A well-functioning loading dock is the heart of any efficient warehouse or distribution center, and at its core is the dock leveler. This guide will walk you through everything you need to know about dock levelers for loading docks, from their critical role in safety and efficiency to choosing the right type, size, and capacity for your specific needs. You'll learn how to identify essential safety features, understand Canadian compliance standards, and implement a maintenance strategy that protects your investment for years to come.

A dock leveler is the essential piece of hardware that bridges the gap between your facility’s floor and the bed of a transport truck. The best way to think of it is as a drawbridge for your warehouse. It creates a secure, stable connection that lets your forklifts and staff move goods in and out safely and efficiently. Without proper dock levelers for loading docks, you're looking at significant risks—dangerous gaps that can lead to accidents, damaged products, and delays that hit your bottom line.

The Critical Role of Dock Levelers in Your Operations

Every single time a truck backs into one of your loading bays, a gap is created between the trailer and your dock floor. This isn't just a minor inconvenience; it's a serious safety hazard and a major bottleneck for your entire operation. A dock leveler solves this problem by creating a smooth, even surface, basically extending your warehouse floor right into the back of the truck.

This simple function is absolutely fundamental to keeping a supply chain moving. Think about it: a busy distribution centre in Mississauga can't afford any slowdowns. A reliable, well-maintained dock leveler lets a forklift operator move pallets quickly and confidently, turning trucks around faster and keeping everything on schedule. On the flip side, a facility that's still using flimsy, temporary dock plates is creating a dangerous work environment where one wrong move could result in thousands of dollars in damaged goods or, even worse, a serious injury to an employee.

More Than Just a Bridge

Beyond just filling a space, dock levelers perform several vital functions that protect your assets and, most importantly, your people.

- Enhanced Safety: They eliminate that uneven, hazardous transition between the dock and the trailer, which is a notorious spot for forklift tip-overs and staff injuries.

- Increased Efficiency: A stable, dependable path for loading and unloading means your team can work faster and with more confidence. This directly improves throughput and cuts down on how long vehicles have to wait.

- Protection for Goods and Equipment: By providing a smooth ride, dock levelers prevent those jarring bumps that can damage sensitive cargo. They also reduce the wear and tear on your material handling equipment, like forklifts and pallet jacks.

- Improved Environmental Control: When paired with the right accessories, they help create a much better seal at the loading dock opening. You can learn more about how dock seals and shelters complete your setup in our related guide.

A well-maintained dock leveler is one of the most important investments a facility can make. It’s the linchpin of a safe and efficient loading dock, directly impacting everything from employee morale to your bottom line.

Ultimately, understanding the importance of dock levelers for loading docks is the first step toward building a safer, more productive workspace. They aren't just accessories; they are core components of any modern logistics operation.

Choosing Your Dock Leveler: Mechanical, Hydraulic, or Air-Powered

Picking the right power type for your dock levelers for loading docks is a huge decision. It directly impacts your loading bay’s efficiency, your budget, and how reliable your equipment will be for years to come. The three main players—mechanical, hydraulic, and air-powered—each have their sweet spots. Knowing how they work and where they shine is key to making the right call for your facility.

First, let's confirm if a dock leveler is even what you need. This simple flowchart breaks it down.

Alt text: Flowchart guiding the decision between a dock leveler and a vehicle restraint, emphasizing that a leveler is needed when a loading dock is present.

As you can see, it all starts with the loading dock itself. The leveler is the essential bridge that makes that gap between the dock and the truck safe and functional.

Mechanical Dock Levelers: The Reliable Workhorse

Mechanical dock levelers are the original, time-tested solution. Think of them as the classic manual transmission car of the dock world—dependable and straightforward. They work with a system of springs and a simple pull-chain. An operator gives the chain a tug, which releases a lock and allows heavy-duty springs to pop the platform up.

From there, the operator walks onto the deck, using their own weight to lower it until the lip rests securely on the truck bed. Because they don’t need electricity or hydraulic fluid, they’re an incredibly reliable choice, especially for facilities with lighter traffic.

Best For:

- Facilities with 1-3 daily truck deliveries per bay.

- Operations where the initial budget is the biggest factor.

- Dock bays where getting electrical power is a hassle.

Hydraulic Dock Levelers: Power and Precision

For high-volume, demanding environments, hydraulic levelers are the industry standard. These units are the automatic transmission—smooth, powerful, and effortless. Powered by an electric motor and hydraulic cylinders, they offer push-button operation. One press of a button raises the deck and extends the lip automatically, giving you precise control as it gently lowers onto the trailer floor.

Their power and automation make them perfect for facilities that can't afford a second of downtime. For example, a 24/7 pharmaceutical distribution center relies on hydraulic levelers to move temperature-sensitive cargo quickly and smoothly, without the jarring motion that could damage products. They can handle incredibly heavy loads—up to 80,000 lbs—which is why they are the go-to for our Wilcox Door Service clients in demanding sectors.

Best For:

- Busy distribution centres and 24/7 manufacturing plants.

- Handling heavy or delicate cargo that needs a perfectly smooth transition.

- Operations that want to prioritize ease of use and reduce physical strain on employees.

Air-Powered Dock Levelers: The Clean Alternative

Air-powered, or pneumatic, dock levelers offer a great mix of modern tech and simple design. Instead of springs or hydraulics, they use a high-volume, low-pressure industrial airbag to lift the deck. An activation button inflates the bag, the platform rises, and the lip extends into place.

This design has fewer moving parts than a mechanical unit and completely avoids hydraulic fluids, making it a fantastic low-maintenance and environmentally friendly option. You get the convenience of a push-button system without the complexity of hydraulics. This makes them ideal for a food processing plant, where eliminating the risk of a hydraulic fluid leak is critical for hygiene and safety compliance.

Best For:

- Food, beverage, or pharmaceutical facilities where preventing any kind of fluid spill is non-negotiable.

- Businesses looking for an eco-friendly and energy-efficient solution.

- Operations that want push-button control but with simpler maintenance needs.

To make the choice a bit clearer, here’s a quick side-by-side comparison.

Comparing Key Features of Dock Leveler Types

| Feature | Mechanical Leveler | Hydraulic Leveler | Air-Powered Leveler |

|---|---|---|---|

| Operation | Manual pull-chain and body weight | Push-button (electric-hydraulic) | Push-button (airbag inflation) |

| Upfront Cost | Lowest | Highest | Moderate |

| Maintenance | Moderate (springs need adjustment) | Higher (fluid, seals, motor) | Low (fewer moving parts) |

| Ideal Traffic | Low (1-3 trucks/day) | High (24/7 operations) | Low to Medium |

| Ergonomics | Physically demanding | Very low physical strain | Very low physical strain |

| Cleanliness | No fluid leaks | Potential for hydraulic fluid leaks | No fluid leaks |

| Reliability | Very reliable, simple mechanics | Very reliable, industry standard | High reliability, simple design |

This table highlights the core trade-offs between cost, convenience, and maintenance.

Choosing the right power system is all about matching the equipment to your workflow. A small manufacturing site might do just fine with a mechanical leveler for years. On the other hand, a high-turnover logistics hub will see a rapid return on investment with a hydraulic system's speed and durability.

Each type of dock leveler brings a distinct set of benefits to the table. By taking a hard look at your facility's traffic, budget, and day-to-day demands, you can pick a system that delivers the safety and efficiency your loading dock needs. As trusted partners in this industry, we help facilities make this exact choice every single day, ensuring their operations stay reliable for years to come.

Selecting the Right Size and Capacity for Your Needs

Picking the right size and capacity for your dock levelers for loading docks isn’t just a small technical detail—it’s one of the most important safety and operational calls you'll make. A leveler that’s too small is a catastrophic failure waiting to happen. An oversized one? That’s just money down the drain.

Getting this right from day one is the key to a safe, efficient, and long-lasting loading dock.

Alt text: A forklift on a dock leveler with a checklist graphic illustrating how to select the right size and capacity for loading docks.

Before we jump into calculations, let's get the industry terminology straight. You'll hear two key terms thrown around: static capacity and dynamic capacity.

- Static Capacity: This is how much weight the dock leveler can hold when it’s not moving—just sitting in its stored position. Think of it like the weight limit for parked cars on a bridge.

- Dynamic Capacity: This is the big one. It’s the maximum weight the leveler can handle while in motion, factoring in the combined force of a moving forklift, its driver, and the pallet it's carrying. This is the bridge's weight limit for moving traffic—a much tougher scenario.

For your day-to-day operations, dynamic capacity is the number that truly matters. It reflects the real-world stress your equipment will face every single shift.

How to Calculate Your Required Capacity

A classic mistake is just matching the leveler's capacity to your forklift's maximum weight. This is a dangerous shortcut. It completely ignores the speed, the angle of the ramp, and how often your team crosses it, all of which multiply the actual force hammering down on the leveler deck.

The industry standard involves calculating your Gross Vehicle Weight (GVW) and then applying a multiplier. To figure out the dynamic rating you actually need, you need to consider the total weight of your heaviest forklift plus its heaviest load, and then apply a safety factor based on your operational intensity. You can dive deeper into how to understand loading dock capacity ratings and how these numbers work in the real world.

Let’s walk through a quick example for a busy warehouse:

- Forklift Weight: Your heaviest forklift weighs 9,000 lbs.

- Maximum Load Weight: The heaviest pallet you ever move is 4,000 lbs.

- Gross Load: Add them up: 9,000 + 4,000 = 13,000 lbs.

- Frequency Factor: You run a high-volume, multi-shift operation. You need a higher multiplier to account for that, maybe 3x or even 4x. Let’s go with 3x.

- Calculated Dynamic Capacity: 13,000 lbs x 3 = 39,000 lbs.

In this case, you’d want a dock leveler with a minimum dynamic capacity of 40,000 lbs to operate safely and make sure the equipment lasts.

Standard Sizing and Custom Solutions

Capacity is only half the battle; the physical size—width and length—is just as crucial. The main goal here is to create the gentlest, smoothest slope possible for your forklifts. A steep incline is hard on both your equipment and your operators.

- Standard Widths: Most dock levelers come in 6 ft, 6.5 ft, or 7 ft widths. We almost always recommend 7 ft. That extra bit of space gives drivers more room to manoeuvre and seriously reduces the risk of driving off the edge.

- Standard Lengths: Common lengths are 6 ft, 8 ft, and 10 ft. The longer the leveler, the more gradual the slope. An 8 ft length is a fantastic, versatile choice for most applications.

But sometimes, off-the-shelf sizes just don’t cut it. If you have unusual dock heights, a wide variety of truck bed heights pulling up, or specialized handling equipment, you might need a custom-built solution. This is where talking to an expert partner like Wilcox Door Service makes all the difference. We can help you figure out if a custom-engineered leveler is what you need to keep things safe and efficient. We’re here to be your respected partners, providing reliable service you can count on. For a full breakdown of your facility's needs, check out our expert commercial door services.

Under-specifying your dock leveler is one of the most dangerous and costly mistakes a facility can make. Always calculate for your heaviest, most frequent loads, not the average.

Getting the size and capacity right is the foundation of a safe loading dock. By understanding these calculations and standard dimensions, you can choose dock levelers for loading docks that will serve you well for years. And if you’re ever in doubt, our team is ready to help you analyze your operation and find the perfect fit. Your next step could be scheduling a loading dock safety inspection to see if your current setup is truly up to the task.

Essential Safety Features and Canadian Compliance

A safe loading dock is a productive one. It's as simple as that. Beyond picking the right size and capacity, the built-in safety features of your dock levelers for loading docks are what really protect your team, your equipment, and your cargo, day in and day out. Getting a handle on these components and the Canadian regulations that govern them isn’t just a good idea—it’s fundamental to running a responsible operation.

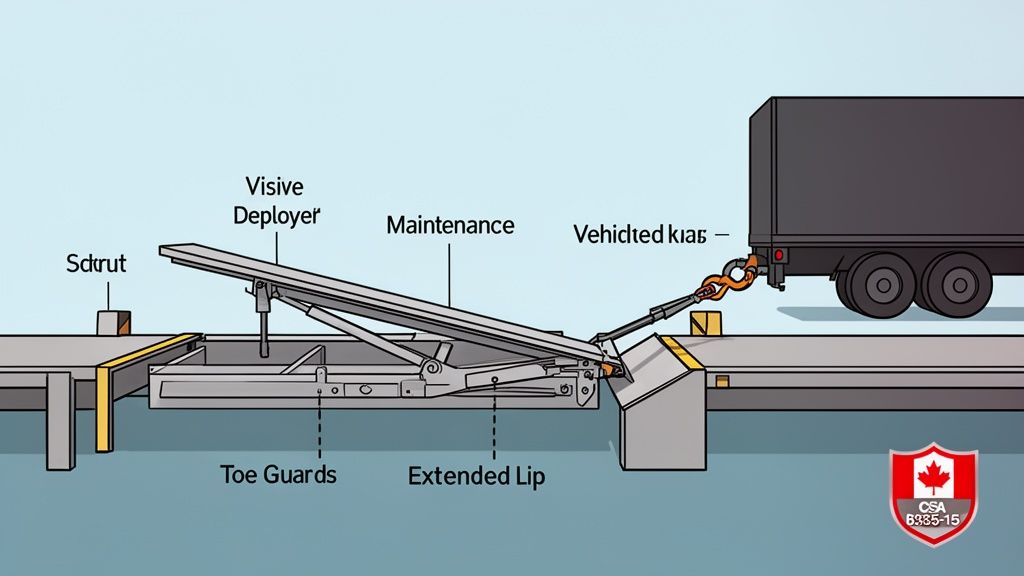

Alt text: Detailed diagram showing the key components and safety features of a dock leveler for loading docks in operation.

These features all work together to head off the most common and dangerous loading dock accidents. Think of them as the essential safety net that keeps your whole operation running without a hitch.

Key Safety Components You Need to Know

A dock leveler might look like a simple steel platform, but it’s actually engineered with some critical safety mechanisms. Three of the most important ones you’ll find are maintenance struts, toe guards, and automatic lip extension.

Maintenance Struts: Picture these as the heavy-duty kickstand for your dock leveler. These beefy steel bars are swung into place to physically stop the leveler from lowering while someone is doing service or cleaning underneath. Without a maintenance strut, a technician working under a raised leveler would be at risk of a catastrophic accident if the system failed or was accidentally turned on.

Toe Guards: These are the protective shields you see along the sides of the dock leveler. When the leveler is raised, these guards block the dangerous gap that opens up between the moving platform and the concrete pit edge. It's a simple feature that prevents feet and limbs from getting caught in a powerful pinch point.

Automatic Lip Extension: On hydraulic and air-powered models, the lip needs to extend smoothly and automatically as the platform hits its highest point. This ensures a secure, reliable bridge to the truck bed every single time, preventing the lip from getting stuck or failing to deploy, which could create a dangerous gap.

The Bigger Picture: An Integrated Safety System

No matter how advanced it is, a dock leveler doesn't operate in a vacuum. It's really the centrepiece of a complete loading dock safety system. To be truly effective, it has to work seamlessly with other critical components that prevent common hazards.

Vehicle restraints, for instance, are an essential partner to your leveler. They actively lock a trailer to the dock, stopping "trailer creep" or a premature departure—one of the biggest causes of forklift accidents. You can check out our guide on why it's so important to move beyond simple tire chocks to fully grasp this risk. When you pair these with dock seals that create an environmental barrier, all the elements come together to form a secure, controlled, and safe loading environment.

A dock leveler with robust safety features is your first line of defense, but integrating it with vehicle restraints and proper lighting transforms your loading bay from a high-risk area into a controlled, safe workspace.

Staying Compliant with Canadian Standards

In Canada, loading dock safety isn't just a best practice; it's the law. The key regulation to have on your radar is the CSA Standard B335-15. This standard requires, at a minimum, annual inspections for lift truck maintenance, which explicitly includes the loading dock infrastructure they rely on—like your dock levelers.

Ignoring these regulations can lead to hefty fines, but the real cost is the risk of an accident. A forklift falling from a dock due to an unsecured trailer or faulty leveler is a preventable tragedy. Data from provincial safety authorities consistently shows that loading docks are a high-risk zone, highlighting the importance of adhering to these regulations. While general workplace safety standards provide a broad framework, these specific CSA rules are what keep your dock operations in line.

As your partners in reliable service, we help facilities meet and exceed these standards every single day. Making sure your dock levelers are properly equipped, regularly inspected, and fully compliant is our top priority.

A Lifecycle Approach to Installation and Maintenance

Picking the right dock levelers for loading docks is really just the first step. The real-world performance and longevity of your investment depend entirely on what happens next: a flawless installation and a consistent maintenance strategy. If you take a lifecycle approach, you can ensure your equipment operates safely and efficiently from day one and for many years to come.

This roadmap covers what a professional installation actually entails and how to build a maintenance plan that keeps you ahead of problems. We'll show you how to spot early warning signs of trouble and explain why a Planned Maintenance Program is the best way to prevent expensive downtime and protect your assets. Think of us as your partners—we're here to deliver reliable service at every stage.

The Foundation of Performance: Professional Installation

A professional installation is far more than just dropping a leveler into a pit. It's a precise process that sets the stage for years of safe, trouble-free operation. Rushing this stage or cutting corners is a recipe for constant operational headaches and serious safety risks down the line.

The whole process starts with the pit construction. Whether it's a pre-formed pit in new construction or a retrofitted opening, the concrete work has to be exact. The dimensions, angles, and structural integrity of the pit are foundational to the leveler’s stability. Any imperfections here can cause the unit to sit unevenly, which leads to premature wear on its components.

For hydraulic and air-powered units, the electrical requirements come next. This involves running the correct power supply and integrating the control panel with other dock equipment, like vehicle restraints or overhead doors. A certified technician ensures all wiring is compliant and safely installed, preventing electrical faults that could disable your entire loading bay. The final step is commissioning—testing the leveler through its full range of motion, calibrating its systems, and making sure it operates smoothly before it’s handed over for daily use.

A Proactive Maintenance Strategy

Once your dock leveler is installed, its operational life begins, and this is where proactive maintenance becomes critical. Waiting for something to break is a surefire way to face costly emergency repairs and lost productivity. A structured maintenance schedule, broken down into daily, monthly, and annual checks, is your best defence.

A simple daily check can easily be performed by your own staff. It’s just a quick visual inspection before the start of a shift.

- Look for Debris: Check that the pit area is clear of dirt, broken pallet wood, or other obstructions that could jam the mechanism.

- Inspect the Surface: Ensure the deck and lip are in good condition, without significant damage or warping.

- Test the Operation: Briefly run the leveler through a cycle to confirm it moves smoothly, without any jarring or unusual noises.

These quick checks take less than a minute but can catch small issues before they snowball into major problems. For a more detailed guide on what to look for, exploring resources on common issues can help you find what other loading dock repair companies recommend checking.

When to Call a Certified Technician

While daily checks are useful, some symptoms are clear signals that it's time to bring in a professional. Ignoring these warning signs can lead to a catastrophic failure.

Think of a dock leveler like any other piece of heavy machinery in your facility. You wouldn't ignore a strange noise coming from a production line conveyor, and you shouldn't ignore a warning sign from your loading dock equipment either.

Be on the lookout for these red flags:

- A "Spongy" Feel: If the leveler feels bouncy or sinks under the weight of a forklift, it could indicate a hydraulic fluid leak or pressure loss.

- Unusual Noises: Grinding, scraping, or loud banging sounds during operation often point to worn-out parts or a mechanical problem that needs immediate attention.

- Sticking or Hesitation: If the leveler struggles to raise, lower, or extend the lip, it could be a sign of a failing motor, a hydraulic issue, or a problem with the release mechanism.

Attempting to diagnose or fix these issues without proper training is incredibly dangerous. A certified technician from Wilcox Door Service has the expertise and tools to safely identify the root cause and perform the necessary repairs, ensuring your equipment is returned to safe working order. Adopting a Planned Maintenance Programs is the most effective way to prevent these issues, extend the life of your equipment, and ensure your loading dock remains a reliable asset.

Your Partner for a Safer, More Reliable Loading Dock

You’ve now got the essential knowledge to make smart decisions about your dock levelers for loading docks. But picking the right hardware is just the first step. The real long-term value—and safety—comes from getting the installation right, staying ahead of problems with proactive maintenance, and having a team you can count on when things go wrong.

This is where a solid partnership makes all the difference.

At Wilcox Door Service, we live by our promise of “Respected Partners, Reliable Service.” We get it: a loading dock isn't just a part of your building; it's the heart of your operation, directly impacting your productivity and profit. Our entire focus is on making sure this critical asset runs at its peak, safely and without fail.

From First Installation to 24/7 Emergency Support

Our entire approach is built around professional expertise and being there when you need us. We manage every stage of your dock leveler’s life with precision, making sure disruptions to your business are kept to an absolute minimum.

- Expert Installation: Our union-certified technicians get your equipment installed right the first time, meeting every Canadian safety standard and manufacturer spec. A proper installation is the foundation for a long, trouble-free service life.

- Proactive Maintenance: Unexpected failures mean expensive downtime. Our Planned Maintenance Programs are designed to catch issues before they become emergencies, keeping your operation humming and protecting your investment.

- Dependable Emergency Service: Breakdowns don't stick to a 9-to-5 schedule. That’s why we offer 24/7 emergency support to handle urgent repairs, minimize the hit to your workflow, and get you back in business fast.

A loading dock is only as strong as its weakest link. By partnering with a dedicated service provider, you transform your equipment from a potential liability into a reliable asset that supports your business goals.

We’re committed to being the partner you can count on for a safer, more efficient loading dock. Our team is ready to deliver the reliable service you need to protect your people, your products, and your bottom line.

Your next step is to ensure your equipment is performing as it should. Contact us today for a professional consultation or to schedule a comprehensive safety inspection of your loading dock.

Got Questions About Dock Levelers? We've Got Answers.

Here are some of the most common questions we hear from facility managers about dock levelers for loading docks. We'll give you the straight-up, practical answers you need to manage your equipment with confidence.

How Long Does a Dock Leveler Typically Last?

If it's installed by a pro and you stick to a solid maintenance schedule, a quality dock leveler can easily last 10 to 20 years. But that's a big range, right? The real lifespan comes down to how hard it works. Think about daily usage, the weight of your loads, and the environment it's in.

A hydraulic leveler in a non-stop, 24/7 distribution centre is going to see a lot more action than a mechanical one at a small-scale manufacturing site. As a general rule, hydraulic and air-powered levelers tend to have a longer service life because their simpler designs have fewer high-wear mechanical parts compared to spring-operated systems.

What Is the Difference Between a Pit-Style and an Edge-of-Dock Leveler?

The one you see most often is the pit-style leveler. It's installed in a concrete pit that's recessed right into your building’s foundation. This design makes it a seriously robust, permanent part of your dock, ready to handle high traffic and big differences in truck heights. It’s the go-to for most commercial and industrial spots.

On the other hand, you have the edge-of-dock (EOD) leveler. This is a smaller, more budget-friendly unit that bolts directly onto the face of the dock wall. It's the perfect fit for places where there's not much height difference between the dock floor and the truck beds—usually in the ballpark of +/- 3 inches.

The choice between a pit-style and an edge-of-dock leveler really boils down to your day-to-day operations. A pit leveler is a long-term workhorse for high-volume docks, while an EOD is a smart, practical fix for less demanding situations.

How Often Should My Dock Levelers Be Professionally Serviced?

To meet Canadian safety standards like CSA B335-15, you absolutely must have your dock levelers inspected and serviced by a qualified technician at least once a year. That's the bare minimum for compliance and keeping everyone safe.

However, for busy facilities or those with tough conditions (like a cold storage warehouse), we strongly recommend getting them checked quarterly as part of a Planned Maintenance Program. Taking this proactive approach is the single best way to keep things running smoothly, dodge unexpected—and expensive—downtime, and get the most life out of your equipment. A good service partner isn't just a vendor; they're part of your operational team.

At Wilcox Door Service Inc., we believe in being respected partners who deliver reliable service. Ensure your loading dock is safe, compliant, and efficient by scheduling a professional inspection with our union-certified technicians.