When a garage door cable snaps, your door becomes unbalanced, unstable, and extremely dangerous. This guide explains why a broken garage door cable is a serious safety risk, what immediate steps you must take to secure the area, and why this critical repair should only be handled by a trained professional. You will learn the common causes of cable failure, the importance of replacing cables in pairs, and how a preventive maintenance plan can help you avoid this hazardous situation altogether.

The Critical Dangers of a Snapped Garage Door Cable

Discovering a broken garage door cable can bring your facility’s operations to a grinding, dangerous halt. That loud bang you might have heard? That’s the sound of immense tension being violently released—a clear signal that the door is no longer secure and poses a significant safety threat.

Imagine a busy loading dock during the morning rush. A high-cycle overhead door, one that opens and closes dozens of times a day, suddenly fails. One of its main lift cables snaps. The door, weighing hundreds of pounds, slams down crookedly and jams in its tracks. This isn’t just a workflow stoppage; it’s an immediate hazard for everyone and everything nearby. The potential for serious injury or catastrophic equipment damage is incredibly high.

Whatever you do, do not attempt to operate the door, either with the opener or by hand. This is a situation that requires immediate professional service from a company you can trust.

Understanding the System Failure

To fully appreciate the danger, it helps to understand how the system works. The cables and springs on your garage door work together in a finely balanced partnership to manage the door’s immense weight.

- Torsion Springs: These are the powerful, coiled springs mounted on a shaft above the door. They store a massive amount of mechanical energy, similar to a wound-up mousetrap.

- The Cables’ Role: The cables are the crucial link that transfers this stored energy from the springs to the door, allowing it to lift smoothly. They are under constant, extreme tension.

When one cable snaps, this balanced system collapses. The other cable and spring are instantly forced to handle double the load they were designed for, making a second failure extremely likely. The door is now dangerously unbalanced and can fall at any moment.

Immediate Safety Actions for a Broken Cable

When you find a broken cable, your immediate response is critical for safety. This table outlines the essential first steps.

| Action to Take | Why It Is Important | Who Should Perform This |

|---|---|---|

| Clear and Secure the Area | Prevent anyone from walking under or near the unstable door. Use cones or caution tape. | Facility manager or safety officer |

| Lockout/Tagout the Power | Disconnect the garage door opener from its power source to prevent accidental activation. | Authorized personnel only |

| Do Not Touch the Door | Do not attempt to move, lift, or adjust the door or any of its components. | Everyone in the facility |

| Call a Professional Immediately | Only a trained technician has the tools and expertise to safely handle the stored energy. | Anyone who discovers the issue |

Following these steps is the only way to safely manage the situation until a professional technician arrives.

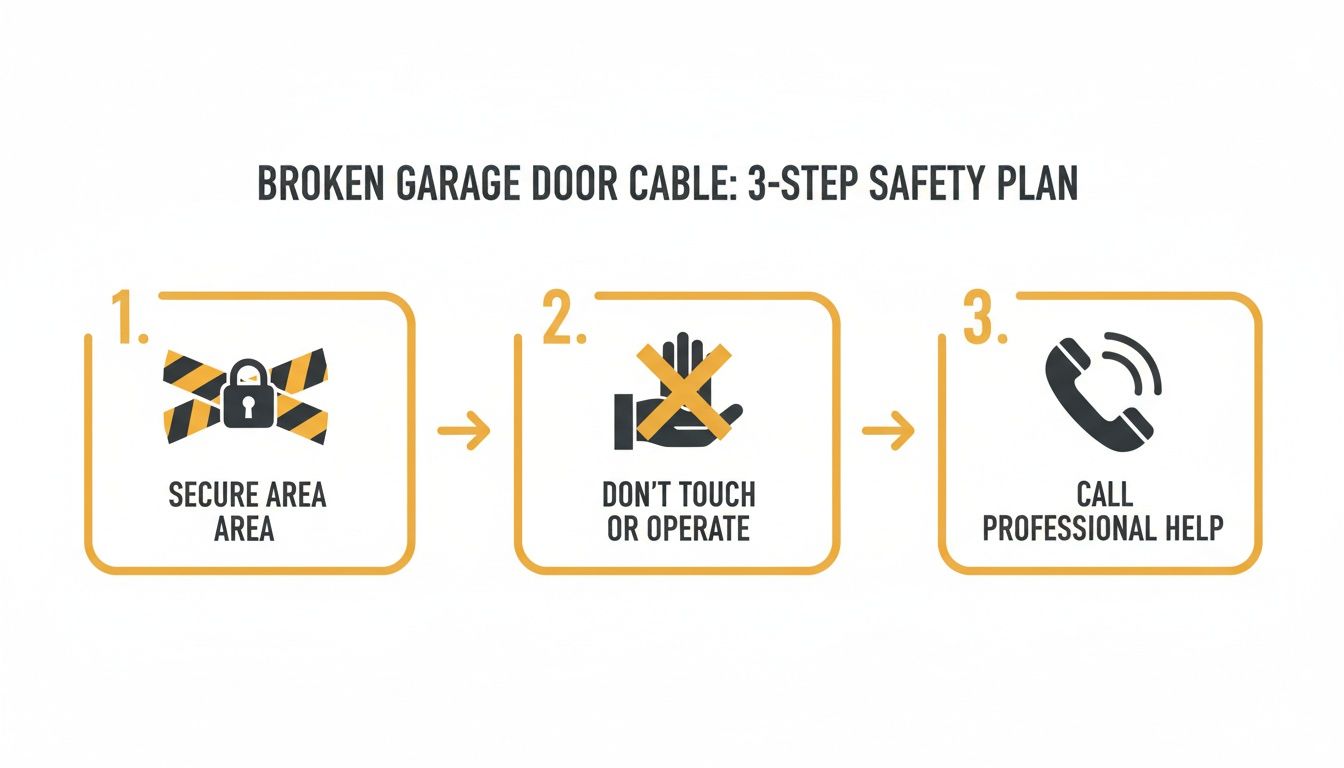

This infographic breaks down the essential three-step safety plan to follow the moment you discover a broken garage door cable.

Securing the area, avoiding all contact with the door, and calling for professional help is the only safe way to handle a snapped cable.

Why You Must Replace Both Cables

We get this question all the time: “Can’t you just replace the one cable that broke?” The answer from any reputable professional is always a firm no. It’s a non-negotiable principle of safe, effective service. Both cables were installed at the same time and have endured the exact same number of cycles and level of stress. The one that hasn’t broken yet has already stretched and weakened significantly.

If you only replace the broken cable, you create a dangerously unbalanced system. The new, unstretched cable will be tighter and carry more of the load, causing the door to lift unevenly. This puts incredible strain on every other component, from the rollers to the opener itself. It’s a recipe for another failure in the very near future. For a safe, reliable, and lasting repair, both cables must always be replaced together.

The energy stored in a torsion spring system is no joke. Trying to adjust or repair any of these components without the right tools and training is like trying to defuse a bomb. That potential energy can be released uncontrollably, turning tools and door parts into deadly projectiles. You can learn more by exploring our resources on spring replacement safety.

Why Garage Door Cables Actually Fail

When a garage door cable snaps, it’s easy to just chalk it up to “wear and tear.” But understanding the specific reason a broken garage door cable failed is the first step in preventing it from happening again. These failures are almost always the final result of smaller, progressive issues.

The Unseen Forces Behind a Snapped Cable

Garage door cables are constantly under incredible tension, transferring lifting force from the springs to a door that can weigh hundreds of pounds. Over time, several key factors work to weaken these critical parts.

One of the biggest culprits is material fatigue. Imagine a high-traffic loading dock door that cycles 50 times a day. That’s more than 18,000 cycles of stretching and relaxing in a single year. Each cycle creates microscopic weaknesses in the galvanized steel strands, making them more likely to break under load.

Then, you have the environment itself. Moisture, road salt tracked in by vehicles, and industrial chemicals can all lead to corrosion—a slow but relentless process that destroys steel cables from the inside out.

A cable showing even a little bit of rust has already lost a good chunk of its original strength. Rust isn’t just a cosmetic problem; it’s a clear sign of structural decay and a major red flag for an impending failure.

We’ve seen how much the environment matters. For instance, in coastal parts of California like Orange County, garage door cable failures have jumped by roughly 25% in the last five years, largely due to the salty air. Local service data shows that between 2020 and 2024, service companies in Orange County handled over 1,200 calls for cable replacements, with 65% traced back to rust, as detailed in these insights on garage door cable issues from Heritage Door Company.

The Spring and Cable Connection

The relationship between your garage door’s springs and cables is a true partnership—they completely depend on each other. If one part of that system is compromised, it puts a ton of unintended stress on the other.

A classic scenario we encounter involves weakening torsion springs. As springs age, they lose tension and can’t provide the same lifting power. This forces the automatic opener and the cables to work much harder, accelerating cable wear and often causing a frayed cable to finally give way.

On top of that, physical damage or even slight misalignment can create big problems. Here are a few common mechanical issues that lead directly to cable failure:

- Misaligned Tracks: If the door tracks are bent or knocked out of place, the door can rub or bind, putting unnatural stress on the cables.

- Worn Pulleys or Drums: The pulleys and drums guide the cables. If their bearings are worn or the grooves are damaged, the cable will chafe, fray, and eventually snap.

- Incorrect Tension: If the cables weren’t tensioned evenly during installation, one side does more work, guaranteeing that one cable will fail long before it should.

For a safe and complete solution to your broken garage door cable, it’s crucial to work with pros who understand these dynamics. Schedule a service inspection with Wilcox Door Service today and ensure your facility’s doors operate safely and efficiently.

Why This Repair Is Never a DIY Job

When a **broken garage door cable** brings your operations to a halt, the urge to find a quick, in-house fix is understandable. However, this is one repair where the DIY approach is extremely dangerous. The forces at play in a commercial or residential garage door are massive and unforgiving.

At the very heart of the danger is the torsion spring system. These heavy-duty springs are wound under incredible tension, storing the energy needed to lift a door that can weigh hundreds of pounds. When a cable breaks, that energy becomes dangerously unstable.

Trying to replace a cable without specialized training and the right tools is a high-stakes gamble. One wrong move, and the spring can release its energy in an explosive, uncontrolled burst. This can launch tools or door parts across a room like projectiles, causing catastrophic injuries or thousands of dollars in damage.

The Dangers of Stored Energy

Think about the spring system on a busy loading dock door in a distribution center. The tension needed to lift a heavy, insulated steel door day in and day out is immense. Our certified technicians use purpose-built tools, like solid steel winding bars, to safely manage this tension.

One of the most common—and devastating—mistakes in DIY attempts is the use of improper tools like screwdrivers. These are guaranteed to slip under pressure, leading to the violent, uncontrolled release of the spring’s power. Professionals follow strict safety procedures to secure the door and fully unwind the springs before any repair begins.

“Each year, thousands of people are seriously injured while attempting to repair their own garage doors. The immense tension in the spring and cable system creates a level of risk that simply isn’t worth taking on without professional training and equipment.”

This isn’t just about personal safety. For any business, an employee attempting an unauthorized repair creates a huge liability. An accident can lead to severe workplace safety violations and operational downtime that far exceeds the cost of a professional service call. You can learn more about our rigorous safety standards on our overhead doors repair service page.

Why Precision and Balance Are Critical

Beyond the immediate physical danger, a successful cable replacement requires absolute precision. A professional repair always includes several key steps that DIY fixes almost always miss:

- Correct Cable Selection: Cables must be perfectly matched to your door’s specific weight, height, and drum size. The wrong cable is destined for premature failure.

- Perfect Balancing: After replacing both cables—a mandatory safety practice—the technician meticulously re-tensions the springs to balance the door. This ensures it lifts evenly, preventing damage to the opener and track system.

- Full System Inspection: A true professional doesn’t just fix the obvious problem. They perform a full inspection of the entire system—rollers, tracks, drums, and springs—to find out why the cable failed in the first place and prevent it from happening again.

A DIY repair that misses these details will, at best, fail again soon. At worst, it creates an unbalanced, unstable door that’s a ticking time bomb.

What to Expect from a Professional Repair

Knowing what happens during a service call for a broken garage door cable can demystify the process. When a certified technician arrives, they follow a strict procedure designed to ensure safety, pinpoint the root cause of the failure, and deliver a repair that lasts. This is about restoring your entire system to a safe, balanced, and reliable state.

The Professional Repair Process Unpacked

A professional repair is far more involved than just replacing a broken cable. It’s a comprehensive service that addresses both the symptom—the snapped cable—and the underlying issue that caused it.

The technician will start with a thorough safety inspection of the entire door system, looking at the condition of the rollers, tracks, drums, and springs to find out why the cable failed. Was it rust? A misaligned drum? Or a weakening spring that put too much stress on everything?

Once the area is secure and the door is properly braced, the technician will use specialized winding bars to safely release the immense tension from the torsion springs. This is the single most critical and dangerous step. Only after all that stored energy is neutralized can the old, damaged cables be safely removed.

Why Both Cables Are Always Replaced

Here’s a non-negotiable rule you’ll see every professional follow: cables are always replaced in pairs. Even if only one cable snapped, the other has gone through the exact same number of cycles and endured the same stress. It has stretched and fatigued right alongside its broken partner.

Trying to replace only one cable creates an immediate and dangerous imbalance.

- The new cable will be shorter and tighter than the old, stretched one.

- This imbalance forces the door to lift unevenly, putting a huge amount of strain on the tracks, rollers, and opener.

- The older, weaker cable is now under even more stress, making its failure almost guaranteed.

A professional’s goal is to provide a reliable, long-term solution, not a quick patch. Insisting on replacing both cables is a hallmark of quality service, ensuring your door operates safely and predictably for years to come.

This commitment to a complete and balanced repair is fundamental. In fact, industry data shows that a startling 75% of broken cable incidents can be traced back to a lack of proper maintenance, which is why a full system check is so crucial.

Final Adjustments and System Testing

After installing the new, perfectly matched pair of cables, the technician will meticulously re-tension the springs to precisely balance the door. They’ll test it by hand, making sure it stays put when halfway open—the classic sign of a perfectly balanced system.

Finally, they will reconnect the operator and run the door through several full cycles, listening for smooth, quiet operation and making any last-minute adjustments. This final testing phase confirms that the repair is complete and the door is once again safe to use. You can learn more about the details involved in professional overhead doors repair on our blog.

How To Prevent Future Cable Breaks

A snapped garage door cable is more than just an inconvenience—it’s a dangerous event that can shut down your operations in an instant. While a professional repair is the only way to safely fix the immediate problem, the smartest strategy is to prevent the break from ever happening. The key is shifting from reactive emergency repairs to a proactive, planned maintenance mindset.

Preventing a cable break starts with paying attention. Small things that are easy to ignore—a bit of rust, some light fraying, or a strange new noise—are the earliest warning signs that your door system is under stress. Catching these tells early can stop a minor issue from becoming a full-blown failure.

Simple Visual Inspections You Can Perform

As a facility manager or homeowner, you can play a huge part in spotting trouble before it starts. A few minutes each month for a quick visual check can make all the difference.

- Look for Fraying: Get a good look at the entire length of both cables. Do you see any spots where the individual steel strands have started to unravel? Fraying is a non-negotiable red flag that the cable’s integrity is compromised.

- Check for Rust: Scan the cables, springs, and the bottom brackets where the cables attach. Corrosion eats away at steel’s strength and makes a snap almost inevitable.

- Watch the Pulleys and Drums: While the door is running, watch the pulleys and the drums at the top. The cable should wind and unwind smoothly, without any jerks or jumps. Grinding noises or wobbling likely mean the bearings are worn out.

The Value Of Professional Maintenance Plans

While your visual checks are a great first line of defense, they can’t replace an in-depth service from a trained technician. A professional maintenance plan is more than a quick look-over; our techs can spot problems not obvious to the untrained eye and perform critical adjustments to keep the system running safely. To truly get the most out of your garage door system, it’s essential to understand the value of implementing a robust preventive maintenance schedule.

Here’s a look at what sets a professional service apart.

DIY Visual Checks vs Professional Maintenance

| Maintenance Task | Your Monthly Visual Check | Annual Professional Service |

|---|---|---|

| Lubrication | N/A – Best left to pros to avoid wrong products. | Lubricates all moving parts (springs, rollers, hinges) with correct industrial-grade lubricants. |

| Door Balance Test | Not recommended to perform. | Safely disconnects the opener and tests the door’s balance, ensuring it holds steady mid-travel. |

| Spring Tension Adjustment | NEVER attempt to adjust springs. | Makes micro-adjustments to spring tension to compensate for wear and ensure perfect balance. |

| Component Inspection | Visual check for obvious rust or fraying. | In-depth check of bearings, drums, fasteners, and tracks for subtle signs of wear and fatigue. |

A professional maintenance plan is more than just a service—it’s an investment in operational continuity. It positions you as a proactive manager who prioritizes uptime and safety over costly, last-minute emergency calls.

Regular, professional servicing is the single most effective way to prevent a broken garage door cable. It ensures your system is properly balanced, lubricated, and free from the hidden stress that causes parts to fail. Explore the benefits of a planned garage door maintenance program to see how it can protect your facility.

Common Questions About Broken Garage Door Cables

When you’re staring at a broken garage door cable, your mind is probably racing with questions. It’s a stressful situation for any homeowner or facility manager. Here are straightforward answers to the questions we hear most often.

Can I Still Open My Garage Door If a Cable Is Broken?

The short, simple, and most important answer is no. Please, don’t even try. Never attempt to operate the door, either with the automatic opener or by hand, if a cable has snapped.

Without both cables supporting the load, the door is dangerously unstable and can crash down without warning. Forcing it open puts incredible stress on the single remaining cable, the tracks, and the opener, almost certainly causing more damage. The safest thing to do is unplug the opener, leave the door completely alone, and call a professional right away.

Why Did I Hear a Loud Bang?

That sudden, loud bang is the signature sound of a garage door system failing under immense tension. It’s almost always one of two things:

- A Torsion Spring Breaking: The spring, which holds all the door’s energy, unwinds violently in a fraction of a second.

- A Cable Snapping: The cable, holding hundreds of pounds of force, breaks and whips against the door or wall.

If you hear that noise, treat it as a serious warning. Your door is officially unsafe to use until it’s been inspected and repaired by a professional.

How Much Will a Professional Cable Replacement Cost?

The cost can vary based on a few key factors: the size and weight of the door, the type of spring system, and whether other parts like pulleys or drums were damaged. Unexpected repairs are never fun, and it’s always a good idea to understand what your homeowners insurance policy actually covers for situations like this. While we’ll always provide a custom quote for an accurate price, a professional cable repair is a critical investment in safety and is far more affordable than replacing an entire door wrecked in a fall.

How Long Are Garage Door Cables Supposed to Last?

Garage door cables are typically rated for 10,000 to 15,000 cycles (one cycle is one full open and close). For most homes, that works out to about 8-12 years. For a busy loading dock door, that lifespan could be much shorter.

Several things can shorten a cable’s life:

- High humidity or exposure to salt and moisture, which leads to rust.

- Misaligned tracks or drums that cause the cable to rub and fray.

- A simple lack of regular lubrication and maintenance.

The best way to get the most out of your cables and avoid a sudden failure is with proactive, planned maintenance.

A broken garage door cable is a serious safety issue that requires immediate professional attention. Don’t risk injury or further damage. For reliable repairs that restore safety and function, contact the experienced team at Wilcox Door Service.