In this guide, you will learn how automatic door weather stripping can significantly cut your facility's energy costs, improve environmental control, and block pests. We'll explore the best materials for different commercial applications, walk through proper installation and maintenance, and clarify when professional service is essential for achieving a perfect, long-lasting seal. This is your expert resource for turning a simple doorway into a high-performance asset.

Understanding Automatic Door Weather Stripping And Its Importance

Imagine trying to heat a massive warehouse through a Canadian winter while leaving a window wide open. That’s the kind of financial and operational drain an unsealed commercial door creates. Automatic door weather stripping is the professional solution that seals this expensive gap for good.

In simple terms, it's a dynamic seal that actively blocks the gaps between a door and its frame. Unlike a static seal that just drags along the floor and wears out quickly, an automatic system is smarter. It only engages when the door is fully closed, creating a tight, reliable seal every single time without the constant friction.

For a facility manager, this is about more than just stopping a chilly draft; it's a strategic tool for operational excellence. A properly sealed entryway has a direct impact on your bottom line and the safety of your environment.

It really comes down to three core functions:

- Energy Conservation: It takes a huge load off your HVAC systems by preventing conditioned air from leaking out and stopping outside air from rushing in.

- Environmental Control: It helps you maintain stable temperature and humidity levels. This is non-negotiable for sensitive operations like cold storage, food processing, and clean rooms.

- Pest and Contaminant Prevention: It forms a solid physical barrier against insects, rodents, dust, and debris, which goes a long way toward improving hygiene and protecting your inventory.

A First Line Of Defence

Beyond just saving on your energy bills, automatic door weather stripping is your first line of defence in a comprehensive pest control strategy. It plays a vital role in sealing entry points to prevent pests like larder beetles. A tiny gap at the bottom of a loading dock door is basically an open invitation for critters that can ruin sanitation standards and damage valuable goods.

Here in Canada, its value becomes even clearer during our harsh winters. For warehouses in the Greater Toronto Area, where temperatures can plummet, facilities that installed automatic door bottoms saw air infiltration drop by 28%. That translated to real-world annual energy savings of $1,200 per loading dock.

At its core, this system transforms a simple door into an active component of your building's efficiency and security envelope. It’s a proactive measure that pays for itself.

Ultimately, investing in the right weather stripping system is a critical decision that elevates your building’s entire performance. These systems are engineered to work in perfect sync with the mechanics of your entryway—a concept we dive into deeper in our guide to understanding the mechanics of an automatic door operator. As we'll get into, choosing the right material and profile for your specific needs—whether it’s a high-traffic distribution centre or a sterile pharmaceutical facility—is the key to getting the maximum return on your investment.

The Real-World Payback of High-Performance Door Seals

Effective automatic door weather stripping does a lot more than just block a chilly draft. When you step up from basic seals to a high-performance system, you’re not just plugging a gap—you’re turning a simple entryway into a strategic asset. For any facility manager, this translates into real, measurable wins across four key areas of your operation.

Think of these not as abstract concepts, but as direct improvements to your efficiency, safety, and bottom line. A quality seal is a silent workhorse, quietly supporting your core business functions day in and day out.

Slashing Your Energy Bills

The most immediate and obvious impact you'll see from a high-performance seal is on your energy bill. Every unsealed gap around a commercial door is an open invitation for your expensive, conditioned air to leak out while the outside air pours in. This puts your HVAC system into overdrive, sending your utility costs soaring.

Picture a busy distribution centre where loading dock doors are opening and closing all day. Even tiny gaps can add up, acting like a window that’s permanently cracked open. By installing robust perimeter seals and automatic door bottoms, you drastically cut down on this air exchange. The result is a much lighter load on your heating and cooling equipment, which can lead to energy savings of 15-30% directly related to your doorways.

A properly sealed door isn't just an expense; it's a direct investment in operational efficiency that pays for itself. The energy savings alone often deliver a full return on investment in under two years.

Nailing Down Precise Environmental Control

For many industries, maintaining a specific indoor environment isn't just a nice-to-have—it's non-negotiable. Think of a food processing plant where temperature and humidity have to stay within strict limits to guarantee product safety. Or consider a pharmaceutical cleanroom where keeping out dust and airborne contaminants is essential for regulatory compliance.

In these situations, automatic door weather stripping is a critical tool for control. It creates an airtight barrier that helps stabilize the internal atmosphere. This means you get:

- Temperature Stability: Absolutely crucial for cold storage facilities, where even a small temperature swing can ruin an entire pallet of inventory.

- Humidity Management: Prevents excess moisture from creeping into sensitive manufacturing or storage areas, cutting the risk of mould and product damage.

- Contaminant Prevention: Blocks dust, pollen, and other particles from entering sterile environments.

By creating a stable, predictable environment, you cut down on product loss, improve safety, and ensure your operations run like clockwork. For a deeper look at optimizing your building envelope, check out our guide on enhancing commercial door energy efficiency during seasonal shifts.

A Stronger Defence Against Pests and Compliance Headaches

A well-sealed door is also your first line of defence against pests. For any warehouse or food-grade facility, that gap under the door is a welcome mat for rodents and insects. A snug-fitting automatic door bottom slams that entry point shut, boosting sanitation and helping you nail your health code inspections.

Beyond keeping critters out, high-performance seals are vital for safety and regulatory compliance. In Canada, facilities like airports and healthcare centres have seen major operational gains by upgrading their door seals. In fact, facilities with proper automatic seals saw 32% fewer incidents of pest intrusion and moisture damage. For government operations, using specialized intumescent seals on fire-rated doors helped them avoid 75% of audit failures, saving thousands per location. An intumescent seal, by the way, is a special type of seal that expands when exposed to heat, blocking smoke and fire from spreading through door gaps.

Ultimately, these benefits add up to a more reliable and secure facility. You get fewer complaints from staff about drafts, lower utility bills, and a safer environment for everyone. A properly sealed door is a dependable asset—a perfect reflection of our core promise of Respected Partners, Reliable Service.

How to Choose the Right Weather Stripping for Your Doors

Picking the right automatic door weather stripping isn't a one-size-fits-all decision. The needs of a busy loading dock are worlds apart from those of a sterile hospital cleanroom. If you make the wrong choice, you’ll not only undermine your energy savings but also find yourself replacing failed seals far too soon.

This practical guide is here to help you match the right materials and designs to your specific commercial environment. We'll look at common seal types—like automatic door bottoms and perimeter gasketing—and dive into why materials like neoprene or silicone are better for certain jobs. Making a smart choice here is a long-term investment that protects your facility and your bottom line.

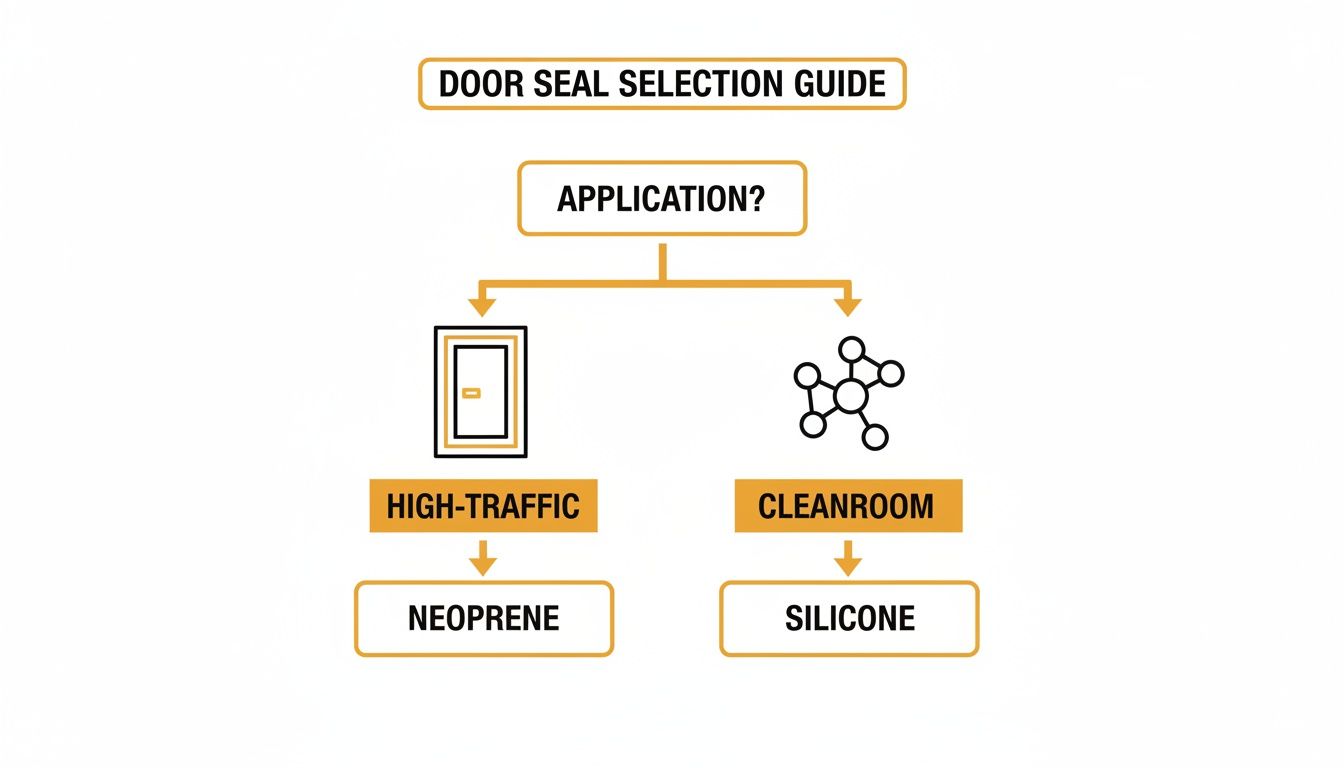

Matching Material to Mission

The first step is to really think about what your door does all day. Is it a high-traffic entry in a warehouse getting hit by forklifts? A temperature-controlled door in a food processing plant? Or a sound-dampening door in a healthcare facility? The material you choose has to be tough enough for its specific environment.

Here are the most common materials you’ll find in commercial door seals and where they shine:

- Neoprene: Think of this as the workhorse. It’s a tough, versatile synthetic rubber that’s an excellent choice for industrial settings and high-traffic areas because it stands up to oil, chemicals, and abrasion. A neoprene seal on a loading dock door will take a beating from constant use and exposure to the elements without giving up.

- Silicone: When temperature is the biggest challenge, silicone is your top performer. It stays flexible in the extreme cold of a walk-in freezer and remains stable in high heat, making it perfect for food service or manufacturing facilities. Many silicone seals also come with antimicrobial properties, which is a non-negotiable for healthcare and cleanroom applications.

- Vinyl: As a cost-effective and common option, vinyl provides a solid seal against air and moisture in standard commercial spaces like retail storefronts or office buildings. While it's not as rugged as neoprene, it’s a reliable choice for doors with moderate traffic.

- Brush Seals: Made of dense nylon or polypropylene bristles, brush seals are the go-to solution for large overhead doors or doors sitting on uneven floors. Their flexibility lets them conform to irregular gaps, effectively blocking dust, debris, and pests without creating the friction that can wear down other seals.

Choosing the right material from the start is half the battle. This table breaks down the key differences to help guide your decision.

Weather Stripping Material Comparison for Commercial Doors

| Material Type | Best For | Durability | Temperature Range | Key Feature |

|---|---|---|---|---|

| Neoprene | High-traffic industrial, loading docks, manufacturing | Excellent | -30°C to 90°C | Resists oil, chemicals, and abrasion |

| Silicone | Freezers, cleanrooms, food service, healthcare | Very Good | -70°C to 200°C | Extreme temperature flexibility, often antimicrobial |

| Vinyl | Offices, retail stores, standard commercial entryways | Good | -20°C to 65°C | Cost-effective general-purpose sealing |

| Brush Seal | Overhead doors, uneven floors, pest control | Good | -40°C to 100°C | Conforms to irregular gaps, minimal friction |

A quick look at this comparison makes it clear that the application—whether it's heavy-duty industrial or a controlled cleanroom—should always drive your material choice.

Understanding the Different Seal Types

Beyond the material, the design of the seal dictates how it actually works. Each type is engineered to solve a specific sealing problem around a door.

An automatic door bottom is a clever mechanical device with a retractable seal inside. When the door closes, a small plunger hits the jamb and smoothly drops the seal to the floor. This creates a perfect seal when you need it, without the constant drag that wears out traditional sweeps.

Perimeter gasketing is installed around the top and sides of the door frame. When the door is closed, it creates a compression seal that's essential for stopping drafts and noise. Finally, threshold seals are installed on the floor right under the door, often working with a door bottom to create a complete, unbroken barrier.

This simple decision tree can help you visualize how to match a seal to its main job.

The key takeaway here is simple: let the application dictate the material. That’s how you ensure durability and performance where it matters most.

Real-World Performance and Value

Across Canada's industrial sector, the shift toward high-performance automatic door weather stripping has picked up speed, driven by the need for better energy efficiency. We've seen manufacturing plants that retrofitted their doors with automatic bottoms achieve a 22% drop in heat loss through their thresholds alone.

For general contractors, specifying high-grade weatherstripping on new builds can also cut sound transmission by up to 35 dB. This is a critical need in places like pharmaceutical cleanrooms, where 60% of facilities reported compliance gains after upgrading their seals. You can explore the performance specifications of ANSI-grade weatherstripping from Hager Company to see the data for yourself.

Choosing the right weather stripping is not an expense—it's an investment in efficiency and compliance. The right seal reduces energy waste, protects sensitive environments, and stands up to the demands of your operation.

Making the correct selection ensures you get the full benefits of your investment, from lower energy bills to a more secure and controlled environment. If you're unsure which combination of materials and seals is right for your facility, our experts can help you conduct a thorough assessment.

Proper Installation and Common Pitfalls to Avoid

Choosing the right automatic door weather stripping is a great start, but even the best seal in the world won't do its job if it isn't installed correctly. It’s the installation that turns a quality product into a high-performing asset, one that actually delivers on the promise of energy savings and climate control.

Even a tiny mistake—a seal that’s slightly off-kilter or an automatic bottom that isn’t calibrated just right—can undo all the benefits and cause the seal to fail years ahead of schedule. We’ll walk through the process of getting a perfect fit and steering clear of the common mistakes that hurt performance. Understanding these details is what separates a quick fix from a lasting solution, and it’s at the core of our commitment as Respected Partners, Reliable Service.

Best Practices for a Perfect Seal

Getting a tight, durable seal starts well before you even touch the weather stripping. Taking the time to prep the surface and focus on the details is non-negotiable if you want a professional result. A rushed job is almost guaranteed to end in air leaks, drafts, and a seal that you’ll be replacing way too soon.

To make sure your installation is a success, stick to these fundamentals:

- Meticulous Surface Preparation: The door and frame have to be perfectly clean, dry, and free of any gunk, rust, or old adhesive. Use a degreasing agent to cut through any oil or grime that could stop the new seal from sticking. A clean surface is the foundation of a strong, lasting bond.

- Accurate Measurements and Cutting: You’ve heard it before: measure twice, cut once. An inaccurate cut can leave small but significant gaps at the corners where air will find a way through. The seal needs to fit snugly from end to end, without being stretched or jammed in too tightly.

- Precise Calibration of Automatic Door Bottoms: This is where a lot of DIY jobs fall apart. The plunger on an automatic door bottom needs to be adjusted so it makes firm, even contact with the jamb. This allows the seal to drop consistently across the entire threshold. Too little pressure and you’ll have gaps; too much, and you risk damaging the mechanism or the door itself.

Tackling Real-World Installation Challenges

Out in the real world, door frames aren't always perfectly square and floors aren't always level. These are the kinds of imperfections where professional expertise really shines. Just slapping a standard seal on a warped door or an uneven floor is setting yourself up for failure.

One of the most common issues we see is an uneven floor, especially at a loading dock that’s taken a beating over the years. An automatic door bottom is usually the best answer here, since its adjustable drop can handle minor variations. For more serious slopes, you might need a combination of a new threshold and a heavy-duty, adjustable door bottom to create a complete barrier.

A common pitfall is ignoring a slightly warped door frame. Over time, buildings settle and frames can lose their alignment, creating uneven gaps. A skilled technician can often compensate for this by strategically shimming the gasketing to ensure consistent pressure all the way around the door.

When to Call a Professional

Sure, you might be able to handle a simple adhesive-backed seal on an interior office door. But installing automatic door weather stripping on critical commercial or industrial doors? That's a different game entirely. The stakes are much higher, involving safety, compliance, and significant operational costs.

Calling in a professional is the only smart move in a few key situations:

- Fire-Rated Doors: These doors need specific, certified seals to keep their fire rating. The wrong seal or a botched installation can void that certification and create a massive safety liability.

- Large-Scale Retrofit Projects: When you’re outfitting an entire facility, you need efficiency, consistency, and a deep understanding of all the different door systems involved.

- Complex or High-Traffic Doors: High-speed doors, cold storage doors, and busy loading docks need precision installation techniques that can stand up to constant, heavy use.

- Persistent Air Leaks: If you've tried the standard fixes and you can still feel a draft, it’s time for an expert diagnosis. Our technicians can pinpoint the real cause, whether it's a warped frame, a failing seal, or an improperly balanced door.

A professional installation from a partner like Wilcox Door Service isn't just about getting it done—it's an investment in guaranteed performance and peace of mind. If you’re facing a complex sealing challenge or need to be sure your installation meets strict standards, our team is ready to help. And if a problem pops up out of the blue, our 24/7 emergency repair services are always on standby.

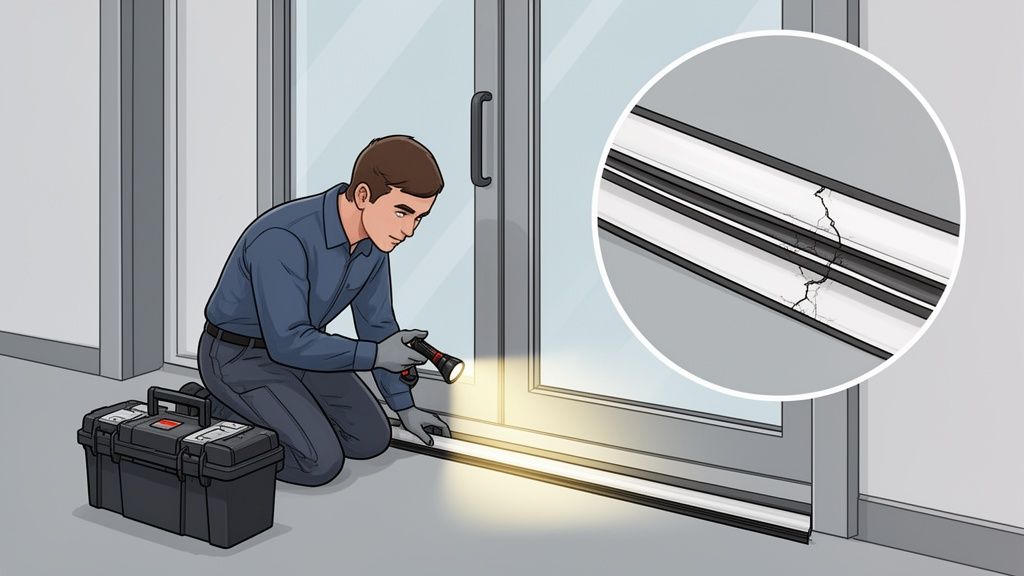

Your Proactive Maintenance and Inspection Checklist

Just like any other hard-working piece of equipment in your facility, your automatic door weather stripping needs regular attention to perform at its best. Think of proactive maintenance as the best way to protect your investment. It’s what extends the life of your door seals and stops minor wear and tear from turning into a full-blown emergency repair.

We’ve put together this straightforward checklist with busy facility teams in mind. It breaks down simple visual checks, monthly functional tests, and a more thorough annual inspection to keep your seals in top shape.

Simple Daily and Monthly Checks

The best maintenance plans are built on consistency. By folding these quick checks into your team’s daily and monthly routines, you can catch problems long before they start affecting your operations.

-

Daily Visual Sweep: Make this part of your opening or closing procedures. Just take a quick walk around your main entry points and look for any seals that are visibly ripped, peeling away from the door, or dragging on the floor. This five-second check can spot damage from a forklift bump or pallet jack hit before it gets any worse.

-

Monthly Functional Test: Once a month, give any automatic door bottoms a quick test. Slowly open and close the door while watching the seal. A healthy seal will drop smoothly and evenly as the door closes and pull back up completely when it opens. If you notice any stuttering, grinding, or lopsided movement, that’s a clear sign the internal mechanism needs an adjustment.

In-Depth Annual Inspection

You’ll want to do a more thorough inspection at least once a year—ideally before winter kicks in and energy loss really starts to sting. This is your chance to hunt for the more subtle signs of material fatigue, which is just the natural breakdown of materials from constant exposure and use.

A proactive inspection is the difference between a simple seal replacement and an emergency callout for a failed door system. Catching wear early aligns with a reliable, forward-thinking facility management strategy.

Running a detailed annual inspection helps you get ahead of material fatigue before it becomes a major problem. Use the following checklist as your guide to identify subtle but significant signs of wear.

Annual Weather Stripping Inspection Checklist

| Inspection Area | Check For | Status (Pass/Fail) | Action Required |

|---|---|---|---|

| Rubber/Vinyl Seals | Fine cracks, hardening, or brittleness. The material should feel flexible, not stiff. | Replace seal if it feels brittle or shows signs of cracking. | |

| Perimeter Gasketing | Compression set—a permanent indent where the seal no longer springs back to its original shape. | Replace gasketing if a permanent indentation is visible. | |

| Entire Door Edge | Gaps allowing light to pass through. Conduct the Flashlight Test in a darkened interior. | Adjust or replace the seal in any area where light is visible. | |

| All Seal Surfaces | Buildup of dirt, grime, salt, or chemical residue that could speed up material breakdown. | Clean all seals with a mild detergent and water. | |

| Brush Seals | Clogged or matted bristles. Debris can prevent the bristles from flexing properly and creating a complete seal. | Clear away any trapped debris and ensure bristles are free-moving. |

By following this checklist, you can systematically identify issues that might otherwise go unnoticed. This simple annual review is a small investment of time that pays off by preventing much larger operational headaches down the road.

This structured approach to maintenance is a huge part of keeping your entire door system healthy. For a wider view on door care, you might find our guide on essential maintenance tips for your commercial garage door useful.

By spotting these early warning signs, your team can handle wear and tear before it leads to serious energy loss, pest problems, or moisture damage.

Knowing When to Partner with a Door Service Professional

While handling some basic upkeep on your automatic door weather stripping is one thing, there are moments when you absolutely need to bring in a professional. Knowing when to put down the tools and call a certified technician is the key to protecting your investment, keeping everyone safe, and getting a perfect seal that actually lasts.

Let's be honest, trying to DIY a complex installation can quickly snowball into a much bigger headache. You could end up voiding a fire rating or causing premature wear on expensive door parts. It’s all about recognizing when professional precision isn’t just a nice-to-have, but a flat-out necessity.

Scenarios That Demand Expert Intervention

Some jobs just have higher stakes. Calling in an expert isn’t a cost—it’s an investment in guaranteed performance, code compliance, and your own peace of mind. You should always partner with a professional service provider for these situations:

-

Installations on Fire-Rated Doors: These doors are a critical life-safety system, period. They require specific, certified intumescent seals installed to exact specifications to keep their fire rating intact. A botched installation isn't just a mistake; it can have serious legal and safety consequences.

-

Large-Scale Retrofit Projects: Outfitting an entire facility or multiple sites with new seals is a big job. It requires consistent, efficient work across all kinds of different door types. A professional team makes sure every single seal is installed to the same high standard, which maximizes your return on the project.

-

Diagnosing Persistent or Complex Air Leaks: If you’ve already replaced a seal but can still feel a draft, the problem probably runs deeper than the weather stripping. A trained technician can spot underlying issues you might miss, like a warped door frame, an unbalanced door, or a failing operator that’s preventing a proper seal.

-

Doors in Specialized Environments: Installing seals on doors for cleanrooms, cold storage units, or sound-rated rooms isn't a standard job. It takes specialized knowledge to meet the strict performance and regulatory codes these environments demand.

A professional partnership ensures the job is done right the a first time, preventing costly rework and extended downtime. It aligns with our promise of being Respected Partners, Reliable Service.

When you run into these kinds of challenges, the smartest move you can make is to bring in the pros. For a full assessment of your facility’s needs or a quote on a complex installation, our team is ready to help.

Got Questions? We’ve Got Answers.

When you're digging into the details of running a facility, it's natural for questions about components like automatic door weather stripping to pop up. Getting the right answers can make a huge difference in your building's efficiency and the lifespan of your doors. Let's tackle some of the most common questions we hear from facility managers just like you.

Think of this as your quick guide to the practical side of things—from energy savings and door compatibility to how these essential seals actually work.

How Much Can I Realistically Save On Energy Costs?

While your exact savings will depend on your local climate, how often the door is used, and the type of facility you run, the impact is almost always significant. According to the Canadian government, simply sealing up your loading docks properly can cut air infiltration by as much as 28%. For many businesses, that translates into real money—often over $1,200 annually for a single door.

It’s all about reducing the strain on your HVAC system. By stopping conditioned air from leaking out and preventing outside air from sneaking in, you’re making your heating and cooling systems work smarter, not harder. Most facilities we work with see their doorway-related energy use drop by 15-30%. Because of this, it's common to see a full return on your investment in just 18 to 24 months.

Can This Be Installed On Any Commercial Door?

Just about, yes. Modern weather stripping has been designed to work with nearly every kind of commercial door you can think of. This includes:

- Standard hinged pedestrian doors

- Rolling steel service doors

- Large sectional overhead doors

- High-speed fabric doors

The secret is in matching the right product to the right job. For example, a sleek, mortised automatic bottom is the perfect, almost invisible solution for a professional office entrance. A mortised seal is one that is recessed into the door itself for a clean, flush appearance. On the other hand, a heavy-duty, surface-mounted model is built like a tank to handle the rough-and-tumble environment of a warehouse. The best way forward is always a professional assessment to pinpoint the most effective and compatible seal for each door in your facility.

What Is An Automatic Door Bottom?

This is where the technology gets clever. Unlike a basic weather stripping sweep that’s always dragging on the floor, an automatic door bottom is a mechanical device that’s much more advanced and durable. It’s essentially a retractable seal tucked inside a protective casing. When you open the door, the seal lifts up, completely clear of the floor, which stops it from getting scraped, torn, or worn down.

Here’s how it works: As the door swings shut, a small, adjustable plunger on the hinge side of the door presses against the door jamb. That simple contact triggers the mechanism, which smoothly lowers the seal to create a perfectly tight barrier against the threshold.

This "active" sealing mechanism is far more reliable than old-school sweeps, especially on floors that aren't perfectly level. It guarantees a consistent, positive seal every single time the door closes—which is exactly what you need to maintain tight environmental control and keep those energy bills in check.

When an inspection turns up advanced wear or you need professional advice, it’s time to bring in the pros. Contact us for a quote and let our certified technicians provide the reliable service you need.