This guide will walk you through everything you need to know about choosing and using a dock loading ramp. You'll learn what these essential tools are, how to select the right type and size for your facility, and the critical safety and maintenance practices that ensure your loading operations are both efficient and secure. We'll also cover portable steel ramps designed for flexible use with offsized trucks and varied loads.

Why a Dock Loading ramp is Your Facility's Unsung Hero

Think of a dock loading ramp as the crucial link between your loading bay and a waiting truck or trailer. It’s the essential bridge that creates a smooth, safe path for forklifts, pallet jacks, and your team to move goods. You'll find these ramps are a game-changer for any facility that handles cargo from vehicles of different heights, especially when you don't have a permanent, built-in dock leveler.

Picture your loading dock as the heart of your operation—the central point where everything flows in and out. Now, imagine a truck pulls up, but its trailer bed is way higher or lower than your dock. Suddenly, everything grinds to a halt. This kind of mismatch causes frustrating delays, encourages risky manual handling, and creates a logistical nightmare. This is the exact problem a solid dock loading ramp is built to solve.

These ramps, especially the portable steel models, bring an incredible amount of flexibility to the table. You can easily move them to different bay doors or even use them at ground level to load vehicles straight from the yard. That kind of adaptability is priceless when you're dealing with off-sized trucks, unusual containers, or simply the fluctuating demands of a busy day. For example, a warehouse might use a portable ramp to service a delivery van in the morning and a large semi-trailer in the afternoon, all without needing a dedicated, fixed-height dock for each.

By providing a stable, inclined surface, a dock loading ramp lets your team:

- Boost Efficiency: Forklifts can drive right into trailers, which dramatically speeds up loading and unloading compared to doing it all by hand.

- Improve Safety: Ramps close the dangerous gap between the dock and the truck, which goes a long way in preventing forklift accidents and injuries to your staff.

- Expand Your Capabilities: You can confidently handle a much wider range of vehicles without being limited by your dock’s fixed height.

In Canada’s fast-moving warehousing and logistics sector, these ramps are non-negotiable for keeping operations flowing smoothly. The global market for dock loading ramps, valued at USD 450 million in 2024, is expected to hit USD 750 million by 2033, which shows just how vital they've become. You can check out more details on the dock loading ramp market growth. Here at Wilcox Door Service, we provide rugged loading dock solutions designed to meet these exact needs, making sure you’re always ready for the next shipment.

Choosing The Right Type of Dock Loading Ramp

Not every loading challenge is the same, and neither are the dock loading ramps built to solve them. Picking the right one comes down to matching the equipment to your specific workflow, the kinds of vehicles you service, and the physical layout of your facility. Getting a handle on the key differences between models is the first real step toward a safer, more efficient loading dock.

The main distinction boils down to a single question: mobility. Do you need a ramp that stays put for consistent, high-volume work, or one you can move wherever the action is? Answering that one question will point you straight to the best solution for your operation.

Stationary Yard Ramps for Consistent Ground-Level Access

Think of a stationary yard ramp as a semi-permanent bridge. It’s the perfect solution for facilities that don't have a built-in elevated dock but still need a reliable way to get forklifts from the ground up into truck trailers. These ramps are set up at a specific bay door and generally stay there, giving you a stable and dependable access point day in and day out.

For example, a manufacturing plant that gets raw materials delivered to the same bay door every single day would see a huge benefit from a stationary ramp. It creates a dedicated, predictable workflow, cutting down on setup time and maximizing throughput for those routine jobs. Because they aren't designed to be moved around, they offer rock-solid stability for heavy, repetitive use.

Mobile Yard Ramps and Portable Ramps for Maximum Flexibility

On the other hand, a mobile yard ramp is the versatile problem-solver of the loading dock world. Outfitted with wheels and a positioning mechanism (often a simple hydraulic pump or tow bar), these ramps can be easily moved by a forklift to serve multiple bay doors or different spots around your property. This adaptability is a lifesaver for operations with varied or unpredictable logistical needs.

Picture a busy distribution centre that needs to unload several trucks at once but only has one permanent dock. A mobile dock loading ramp can quickly create a temporary loading station at another ground-level door, effectively doubling their capacity during a rush. Similarly, portable steel loading dock ramps are perfect for handling occasional off-sized trucks or containers that don't align with standard dock heights. If a flatbed trailer arrives with an unconventional load, a portable ramp can be brought in to create a safe unloading path, preventing costly delays.

This flowchart breaks down the core benefits that a well-chosen dock loading ramp brings to any operation.

As you can see, the right ramp fundamentally improves your entire logistics chain by boosting efficiency, reinforcing safety, and expanding your material handling capacity.

Heavy-Duty Models for Extreme Loads

Beyond just portability, capacity is a massive factor. Heavy-duty dock loading ramps are engineered with reinforced steel construction specifically to handle extreme weights. These are non-negotiable for industries moving dense materials, heavy machinery, or fully loaded, high-capacity forklifts.

A facility handling massive steel coils or granite slabs, for instance, simply couldn’t get by with a standard-duty ramp. The dynamic forces—the forces created by a moving load—from those kinds of items demand a structure built to take immense stress without flexing or failing. Choosing a heavy-duty model means you can manage your most demanding tasks safely and with confidence.

While a ramp is a crucial bridging tool, for permanent docks, you might also be interested in our guide on how to choose the right dock leveler for your facility.

How to Select the Perfect Ramp for Your Facility

Choosing the right dock loading ramp is a critical decision, one that has a direct line to your facility's safety and day-to-day productivity. This isn't just about finding the lowest price; it's an investment in a piece of equipment that has to perform reliably under some seriously demanding conditions. Let’s walk through the essential factors to consider, making sure you end up with a ramp that’s not just effective, but built to last.

We'll break down how to calculate the right load capacity for your actual needs, figure out the ideal ramp dimensions, and understand why certain materials and features are non-negotiable for a safe, efficient operation.

Calculating the Right Load Capacity

Without a doubt, the single most important factor is the ramp's load capacity—the maximum weight it can safely handle. Undersizing a ramp is one of the most dangerous mistakes you can make, as it risks catastrophic failure. Calculating the capacity you need is pretty straightforward, but it requires you to think beyond just the weight of your cargo.

You have to account for the dynamic load, which is the force created by a moving forklift carrying a full load. A simple and safe rule of thumb is to take the weight of your heaviest forklift and multiply it by three.

For example, if your heaviest forklift weighs 7,000 lbs and its maximum load is 5,000 lbs, you're looking at a combined weight of 12,000 lbs. To be safe, you should be shopping for a ramp with a capacity of at least 36,000 lbs (12,000 x 3). This generous safety margin accounts for the momentum and stress of a moving vehicle.

Always choose a capacity that comfortably exceeds what you've calculated. This sets you up for future equipment upgrades and ensures your team can operate with complete peace of mind.

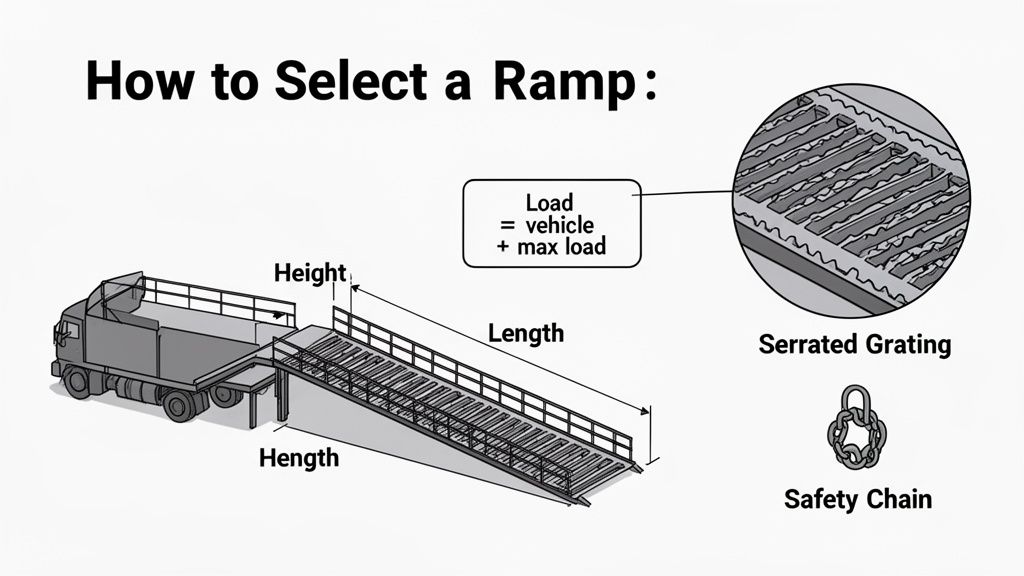

Determining the Ideal Ramp Dimensions

Once you've nailed down your capacity needs, the next step is figuring out the right size. The key dimensions here are length and width, and they're dictated by how you'll use the ramp and the equipment you run.

Ramp Length and Height Difference

The length of your ramp depends entirely on the height difference between the ground (or your dock) and the truck beds you're servicing. A longer ramp creates a gentler, safer slope for forklifts to climb and descend. A ramp that's too short for the height will create a dangerously steep incline, which drastically increases the risk of tipping or losing control of a load.

- Standard Truck Beds: These typically sit about 48 to 52 inches high.

- Best Practice: A gradual incline is always safer. It's best to work with a professional to figure out the optimal length that keeps the slope manageable for your forklifts, especially when you're moving heavy or unstable loads.

Ramp Width

The width of your ramp should be based on the widest piece of equipment that will ever drive on it. You need to ensure there’s enough clearance on both sides for safe and easy maneuvering. A ramp that’s too narrow forces operators to be overly precise and raises the risk of a wheel slipping off the edge. As a general rule, the usable width of the ramp should be at least 15 inches wider than your widest machine.

Materials and Essential Safety Features

The way your ramp is built is just as important as its size and capacity. The materials and built-in safety features are what determine its durability, usability in different weather, and overall safety.

Key Features to Look For:

- High-Strength Steel Construction: This is the industry standard for a good reason. Steel provides the raw durability needed to withstand the daily punishment of heavy loads and constant use.

- Serrated Steel Grating: A flat, smooth surface on a ramp is a huge hazard, especially in wet or icy Canadian weather. Serrated grating offers excellent, all-weather traction, allowing forklift tires to get a secure grip and preventing dangerous slips.

- Safety Chains or Locks: These are absolutely non-negotiable. Safety chains are used to securely anchor the ramp to the truck trailer or dock, preventing it from shifting or pulling away during use. This simple feature eliminates the dangerous gap that can cause serious accidents.

At Wilcox Door Service, we provide robust loading dock equipment that is built with these critical features in mind. Our "Respected Partners, Reliable Service" approach ensures your loading dock is both productive and safe.

Meeting Safety Standards and Compliance

In the fast-paced world of a loading dock, safety isn't just a suggestion—it's the bedrock of a productive, responsible operation. A dock loading ramp is a serious piece of equipment, and its safe use is governed by clear regulations. Understanding these rules isn't about ticking boxes on a checklist; it's about protecting your team, your equipment, and your business from very real risks.

Let's break down the key safety requirements that govern dock loading ramp use here in Canada. We’ll explain what you need to know about things like load capacities, proper anchoring, and why the slope of your ramp matters so much.

Understanding Canadian Safety Regulations

If you’re using a portable dock loading ramp, there’s no getting around national and provincial regulations. These rules are in place for one reason: to prevent the most common and dangerous types of loading dock accidents.

Safety standards for these ramps are taken very seriously. According to the Canada Occupational Health and Safety Regulations (SOR/86-304), every portable ramp must be clearly marked with its maximum safe load and securely fastened to prevent it from moving. In British Columbia, WorkSafeBC data from 2023 showed that improper ramp slopes were a factor in 18% of the 5,500 forklift-related injuries, a stark reminder of why a safe slope is so critical.

Two of the most important rules to live by are:

- Clear Load Capacity Markings: Every single ramp needs its maximum safe load capacity displayed where it can’t be missed. This stops operators from guessing and accidentally overloading the ramp, which could lead to a catastrophic failure.

- Secure Anchoring: The ramp absolutely must be locked firmly to the truck or trailer. Any shifting or gap during use is a recipe for disaster. Safety chains or other positive locking devices are non-negotiable.

The Critical Importance of a Proper Slope

One of the most overlooked—yet vital—parts of ramp safety is the slope, or grade. A grade is simply the steepness of the ramp. Think about walking up a hill. A gentle incline is manageable, but a steep one is a struggle. Now imagine that hill with a 2,000 kg forklift carrying a heavy load.

When a ramp is too short for the height it needs to span, it creates a dangerously steep angle. This can lead to a few terrifying situations:

- Forklift Tipping: A steep incline dramatically increases the chances of a forklift tipping backward on the way up or pitching forward on the way down.

- Runaway Loads: Pallets and other cargo can easily slide right off the forks if the angle is too aggressive.

- Loss of Traction: Forklift tires can lose their grip, causing the machine to slide uncontrollably, especially if it’s wet or icy.

Common Compliance Missteps and Their Consequences

Ignoring these standards can lead to serious trouble, from hefty fines and operational shutdowns to tragic accidents. A common mistake is failing to secure the ramp to the truck, often paired with forgetting to use wheel chocks to stop "trailer creep." You can get a deeper dive on why vehicle restraints are so essential in our guide on the importance of wheel chocks for trailer safety.

For facilities looking to build a truly robust safety culture, looking into frameworks like ISO 45001 is a smart move. Resources like a practical guide to ISO 45001 certification can help you integrate safety into every corner of your operation, making prevention second nature.

Working with an expert like Wilcox Door Service ensures your equipment is not only top-notch but also fully compliant with all Canadian safety standards. Our "Respected Partners, Reliable Service" promise means your team's well-being is our top priority.

Installation and Maintenance Best Practices

A dock loading ramp is a true workhorse, but like any piece of heavy-duty equipment, its performance and lifespan hinge on proper care. Getting a high-quality ramp is the first step; the real secret to keeping it a safe, reliable asset for years is committing to correct installation and consistent maintenance.

Let’s walk through the essential steps for a safe setup and a proactive maintenance checklist your team can use for regular inspections. It’s all about catching the small issues before they snowball into major problems and costly downtime.

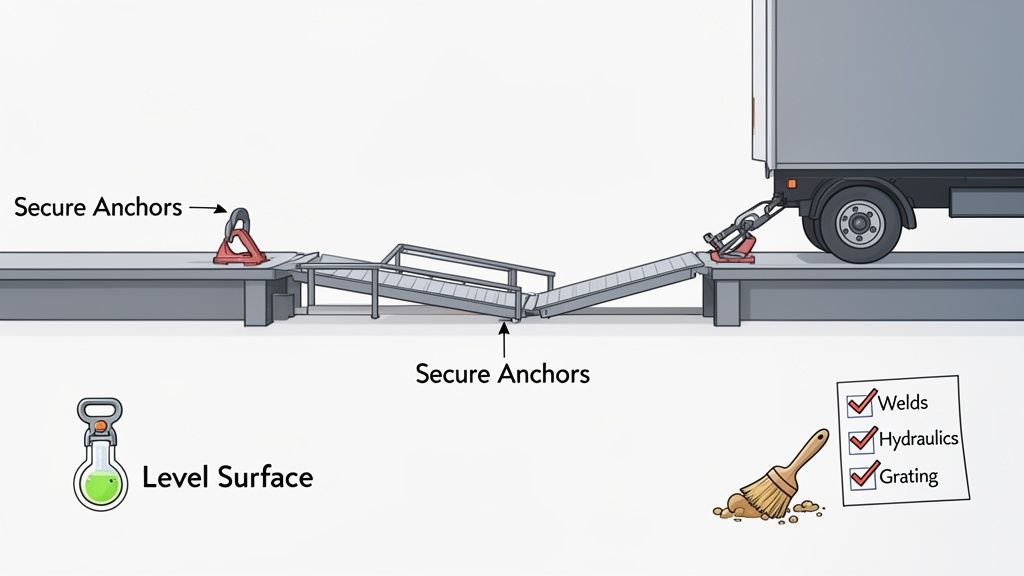

Safe and Secure Ramp Installation

A solid installation is the bedrock of safe ramp operation. While setting up a portable steel ramp is generally straightforward, cutting corners can introduce some serious risks. The entire goal is to create a stable, unmoving bridge between the truck and your dock or the ground.

We always recommend professional installation. Technicians are trained to handle the heavy equipment and know exactly how to verify every connection point. Still, it’s crucial for any facility manager to understand the core principles. You can find a deeper dive into the full process in our guide to professional door and dock operator installation.

Here are the key steps that can't be skipped:

- Prepare a Level Surface: The base of the ramp needs to sit on firm, level ground. An uneven surface can cause the ramp to rock or shift under a heavy load.

- Position the Ramp Correctly: Carefully move the ramp into place, making sure the top lip rests squarely and securely on the edge of the dock or truck bed.

- Secure the Safety Chains: This is the most critical step. Firmly attach the safety chains from the ramp to a solid point on the truck or dock. These chains are what stop the ramp from pulling away from the vehicle.

- Test Before Use: Before the first forklift goes across, do a quick visual check. Confirm all connections are tight and the ramp feels completely stable.

A Proactive Maintenance Checklist

Ongoing maintenance isn't just a good idea; it's an operational necessity. Regular inspections help you spot wear and tear before it leads to equipment failure, which protects your team and prevents unexpected downtime.

A well-maintained dock loading ramp is a predictable asset. Neglecting it turns it into a potential liability. Proactive checks take minutes but can save thousands in emergency repairs and lost productivity.

Your team should run through these checks on a routine basis—weekly is ideal for high-use ramps.

Weekly Visual Inspection Checklist:

- Check Welds for Stress Fractures: Take a close look at all weld points. You're looking for any visible cracks or signs of metal fatigue.

- Inspect the Grating Surface: Clear away any debris from the serrated grating. Also, keep an eye out for any bent or broken grating bars.

- Examine Hydraulic Systems (If Applicable): For ramps with hydraulic lifts, check the hoses for any leaks, cracks, or signs of abrasion. Make sure the fluid level is correct.

- Verify Safety Chains and Hooks: Inspect the safety chains and their attachment points. Look for any bent links, significant rust, or damage.

- Test All Moving Parts: If your ramp is mobile, check that the wheels and axles operate smoothly and are properly lubricated.

Simple Troubleshooting for Common Issues

Even with great maintenance, small issues can still pop up. The key is knowing how to spot them and when it's time to call in a professional.

- Ramp Creep: If you notice the ramp shifting during use, the first thing to check is that the safety chains are properly tensioned and the truck's wheels are chocked.

- Surface Wear: If any sections of the grating become smooth or damaged, it’s a big problem for traction and needs to be addressed right away.

- Difficulty with Hydraulic Lifts: If the hydraulic system is sluggish or won't lift, it could be low on fluid or signal a more complex issue. This is a clear sign to call a technician.

While your team can handle routine inspections, any significant repairs involving welds, structural components, or hydraulic systems should always be left to certified professionals.

Why Partner with Wilcox for Your Loading Dock Solutions?

Picking the right equipment is a great start, but making sure it runs perfectly for years to come is what really protects your investment. At Wilcox Door Service, we’re more than just a supplier; we are your strategic partner in keeping your operations safe and running at full tilt.

It all starts with a real conversation. Our team takes the time to understand your specific workflow, the kinds of trucks you're servicing, and the unique layout of your facility. This allows us to match you with the perfect solution, whether that’s a portable dock loading ramp for ultimate flexibility or a heavy-duty model built for extreme loads.

Professional Installation and Maintenance

Once we've pinpointed the ideal ramp, our union-certified technicians take over for a professional installation. They make sure every single component is set up for peak performance and is fully compliant with Canadian safety standards.

To keep your equipment in top shape, we offer customized planned maintenance programs. These proactive service plans are designed to spot small issues before they snowball into costly failures, preventing the kind of unexpected downtime that can throw a wrench in your whole operation.

"Respected Partners, Reliable Service." That’s not just a tagline for us; it’s a promise we’ve been keeping for over a century. It's about giving you the peace of mind that comes from knowing your most critical infrastructure is backed by dedicated experts.

Around-the-Clock Emergency Support

We get it—in the world of logistics, problems don't punch a clock. A breakdown in the middle of a critical shipment can bring your entire business to a standstill. That’s exactly why we offer 24/7 emergency repair services to keep you moving, no matter the time of day or night. Our technicians are always on standby, ready to get your loading dock back online, fast.

From the first consultation to ongoing maintenance and emergency calls, Wilcox is the only partner you need for all your loading dock equipment needs.

Common Questions We Hear About Dock Ramps

When it comes to outfitting your facility, you’ve got questions, and we’ve got answers. Over our decades in the business, we’ve heard it all. Here are a few of the most common things facility managers ask when they’re looking at getting a new dock loading ramp.

How Do I Figure Out the Right Capacity for My Dock Ramp?

This is probably the most critical question, and there’s a simple rule of thumb that keeps everyone safe. Take the total weight of your heaviest forklift and multiply it by three. It's that straightforward.

So, if your forklift weighs 8,000 lbs, you should be looking for a ramp with a capacity of at least 24,000 lbs. This isn’t about overkill; it’s about creating a crucial safety margin. That extra capacity accounts for the dynamic forces of a moving, fully-loaded forklift, ensuring the ramp holds up year after year without compromising structural integrity or operator safety.

Can I Use a Portable Dock Ramp as a Permanent Fix?

Absolutely. We see this all the time. Many facilities find that portable steel ramps, especially the stationary yard ramp models, work perfectly as semi-permanent solutions. They give you incredible flexibility if your facility layout changes down the road or you need to shift your loading processes.

Now, if you have a fixed bay with constant, high-volume traffic, a permanently installed dock leveler might offer a more seamless experience. But for creating a durable and versatile loading point almost anywhere, a heavy-duty yard ramp is an excellent, reliable alternative.

What's the Single Most Important Safety Feature to Look For?

It's tough to pick just one, but if we had to narrow it down, it would be a tie between two features: a high-traction surface and a secure locking mechanism.

- Serrated steel grating is a must-have for preventing dangerous slipping, especially with the kind of weather we get here in Canada. Rain, snow, or ice, you need a surface that grips.

- A heavy-duty safety chain or similar locking system is non-negotiable. It ensures the ramp stays cinched tight to the trailer during loading and unloading, preventing a dangerous gap from opening up.

Ready to build a safer, more productive loading dock? Contact the Wilcox Door Service team today for a full consultation and let’s find a solution built to last. Visit us at https://www.wilcoxdoor.com to learn more.