This guide will walk you through everything you need to know about the automatic door operator, the powerful system that automates your commercial and industrial doors. You will learn what these systems are, how to choose the right one for your facility, and how different activation methods can be tailored to streamline your specific workflow, from a busy retail entrance to a high-traffic loading dock. We’ll also cover critical safety codes and the importance of professional installation and maintenance to ensure long-term reliability.

At its core, an automatic door operator is the motorized system that serves as the brain and the muscle behind any door that opens and closes on its own. It’s the technology that gets rid of the need to manually push or pull a door, creating smooth, accessible entryways for commercial and industrial buildings. Put simply, it’s what turns a regular door into an automated one.

What’s Really Inside an Automatic Door Operator?

Think of an automatic door operator as the most reliable doorman you could ever hire—one that works 24/7 without a single complaint or coffee break. It’s a sophisticated piece of equipment built to improve convenience, accessibility, and the overall flow of traffic in and out of a building. For any facility manager, understanding its basic parts is the first step in seeing how it can genuinely improve your building’s daily operations and safety.

This kind of technology is no longer a luxury; it’s a fundamental part of modern buildings. The demand for automated entry is booming, with the North American market valued at around USD 900 million and projected to nearly double by 2035. This surge is all about making commercial spaces more efficient and accessible for everyone. You can find more insights on the future trends of the automatic door operator market.

Alt text: A man stands next to an open automatic glass door with a visible automatic door operator installed above the frame.

Key Components of an Automatic Door Operator

To really understand what makes these systems tick, it helps to break them down into their essential parts. Each component has a specific job, and they all work together like a well-oiled machine. We’ve explained them here in simple terms to make it crystal clear.

| Component | Function | Real-World Analogy |

|---|---|---|

| The Motor | This is the powerhouse. It provides the physical force needed to open and close the door, handling everything from a heavy industrial door to a sleek glass entrance. | The muscle of the system. |

| The Controller | This microprocessor is the decision-maker. It takes signals from sensors or buttons and tells the motor exactly what to do—when to start, how fast to go, and when to stop. | The brain of the operation. |

| Activation Devices | These are the triggers, like motion sensors or push plates. They detect when someone is approaching and send the signal to the controller to get things moving. | The eyes and ears of the door. |

Understanding these parts shows you how an automatic door operator is far more than just a gadget; it’s a system designed for precision, safety, and reliability.

A well-designed automatic door operator does more than just open a door. It weaves itself into the daily rhythm of your building, improving everything from the customer experience in a retail store to the logistical flow on a busy loading dock.

With these fundamentals in mind, you can start to see how an automatic door operator isn’t just a convenience—it’s a strategic asset. It’s a critical piece of the puzzle for making sure your facility is accessible, efficient, and safe for every single person who walks through its doors. At Wilcox Door Service, we believe in being “Respected Partners, Reliable Service,” and that starts with helping you understand the technology that keeps your business moving.

Choosing the Right Operator for Your Facility

Picking the right automatic door operator is a critical decision for your facility’s flow, safety, and efficiency. It’s not a one-size-fits-all situation; the perfect match depends on your specific environment, from daily foot traffic to the type of work happening inside. Making a smart choice means understanding the options available and how they align with your operational needs.

This decision is more important than you might think. North America is a huge player in the global automatic door market, holding about 40% of the total share, with sliding doors leading the charge. This isn’t just a random trend—it’s driven by a big push for accessibility and touch-free solutions in places like hospitals and retail stores. It shows a clear move towards smarter, more convenient entryways. You can dive deeper into the automatic door market on strategicmarketresearch.com.

Matching Operator Type to Your Environment

First things first: what is this door’s primary job? Is it the main entrance for a flood of customers, a secure checkpoint for staff, or a massive bay for trucks and equipment? Each of these scenarios points to a different kind of automatic door operator.

- Sliding Door Operators: These are the workhorses for any high-traffic area. Picture a busy hospital lobby, a grocery store on a Saturday, or an airport terminal. They open fast, save space by moving parallel to the wall, and can handle a constant stream of people without creating a logjam.

- Swinging Door Operators: Perfect for places like office buildings, clinics, and restrooms, these operators offer a quiet, smooth opening. They’re often the go-to solution for retrofitting old manual doors to meet today’s accessibility standards, giving you a welcoming entrance without needing a massive renovation.

- Overhead Door Operators: Built tough for the most demanding environments, these are non-negotiable for industrial settings. A warehouse loading dock or a manufacturing plant’s vehicle bay needs a heavy-duty operator that can lift massive sectional or rolling steel doors all day, every day, without skipping a beat.

Low-Energy vs Full-Energy Operators

Beyond how the door moves, you have to think about its power and speed. This is where the difference between “low-energy” and “full-energy” operators becomes critical for keeping everyone safe and staying compliant with regulations.

A low-energy automatic door operator is designed for accessibility. It opens slowly and with limited force, which means it can be used safely without needing a full suite of presence sensors. You’ll see these on single-person washroom doors or in quiet office corridors where they help individuals who might need a bit more time to get through.

Key Takeaway: Think of a low-energy operator as a helpful hand. It’s there to provide assistance, not to rush people through. Its main job is to prioritize safety and accessibility over raw speed.

On the flip side, a full-energy operator is built for speed and high volume. These are the systems you encounter at the entrance of a big-box retail store. They open and close quickly to manage crowds and keep the indoor climate stable. Because of that speed, they absolutely require a full suite of safety sensors—like motion detectors and presence-sensing beams—to make sure they never make contact with a person or object.

For facilities with tricky layouts, like those with very little headroom above the door, looking into alternatives like a side-mounted commercial door operator can be a game-changing solution.

Choosing between these types isn’t just a matter of preference. It’s about matching the operator’s power and function to the daily rhythm of your facility and, most importantly, ensuring the safety of every single person who passes through that door.

How Activation Sensors Streamline Your Workflow

An automatic door operator is impressive on its own, but the real magic is how it knows exactly when to open. This is where activation sensors and controls come in, turning a simple doorway into a smart, responsive part of your building’s workflow. When you pick the right activation method, you create a seamless, safe, and efficient flow of traffic that’s perfectly matched to your environment.

The key is to think beyond just opening a door. It’s about weaving the door’s function directly into the daily rhythm of your team. For example, a hospital needs a completely touchless solution to keep things sterile, while a busy warehouse needs a system that lets forklifts move through without missing a beat. This is how an automated overhead door goes from being a simple convenience to a real productivity driver.

Choosing the Right Activation for Your Operations

Matching the sensor to the environment is absolutely critical for both efficiency and safety. A sensor that works great in a quiet office could cause a major bottleneck on a busy loading dock. The goal is to choose a trigger that feels completely natural and intuitive for the people and equipment that use it every single day.

- Classic Motion Sensors: Using microwave or infrared technology, these sensors spot movement from a distance. They’re ideal for high-traffic public entrances like retail stores or airports, ensuring the door is open well before anyone gets there to keep foot traffic flowing.

- Push Plates: These are the familiar square or round buttons you see next to accessible doorways. They offer a simple, deliberate way to open the door, making them perfect for office buildings, clinics, and restrooms where you don’t want the door swinging open for every person who walks by.

- Touchless ‘Wave-to-Open’ Plates: In places where hygiene is non-negotiable—like healthcare facilities or clean rooms—these are the gold standard. A quick wave of a hand activates the door, eliminating a common touchpoint and helping to reduce the spread of germs.

“The most effective activation system is one your team doesn’t even have to think about. It should integrate so perfectly with their tasks that it feels like an extension of their workflow, not an obstacle.”

For industrial settings, the needs are even more specialized. A forklift operator can’t be expected to stop, get off their vehicle, and manually open a massive overhead door. This is where tough, vehicle-focused activators make all the difference, integrating directly into organizational flows.

- Pull-Cords: A straightforward and reliable option, pull-cords let drivers of forklifts or other vehicles open a large industrial door without ever leaving their seat.

- Remote Controls: For more flexibility, handheld remotes let operators open doors from a distance, preparing their route ahead of time and cutting down on wasted moments.

- In-Floor Loop Detectors: These are wires embedded right into the pavement that detect the large metal mass of a vehicle. As a forklift or truck gets close, the door opens automatically, creating a truly hands-free, high-efficiency path.

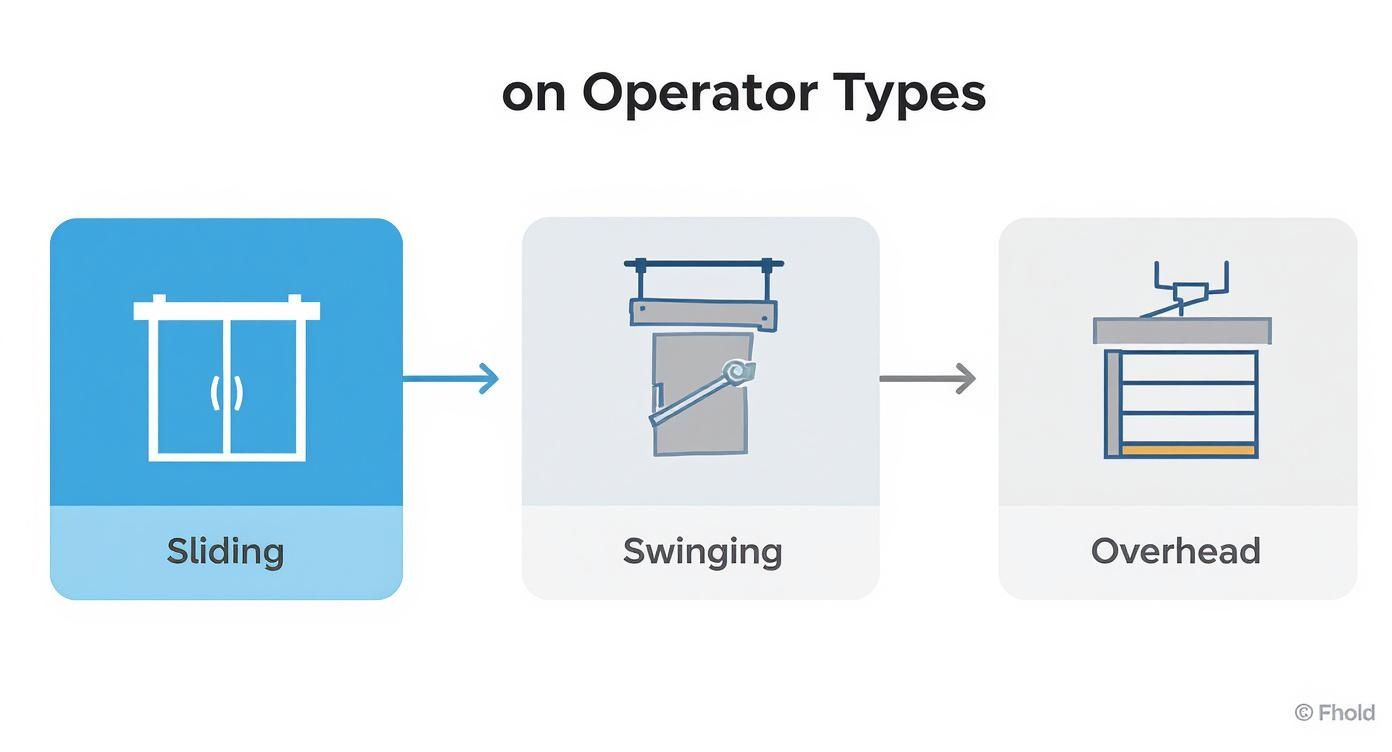

The image below shows some of the most common door systems that benefit from these tailored activation methods.

Alt text: Flowchart of automatic door operator types: sliding for retail, swinging for offices, and overhead for industrial warehouses.

Each of these door types—sliding, swinging, and overhead—can be paired with specific sensors to maximize workflow in different commercial and industrial settings.

Activation Sensor Options for Commercial Doors

Finding the right sensor involves weighing how it works against where you’ll use it. This table breaks down the most common options to help you decide.

| Sensor Type | How It Works | Best For (Example Environments) | Pros & Cons |

|---|---|---|---|

| Motion Sensors (Infrared/Microwave) | Detect movement or body heat in a defined zone near the door. | Retail stores, airports, hospitals, high-traffic public entrances. | Pro: Hands-free and convenient. Con: Can be triggered by non-essential movement, wasting energy. |

| Push Plates | A physical button that must be pressed to open the door. | Office buildings, accessible washrooms, clinics, interior doors. | Pro: Intentional activation prevents unnecessary openings. Con: Requires physical contact; not ideal for hygiene-sensitive areas. |

| ‘Wave-to-Open’ (Touchless) | Uses short-range sensors to detect a hand wave, opening the door without contact. | Healthcare facilities, clean rooms, food processing plants, modern offices. | Pro: Excellent for hygiene and accessibility. Con: Shorter detection range than standard motion sensors. |

| In-Floor Loop Detectors | A wire loop buried in the ground detects the metal mass of a vehicle. | Warehouses, distribution centres, parking garages, loading docks. | Pro: Highly reliable for vehicle traffic and won’t trigger for pedestrians. Con: Requires cutting into pavement for installation. |

| Remote Controls / Pull-Cords | Manual triggers operated by a person, either via a handheld remote or a physical cord. | Industrial bays, fire stations, secure vehicle entry points. | Pro: Gives the user complete control over when the door opens. Con: Requires a manual action from the operator. |

The Non-Negotiable Role of Safety Sensors

While activation sensors are the “go” signal, safety sensors are the “stop” signal. They tell the door when not to close, and they are an absolutely critical part of any automatic door operator installation. Their entire job is to prevent accidents and protect people, products, and equipment from getting hurt or damaged.

These safety devices work by detecting presence. If anything is in the doorway, the door will refuse to close or will immediately reverse its motion. Common types include safety beams (often called photo-eyes) that send an invisible beam of light across the opening and presence detectors mounted overhead that scan the entire threshold area. This double-check ensures your doors aren’t just efficient, but fundamentally safe for everyone who uses them.

At Wilcox Door Service, ensuring safety is at the heart of our “Respected Partners, Reliable Service” promise. You can learn more about how we prioritize safety in our commercial door services.

Getting to Grips with Safety and Accessibility Codes

Installing an automatic door operator is about so much more than convenience. It’s a fundamental commitment to safety and accessibility for everyone who comes through your doors. The regulations might look like a complicated web of rules at first, but they all share one simple goal: to protect every single person who enters your facility. Getting these standards right isn’t just about ticking a box to avoid a fine—it’s about creating a space that is genuinely safe and welcoming for your employees, visitors, and customers.

From a business standpoint, following these codes is non-negotiable. It protects you from liability and cements your reputation as a responsible operator. At Wilcox Door Service, our whole philosophy is built on “Respected Partners, Reliable Service,” and for us, compliance is the absolute foundation of every single installation we do.

This focus is reflected across the industry. The Canadian automatic door operator market is valued at around USD 141.1 million and is expected to see steady growth. A huge part of that is driven by the strong emphasis on making buildings accessible and energy-efficient. Swing door operators, in particular, are becoming the go-to choice for commercial spaces like offices and airports to manage crowds and boost safety. You can dive deeper into the market trends by reading the full analysis on North American automatic door trends.

The AODA: Your Foundation for Accessibility

Here in Ontario, the Accessibility for Ontarians with Disabilities Act (AODA) is the gold standard for accessible public and commercial spaces. For an automatic door operator, this means hitting specific benchmarks that remove physical barriers for people with disabilities. These aren’t just abstract rules; they’re practical requirements that directly shape how your doors need to work.

Here’s what the AODA boils down to for your doors:

- Clear Width: The doorway has to be wide enough for a wheelchair to pass through easily, which usually means a clear space of at least 865 mm (34 inches).

- Activation Controls: Push plates or other activators need to be mounted at a height that’s easy to reach, typically between 900 mm and 1,100 mm from the floor. Their placement is also critical—they must be located so a person in a wheelchair can press them without being in the path of the door as it swings open.

- Closing Speed: The door must close slowly enough that someone with mobility challenges has plenty of time to get through safely. This is where a low-energy operator often becomes the perfect solution.

Fire Safety and Your Automated Doors

Things get even more serious when an automatic door operator is installed on a fire-rated wall. These doors aren’t just for passage; they are a critical part of your building’s fire containment strategy, designed to halt the spread of smoke and flames in an emergency.

A fire-rated door that doesn’t close and latch properly during a fire is more than a compliance problem—it’s a catastrophic safety failure. This is why regular inspections and drop tests are non-negotiable; they ensure these life-saving systems work when it matters most.

These specialized doors must be hard-wired into the building’s fire alarm system. The moment an alarm sounds, the operator has to get that door shut and secured—no exceptions. That’s why professional installation and routine fire door drop testing are so vital. Our certified technicians make sure your automated fire doors not only meet the code but are flawlessly integrated to perform under the worst-case scenario.

Navigating these codes is a huge part of a successful automatic door operator project. It takes real technical expertise and a solid understanding of both national and local standards. When you partner with a team that sweats these details, you get a facility that’s not just more efficient and accessible, but fundamentally safer for everyone.

Why Professional Installation Matters

An automatic door operator is a complex piece of machinery, and its long-term performance is only as good as its installation. While a DIY approach might seem tempting, the difference between an amateur setup and a professional one is night and day. It impacts everything from daily reliability to the safety of everyone walking through that door.

Whether you’re installing a brand-new system or retrofitting an old manual door, professional service is the cornerstone of getting real, lasting value. This isn’t just about connecting a few wires; it’s a technical process that demands precision. Our commitment to being “Respected Partners, Reliable Service” means every job starts with a thorough, on-site assessment. This crucial first step sidesteps the common pitfalls that lead to premature wear, constant breakdowns, and dangerous failures.

Alt text: A service technician inspecting an automatic door operator control panel with a maintenance checklist.

The Pre-Installation Assessment

Before a single tool comes out, our certified technicians conduct a meticulous evaluation of your existing door and frame. This isn’t a quick glance—it’s a deep dive into the factors that will make or break the installation.

- Door Condition and Balance: First, we check the door itself. Is it warped, damaged, or out of balance? An automatic operator is built to automate a perfectly functioning manual door, not to fix an existing problem. Forcing an operator to wrestle with a poorly balanced door is a surefire recipe for a burnt-out motor.

- Structural Integrity: Is the door frame and the wall around it strong enough to handle the operator’s weight and the forces of its constant movement? We inspect for structural soundness to make sure the mounting points are secure and can handle thousands of cycles without a problem.

- Electrical Requirements: Our team verifies that the right power source is available and correctly routed. Improper wiring isn’t just a fire hazard; it can also cause erratic performance and fry the operator’s sensitive electronics.

Common Pitfalls of Improper Installation

A rushed or inexpert installation usually creates more problems than it solves, resulting in significant operational headaches and unforeseen expenses.

For example, a misaligned sensor on a busy entrance can cause the door to close unexpectedly, creating a serious safety risk and a frustrating bottleneck for foot traffic. Or, an incorrectly calibrated motor might cause an overhead door to slam shut, damaging the door and anything—or anyone—underneath. These aren’t just minor annoyances; they’re costly liabilities that bring your workflow to a halt.

An investment in professional installation is an investment in prevention. It’s about ensuring your automatic door operator functions as a reliable asset from day one, rather than becoming a recurring source of maintenance headaches and downtime.

The principles of a solid mechanical and electrical setup apply to all types of operators, from the swing doors at a storefront to heavy-duty industrial systems. Understanding the unique needs of different systems, like a jackshaft operator installation for a commercial overhead door, is absolutely critical for safe, efficient operation in a demanding environment.

Ultimately, choosing a professional protects your investment. It guarantees that every single component, from the motor to the safety sensors, is installed to meet manufacturer specifications and all relevant safety codes.

Keeping Your Operator Running with Preventive Maintenance

Just like any piece of critical equipment in your facility, an automatic door operator is a sophisticated system that needs regular tune-ups to work safely and reliably day in, and day out. You wouldn’t skip an oil change on a company vehicle, and the same thinking applies here.

Being proactive with planned maintenance is the best way to extend the life of your system. More importantly, it helps you sidestep those unexpected breakdowns that always seem to happen at the worst possible time, leading to costly downtime and serious safety risks.

This approach isn’t just about fixing things; it’s about building a partnership focused on keeping your facility running smoothly. When you invest in preventive care, your automatic door operator stops being a potential headache and becomes a dependable asset you don’t have to worry about.

What a Professional Inspection Involves

A professional maintenance visit is much more than a quick look-over. It’s a deep dive where certified technicians go through a detailed checklist, making sure every single component is working exactly as the manufacturer intended and in line with all safety standards. Think of it as a comprehensive health check-up for your doors.

Here’s a glimpse of what a typical service call covers:

- Lubrication of Moving Parts: Technicians apply the right lubricants to gears, chains, and hinges. This cuts down on friction, a major culprit behind premature wear and motor strain.

- Sensor and Activation Testing: We meticulously test every activation and safety sensor to confirm its accuracy and range. This ensures your doors open when they should and, crucially, stay open when someone is in the doorway.

- Hardware and Electrical Checks: This involves tightening any loose fasteners, inspecting all wiring for signs of fraying or damage, and making sure every electrical connection is solid and secure.

- Safety Feature Verification: All safety mechanisms, from emergency-reverse functions to manual overrides, are put through their paces to guarantee they’ll perform flawlessly when you need them most.

Catching a small issue like a misaligned sensor or a frayed wire during a routine check can prevent a complete system failure that might otherwise shut down a key entrance for hours or even days.

Early Warning Signs to Watch For

While professional service is essential, your on-site team is often the first line of defence. Teaching your staff to spot the early signs of trouble helps you get ahead of major repairs before they become emergencies. Give us a call if you notice any of the following:

- Unusual Noises: Grinding, scraping, or squeaking sounds are almost always a sign of mechanical strain or a component on its way out.

- Jerky or Slow Operation: If the door hesitates, stutters, or just seems to be moving slower than usual, it could point to a problem with the motor, controller, or even the door’s balance.

- Failure to Fully Open or Close: A door that doesn’t complete its cycle is a dead giveaway that something is wrong with its calibration, sensors, or mechanical parts.

The best way to deal with these problems is to prevent them from happening in the first place with a structured upkeep plan. You can learn more about the benefits of a planned garage door maintenance program to see how this proactive approach works.

Answering Your Questions About Automatic Door Operators

When you’re running a facility, every decision comes down to practicals. So, when it comes to adding an automatic door operator, you’ve probably got some questions. To help you feel confident about your options, we’ve put together some straightforward answers to the questions we hear most often from facility managers just like you.

Our whole philosophy is “Respected Partners, Reliable Service,” and that starts with giving you honest, clear information. Let’s dig in.

Can Any Commercial Door Be Automated?

The short answer is yes, almost any commercial door can be automated. We regularly retrofit the hollow metal, wood, and aluminum storefront doors you see everywhere. The real question isn’t if it can be done, but if the current door is ready for it. A successful retrofit depends entirely on the door’s condition, which is why a professional assessment is non-negotiable.

Before we even think about installation, our technicians will do a thorough evaluation, looking at:

- Door Condition and Weight: The door needs to be in solid shape and properly balanced. If it’s warped, damaged, or too heavy for the operator, you’re just asking for trouble down the line.

- Framing and Structure: We’ll inspect the doorframe and the wall around it. Can it handle the constant pull and push of an automated system? It needs to be strong enough to securely anchor the operator.

- Hinge and Hardware Health: Your existing hinges, pivots, and closers have to be in great working order. If they’re worn out, the new motor will be fighting against them, leading to premature failure.

How Much Energy Does an Automatic Door Use?

This is a common concern, but most people are pleasantly surprised by the answer. Modern automatic door operators are designed to be incredibly energy-efficient.

Low-energy operators, the kind often used to meet AODA accessibility standards, consume very little electricity. Even the full-energy systems built for the busiest entrances are optimized to keep power consumption low. Plus, there’s a hidden benefit: by ensuring a tight, reliable seal every time it closes, an automatic door cuts down on your building’s heating and cooling losses. That adds up to real savings on your utility bills.

What Is the Lifespan of an Automatic Operator?

With a professional installation and a consistent maintenance schedule, a quality commercial automatic door operator should easily give you a decade of reliable service, and often much longer. Of course, the exact lifespan will depend on a few factors, like how many people use it daily, its exposure to the elements, and the quality of the unit itself.

Key Takeaway: If you want to get the most out of your investment, a planned maintenance program is the single best thing you can do. Regular service catches small problems before they turn into major, business-stopping failures. It keeps your operator a dependable asset for years to come.

Ready to see how an automatic door operator could improve your facility’s flow and accessibility? The team at Wilcox Door Service is here with the expert guidance and reliable solutions you need.

Contact us today to schedule a consultation or request a quote.