A fire rated door is more than just a heavy-duty door; it’s a complete, engineered life-safety system designed to save lives by containing fire and smoke. This guide will provide a clear, practical understanding of these critical systems. You’ll learn what fire ratings mean, the codes you must follow, the different types of doors available for personnel and large openings, and why professional inspection and maintenance are non-negotiable for keeping your facility safe and compliant.

What Makes a Fire-Rated Door a Critical Life-Safety System?

Imagine a fire breaks out in your facility. The fire rated door is the silent guardian that springs into action, holding back the blaze and toxic smoke, giving people precious time to evacuate safely. To do this, every component—the door, frame, hardware, and seals—must work together perfectly as a single, certified assembly.

This guide will walk you through everything you need to know, explaining technical terms in simple language. We will explore what ratings like 20, 45, 60, and 90-minute actually mean for the safety of your building and the people inside it.

Alt: A person silhouetted against a fire rated door, providing a safe escape route from flames.

We’ll break down the must-know codes from governing bodies like the NFPA and look at the different types of fire doors available, from standard pedestrian doors to massive overhead coiling doors designed for industrial spaces like loading docks.

It’s not enough to just have a fire door; it needs to be professionally installed and meticulously maintained to work when it matters most. That includes mandatory annual inspections and procedures like drop testing to guarantee your doors will perform without a hitch in an emergency.

What You’ll Learn in This Guide

- Understanding Ratings and Codes: We’ll break down what classifications like “90-minute” really mean and how standards from organizations like UL and NFPA dictate their use.

- Exploring Door Options: We’ll look at options for both personnel (pedestrian doors) and large vehicle openings (coiling overhead doors) found in warehouses and loading docks.

- The Importance of Hardware: Discover why components like closers, latches, and seals aren’t just accessories—they’re non-negotiable parts of a compliant fire door assembly.

- Inspection and Maintenance: Get practical, actionable steps for keeping your fire doors in a constant state of readiness.

By the end of this guide, you’ll have the knowledge to confidently manage your facility’s fire door systems. As your partners in reliable service, Wilcox Door is here to help you navigate these critical requirements.

Decoding Fire Ratings and Safety Standards

Understanding fire safety language is the first step toward protecting your facility. When you see a fire rated door with a “90-minute” rating, that number is a promise: the entire door assembly is engineered to withstand intense heat and block flames for at least 90 minutes. This provides crucial time for occupants to evacuate and for first responders to arrive.

Think of a fire door as a compartmentalization tool. In an emergency, it seals an opening to contain a fire in one area, preventing it from spreading throughout the building. This function depends on the entire system—the door, frame, and all hardware—working together flawlessly.

The Rulebook for Fire Safety: NFPA 80

These life-saving systems are governed by strict standards. The primary rulebook is NFPA 80, Standard for Fire Doors and Other Opening Protectives. This document provides the minimum requirements for the installation, inspection, testing, and maintenance of fire door assemblies.

Following NFPA 80 isn’t optional—it’s the cornerstone of building safety and is often required by law. The standard ensures a fire door will perform as designed, covering every detail from the gap size around the door’s edge to the specific fasteners used for hinges.

Why Certification Labels Matter

How can you be sure a door meets these rigorous standards? Look for the label.

Testing agencies like Underwriters Laboratories (UL) and Underwriters Laboratories of Canada (CAN/ULC) subject fire door assemblies to intense fire and hose stream tests that simulate real-world conditions. It’s a grueling process designed to verify performance under extreme stress.

A fire door assembly is only as strong as its weakest component. The UL or ULC label is your assurance that the door, frame, and hardware have all been tested and certified to function together as a complete, life-saving system.

If an assembly passes, it earns a certification label that must remain visible on both the door and frame. This label contains vital information:

- The Manufacturer: Who built the component.

- The Certification Mark: The logo of the testing agency (e.g., UL).

- The Fire Rating: The duration (in minutes or hours) the assembly can resist fire.

This label is your proof of compliance. If it’s missing, painted over, or unreadable, the assembly is considered non-compliant.

Common Fire Door Ratings and Their Typical Locations

The required fire rating for a door is determined by the fire-resistance rating of the wall it is installed in. For example, a 2-hour rated stairwell wall will require a 90-minute rated door. While regulations vary, for more comprehensive details on regulatory frameworks, one can reference the requirements found in the Building Code of Australia (BCA).

Here’s a practical breakdown of common ratings and where you’d typically find them in a commercial facility:

| Fire Rating (Minutes) | Typical Application / Location | Primary Purpose |

|---|---|---|

| 20 Minutes | Corridor doors and doors leading from corridors to rooms (e.g., offices, hotel rooms). | To block smoke and provide a barrier against initial fire spread into escape routes. |

| 45/60 Minutes | Doors in fire barriers separating different occupancies or hazardous areas within a building. | To contain a fire within a specific zone, protecting adjacent areas for a longer period. |

| 90 Minutes | Doors in stairwell enclosures and elevator shafts, which are critical vertical escape routes. | To protect essential evacuation paths from fire, heat, and smoke for an extended time. |

| 180 Minutes (3 Hours) | Doors in fire walls that divide a single building into separate fire areas or connect two buildings. | To provide the highest level of compartmentalization and prevent fire from spreading. |

At Wilcox Door Service, our expertise ensures every fire rated door in your facility meets these critical safety requirements, reflecting our commitment: “Respected Partners, Reliable Service.”

Exploring Your Fire Rated Door Options

Choosing the right fire rated door means matching the door’s design to the specific needs of your facility. A door suitable for an office corridor is very different from one needed for a busy loading dock. Understanding the options available for both pedestrian traffic and large openings is key to ensuring safety and compliance.

Alt: Four types of fire rated doors: steel, wood, coiling overhead, and glass, on a yellow background.

Pedestrian Fire Doors: Materials and Applications

For openings used by people, the material choice balances durability, appearance, and fire resistance. The two most common types in commercial settings are hollow metal and solid-core wood.

- Hollow Metal (Steel) Doors: These are the industry workhorses. Known for exceptional durability, steel fire doors are ideal for high-traffic, demanding environments like manufacturing plants, warehouses, and exterior exits. Their robust construction withstands heavy use while providing superior fire protection.

- Solid-Core Wood Doors: Often found in offices, hotels, and healthcare facilities, fire-rated wood doors offer a warmer aesthetic without compromising safety. They are built with a special fire-resistant core that allows them to meet strict codes while blending with interior designs. To learn more, see our guide on the best interior fire rated door options.

Coiling Overhead Fire Doors for Large Openings

For large openings at loading docks, parkades, or warehouses, coiling overhead fire doors are essential. During normal operations, they function like standard coiling overhead doors, remaining neatly stored above the opening.

In an emergency, their life-safety features activate automatically.

A coiling fire door is an automated containment solution. When triggered by a smoke detector or building alarm system, it automatically closes, creating a massive fire barrier that can seal off an entire section of your facility in seconds.

This automatic closing is often triggered by a fusible link—a simple, heat-sensitive device that melts at a specific temperature. When it melts, the door is released and closes at a controlled speed, even without power. This fail-safe mechanism is crucial for containing fires in large, open industrial spaces.

Maintaining Visibility With Fire-Rated Glass

A fire rated door doesn’t have to block visibility. Modern fire-rated glass, or glazing, allows light to pass through and maintains open sightlines—a critical safety feature in corridors and stairwells—without compromising the door’s integrity.

This isn’t standard glass. It’s a specially engineered product that has been tested to withstand extreme heat and impact, ensuring the entire unit, window included, functions as a cohesive fire barrier.

Why Hardware and Seals Are Non-Negotiable

A fire-rated door is a precisely engineered system, and the door slab is just one part. The entire assembly is only as strong as its weakest link. Without the correct fire-rated hardware and seals, even the most robust door will fail in a fire.

Every component—from hinges and latches to closers and seals—must be fire-rated and tested to work in harmony. If one part fails under the extreme stress of a fire, the entire system’s integrity is compromised.

The Unsung Heroes: Fire-Rated Hardware

Hardware components are the active parts of a fire door assembly. They are not accessories; they are essential elements that ensure the door provides a reliable barrier.

Three of the most critical hardware components include:

- Hinges: Fire-rated hinges are built to withstand intense heat without warping, keeping the door securely in its frame. Standard hinges would melt and fail, allowing the door to fall and creating an opening for fire to spread.

- Latching Devices: To be effective, a fire door must remain closed and latched. The latching mechanism, whether a standard latch or a panic bar, must be fire-rated to hold the door shut against the immense pressure created by a fire.

- Door Closers: This is arguably the most critical piece of active hardware. A fire-rated closer ensures the door automatically swings shut and latches after use. This removes the risk of human error, such as someone forgetting to close a door during an evacuation.

The Science of Sealing the Gaps

While hardware secures the door, specialized seals are what stop deadly smoke. These components activate with heat, turning a simple doorway into an impenetrable barrier.

Smoke inhalation is the leading cause of fire-related deaths, often incapacitating individuals long before the flames reach them. Effective seals are just as critical as the door’s fire rating itself in protecting lives.

Two types of seals provide complete protection:

- Intumescent Seals: These unassuming strips are fire-activated foam. When exposed to high heat, they expand dramatically—up to 25 times their original size—to form a dense, fire-resistant char. This foam fills every gap, blocking flames and hot gases.

- Smoke Seals: These gaskets, which look like weatherstripping, block the movement of cold smoke at the start of a fire. While intumescent seals require heat, smoke seals provide immediate protection from toxic fumes. This is similar to how other seals create a tight barrier, which you can learn more about with garage door seals for top and sides.

It is the combination of a rated door, certified hardware, and advanced seals that makes a fire-rated door assembly an effective life-saving system.

Mastering Fire Door Inspection and Maintenance

A fire-rated door is an active life-safety device that must function perfectly on demand. This reliability is achieved through professional installation and consistent, diligent maintenance.

A minor installation error—an incorrect gap measurement, the wrong type of fastener, or a misaligned frame—can cause a catastrophic failure during a fire. This is why professional installation is the first and most critical step.

The Foundation of Reliability: NFPA 80 Inspections

Ongoing maintenance is not optional; it’s mandated. NFPA 80 requires every fire door assembly to be inspected and tested at least annually by a qualified person. This inspection is designed to identify and correct small issues before they become life-threatening liabilities.

During the inspection, a certified technician verifies that every component is present, functional, and undamaged, ensuring your facility remains compliant and safe.

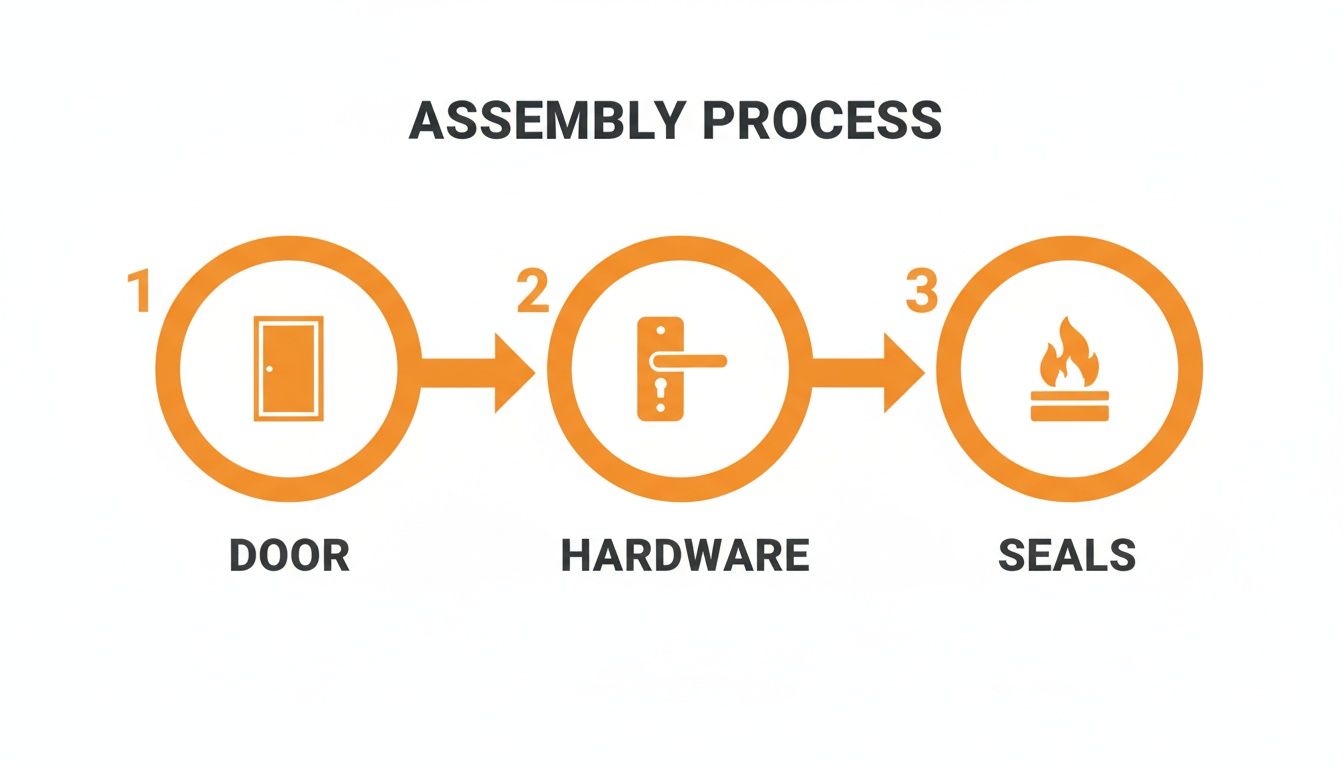

This infographic breaks down the three core components that must work together seamlessly in a certified fire-rated door assembly.

Alt: Diagram showing the assembly process of a fire-rated door, highlighting the door, hardware, and seals.

This visual shows how the door, hardware, and seals form an integrated system that must be inspected as a whole.

Your Practical Inspection Checklist

While a formal annual inspection must be performed by a professional, facility managers can conduct regular visual checks. NFPA 80 outlines 13 specific verification points, but here are common red flags to look for:

- Visible Damage: Look for dents, holes, or bent edges on the door and frame that could compromise structural integrity.

- Missing or Illegible Labels: The certification labels on the door and frame must be present and readable. If not, the door is non-compliant.

- Improper Gaps: Clearances around the door must be within tight tolerances (typically under 4.8 mm for steel doors) to prevent smoke and flame penetration.

- Non-Functional Hardware: Ensure the door closes and latches completely on its own. The closer must pull the door shut, and the latch must engage securely.

- Propped Open Doors: A fire door wedged open is useless. This is one of the most common and dangerous violations.

The Annual Drop Test for Coiling Overhead Doors

For facilities with coiling or rolling overhead fire doors, the annual inspection must include a “drop test.” This is the only way to verify that the door’s automatic closing mechanism works correctly.

A successful drop test provides documented proof that your overhead fire door is ready to protect your people and property. Failing to perform and document this test annually can lead to major fines and serious liability if a fire occurs.

During the test, a certified technician simulates a fire alarm to verify two things:

- The Release: The door releases immediately without hesitation.

- The Descent: The door closes completely at a safe, controlled speed.

The technician then resets the door and provides documentation for your records. For more details on this process, our experts explain fire door drop testing in manufacturing facilities.

As your trusted partner, Wilcox Door Service provides certified inspections and Planned Maintenance Programs to keep your fire doors ready for anything.

Your Partner in Fire Door Safety and Compliance

Navigating fire door compliance can be complex, but you don’t have to do it alone. A properly functioning fire rated door system is one of the most critical life-safety features in your building. Gaining confidence in that system means partnering with certified experts.

Our philosophy is “Respected Partners, Reliable Service.” We are here to support you through every stage, turning compliance from a concern into a managed, reliable process.

Your Complete Compliance Partner

It starts with selecting the right fire rated door. Our experienced team helps you choose the ideal pedestrian or coiling overhead door for your needs, balancing daily operations with strict fire code requirements.

Our union-certified technicians then ensure every component is installed flawlessly according to NFPA 80 standards, providing a fully compliant assembly from day one.

Partnering with a certified expert takes the guesswork out of safety and compliance. It provides documented proof that your fire door systems are installed, inspected, and maintained to the highest industry standards, safeguarding both people and property.

Proactive care is the secret to long-term safety. Our Planned Maintenance Programs are designed to keep your fire doors in a constant state of readiness, including certified annual inspections and mandatory drop testing for overhead doors.

Ready to ensure your fire door systems are safe and compliant? Contact Wilcox Door Service today to schedule an inspection or discuss a maintenance plan.

Frequently Asked Questions About Fire Rated Doors

Here are straightforward answers to the questions we hear most often from facility managers about fire rated doors.

Can I Paint or Modify a Fire Rated Door?

Yes, you can paint a fire rated door, but there are critical rules. The certification labels on the door and frame must remain visible and legible. Avoid thick coats of paint that could interfere with the door’s ability to close and latch properly.

Other modifications, however, are strictly prohibited. Drilling new holes, adding non-rated hardware, or altering the door in any way will void its fire rating. Always consult a certified professional before making any changes to a fire door assembly.

What Is the Difference Between a Fire Door and a Smoke Door?

This is an excellent question. A fire rated door is engineered to stop flames and contain intense heat for a specific duration (e.g., 90 minutes). Its primary job is to prevent the spread of fire.

A smoke door is designed specifically to block the passage of smoke and toxic gases, which are often the greatest threat to life in a fire. While some doors are rated for both fire and smoke (indicated by an “S” on the label), a dedicated smoke door must have specialized gaskets to create an airtight seal, a feature not standard on all fire doors.

How Do I Know if My Door Is a Fire Rated Door?

Look for the label. A certified fire rated door will have a permanent metal or mylar label, usually on the hinge-side edge of the door, with a matching label on the frame. This label is the official proof that the assembly has been tested and certified by an agency like Underwriters Laboratories (UL).

This label is non-negotiable proof of compliance. It contains crucial information, including the manufacturer, the fire-resistance rating in minutes, and other testing details.

If the label is missing, painted over, or unreadable, the assembly is no longer considered compliant. In this case, a professional inspection is needed immediately to determine its status and ensure your building is protected.

At Wilcox Door Service, our experts are here to answer all your questions and provide the reliable service you need to keep your facility safe and compliant.

Schedule a professional fire door inspection or request a quote today.