This guide will explain the critical importance of annual fire door drop testing in a manufacturing environment. You will learn what the process involves, why it’s legally required by Canadian fire codes and NFPA 80, the common reasons for test failures, and why this life-safety task must be handled by certified professionals. Understanding these key points will help you ensure your facility is not just compliant, but genuinely safe.

{: alt=”A rolling fire door successfully contains a fire in a manufacturing facility during a fire door drop testing simulation.”}

The Critical Role of Fire Door Drop Testing in Manufacturing

In the fast-paced, high-risk environment of a manufacturing plant, a fire can spread in the blink of an eye. With welding sparks, high-powered electrical equipment, and flammable materials often present, the potential for ignition is constant. This is where fire door drop testing stops being just a compliance task and becomes a core part of your operational survival plan. It’s not about ticking a box; it’s about making absolutely sure a life-saving system performs when every second is critical.

A fire door has one job: to automatically form a solid barrier that stops fire and smoke in their tracks. A drop test is a controlled simulation of an emergency to verify the door closes correctly. If it fails, the results can be devastating. The annual drop test is the only real way to prove this crucial system is ready to go.

Beyond Compliance: A Real-World Scenario

Picture this: a small electrical fire sparks up near a CNC machining area. The heat instantly triggers the fire door’s fusible link—a small, heat-sensitive device designed to melt and release the door. Because the door was recently tested, the heavy steel panel glides down smoothly, sealing the area off completely.

The fire is contained. Here’s what that successful test just did for the facility:

- Asset Protection: The flames were stopped before they could reach a nearby storage area filled with thousands of dollars in raw materials and chemicals.

- Operational Continuity: What could have been a plant-wide disaster was contained to a small, manageable incident. The business avoided a costly shutdown, saving a fortune in lost production and contractual penalties.

- Personnel Safety: Most importantly, the fire door created a protective barrier, giving employees the time they needed to evacuate safely, away from the spreading smoke and flames.

This one event highlights why consistent testing is so vital. A door that fails its drop test is no better than a standard rolling door—it offers zero fire protection.

A fire door that hasn’t been tested and verified is a gamble you can’t afford to take. It represents a critical failure point in your facility’s entire life-safety system, turning a reliable barrier into an unpredictable liability.

What the Test Verifies

The fire door drop testing process is designed to check several key performance factors. A certified technician isn’t just looking to see if the door closes. They are making sure it operates within specific, safe parameters. For a deeper dive into this crucial safety measure, check out our guide on everything you need to know about fire doors and their maintenance.

During the test, a professional will ensure:

- The door’s descent is smooth and completely unobstructed.

- It closes at a controlled, safe speed—not so fast it becomes a hazard, but not so slow it’s ineffective.

- The automatic release mechanism trips correctly when triggered.

- The door forms a complete, tight seal against the floor and guides once it’s fully closed.

This annual check is your proof that the passive fire protection system you count on is ready for action. It’s a small investment of time that delivers massive protection for your people, property, and your entire operation. As your partners in facility safety, we know that reliable service in this area is simply non-negotiable.

Getting to Grips with Canadian Fire Codes and NFPA 80 Compliance

For any facility manager in Canada, understanding the rules for fire door drop testing is non-negotiable. This isn’t about navigating bureaucratic red tape; it’s about grasping the core safety standards that protect your people and your property. Let’s cut through the jargon and get straight to what the codes demand.

In Canada, fire door safety boils down to two key documents: the National Building Code (NBC) of Canada and NFPA 80, the Standard for Fire Doors and Other Opening Protectives. Think of the NBC as the high-level law of the land. NFPA 80, on the other hand, is the detailed, technical playbook—the “how-to” for inspection, testing, and maintenance.

Since provinces and territories adopt these standards, they become legally binding. So, whether your facility is in Ontario, Alberta, or British Columbia, the fundamental requirements for keeping your fire doors in check are consistent across the country.

The Core Requirements You Can’t Ignore

The regulations are specific and leave no room for guesswork. They’re designed to ensure every single fire door in your facility will perform flawlessly when it matters most. Failing to meet these standards isn’t just a paperwork problem; it’s a critical gap in your building’s life-safety system.

Here’s what the codes mandate for your facility:

- Mandatory Annual Testing: Every rolling and sliding fire door has to go through a full operational drop test at least once every 12 months. This isn’t a DIY job—it must be performed by a qualified, certified technician.

- Testing After Installation or Repair: A drop test is also required right after a new fire door is installed. The same goes for any significant maintenance or repair work on the door or its operating mechanism.

- Detailed Documentation: For every test, a written record has to be created and kept on file. This report is your proof of compliance for the fire marshal and your insurance provider.

Understanding Key Performance Criteria

A successful fire door drop test is about more than just watching the door close. Certified technicians are trained to evaluate specific performance metrics laid out in NFPA 80 to confirm the door operates both safely and effectively. Two of the most critical criteria are the door’s descent speed and its ability to form a full seal.

The required descent speed is carefully calibrated for a reason. According to NFPA 80, the door must close at an average speed of not less than 15 cm per second and not more than 60 cm per second.

A door that drops too fast is a serious hazard to anyone nearby. But one that closes too slowly might not seal the opening in time to stop a rapidly spreading fire. This precise speed range is the sweet spot between safety and effectiveness.

Once closed, the door absolutely must form a complete, tight seal with the floor, sill, and guides. Even small gaps can allow dangerous smoke and flames to push through, defeating the door’s entire purpose. During an inspection, a technician will look for any obstructions, damage, or misalignments that could prevent this crucial seal. To keep your equipment in top shape, explore our full range of services for commercial and industrial doors.

The Real Costs of Non-Compliance

Let’s be blunt: ignoring these regulations carries serious consequences that go far beyond a slap on the wrist. For facility managers in manufacturing, the stakes are incredibly high. The National Building Code (NBC) of Canada makes it crystal clear: all fire-rated rolling doors need rigorous drop testing at installation and annually thereafter by certified professionals. This isn’t just a suggestion; it’s a legal requirement reinforced by NFPA 80, with non-compliance fines that can reach CAD 50,000 per violation.

Falling behind on your fire door drop testing schedule exposes your entire operation to a cascade of risks:

- Significant Financial Penalties: Fines for non-compliance can be massive. They’re often levied per uninspected door, which means the costs can multiply quickly across a large facility.

- Increased Legal Liability: If a fire occurs and it’s found that your life-safety systems weren’t properly maintained, the legal and financial fallout can be immense.

- Operational Shutdowns: A fire marshal has the authority to halt your operations on the spot until all fire safety violations are corrected. That means costly, unplanned downtime that hits your bottom line hard.

Staying compliant isn’t just about following the rules—it’s a fundamental part of responsible facility management. Regular, professional testing from a trusted partner ensures your fire-rated doors are always ready to perform their life-saving function.

What a Professional Fire Door Drop Test Actually Involves

Ever wondered what a certified technician really does during a professional fire door drop testing service? It’s far more than just pulling a lever. It’s a methodical, multi-phase process where every detail is checked to make sure your facility’s critical life-safety systems are ready to perform when it matters most.

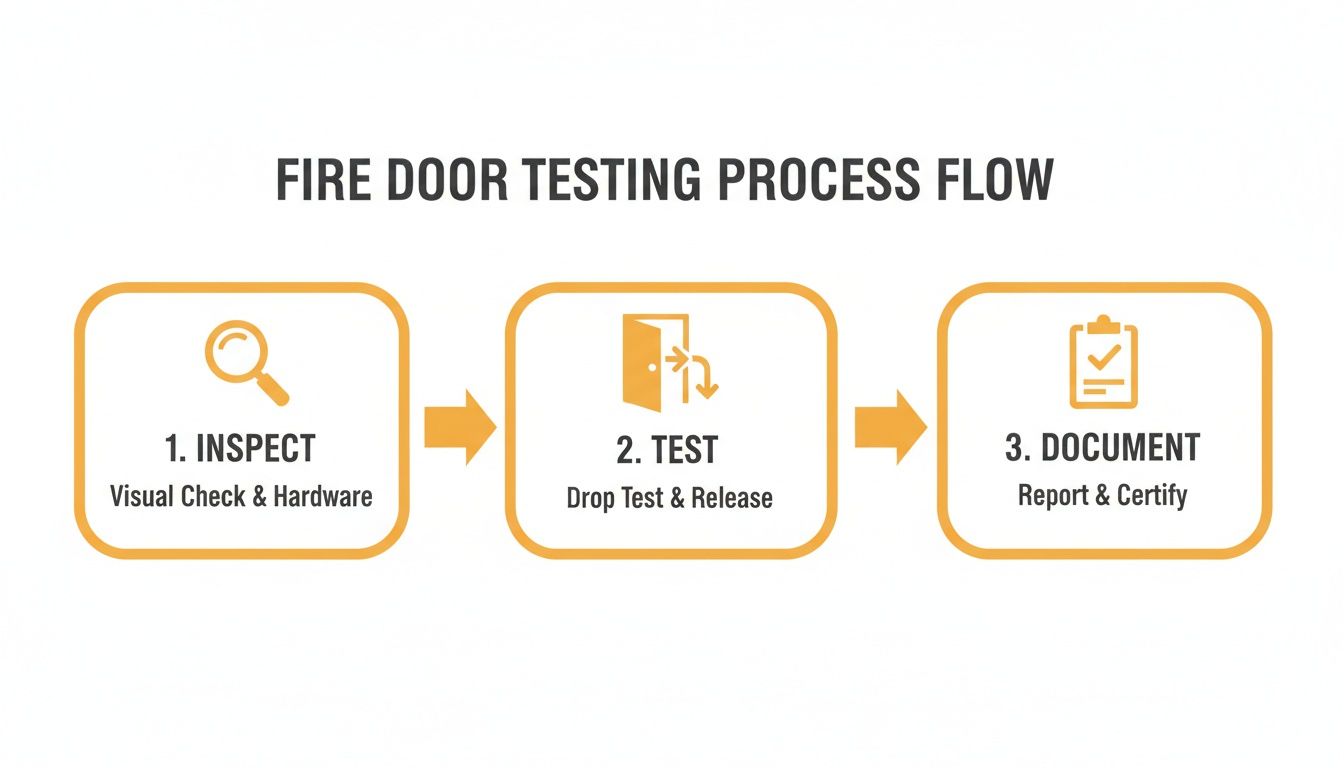

A professional test is broken down into three distinct phases based on the strict standards of NFPA 80:

- A meticulous pre-test inspection.

- The actual controlled drop test.

- The vital post-test reset and documentation.

Phase One: The Pre-Test Inspection

Before anything is released, a qualified technician performs a detailed visual and manual inspection of the entire fire door assembly. You could argue this is the most critical part of the whole process. It’s where potential problems are caught—issues that could cause a test failure or, far worse, a real failure during a fire. Think of it as a pilot’s pre-flight check; you spot trouble on the ground.

During this inspection, the technician will:

- Clear All Obstructions: They make sure the door’s entire path is completely clear. In a busy manufacturing facility, it’s common to see a forgotten toolbox, a stray pallet, or even a buildup of debris that can stop a door from forming a complete seal.

- Check Physical Components: Key parts are meticulously examined for wear and tear. This means inspecting the guide rails for damage, checking fusible links for any signs of corrosion or paint (which can change their melting point), and confirming all springs, chains, and cables are in solid condition.

- Verify the Labels: The technician looks for the fire door’s certification label, ensuring it’s present, legible, and correct. This label is the official proof that the door is built to meet specific fire-resistance standards.

Understanding these detailed procedures is a key part of a broader commitment to building safety, much like following a comprehensive construction quality control checklist ensures every component of a building is up to standard.

Phase Two: The Controlled Drop Test

With the pre-test inspection done and the area secured, it’s time for the drop test itself. This is a controlled simulation of an emergency, designed to verify one thing: the door’s automatic closing function works perfectly.

The technician will manually activate the door’s release mechanism. This action disconnects the door from its normal motor operator, letting gravity do its job, just as it would if a fusible link melted in a fire. While the door descends, the technician is watching closely for several key performance indicators.

The main goal here is to confirm the door closes smoothly and at a safe yet effective speed, without binding or hesitating in its tracks. According to NFPA 80, the descent speed must be between 15 cm and 60 cm per second—a precise window that balances a rapid emergency response with the safety of any personnel nearby.

This controlled test is the only way to be absolutely certain that the automatic release system—the heart of the fire door’s function—is working exactly as intended.

Phase Three: Post-Test Procedures and Documentation

A successful test doesn’t end when the door makes contact with the floor. This final phase is just as important for maintaining compliance and getting the door ready for both daily use and the next potential emergency.

After the drop, the technician gets to work.

First, they carefully re-engage the release mechanism and connect the door back to its operator. They’ll then cycle the door open and closed to ensure it’s functioning correctly for normal, day-to-day use.

Next comes the paperwork—the critical final step for your compliance records. The technician fills out a detailed written report for the door, noting the date, location, test results (pass or fail), and their signature. This form is your official proof of compliance for the fire marshal. While the testing requirements are universal, the specific risks can differ greatly between building types. You can learn more about why this matters in different environments in our article on fire door safety in condominium buildings.

Finally, a new tag is attached to the door assembly, clearly showing the test date and the company that performed it. This gives inspectors a clear, at-a-glance history of the door’s maintenance.

Fire Door Drop Testing Checklist

| Test Phase | Key Action Item | Purpose of Action |

|---|---|---|

| Pre-Test | Visual & Manual Inspection | Identify obstructions, wear, or damage (guides, links, cables) before the test. |

| Pre-Test | Label Verification | Confirm the fire rating label is present, legible, and correct for compliance. |

| During Test | Controlled Release | Manually activate the release mechanism to simulate an emergency closing. |

| During Test | Monitor Descent Speed | Ensure the door closes at the NFPA 80-mandated speed of 15-60 cm/sec. |

| Post-Test | System Reset & Cycle | Re-engage the operator and run the door to confirm normal functionality is restored. |

| Post-Test | Complete Documentation | Fill out and sign the official test form as proof of compliance for records. |

| Post-Test | Affix New Test Tag | Attach a tag with the test date and service provider’s name for easy verification. |

Common Drop Test Failures and How to Fix Them

A failed fire door drop testing result can throw a wrench into any facility manager’s day, but it’s not an insurmountable problem. Understanding why a door failed is the first and most important step toward getting it fixed quickly and correctly. Let’s walk through the most frequent issues we see in the field and the practical steps to get your doors back in compliance.

The entire process really boils down to three key stages: inspect, test, and document.

{: alt=”Flowchart shows the fire door drop testing process: Inspect, Test, Document.”}

This simple flow is the backbone of any solid fire door safety program. It’s how you ensure nothing gets missed.

Incorrect Descent Speed

One of the most common red flags is a door that doesn’t close at the proper speed. According to NFPA 80, the door must descend at a rate between 15 cm and 60 cm per second. Anything outside this range is an immediate fail, and for good reason.

- Door Drops Too Slowly: A sluggish door is almost always a sign of obstruction or friction. In a manufacturing setting, dust, grease, and other debris can build up in the guide rails. Worn-out springs or bearings that have lost their lubrication are also common culprits.

- Door Drops Too Quickly: On the flip side, a door that slams shut is a massive safety hazard. This usually points to a problem with the door’s governing mechanism or an issue with the counterbalance springs being incorrectly tensioned or damaged.

What this means: If it’s too slow, the door can’t guarantee effective containment in a fire. If it’s too fast, it poses a direct risk to your personnel.

How to resolve it: A certified technician from a provider like Wilcox Door Service will start by thoroughly cleaning and lubricating the guide rails. They’ll then check and adjust the spring tension and replace any worn components to get that descent speed back within the safe, compliant range.

Failure to Achieve a Full Seal

Another critical failure is when the door doesn’t form a complete seal against the floor and side guides when it closes. A small gap is more than enough for deadly smoke and intense heat to push through, completely compromising the fire barrier.

We see this a lot in facilities with busy loading docks or production floors. An impact from a forklift can subtly misalign the door guides just enough to cause a problem. Even a building’s foundation settling over time can create an uneven floor that prevents a proper seal. For a deeper dive on this, check out our guide on fire-rated doors.

Real-World Example: A Food Processing Plant

We ran into a perfect example of this at a food processing facility. The frequent high-pressure washdowns—essential for their sanitation protocols—had caused subtle corrosion inside the steel guide rails. During the annual fire door drop testing, that corrosion created just enough friction to stop the door about a foot from the floor. It was a critical failure. Our technicians had to meticulously clean and treat the guides before the door could pass its re-test.

Fusible Link Problems

The fusible link is that small, unassuming device that triggers the door’s automatic release in the event of a fire. It’s designed to melt at a specific temperature, releasing the door. For it to work, it has to be in pristine condition.

Common issues we find include:

- Paint or Grease: It happens all the time. A maintenance team paints the area, and the fusible link gets coated. That paint or a heavy layer of grease can alter its melting point, delaying the door’s release when every second counts.

- Corrosion: In damp or caustic environments, these links can corrode, which also interferes with their activation temperature.

- Physical Damage: Any dents or dings can compromise the link’s integrity.

These issues are a big part of why non-compliance is such a serious concern. Failures during fire door drop testing pose severe risks, especially when you consider that non-compliance rates in Canada have hovered around 22% in recent provincial inspections. Common failure points like gap violations and untested doors allow fire to spread faster, while fusible links must activate within a very precise temperature range of 57-75°C to be effective. You can find more details in these Canadian fire door compliance statistics.

When a test fails, the next step is clear: call in a professional. Partnering with a reliable service provider ensures these issues are diagnosed accurately and fixed right the first time, keeping your facility both safe and compliant. Whether it’s a fire door issue or a problem with your loading dock equipment, we’re here to help.

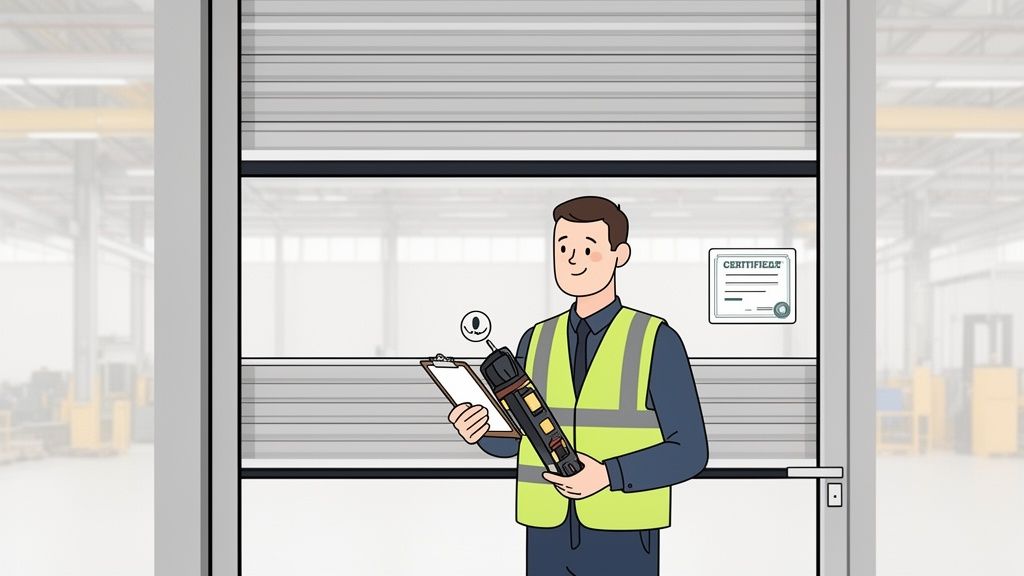

Why a Certified Professional Is Your Best Safety Strategy

While it’s good for any facility manager to understand the mechanics of fire door drop testing, actually performing the test is a job that absolutely must be left to certified experts. Calling in a professional isn’t just a best practice; it’s a non-negotiable part of your safety strategy to ensure compliance and protect your entire operation from serious risks.

{: alt=”A certified technician performs professional fire door drop testing with a clipboard and testing device.”}

Trying to run the test in-house without the right training and certification is just asking for trouble. The risks are substantial, with consequences that can ripple through your facility.

The Dangers of a DIY Approach

First off, there’s a serious risk of personal injury. These are heavy, powerful doors controlled by complex spring and release systems. One wrong move during a test could result in a serious accident.

Beyond the immediate safety concerns, an improper test can lead to expensive damage. Releasing or resetting the mechanism the wrong way can break the operator, warp the guides, or snap critical components. This doesn’t just mean costly emergency repairs; it means operational downtime.

Most importantly, any test performed by an uncertified person is completely invalid. It instantly voids your compliance, leaving you wide open to fines and liability—even if you think the door passed. In a fire inspector’s eyes, an undocumented or improperly performed test is the same as no test at all.

What to Look for in a Trusted Partner

Choosing a professional service is about more than just hiring someone to check a box. It’s about finding a partner that acts as an extension of your own safety team. A true professional service goes far beyond a simple pass/fail check.

When you’re selecting a partner for your fire door drop testing, look for these key things:

- Certified and Experienced Technicians: Make sure their technicians have verifiable credentials and a deep, practical understanding of NFPA 80 standards. They bring an expert eye that can spot subtle signs of wear and tear you might miss.

- Comprehensive Documentation: A professional provider will give you meticulous, audit-ready documentation for every single door they test. This report is your official proof of compliance and is absolutely essential for inspections.

- Immediate Repair Capabilities: What happens if a door fails? You need a partner who can diagnose the problem and fix it right then and there. This ability to provide an immediate solution is what separates a simple tester from a full-service provider. You can read more about what makes up a proper fire-rated door assembly in our detailed guide.

Professional testing isn’t an expense—it’s a critical investment. It safeguards your people, protects your assets, and reinforces the resilience of your entire operation, ensuring you are always audit-ready.

The Value of Professional Insight

In manufacturing environments, the stakes for annual fire door drop testing are particularly high. For these teams, this procedure is non-negotiable under NFPA 80, and fire inspectors demand documented evidence of compliance. Failing to provide it can lead to insurance premium hikes of 20-40%. A certified professional brings an expert eye, catching critical issues like flammable materials stored within one metre of the door—an obstruction found in 35% of site visits that immediately violates code.

Ultimately, entrusting this critical life-safety task to a certified professional like Wilcox Door Service is the only way to ensure it’s done right. Our “Respected Partners, Reliable Service” promise means we deliver not just a test, but peace of mind.

Your Questions Answered: Fire Door Drop Testing

When it comes to fire door drop testing, we find that facility managers often have some very specific questions. As your partners in facility safety, we’ve put together some clear, straightforward answers to the questions we hear most often from teams in manufacturing and industrial settings. Our goal is to give you the confidence you need to manage your building’s life-safety systems effectively.

How Often Do Our Fire Doors Need to Be Drop Tested?

According to the Canadian National Fire Code and NFPA 80 standards, every rolling and sliding fire door in your facility needs to be tested at least once a year. A test is also mandatory right after a new door is installed or anytime major repairs are done on the door or its operating mechanics.

This annual schedule isn’t arbitrary—it ensures your doors are always ready to do their job in an emergency. Think of it as a required annual check-up for some of the most critical safety gear in your building.

What Documentation Do We Need to Keep for Audits?

After each drop test, your certified provider is required to give you a detailed written report for every door they tested. This form needs to clearly show the test date, the specific door location, the technician’s name, and a simple pass or fail result.

This paperwork is your official proof of compliance. It’s absolutely essential for fire marshal inspections and for keeping your insurance policy in good standing. From an auditor’s perspective, if it isn’t documented, it never happened.

We recommend keeping these records where you can get to them quickly, whether that’s in a physical binder in your office or a dedicated digital folder. When an inspector shows up, having this documentation organized and ready to go shows your commitment to safety and due diligence.

Can My In-House Maintenance Team Perform the Drop Test?

While your team’s regular visual inspections are a crucial part of day-to-day safety, the official annual drop test must be performed by a qualified person with the proper certification. This is a non-negotiable requirement under Canadian fire codes because the procedure demands specialized knowledge of complex life-safety systems.

An in-house test, no matter how capable your team is, simply won’t meet the legal requirements and could expose your company to significant liability. Bringing in a certified professional ensures the test is done correctly and safely, keeping your facility fully compliant. It’s about both expertise and legality. Our team can also help with maintaining other critical systems, like your commercial doors.

What Happens If One of Our Doors Fails the Test?

If a fire door fails its drop test, it has to be repaired and brought back to full operational condition immediately by a qualified technician. Until that happens, the door is considered non-compliant and a serious safety risk.

A responsive service partner like Wilcox can quickly get on-site to figure out what went wrong—maybe it’s debris stuck in the guides, a faulty fusible link, or incorrect spring tension. Once the repairs are made, they will perform a re-test. Only after the door successfully passes this re-test and the result is properly documented is it considered compliant again, minimizing your facility’s downtime and risk.

Your facility’s safety is our top priority. As Wilcox Door Service, we are your respected partners, delivering reliable service to keep you compliant and protected. Ensure your fire doors are ready for anything. Schedule your certified fire door drop test with our expert team today.