, seal failure, safe cleaning, and 24/7 emergency service.

Routine Inspections: Your First Line of Defence

The most effective way to catch problems early is through regular visual checks. By incorporating this into your maintenance team’s daily or weekly rounds, you can spot subtle signs of wear and tear before they become serious.

A simple checklist can make a significant difference, ensuring a consistent and thorough inspection every time. This small step can save you from major headaches and expenses down the line.

Here is a simple schedule to help your team stay on top of routine checks and keep your commercial door glass safe and functional.

Preventive Maintenance Checklist for Commercial Door Glass

| Frequency | Inspection Point | What to Look For | Action Required |

|---|---|---|---|

| Weekly | Glass Surface | New chips, scratches, or small cracks. | Note the location and size; monitor for any changes. |

| Monthly | Insulated Glass Units | Any fogging, haze, or condensation between the panes. | This is a clear sign of a failed seal, indicating the unit needs replacement. |

| Monthly | Gaskets and Seals | Cracking, shrinking, or visible gaps around the glass perimeter. | Damaged seals compromise energy efficiency and security. Plan for replacement. |

| Quarterly | Door Hardware | Loose handles, hinges, or closers near the glass. | Tighten or adjust immediately to prevent undue stress on the glass panel. |

Making these quick checks a regular habit is not just about maintaining glass; it’s about actively preventing costly future repairs and ensuring a safer environment.

Smart Repair Decisions: Repair or Replace?

One of the most common questions from facility managers is whether to repair a small chip or replace the entire glass pane. The correct decision depends on the type of glass, the extent of the damage, and the associated safety risks.

While a small, isolated chip in a large laminated glass panel might be professionally repaired with resin, this is rarely a permanent solution in a high-traffic commercial setting.

Any crack, no matter how small, compromises the structural integrity and safety of tempered glass. Once tempered glass is cracked, it has lost its strength and must be replaced immediately to maintain safety standards.

With laminated glass, even if the vinyl interlayer holds the fragments together, a crack means the outer layer is compromised. This creates a security risk and makes a full replacement the only safe and reliable option. To better understand these factors, review our detailed guide on when to replace a glass door.

Safe Cleaning Practices for Longevity

Specialty commercial door glass, such as panes with Low-E (low-emissivity) coatings or tints, requires a gentle touch. Using harsh chemicals or abrasive tools can easily strip these coatings, reducing their energy efficiency and damaging their appearance.

Follow these simple best practices:

- Use the Right Solution: A mixture of mild soap and water or a non-ammonia-based glass cleaner is ideal.

- Choose Soft Materials: Always use soft, lint-free microfiber cloths or a squeegee with a clean rubber blade.

- Avoid Abrasives: Never use scrapers, razor blades, or gritty cleaning pads, as they will permanently scratch the glass and its coatings.

Partnering for 24/7 Emergency Service

Accidents are inevitable. Whether it's from a forklift collision, severe storm damage, or a break-in attempt, shattered door glass poses an immediate security and safety threat. In these situations, waiting until the next business day is not an option.

This is where having a reliable service partner is invaluable. Access to 24/7 emergency service ensures your facility can be secured quickly, minimizing downtime and protecting your assets. As "Respected Partners, Reliable Service," our mission is to restore your building’s safety and security with speed and professionalism, day or night.

When your facility's security is compromised, you need a team that responds immediately. Contact Wilcox Door Service to learn about our 24/7 emergency repair services and ensure you’re prepared for anything.

Your Partner in Commercial Door Solutions

Choosing the right commercial door glass is a critical first step, but partnering with the right service provider ensures its lasting value and performance. You now understand the essentials—from selecting durable laminated glass for security to deciphering the performance ratings that impact your bottom line. The next step is connecting that knowledge to a reliable, long-term solution.

A true partnership extends beyond a single transaction. It’s about having a team that understands the unique pressures of your facility and provides expert guidance from initial consultation through installation and ongoing maintenance.

Expertise You Can Trust

Making an informed decision requires having all the facts. Our team offers professional consultations to help you navigate the options. We assess your operational needs, security vulnerabilities, and energy goals to recommend the ideal glass solution, ensuring you meet all Canadian building code requirements along the way.

This approach ensures you invest in a product that delivers tangible, real-world benefits.

We believe an informed choice leads to better performance, lower operating costs, and a safer environment. Our commitment is to provide the clarity you need to make that choice confidently, reinforcing our brand promise of “Respected Partners, Reliable Service.”

Installation and Service by Certified Professionals

Even the highest quality glass will underperform if not installed perfectly. Our union-certified technicians are trained to execute every step of the process with precision. They ensure every panel is installed, sealed, and tested to meet the highest industry standards, guaranteeing the performance and longevity you expect from your investment.

This level of professionalism is what distinguishes an adequate solution from an exceptional one. It is the difference between a door that simply functions and a door system that enhances your facility's efficiency and security for years to come. You can learn more about our commitment to quality on our commercial door services page.

Ready When You Need Us Most

Finally, a true partner is there when things go wrong. A broken glass door is more than an inconvenience; it's an immediate security breach and a serious safety hazard. That's why we offer responsive 24/7 emergency repair services to secure your facility quickly, minimizing downtime and protecting your assets.

Whether you are looking to upgrade, need routine maintenance, or are facing an unexpected repair, we are here to support you.

Take the next step toward a safer, more efficient facility. Contact Wilcox Door Service today for a professional assessment or to schedule a service inspection with our expert team.

Your Questions, Answered

When it comes to commercial door glass, making the right choice saves you headaches and money down the road. Here are a few of the most common questions we get from facility managers, along with some straight-shooting answers from our team.

What Is the Most Durable Glass for a High-Traffic Warehouse?

For a busy warehouse with forklifts and constant movement, you need glass that can withstand significant impact. Laminated glass or polycarbonate panels are your best options. Laminated glass is designed to hold together even when it shatters, which prevents dangerous flying shards and maintains the security barrier.

For the absolute toughest solution, polycarbonate is the top choice. It is virtually unbreakable and provides the highest level of impact resistance for demanding industrial environments.

How Do I Know if My Insulated Glass Unit Seal Has Failed?

The telltale sign of a failed insulated glass unit (IGU) is a foggy or misty appearance between the panes of glass. You might also notice condensation. This occurs when the airtight seal is broken, allowing moisture-filled air to enter and completely neutralizing the unit's insulating properties.

Once you see fogging, the unit is no longer energy-efficient and needs to be replaced to restore its thermal performance.

Are There Energy Rebates in Canada for Upgrading Commercial Door Glass?

Yes, absolutely! Several federal and provincial programs across Canada offer incentives for improving the energy efficiency of commercial buildings. Upgrading to high-performance IGUs in your doors and windows often qualifies for these rebates.

We recommend checking with your local utility providers and consulting resources like Natural Resources Canada (NRCan) for the latest programs. Eligibility criteria and rebate amounts vary by region, but taking advantage of these programs is a great way to improve your facility and achieve a faster return on your investment.

At Wilcox Door Service Inc., we believe an informed partner is a prepared partner. Our team is ready to answer any other questions you have about selecting, installing, or maintaining your facility's door systems.

For expert guidance on your next project, explore our commercial door services or contact us for a consultation.