A fire rating door is much more than a simple barrier; it’s an engineered life-safety system designed to save lives and protect property. In the event of a fire, this entire assembly—including the door, frame, and hardware—works together to contain flames and smoke for a specific period, securing escape routes and preventing a minor incident from escalating into a major disaster.

In this guide, you’ll learn about the critical importance of a fire door’s rating, why its certification label is absolutely non-negotiable, and your legal responsibility to ensure annual testing is completed. Understanding these fundamentals is the first step toward robust fire protection, ensuring safety, and maintaining full compliance for your facility.

Key Takeaways What You Will Learn

This table gives you a snapshot of the core concepts we’ll cover, helping you understand everything from basic definitions to your maintenance responsibilities.

| Topic | Key Learning Outcome |

|---|---|

| What is a Fire Door? | Understand its function as a complete, engineered life-safety system. |

| Fire Resistance Ratings | Learn how fire ratings (e.g., 20-min, 90-min) are determined and what they mean. |

| Standards and Codes | Get familiar with the key standards from NFPA, UL, and local codes. |

| Fire vs. Smoke Doors | Differentiate between doors designed for fire, smoke, or both. |

| Selection Criteria | Know what to look for when choosing a fire door for your facility. |

| Best Practices | Learn the correct procedures for installation, inspection, and maintenance. |

| Compliance and Safety | Understand common compliance pitfalls and the importance of record-keeping. |

Now that you have a roadmap, let’s get into the details of this critical safety system.

Understanding Your Critical Safety System

A fire-rated door is one of the most vital, yet often overlooked, components of your building’s passive fire protection strategy. Unlike a standard commercial door used for access and security, a fire door is engineered to perform a critical job: compartmentalize a building during a fire. This means the entire assembly—the door slab, frame, and hardware—is tested and certified to contain a blaze to a single area, effectively starving it of oxygen and dramatically slowing its spread.

Alt text: A fire-rated door contains a fire, allowing two people to evacuate safely through a marked exit.

The importance of this function cannot be overstated. With nationwide fire property damage hitting $21.9 billion in 2020, the value of a properly working fire door in protecting people and property is crystal clear. For facility managers, ensuring these doors are functional is a core responsibility. You can dig deeper into fire safety trends by checking out our comprehensive guide to fire-rated doors.

The Non-Negotiable Fire Door Label

One of the most common—and costly—mistakes we see facility managers make is overlooking the door’s certification label. This small metal or paper tag, usually found on the hinge edge of the door, is the only official proof that your door assembly meets the required safety standards.

A fire door without a legible, intact label is not a fire door in the eyes of an inspector. It is simply an unrated door that fails inspection.

If this label is painted over, damaged, or missing, the door’s fire rating is instantly void. This isn’t a minor issue. An inspector will fail the door on the spot, which can lead to hefty fines and an order to replace the entire assembly—an expensive and disruptive fix for something so preventable. For example, a maintenance crew painting a hallway might carelessly cover the label, unknowingly rendering a perfectly good door non-compliant. Keeping that label visible and readable is a fundamental part of your facility maintenance.

Your Responsibility for Annual Testing

Ultimately, as a building owner or facility manager, the responsibility for ensuring your fire doors are functional and compliant rests squarely on your shoulders. The NFPA 80 standard is very clear: it is up to you to ensure your fire doors are professionally inspected and tested every year.

For rolling or sliding fire doors, common in loading dock areas or between warehouse zones, this includes a critical “drop test” to prove the automatic closing mechanism works exactly as it should. This isn’t a suggestion; it’s a legal requirement. Proactive, scheduled fire door maintenance and testing is the only way to guarantee both safety and compliance.

Ready to ensure your facility’s fire doors meet all safety standards? As your “Respected Partners, Reliable Service” provider, Wilcox Door Service can help. Schedule a professional fire door inspection and drop test today.

Decoding Fire Ratings and Temperature Rise Labels

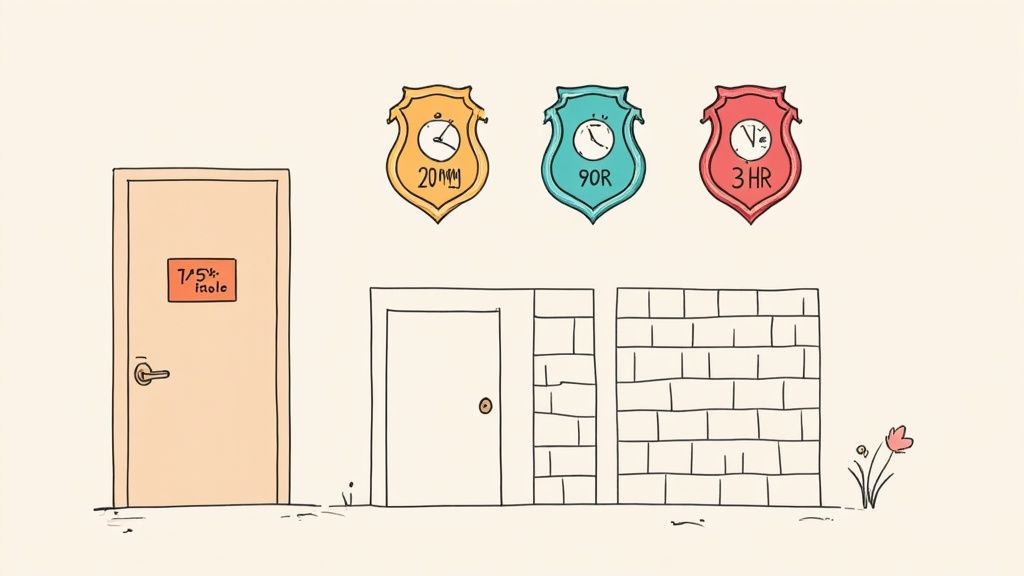

At first glance, the labels on a fire-rated door can look like a jumble of technical codes. But it all boils down to one simple, critical concept: time. Let’s demystify those numbers and letters so you can understand exactly what level of protection your doors are providing.

The fire rating is essentially a measure of how long a door assembly can withstand fire and smoke. When you see a rating like 20-minute, 90-minute, or 3-hour, it tells you precisely how long that door, frame, and hardware are certified to hold back a blaze. This containment is absolutely vital for protecting escape routes and buying first responders the time they need to manage the emergency.

Alt text: Illustration of fire rating door time ratings on different door types and a brick wall.

Matching the Door to the Wall

A fire door doesn’t operate in a vacuum; its rating must be correctly matched to the fire-resistance rating of the wall it’s installed in. A simple guideline is the “75% rule,” which ensures the entire barrier—wall and door together—works as a complete system.

For example, a stairwell wall in a commercial building is often required to have a 2-hour fire-resistance rating. Applying the 75% rule, the fire door installed in that wall must have at least a 90-minute (1.5-hour) rating. This ensures the door, an inherent weak point in any wall, doesn’t fail long before the wall itself gives way.

Fire-rated doors in Canada must follow precise standards where the door’s rating is 75% of the wall’s fire-resistance rating.

- For walls rated at 4 hours that separate buildings, doors need a 3-hour (180-minute) rating.

- 2-hour walls, common for stairwells, require 1.5-hour (90-minute) doors.

You can find more details on these code requirements in this technical bulletin about rolling fire doors.

Understanding Temperature Rise Ratings

Beyond just stopping flames, another critical factor is how hot the unexposed side of the door gets. This is where the temperature rise rating comes in. This tells you the maximum temperature increase allowed on the non-fire side of the door during the first 30 minutes of a fire test.

Imagine a fire raging in a warehouse. A 3-hour fire door is doing its job, successfully blocking flames from reaching an adjacent office corridor—a designated escape route.

While the door stops the fire, if its surface on the corridor side heats up to hundreds of degrees, it could ignite combustible materials nearby or make the escape path impassable due to radiant heat. The temperature rise rating prevents this dangerous scenario.

These ratings are typically specified in degrees, such as 250°F (121°C), 450°F (232°C), or 650°F (343°C). A lower number means better heat insulation and is essential for doors protecting critical exit paths. The label on your fire-rated door will specify this, ensuring the path to safety remains tenable.

Is it time to verify your fire doors meet current codes? Contact Wilcox Door Service to schedule a professional assessment and ensure your facility is fully protected and compliant.

Why a Missing Label Can Invalidate Your Fire Door

A fire-rated door is an engineered life-safety system, but its compliance hinges on a small, easily overlooked detail: its certification label. This tag, usually found on the door’s hinge edge or the frame, is the only official proof that the assembly has been tested to meet strict safety standards. If that label is missing or illegible, you no longer have a compliant fire door; you have a major liability.

Think of the label as the door’s passport. It’s issued by an accredited agency like Underwriters Laboratories (UL) or Intertek and confirms the complete assembly—door, frame, and hardware—passed standardized fire endurance tests. An inspector relies on this label to verify the door’s rating and legitimacy at a glance.

What the Label Tells You

The label contains critical information that confirms the door’s protective capabilities. An inspector, also known as the Authority Having Jurisdiction (AHJ), uses this data to ensure the door is correct for its location within your building’s fire safety plan.

Key details on a fire door label include:

- Manufacturer’s Name: Identifies who built the door.

- Third-Party Certification Mark: The logo of the testing agency (e.g., UL) provides proof of independent verification.

- Fire-Resistance Rating: The most critical detail, stating how long the door can withstand fire (e.g., 90 minutes, 3 hours).

- Suitability for Smoke Control: Some labels will indicate if the assembly is also rated to block smoke, often marked with an “S.”

The Consequences of a Missing or Damaged Label

Here’s the harsh reality: if a fire marshal cannot find or read the label, the fire rating door is automatically considered non-compliant. The logic is simple—without official verification, there is no way to prove the door will perform as designed. This leads to immediate and often expensive consequences.

A common and completely preventable scenario we see is a perfectly functional fire door failing an annual inspection because the label was carelessly painted over during routine facility maintenance. The outcome is the same as if the label were missing entirely: the door’s rating is void.

A missing, damaged, or illegible label will cause your door to fail its annual inspection, which can trigger:

- Significant Fines: Penalties for non-compliance with fire codes can be steep.

- Mandatory Replacement: You will likely be required to replace the entire door assembly—door, frame, and hardware—with a new, properly labelled system.

- Increased Liability: In the event of a fire, a non-compliant door could void your insurance coverage and expose your business to immense legal risk.

Your Responsibility as a Facility Manager

As a building owner or facility manager, you are legally responsible for ensuring every fire door is inspected annually. A key part of that duty is ensuring the certification label remains visible and intact. This simple act of preservation is a fundamental part of your overall fire door maintenance and testing program. Protecting this label protects your investment and, most importantly, keeps your building’s occupants safe.

Unsure if your fire door labels are compliant? Don’t wait for a failed inspection to find out. Contact us today to schedule a professional assessment and ensure your facility is fully protected.

Your Annual Drop Testing and Maintenance Responsibilities

Having a fire rating door installed is just the beginning of your commitment to safety. As a facility manager or building owner, you are responsible for keeping these life-saving systems in perfect working order. This is not just a best practice; it is a legal requirement.

The NFPA 80 standard is clear: every fire door must be inspected and tested annually by a qualified professional. This is a comprehensive evaluation of every component, designed to identify any issue that could lead to a catastrophic failure during an emergency.

For rolling and sliding fire doors, the cornerstone of this process is the annual drop test. This is a hands-on test to prove the door’s automatic closing system is ready to perform, ensuring it will self-close and latch to create that critical barrier against fire.

The Non-Negotiable Annual Drop Test

The drop test is a real-world simulation of a fire event. A certified technician triggers the release mechanism to confirm the door descends at a controlled, safe speed and completely seals the opening. Skipping this test is a serious compliance breach and leaves a gaping hole in your facility’s safety plan.

As the building owner or facility manager, you are legally responsible for ensuring these annual tests are performed and properly documented. Failure to do so can result in significant liability and may even void your insurance coverage if a fire occurs.

Regular, scheduled maintenance is the only way to guarantee safety and maintain a clean compliance record. Learn more about the critical steps in our guide on fire door drop testing in manufacturing facilities.

Why a Visible Label is Crucial for Passing Inspection

When an inspector arrives, one of the first things they will look for is the certification label. This small tag is the only official proof that your door assembly meets fire-resistance standards. If that label is missing, painted over, or unreadable, the door fails the inspection. Period.

This infographic shows the simple process an inspector uses when checking your fire door label.

Alt text: An infographic showing the three steps of a fire door label check: a certified label passes, a missing label fails inspection, resulting in a failed door.

As you can see, there is no grey area. The label must be present and legible to pass. Even if the door is in perfect mechanical condition, a missing label voids its fire rating, potentially forcing you into an unexpected and expensive replacement. It is your job to ensure these labels are protected.

Your maintenance plan should cover these key points:

- Annual Professional Inspection: A qualified technician must perform the inspection and drop test at least once every 12 months.

- Written Documentation: You must keep a detailed, written record of every inspection and test, ready for the fire marshal to review.

- Label Preservation: Ensure your maintenance staff knows to never paint over or damage fire door labels during routine upkeep.

Staying on top of these responsibilities is fundamental to running a safe and compliant facility. As your “Respected Partners, Reliable Service” provider, we are committed to making this process straightforward.

Don’t wait for an inspector to find a problem. Contact Wilcox Door Service today to schedule your annual fire door inspection and drop test, ensuring your facility remains safe and compliant.

How to Choose the Right Fire Rating Door

Selecting the right fire rating door is a critical decision for your facility’s safety and compliance. The correct choice depends on the door’s location, its daily function, and the fire-resistance requirements of the wall it’s installed in. Getting this right ensures your building’s passive fire protection system works seamlessly when it counts.

Think of it like choosing the right tool for a job. Each application demands a specific solution built for that environment.

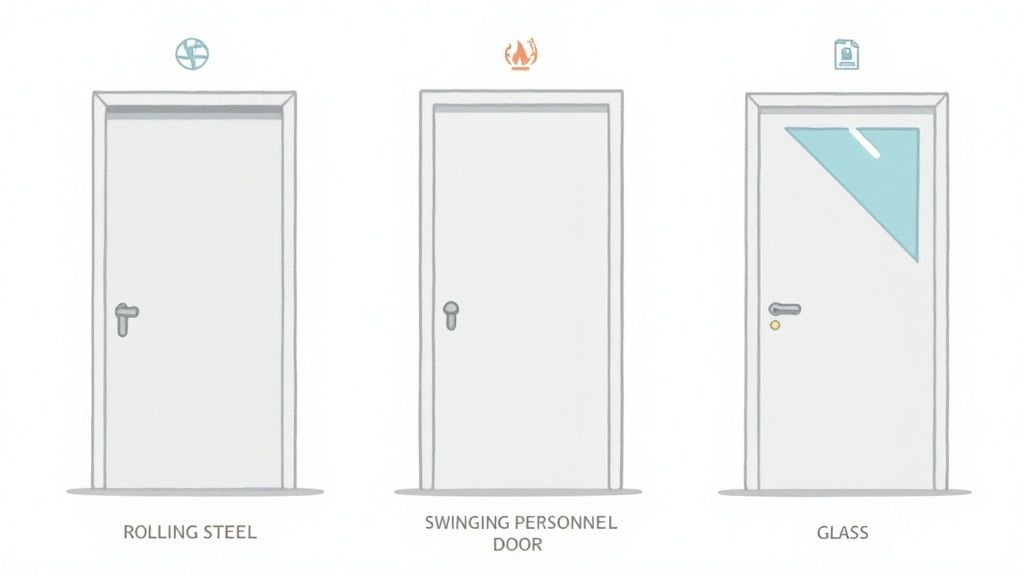

Alt text: Three types of fire-rated doors: rolling steel, swinging personnel, and glass, suitable for different commercial applications.

Matching Door Types to Facility Needs

Different areas of your building have unique operational demands and fire risks, so the type of fire door you choose must align with both its daily function and local safety codes.

For large openings, like those at a busy loading dock or between warehouse zones, rolling steel fire doors are the standard.

- Why they work: They are incredibly durable, can cover massive openings, and are designed to close automatically in a fire, creating a powerful barrier. Their vertical coiling design also saves valuable floor space.

For personnel corridors, stairwells, and office entryways, swinging fire doors are the right choice.

- Why they work: These doors are built for foot traffic and must allow for a quick exit. They typically have lower fire ratings (like 45 or 90 minutes) that match interior hallway walls and come with closers and latching hardware to ensure they seal properly.

For service windows in cafeterias or parts counters, fire-rated counter shutters offer the needed protection in a smaller package.

- Why they work: They operate like a full-sized rolling door but are sized for smaller openings, securing the pass-through area without hindering workflow.

The Importance of Materials and Certified Assemblies

The material of your fire door also plays a huge role. Steel is the most common choice for its strength and high melting point, making it ideal for tough industrial settings. For areas where visibility is needed, like in modern offices or hospitals, fire-resistive glass doors and windows can contain a fire while allowing light to pass through.

The single most critical rule when selecting a fire rating door is that it must be a complete, certified assembly. This means the door, frame, and all hardware—hinges, latches, closers—have been tested and listed together as one system. Mixing and matching unlisted components immediately voids the fire rating.

This is a common and dangerous mistake. Installing a 90-minute door in a non-rated frame makes the entire opening non-compliant and unsafe. Reputable manufacturers ensure their products meet these strict system requirements.

Navigating building codes and your operational needs can be complex. For a deeper dive into specific options for your facility, check out our guide on the best interior fire-rated door options.

Why You Need a Pro for Installation and Compliance

A fire rating door is an engineered life-safety system, not just a heavy-duty door. Every component is designed to work together in a crisis. That’s why its installation, maintenance, and annual testing demand certified expertise. Handling these critical tasks in-house or with an unqualified contractor is a massive gamble that risks safety, compliance, and your bottom line.

One wrong move during installation or a botched repair can render the door useless in a fire. This not only puts lives at risk but also voids its certification and fire rating. To a fire marshal, an improperly serviced fire door is no better than a standard one, leaving your facility open to liability.

This Isn’t a DIY Job

Every piece of a fire door assembly must work in perfect harmony to meet NFPA 80 standards. Only a trained, qualified technician has the specific knowledge to ensure each part is installed correctly and that any repairs use only manufacturer-approved parts.

This expertise is vital for the annual drop test. A professional service will cover:

- Verification of Correct Installation: Ensuring the door was installed according to strict manufacturer and code requirements. We dive deeper into this in our guide on sectional and fire door installation.

- Certified Drop Testing: Performing and documenting the mandatory annual test to confirm the automatic closing function works flawlessly.

- Component Integrity Checks: A thorough inspection for worn or damaged parts that could cause a failure when you least expect it.

- Compliance Documentation: Providing the official, signed reports you need to prove your facility is meeting its legal obligations.

A Universal Rule for Safety Systems

The need for certified professionals isn’t unique to fire doors. It’s a fundamental principle across all regulated safety fields. For example, the same logic applies to specialized electrical work. The core idea behind things like adherence to Australian electrical standards reinforces a universal truth: complex safety systems demand specialized knowledge to ensure they keep people safe.

Bringing in a certified professional for your fire doors isn’t just another expense—it’s an essential investment in risk management. It’s what protects your facility, your people, and your business from the devastating fallout of non-compliance.

As your “Respected Partners, Reliable Service” provider, the Wilcox Door Service team is here to make sure your facility is safe, compliant, and always ready. Don’t wait for a failed inspection or, worse, an emergency to find a problem with your fire rating door.

Protect your facility and everyone in it by trusting your life-safety systems to the experts. Contact us to schedule your fire door maintenance or repair service.

Your Top Questions About Fire Doors, Answered

Even after covering the basics, you may still have specific questions about your fire doors. Here are straightforward answers to the questions we hear most often from facility managers, helping you stay compliant and confident in your safety measures.

How Often Do My Fire-Rated Doors Need to Be Tested?

This is non-negotiable. According to the NFPA 80 standard, every fire-rated door in your building must be professionally inspected and tested at least once a year. Think of it as a mandatory annual check-up for a critical piece of life-safety equipment.

For rolling or sliding fire doors, that annual service must include a “drop test” to ensure the automatic closing feature works correctly. You will also need a formal, written record of the inspection kept on-site, ready for the fire marshal to review at any time.

What if My Fire Door’s Label is Missing or Damaged?

If the certification label on a fire door is missing, painted over, or unreadable, that door is instantly non-compliant. An inspector has no way to verify its fire-resistance rating, so it no longer qualifies as a protective door and will fail inspection.

This is a common but costly mistake. In almost every case, a missing label means the entire door assembly must be replaced with a new, properly certified one. Protecting that label is one of the easiest ways to avoid a huge expense and headache.

Can I Just Fix a Fire-Rated Door Myself?

Absolutely not. All repairs, maintenance, or modifications to a fire-rated door assembly must be done by a qualified and certified technician who knows the NFPA 80 guidelines. This is a highly engineered life-safety system, not a regular door.

A DIY fix or using the wrong parts can destroy the door’s integrity, voiding its fire rating. This creates a massive safety risk and puts your facility in a serious liability position. When it comes to fire door maintenance or repair service, always bring in a certified professional.

At Wilcox Door Service Inc., our union-certified technicians deliver expert fire door inspection, testing, and maintenance to keep your facility safe and fully compliant. As your “Respected Partners, Reliable Service,” we’re here to help you protect your people and property.

Ensure your facility is prepared. Schedule your annual fire door inspection by visiting https://www.wilcoxdoor.com or calling us today.