Your facility’s commercial overhead doors are far more than simple entry points. They are critical pieces of operational equipment that directly influence your daily workflow, energy costs, and the safety of your team. This comprehensive guide will walk you through everything you need to know, from selecting the right door type and materials to understanding mandatory safety standards and the value of professional maintenance. By the end, you’ll be equipped to make confident, strategic decisions that enhance your facility’s efficiency and security.

Your Complete Guide to Commercial Doors

Choosing the right commercial overhead door can feel daunting, but it doesn’t have to be. We’ve put this guide together to walk facility managers and business owners through everything you need to know to make smart decisions that protect your people, your products, and your bottom line.

A well-chosen door can be a game-changer for your workflow. For instance, putting a high-speed door on a busy loading dock can slash energy loss and speed up truck turnaround times, directly boosting productivity. On the flip side, the wrong door—or one that’s poorly maintained—can lead to costly downtime, serious safety hazards, and compliance headaches.

In the sections ahead, we’ll break down the essential aspects of commercial doors, giving you the knowledge to make confident choices. You’ll learn about:

- Different Door Types and Applications: From versatile sectional doors to heavy-duty rolling steel models, we’ll show you where each type shines.

- Materials and Operator Systems: Get to know the components that make a door tough and reliable.

- Safety and Compliance Standards: We’ll cover the non-negotiable rules, including critical fire door testing, that keep your team safe.

- Professional Installation and Maintenance: Discover how proactive service from a partner you trust prevents failures and extends the life of your investment.

Here at Wilcox Door Service, our brand promise is “Respected Partners, Reliable Service.” Our goal is to demystify the world of commercial and industrial door solutions so you can optimize your facility’s access points with total confidence. By the time you finish this guide, you’ll see how a strategic approach to your doors can save you from expensive disruptions and keep your operations running like clockwork.

How to Select the Right Door for Your Facility

Picking the right commercial overhead door isn’t just about filling an opening; it’s a critical decision for your facility’s efficiency, security, and energy bills. This choice directly impacts your daily workflow and safety, so it’s crucial to match the door to the job it needs to do.

Let’s walk through the main options you’ll encounter. We’ll look at everything from the versatile workhorses you see on loading docks to specialized systems that protect temperature-sensitive goods. By exploring real-world scenarios, you’ll see exactly how each door type functions and where it delivers the most value, so you can make a smart, lasting investment.

To make things easier, we’ve put together a quick comparison table. Think of it as a starting point to help narrow down which door type aligns best with what you’re trying to achieve at your facility.

Matching Door Types to Your Business Needs

| Door Type | Primary Benefit | Common Applications | Best For |

|---|---|---|---|

| Sectional Doors | Versatility & Reliability | Loading docks, warehouses, auto shops, fire stations | General-purpose use where durability and insulation options are key. |

| High-Speed Doors | Maximum Efficiency | Food processing, cold storage, high-traffic interior doorways | Operations that can’t afford downtime or environmental cross-contamination. |

| Rolling Steel Doors | Uncompromising Security | Storefronts, parking garages, high-security warehouses | Protecting assets against forced entry and harsh weather. |

| Fire-Rated Doors | Life Safety & Compliance | Firewalls, corridors, areas requiring fire separation | Facilities needing to meet strict building codes and contain potential fires. |

| Insulated Doors | Temperature Control | Freezers, coolers, pharmaceutical clean rooms, food distribution | Environments where maintaining a precise temperature is non-negotiable. |

This table gives you a bird’s-eye view, but the real value is in the details. Let’s dig deeper into what makes each of these doors tick.

Sectional Doors: The Versatile Standard

When most people think of a commercial door, they’re picturing a sectional door. Made up of horizontal panels linked by hinges, they slide up and back along a track system when opened. It’s a simple, robust design that makes them incredibly adaptable for a huge range of commercial and industrial settings.

For a practical example, think about a distribution centre operating in a chilly Canadian climate. An insulated sectional door is a game-changer. The insulation quality is measured by its R-value—a simple term for its ability to resist heat flow. The higher the number, the better it insulates, translating into significant energy savings on heating costs.

You’ll find these doors are the go-to choice for:

- Loading docks and shipping bays

- Warehouses and storage facilities

- Automotive service centres and fire stations

Their solid construction and the wide variety of materials and insulation levels available make them a dependable, all-around solution.

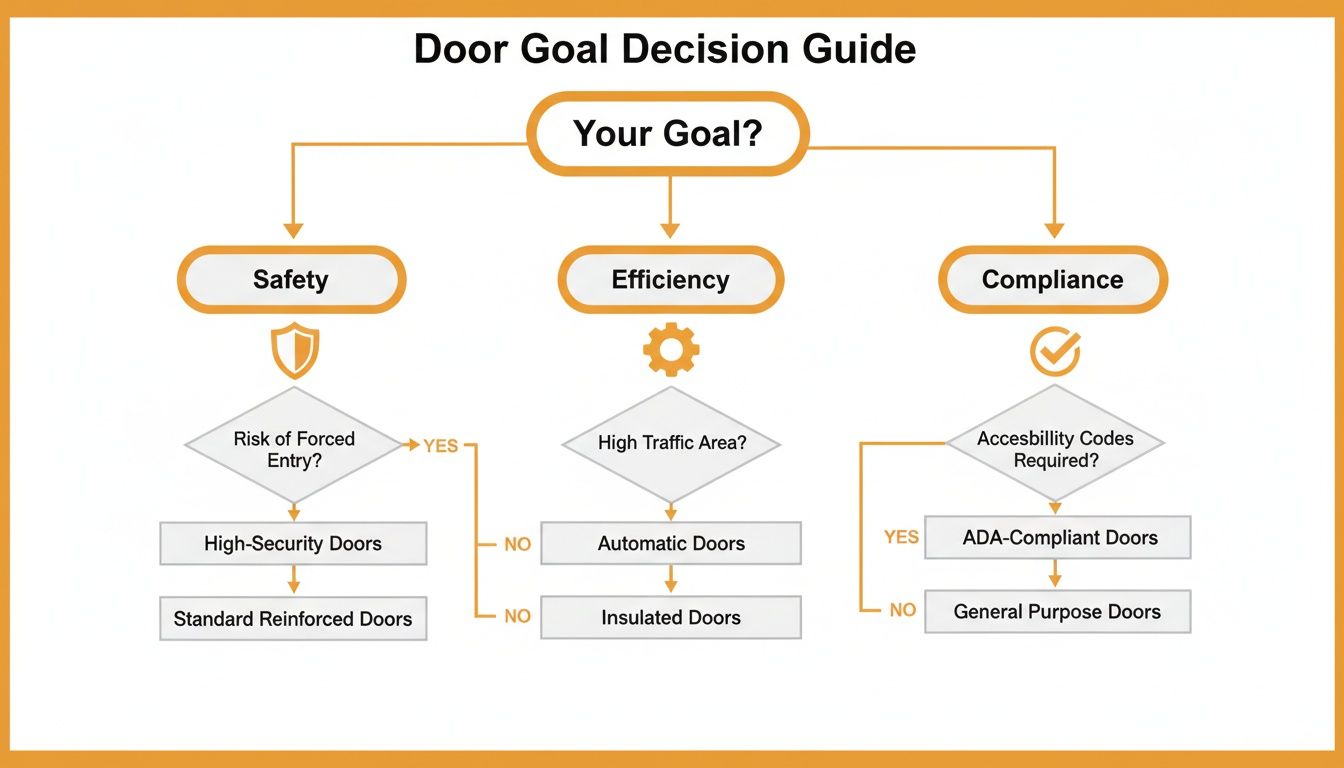

This flowchart gives you a great visual of how starting with your primary goal—whether it’s safety, efficiency, or compliance—can point you toward the right door.

As you can see, once you define what’s most important for an opening, the best door category becomes much clearer.

High-Speed Doors for Maximum Efficiency

When your operations move at the speed of business, you can’t afford to wait for a slow-moving door. That’s where high-speed doors come in. Often built from durable fabric or vinyl, these doors open and close in seconds, dramatically reducing the cycle time compared to a standard sectional door.

Picture a busy food processing facility where maintaining a sterile, climate-controlled environment is everything. Every second a door hangs open, you’re losing expensive conditioned air and risking contamination. A high-speed door slashes that exposure time, protecting both your product and your bottom line. They are essential for any high-traffic area where speed is king.

Rolling Steel and Fire-Rated Doors for Uncompromising Protection

For applications that demand absolute toughness and security, rolling steel doors are the undisputed champions. They’re constructed from interlocking steel slats that coil up into a tight drum above the opening, making them incredibly difficult to breach and very space-efficient. You’ll see them guarding everything from storefronts to warehouses after hours.

A critical offshoot of this category is the fire-rated door. These aren’t just strong; they’re lifesavers. Engineered to close automatically when a fire alarm is triggered, they compartmentalize a building to stop the spread of flames and smoke. In many commercial buildings, these aren’t just a good idea—they’re a legal requirement to protect lives and property.

When thinking about security, remember that a strong door is only half the battle. You need to consider the entire system, including locks and access controls. Having reliable commercial locksmith services on call is crucial for both long-term maintenance and immediate needs.

Specialized Doors for Unique Environments

Some facilities just have needs that a standard door can’t meet. Take insulated and cold-storage doors, for instance. These are meticulously engineered with top-tier insulation and airtight seals to hold precise temperatures in freezers, coolers, and pharmaceutical clean rooms.

These doors are the unsung heroes of the cold chain, preventing temperature swings that could ruin sensitive products. Every part of their design is focused on stopping energy loss, controlling humidity, and maintaining a sterile environment. In these cases, the right door is about more than just access—it’s about protecting your entire process.

Understanding Door Materials and Operator Systems

When it comes to the long-term performance of your commercial overhead doors, it really boils down to two things: what they’re made of and what makes them move. A great door isn’t just a barrier; it’s a system of tough materials, durable hardware, and a powerful operator working in concert. Let’s pull back the curtain on these core components so you can understand what truly makes a door dependable.

We’ll compare common materials like steel and aluminum, breaking down the trade-offs between strength and weather resistance. Then, we’ll get into the hardware that does the heavy lifting—the springs, tracks, and cables—and show you why investing in quality components is your best defense against failure. Finally, we’ll focus on the heart of the setup: the door operator, helping you match the right motor to your door’s size and daily workload.

Choosing the Right Door Materials

The material your door panels are made from directly impacts its durability, security, and even your energy bills. Each option brings something different to the table.

- Steel: This is the industry workhorse for a reason. Steel offers an unbeatable mix of strength, security, and value. You can get it insulated to provide excellent thermal resistance (that’s the R-value we talked about), which is perfect for warehouses dealing with cold Canadian winters. A heavier gauge steel is also great at resisting dents on a busy loading dock.

- Aluminum: Lighter than steel, aluminum is fantastic at resisting rust and corrosion. This makes it the go-to choice for humid environments or facilities that need frequent wash-downs, such as a food distribution center. You’ll often see it used in full-view doors with large glass panels, like at car dealerships where aesthetics matter.

- Composites and Specialty Materials: For more unique situations, other materials enter the picture. For example, specialized fabric doors are built for high-speed applications, while fibreglass doors are great at resisting salt air and moisture. It’s all about matching the material’s strengths to your facility’s specific challenges.

The Unsung Heroes: Door Hardware

While the panels get all the attention, it’s the hardware that does the real work behind the scenes. Skimping on robust hardware is not an option if you care about safety and longevity.

Here are the key players:

- Springs: Torsion springs are the muscle of the system. These tightly wound springs counterbalance the door’s weight, allowing it to open and close easily. They are under incredible tension and must be perfectly sized for the door’s weight and usage frequency.

- Tracks and Rollers: The tracks guide the door, and the rollers keep it moving smoothly. Upgrading to heavy-duty tracks and high-quality nylon rollers makes a world of difference in reducing noise and wear, helping the door last longer.

- Cables and Drums: These parts work with the springs to lift the door evenly from both sides. A frayed cable is a serious safety red flag and requires an immediate service call.

Think of your door’s hardware like the suspension on a transport truck. You wouldn’t put standard car parts on a vehicle hauling heavy loads and expect them to last. In the same way, using residential-grade springs on a high-cycle commercial door is a recipe for costly downtime and potential accidents.

Demystifying Commercial Door Operators

The operator, or motor, is the engine that drives your entire door system. Picking the right one is about matching it to the door’s size, weight, and how often it opens and closes each day. The three main types are each designed for different jobs.

- Trolley Operators: These work much like a residential garage door opener, with a motor on a rail pulling a trolley. They’re a solid choice for smaller, lighter sectional doors with standard overhead clearance.

- Jackshaft Operators: This type is a space-saver. It mounts on the wall next to the door and turns the torsion bar directly. It’s perfect for facilities with high ceilings or where you need to keep the overhead space clear for lights or lifts.

- Gearhead Operators: This is the heavy-duty champion. A gearhead operator is engineered for massive, heavy, or high-cycle industrial doors. It uses a gear-reduction system to deliver maximum lifting power and smooth, controlled movement.

Understanding how these operators function is key to running an efficient and safe facility. To dive deeper, you can learn more about how an automatic door operator works in our detailed guide. Modern control systems can also be integrated, adding features like motion sensors and timers to streamline your workflow and enhance security. As respected partners, our goal at Wilcox is to provide reliable service by ensuring you have the right components working together seamlessly.

Meeting Safety Compliance and Improving Energy Efficiency

Your commercial overhead doors are more than just moving walls; they are active players in your facility’s safety program and energy budget. Understanding your responsibilities in these areas is non-negotiable for preventing accidents, avoiding fines, and controlling operational costs.

We’ll cover the essential safety standards that protect your team, especially the critical role of entrapment protection devices. Think of these as the door’s safety net—features like photo eyes or reversing edges that command it to stop or reverse if an obstruction is detected. This is why regular, professional inspections are mandatory; they prevent serious accidents and the liability that comes with them. We’ll also focus on fire-rated doors and the legal requirement for annual testing. Then, we’ll shift to energy efficiency and show you how a properly insulated door can slash your utility bills, delivering a significant return on investment.

Upholding Safety Standards and Fire Code Compliance

Safety isn’t just a good idea; it’s a legal requirement. Commercial doors are heavy, powerful equipment, and a malfunctioning door is a serious hazard. That’s why standards exist—to protect everyone in your facility.

Regular inspections by certified technicians are your first and best line of defence. They’re trained to spot subtle issues you might miss, like worn-out cables or failing safety sensors, long before they lead to a catastrophic failure. It’s a small investment that prevents costly downtime and, more importantly, keeps your people safe.

A fire-rated door is a silent guardian. It’s engineered to close automatically during an alarm to compartmentalize a building. This simple action contains smoke and flames, buying precious time for people to evacuate. If it fails to close, its protective value is zero.

This brings us to one of your most critical compliance tasks: the annual fire door drop test. This is a mandatory, documented procedure where a certified technician verifies that the door’s automatic closing mechanism works exactly as designed. Failing to perform and document this test can lead to steep fines and unthinkable liability in the event of a fire. As your partners in safety, we provide the reliable, certified service you need to meet these crucial deadlines.

Maximizing Energy Efficiency and Total Cost of Ownership

Beyond safety, your commercial doors have a huge impact on your building’s energy consumption. An uninsulated or poorly sealed door is like leaving a window open 24/7, constantly leaking expensive heated or cooled air and forcing your HVAC system to work overtime.

The key is to think in terms of Total Cost of Ownership (TCO), not just the upfront purchase price. TCO factors in the initial cost plus long-term energy, maintenance, and repair expenses. An insulated door may have a higher initial price tag, but the energy savings it delivers year after year often provide a rapid and significant return on investment.

An insulated sectional door with a high R-value (the measure of thermal resistance) and a solid set of perimeter seals creates a formidable barrier against energy loss. For a practical example, a refrigerated warehouse can see a drastic reduction in compressor runtime—and utility bills—by upgrading to doors with superior insulation and seals. For a deeper look, check out our guide on the benefits of insulated overhead doors in commercial spaces. It’s a straightforward upgrade that directly cuts costs and fosters a more comfortable work environment.

Why Professional Installation and Maintenance Matter

You can buy the best commercial door on the market, but its long-term reliability and safety ultimately hinge on two things: how it’s installed and how it’s maintained. A perfectly good door can fail years ahead of schedule if the installation is botched, while a well-maintained door can outlast expectations.

In this section, we’ll explain why professional installation is the bedrock of your door’s performance. We’ll reframe maintenance, showing how a Planned Maintenance Program (PMP) is a direct investment in your facility’s uptime. Finally, since breakdowns happen, we’ll talk about why having a 24/7 emergency service partner in your corner is non-negotiable for minimizing downtime.

The Foundation of Performance: Professional Installation

Think of professional installation like the foundation for a house. If it’s not done right, everything built on it will have problems. An improper install is a recipe for chronic operational headaches and, worse, serious safety hazards. Certified technicians do more than just hang a door; they ensure every component is perfectly aligned, balanced, and tuned for the long haul.

That level of precision is critical. For instance, the torsion springs—the components that do the heavy lifting—must be calibrated to the door’s exact weight. A small miscalculation puts immense strain on the operator, wears out parts faster, and creates a dangerously imbalanced door.

A professional installation from a team like Wilcox guarantees that:

- Safety systems are installed and tested correctly: This means photo eyes, reversing edges, and other critical features are confirmed to be working before the job is signed off.

- The door is perfectly balanced: A balanced door glides smoothly, which dramatically extends the life of both the motor and the hardware.

- All components are properly secured and aligned: This prevents premature wear and tear on everything from the tracks to the cables.

Investing in Uptime with a Planned Maintenance Program

Once your door is running correctly, the game shifts to preserving that performance. A Planned Maintenance Program (PMP) is the smartest way to do it. It’s a proactive strategy that pulls you out of the reactive “fix-it-when-it-breaks” cycle. This isn’t just an expense; it’s an investment that pays you back in reduced downtime.

During a PMP visit, a certified technician runs through a comprehensive multi-point inspection, catching and fixing small issues before they snowball into major failures.

A PMP is like a regular tune-up for your company vehicle. You wouldn’t wait for the engine to seize before changing the oil. Similarly, proactive door maintenance prevents the operational equivalent of a breakdown on the highway—a failed door during peak shipping hours at a logistics facility.

A typical inspection includes:

- Lubricating all moving parts to keep things running smoothly.

- Checking and adjusting spring tension to maintain perfect balance.

- Inspecting cables and rollers for signs of fraying or wear.

- Testing all safety features, including auto-reverse mechanisms.

- Verifying operator functionality and control settings.

This systematic care is vital for keeping your facility humming. To see how some organizations are taking this even further, you can explore how they’re using modern maintenance augmented reality techniques to enhance safety and efficiency.

Responding to the Unexpected with 24/7 Emergency Service

Even with the best plan, the unexpected can happen. A forklift might clip a track, or a critical component could fail. When a key access point like a loading dock door goes down, your entire operation can grind to a halt.

Picture a failed door at a cold storage facility on a Friday afternoon. Every hour that door stays open, the product is at risk. That’s when a reliable 24/7 emergency service partner becomes invaluable. Having a team on call means you can get a technician on-site fast to diagnose the problem and start the repair, minimizing the disruption. For a deeper dive into what’s involved, our guide on overhead door repair offers practical advice.

The value of this immediate response can’t be overstated. Industry estimates often value a single hour of downtime at a medium-sized distribution dock at several thousand dollars. It’s no wonder facilities increasingly favour service contracts with partners who can deliver rapid, reliable emergency support.

Common Questions About Commercial Overhead Doors

Even with a solid grasp of the basics, facility managers often have specific questions about their commercial overhead doors. To help, here are straightforward answers to the questions we hear most often, giving you the confidence to make the right calls for your facility.

How Often Should a Commercial Door Be Serviced?

The honest answer is: it depends on its usage.

For a door with light traffic, a professional inspection once a year is usually sufficient to keep things running smoothly.

But for high-cycle doors in busy distribution centres or manufacturing plants, we strongly recommend quarterly service. Those doors endure significant wear, and more frequent check-ups are the only way to catch problems before they cause a shutdown.

The smartest approach is a Planned Maintenance Program (PMP). Don’t think of it as a cost—think of it as an insurance policy for your uptime. A good PMP ensures your doors get the right level of attention based on their specific workload.

During a service visit, our certified technicians run through a comprehensive checklist, including:

- Lubricating all moving parts to cut down on friction.

- Checking and tweaking spring tension so the door is properly balanced.

- Inspecting cables, rollers, and hardware for signs of wear.

- Testing all safety features, like photo eyes and reversing edges, to ensure they work perfectly.

This proactive care catches small issues before they become big, expensive problems, extending the door’s life and keeping your facility safe.

What Are the Warning Signs My Door Needs Repair?

Your doors will almost always give you a heads-up that trouble is brewing. If you know what to look and listen for, you can prevent a minor issue from becoming an operational crisis.

One of the most obvious signs is unusual noises. If you suddenly hear grinding, screeching, or popping, it’s a big red flag. These sounds often point to problems with the rollers, springs, or track alignment.

Another clear sign is erratic movement. Is the door moving slower than it used to? Does it seem jerky, or does it get stuck? These are classic symptoms of a failing operator or an issue with spring balance. You might also spot visible damage, like frayed cables or a broken spring. These parts are under incredible tension. Never attempt to fix them yourself. Call a professional immediately.

Finally, if the door has come off its tracks or it’s not sealing properly at the bottom, it needs immediate attention from a qualified technician.

Can I Upgrade a Manual Door to an Automatic System?

Absolutely. Converting a manual commercial door to an automatic one is a common and valuable upgrade that can significantly boost your facility’s efficiency.

The process involves fitting a motor (an operator), a drive system, and the necessary controls for your specific door. Before work begins, a technician will assess your current door to ensure it’s properly balanced and in good shape. An operator is designed to guide a healthy door, not force a broken one, so any existing issues must be fixed first. Based on the door’s size, weight, and cycle count, the technician will recommend the right type of operator—whether that’s a trolley, jackshaft, or a heavy-duty gearhead model.

How Do I Choose Between a Sectional and Rolling Steel Door?

Deciding between a sectional and a rolling steel door boils down to what matters most for that specific opening: versatility and insulation, or maximum security and space-saving design.

Think of sectional doors as the versatile workhorses. They’re made of connected horizontal panels and are your best bet for insulation (measured in R-value). This makes them perfect for most warehouses, loading docks, and auto shops where temperature control is a priority.

Rolling steel doors, on the other hand, are all about unbeatable security and durability. They’re constructed from interlocking steel slats that coil up neatly into a compact drum above the opening. This makes them the go-to solution for high-security areas, very large openings, or anywhere with limited headroom. If you need pure, uncompromising toughness to protect high-value assets, rolling steel is the clear winner.

As “Respected Partners, Reliable Service” has been our promise for over 100 years, the team at Wilcox Door Service Inc. is here to provide the expert guidance you need. To schedule a service inspection, discuss an upgrade, or request a quote for your commercial overhead doors, please contact the Wilcox team today for a consultation or quote.