As a facility manager, business owner, or contractor, choosing the right commercial garage roller doors is a critical decision that impacts your daily operations, security, and energy costs. This guide will walk you through everything you need to know, from the core components and different types available to professional installation and maintenance essentials. You’ll learn how to select a door that not only meets your needs but also provides a strong return on investment, turning a simple entryway into a key business asset.

What Are Commercial Garage Roller Doors

A commercial garage roller door is far more than a simple barrier. It’s a purpose-built system designed for the grind of daily business operations, from bustling loading docks to secure storage facilities. Unlike the door on your home garage, these are engineered to handle high-frequency use and the demanding conditions of a commercial environment.

Their core design feature is how they roll up tightly into a coil above the opening, which saves a ton of valuable ceiling space. In a busy warehouse with tall shelving and constant forklift traffic, a door that disappears overhead is a massive advantage—it eliminates obstructions and maximizes every inch of vertical clearance.

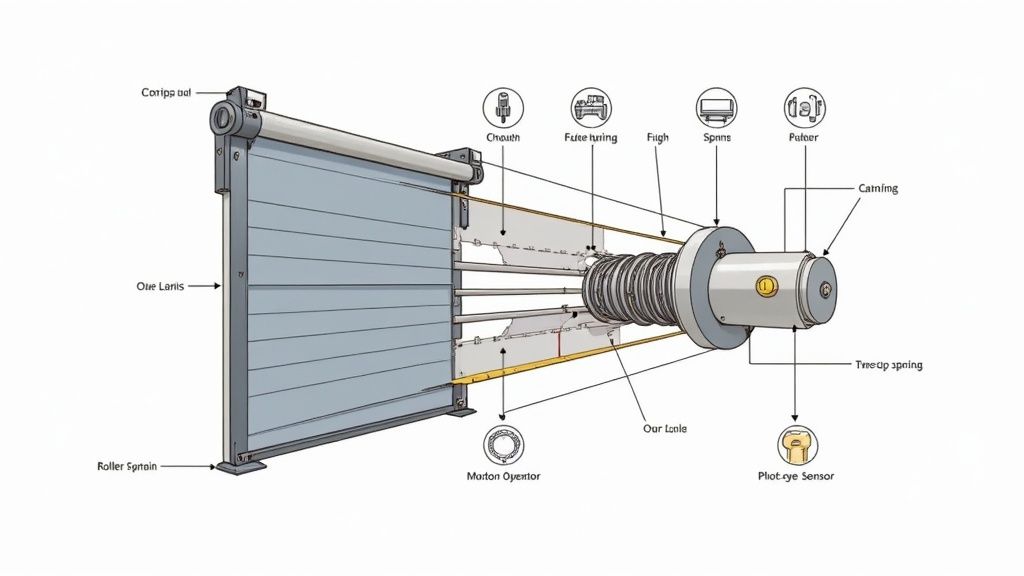

Alt text: Detailed diagram illustrating the internal components and operational roller mechanism of a commercial garage roller door.

Understanding The Core Components

To make a smart decision, you need to know the parts that work together to make your door function safely day in and day out. Understanding these components is like knowing the key parts of a vehicle before you buy it; each has a specific job to do.

- Door Curtain: This is the “face” of the door, the part you see. It’s made from interlocking slats of steel, aluminum, or sometimes a specialized fabric. The curtain’s material and thickness are what determine the door’s security level, durability, and insulation properties.

- Guide Tracks: These are the vertical channels mounted on each side of the doorway. The door curtain travels up and down within these tracks, and their proper alignment is absolutely critical for smooth, quiet operation and preventing jams. In a place like a food distribution centre, for instance, a misaligned track could lead to a door failure that compromises the entire cold chain.

- Roller Barrel Assembly: Housed just above the door opening, this is the large drum that the curtain neatly coils onto. Inside this assembly are the heavy-duty springs that counterbalance the door’s weight, which is what makes it possible to lift either manually or with a motor.

- Operator (Motor): This is the powerhouse of the system. The operator is what automates the opening and closing, and commercial motors are significantly more robust than residential ones. They’re chosen based on the door’s size, weight, and its expected cycle rating—that is, how many times you plan to open and close it every day.

- Safety Systems: These are completely non-negotiable. Components like photo-eye sensors and reversing edges are designed to detect any obstruction and immediately stop the door from closing on a person, vehicle, or product. They are vital for meeting compliance standards and, more importantly, protecting your team.

At Wilcox Door Service, we believe that understanding these fundamentals empowers you to choose a solution that performs for years. It’s about building a partnership based on knowledge and trust—a core part of our “Respected Partners, Reliable Service” promise.

By grasping how these parts function, you’re in a much better position to diagnose issues, schedule the right preventative maintenance, and ultimately select a commercial garage roller door that truly meets the demands of your operation. For a closer look at different door materials, you can explore our insights on commercial steel doors.

Choosing the Right Type of Commercial Roller Door

Picking the right commercial roller door isn’t a one-size-fits-all game. It’s all about matching the door’s design to what your facility actually does day in and day out. This section will walk you through the main categories of commercial roller doors—from insulated and security models to high-performance systems—giving you the confidence to choose the right one for your specific operational needs.

Doors for Climate Control and Security

For a lot of businesses, a commercial door has two primary jobs: keep the indoor temperature stable and protect valuable assets. Two types of doors really shine in these areas.

- Insulated Roller Doors: These are your go-to solution for any building where temperature control is a big deal. Think of a food distribution warehouse or a pharmaceutical clean room—keeping a consistent temperature is everything. Insulated doors are made with a core of polyurethane or polystyrene foam packed between steel slats, creating a thermal barrier that dramatically reduces heat transfer. This stops energy from leaking out and helps lower your HVAC costs.

- Security Roller Shutters: When your number one priority is stopping unwanted entry, heavy-duty steel security shutters are the industry standard. You’ll see them on storefronts, warehouses holding high-value goods, and government buildings. They’re built from thick-gauge steel, and their interlocking slat design makes them incredibly tough to break through, giving you real peace of mind after hours. You can take a closer look at the benefits of different commercial steel door solutions to see how the strength of the material directly ties into security.

Essential Doors for Compliance and Safety

Beyond the day-to-day grind, some doors are actually required by building codes to protect people and property in an emergency.

Fire-Rated Roller Doors are a non-negotiable part of a building’s life safety system. These doors are engineered to close automatically when a fire is detected, usually triggered by a smoke detector or the main alarm system.

Their job is to divide a building into compartments, containing fire and smoke in one area. This vital function slows down the fire’s spread, giving people time to evacuate safely and buying precious time for firefighters to arrive. They are a silent guardian, essential for compliance and, more importantly, for keeping people safe.

High-Performance Doors for Demanding Environments

In places with constant traffic—like manufacturing plants, car service bays, and busy loading docks—a standard door just won’t cut it. This is where high-performance doors, especially commercial high speed roll up door solutions, make a huge difference. These systems are built for one thing: performance. They are absolutely critical in settings where a door might cycle open and closed hundreds of times a day.

High-speed doors generally come in two main material types designed to meet industrial demand:

- High-Speed Fabric (Vinyl) Doors: These doors are incredibly fast, lightweight, and often have a “breakaway” bottom bar. If a forklift bumps into the door, the curtain simply pops out of its guides without getting damaged. It can be reset in seconds, which practically eliminates downtime. They’re perfect for interior spots where you need to separate different climate zones, like between a cold storage area and the main warehouse floor.

- High-Speed Rubber Doors: For the most rugged exterior openings, heavy-duty rubber doors are in a class of their own. They’re built to handle extreme weather, non-stop use, and even direct hits from vehicles. A perfect example is a mining operation or a waste management facility, where doors face harsh elements and heavy machinery all day long. Their tough construction guarantees reliable performance and a very long service life.

To help you visualize the differences, here’s a quick comparison of the main roller door types.

Comparison of Commercial Roller Door Types

| Door Type | Primary Material | Key Benefit | Ideal Application |

|---|---|---|---|

| Insulated Roller | Steel with Foam Core | Energy efficiency, temperature control | Cold storage, food distribution, climate-controlled warehouses |

| Security Shutter | Heavy-Gauge Steel | Maximum security, intrusion prevention | Retail storefronts, high-value storage, secure facilities |

| Fire-Rated | Steel with Fireproof Core | Fire containment, life safety compliance | Warehouses, industrial plants, commercial buildings |

| High-Speed Fabric | Vinyl/PVC Fabric | Speed, breakaway feature, minimal downtime | Interior high-traffic areas, manufacturing, food processing |

| High-Speed Rubber | Reinforced Rubber | Extreme durability, impact resistance | Exterior heavy-duty use, mining, waste management |

Each door is engineered for a specific job. By understanding what makes each one tick, you can make a much smarter choice for your own facility.

Key Factors in Your Roller Door Selection Process

Picking the right type of commercial garage roller door is a great first step, but the real secret to a long-lasting, reliable door is digging into the technical specs. You have to match the door to your actual, day-to-day operations. When you go beyond the basics, you get a solution that performs safely and efficiently for years, not just a few months.

Defining Your Operational Needs

Before you can even look at a door, you need a crystal-clear picture of what you’re asking it to do. A door on a self-storage unit might open twice a day, while one on a busy distribution centre’s loading dock is in constant motion. The demands are worlds apart.

The single most important, yet often overlooked, specification is the cycle rating. This number tells you how many times a door is engineered to open and close in its lifetime before key components like springs and operators are expected to fail.

A standard door might be rated for 20,000 cycles, which is perfectly fine for low-traffic spots. But a high-performance door built for a buzzing warehouse? That could be rated for 500,000 cycles or more. If you put a low-cycle door in a high-traffic opening, you’re just signing up for constant breakdowns and expensive emergency repairs down the road.

Material and Durability Considerations

The material of the door curtain itself has a huge impact on its security, weight, and how long it will last. Each option comes with its own set of pros and cons, making it better suited for certain environments.

- Steel: This is the industry workhorse. Steel offers unmatched strength and security, making it the default choice for any exterior-facing doors where preventing break-ins is a major concern.

- Aluminum: It’s lighter than steel and naturally resistant to rust and corrosion. That makes aluminum a fantastic option for humid environments or facilities with wash-down areas.

- High-Speed Fabric/Rubber: These materials are all about performance. They’re built for speed and, just as importantly, impact resistance. A high-speed roll-up door can take an accidental bump from a forklift and keep on moving, preventing costly downtime.

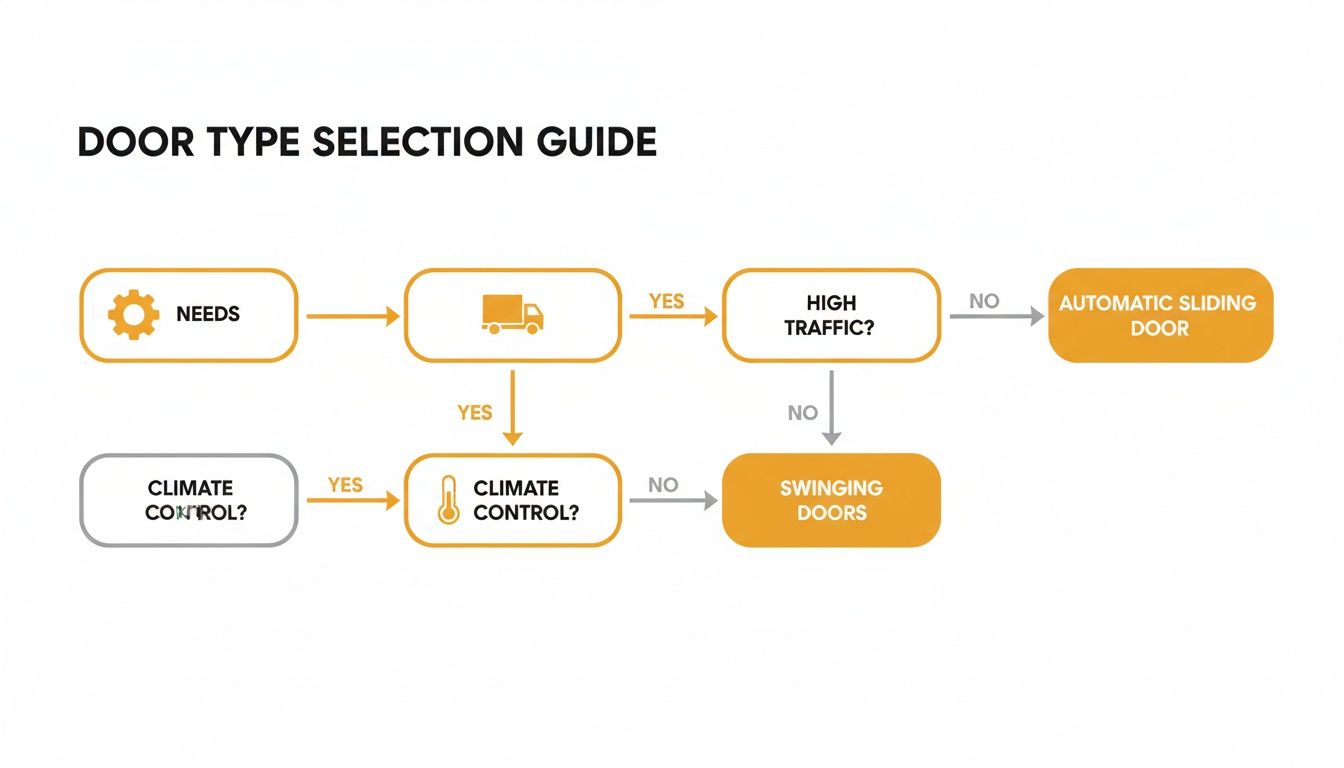

This decision-tree flowchart can help you visualize how your facility’s needs—from traffic volume to climate control—point you toward the right door.

Alt text: Flowchart diagram guiding selection of commercial garage roller doors based on facility needs, traffic, and climate control.

As you can see, high traffic naturally pushes you toward high-speed doors, while a need for environmental control makes insulated doors the obvious choice. It really helps clarify the decision.

Matching Performance Specs to Your Facility

Beyond the basics, a few other technical specs can make a huge difference to your energy bills and your team’s safety.

Insulation (R-Value)

The R-value is a simple measure of a door’s thermal resistance—basically, how well it stops heat from getting through. A higher R-value means better insulation. For any climate-controlled space like a food processing plant or a heated warehouse, a door with a high R-value is non-negotiable. It’s crucial for keeping temperatures stable and energy costs down. The quality of your roller door’s insulation and its seal have a massive effect on the efficiency of heating and cooling solutions for garages.

Wind Load Rating

If your facility is in an area that gets high winds, the wind load rating is a critical safety spec. This tells you how much wind pressure the door can handle before it starts to buckle or fail. An underspecified door isn’t just an inconvenience during a storm; it can become a serious hazard.

Safety and Compliance

Modern commercial garage roller doors aren’t just about opening and closing; they must have several safety features to protect your people and comply with regulations. These are not optional.

- Photo-Eye Sensors: These project an invisible beam of light across the door opening. If anything—a person, a forklift, a pallet—breaks that beam, the door immediately stops and reverses.

- Reversing Edge: This is a pressure-sensitive strip along the bottom edge of the door. If it touches an obstruction while closing, it instantly signals the operator to go back up.

- Manual Override: Usually a chain hoist, this system gives you a way to open the door manually if the power goes out, ensuring you’re never trapped in or out.

Choosing the right door is about a thoughtful analysis of all these factors. As your “Respected Partners, Reliable Service” provider, we’re here to help you navigate these specifications. And if your current systems need attention, remember our 24/7 emergency door repair services are always available.

Why Professional Installation Is Non-Negotiable

You can buy the best commercial garage roller door on the market, but it’ll fail without proper installation. Think of professional installation not as an extra cost, but as a critical investment in your door’s long-term safety, performance, and reliability. It’s the one thing you absolutely can’t afford to get wrong.

Alt text: Two professional technicians in hard hats installing a commercial garage roller door in a warehouse.

What a Professional Installation Actually Looks Like

Putting in a commercial roller door is a job of precision. There’s zero room for “close enough.” A certified team follows a strict process to make sure every single component works together perfectly.

Key steps include:

- Precise Track Alignment: The guide tracks have to be perfectly plumb and parallel. If they’re off by even a fraction of an inch, the door curtain will bind. That leads to jerky, noisy operation, premature wear on the rollers, and a ton of strain on the motor.

- Correct Spring Tensioning: This is easily the most critical—and dangerous—part of the job. Those massive torsion springs are what counterbalance the door’s weight. Too loose, and the motor will burn itself out trying to lift the door. Too tight, and the door can fly up like a rocket. Getting this wrong is a huge safety hazard that can lead to catastrophic failure.

- Motor and Operator Calibration: Modern door operators aren’t just plug-and-play. They need to be precisely calibrated for travel limits (where to stop at the top and bottom) and force settings. This ensures the door closes securely without slamming and that safety features, like the reversing edge, are sensitive enough to stop if they hit something.

The Real Dangers of Cutting Corners on Installation

Trying to DIY a commercial door installation or hiring a general handyman to save a few bucks can backfire spectacularly. The risks go way beyond a door that just doesn’t open smoothly.

Poor installation often leads to:

- Premature Component Failure: When parts are misaligned, they’re under constant stress and friction. This grinds down rollers, cables, and motor gears, causing them to fail years ahead of schedule.

- Voided Manufacturer Warranties: Most manufacturers will void the warranty instantly if the door wasn’t installed by a certified professional. That means you’re on the hook for the cost of any defects.

- Serious Safety Hazards: An improperly balanced door or a poorly calibrated safety sensor creates a life-threatening risk for your employees, customers, and visitors.

There’s a reason the market for professional installers is so robust. Just look at a state like California, where commercial activity has led to 854 garage door dealers. That density—one for every 46,681 residents—shows the massive demand for skilled technicians who can handle complex jobs driven by new construction and strict local building codes. You can see more insights on the competitive landscape of garage door dealers across the nation.

Retrofitting and Structural Considerations

Replacing an old door with a modern one—a process called retrofitting—comes with its own unique challenges. It’s almost never a simple swap.

A professional installer will first assess the existing structure to confirm it can handle the weight and operational forces of the new door. This often means reinforcing the door jambs or header and sometimes requires updating the electrical supply for a more powerful operator.

Getting a sense of the full scope of a commercial construction project can really put into perspective why you need specialists for jobs like this. For a wider view, learning about professional general contractor services helps show how different trades have to work together to get the job done right.

To ensure your new commercial roller door is installed for maximum safety and peak performance, contact Wilcox Door Service for an expert consultation.

A Practical Guide to Roller Door Maintenance and Repair

Consistent maintenance is your best defence against unexpected downtime and expensive repairs for your commercial garage roller doors. This section is a straightforward maintenance playbook for facility managers, giving you the clarity needed to protect your investment and keep your operation running smoothly. You’ll learn which preventative tasks your team can handle and which complex repairs are best left to the professionals, ensuring a safe working environment for everyone.

Think of your roller door like any other critical piece of machinery in your facility. It has moving parts that endure stress with every cycle. Just as you wouldn’t run a delivery truck without regular oil changes, you shouldn’t operate a high-traffic roller door without a consistent maintenance schedule.

Alt text: Facility manager and technicians inspecting commercial garage roller doors as part of a maintenance schedule.

Building Your In-House Maintenance Checklist

Empowering your on-site team with a simple, routine inspection checklist is the first step toward proactive care. These tasks don’t require specialized tools but can catch small issues before they snowball into major problems.

Here are some fundamental checks your team can perform monthly:

- Visual Inspection: Walk the length of the door on both sides. Look for dents, rust, or damage to the door curtain, especially after an impact. Also, check that the guide tracks are free of debris and not bent or misaligned.

- Listen for Unusual Noises: Operate the door and listen for any scraping, grinding, or popping sounds. These noises are often the first warning signs of issues with rollers, springs, or the motor.

- Test Safety Features: Place a cardboard box in the door’s path to test the photo-eye sensors. The door should immediately stop and reverse. You should also test the reversing edge by gently pressing it as the door closes; it should also reverse on contact.

- Check for Smooth Operation: Watch the door as it moves. Does it travel smoothly, or does it seem jerky and unbalanced? An unbalanced door puts immense strain on the operator.

Knowing When to Call the Professionals

While in-house checks are crucial, certain tasks carry significant risks and demand the expertise of certified technicians. Your team should never attempt to adjust, repair, or replace the high-tension components of the door system.

Any work involving the torsion springs, cables, or motor should be left exclusively to professionals. These components are under extreme tension and can cause severe injury or property damage if handled improperly.

A professional maintenance plan covers critical tasks that go well beyond a daily check:

- Lubrication: Applying the correct lubricant to rollers, hinges, and bearings to reduce friction and wear.

- Spring Tensioning: Technicians will ensure the springs are perfectly balanced to correctly support the door’s weight.

- Motor and Limit Adjustments: Calibrating the operator to make sure the door opens and closes to the correct points without strain.

Troubleshooting Common Roller Door Issues

Even with great maintenance, problems can still pop up. Here are a few common issues and their likely culprits:

Issue: The Door Won’t Close

- Most Likely Cause: The photo-eye sensors are misaligned or obstructed. Check to ensure nothing is blocking the beam and that the small lights on both sensors are solid, not blinking.

Issue: The Door Is Making Loud Grinding Noises

- Most Likely Cause: This usually points to worn-out rollers or debris stuck in the guide tracks. While your team can clear debris, worn rollers should be replaced by a technician.

Issue: The Door Only Opens a Few Feet and Stops

- Most Likely Cause: This could be an issue with the operator’s travel limit settings or, more seriously, a broken torsion spring. If you suspect a broken spring, stop using the door immediately and call for emergency service.

For significant physical damage, such as a forklift impact that damages multiple sections of the curtain, a professional assessment is non-negotiable. Our team can help you determine the best course of action; learn more in our detailed guide on garage door panel replacement.

To establish a maintenance plan that minimizes downtime and keeps your facility safe, contact Wilcox Door Service to schedule a professional inspection.

Calculating the True Return on Your Investment

A high-quality commercial garage roller door is never just an expense on a spreadsheet; it’s a hard-working investment that pays you back. To really grasp its value, you have to look past the initial sticker price and think about the total cost of ownership over its entire life. This is where you see the real, tangible returns a well-chosen door delivers—from lower energy bills to serious boosts in productivity.

Tangible Returns from Energy and Productivity

The quickest and most obvious payback often comes from making your daily operations more efficient. For any facility with climate-controlled spaces, the ROI is crystal clear and easy to measure.

- Energy Savings: Think of a properly sealed, insulated roller door as a thermal barrier. It stops expensive heated or cooled air from pouring out of your building, which translates directly into lower monthly utility bills. To see just how significant this can be, check out our guide on the top benefits of an insulated roll-up door for your business.

- Productivity Gains: On a busy loading dock, speed is money. A commercial high-speed roll-up door solution can cycle open and closed in just seconds, slashing wait times for forklifts and transport vehicles. This keeps your people moving and materials flowing without creating costly bottlenecks.

A food distribution centre is a perfect example. A high-speed door doesn’t just speed up loading and unloading; it minimizes how long your temperature-sensitive environment is exposed to the outside air. That dual benefit—a faster workflow and reduced energy loss—means the door can pay for itself surprisingly quickly.

Reducing Risk and Long-Term Costs

Beyond the immediate savings, a dependable commercial roller door cuts down on major long-term costs tied to security breaches, product spoilage, and workplace safety incidents. A durable, properly maintained door minimizes the risk of a sudden failure that could bring your entire operation to a screeching halt.

This kind of proactive investment also makes your facility a safer place to work. Modern doors with integrated safety features like photo-eyes and reversing edges reduce the risk of accidents and potential liability claims, creating a more secure environment for your team.

Choosing the right door is about finding a solution that delivers lasting value. As your “Respected Partners, Reliable Service” provider, our focus is on solutions that will strengthen your operations for years to come.

To find a commercial door solution that delivers a powerful return on investment for your facility, contact our team for a personalized consultation.

Frequently Asked Questions

Got questions about commercial roller doors? You’re not alone. Here are straightforward answers to some of the most common things facility managers and business owners ask.

How Long Does a Commercial Roller Door Last?

A well-maintained commercial roller door can be a real workhorse, lasting anywhere from 20 to 30 years. The key word there is “well-maintained.” Its actual lifespan really comes down to its cycle rating—a term for how many open/close cycles it’s designed for—and how hard you use it. Regular professional maintenance is what gets you to that 30-year mark, ensuring crucial parts like springs and operators don’t give out prematurely.

What’s the Difference Between a Roller Door and a Sectional Door?

The biggest difference is how they open. A roller door is made of a single “curtain” of interlocking metal slats that coils up neatly into a compact barrel above the doorway. This is a huge space-saver, perfect for warehouses trying to maximize every inch of vertical storage. A sectional door, on the other hand, is built from several larger, hinged panels that slide up and then back along tracks, resting flat against the ceiling when open.

Are High-Speed Doors Worth the Extra Cost?

In a high-traffic environment? Absolutely. A commercial high-speed roll-up door opens and closes in just a few seconds, which dramatically cuts down on waiting time for forklifts and staff. For any facility that’s heated or cooled, this speed is a game-changer for energy efficiency. The initial investment often pays for itself surprisingly quickly through faster workflows, lower energy bills, and fewer impact accidents, thanks to smart features like breakaway bottom bars.

To explore the best commercial garage roller door solutions for your business and ensure your operations run smoothly, contact Wilcox Door Service today for an expert consultation.