Planning for a new commercial garage door? The final price can range from a few thousand dollars for a basic model to over $20,000 for a specialized, high-performance door. This guide will break down every factor that influences the total garage door cost. You’ll learn how the door’s materials, size, installation complexity, and long-term maintenance all contribute to your total investment, empowering you to make a smart, cost-effective decision for your facility.

Understanding Your Total Investment

Figuring out the true cost of a commercial or industrial garage door means looking well beyond the initial quote. As “Respected Partners, Reliable Service” is our promise, we want to give you the full financial picture—no surprises. Your total investment is a mix of the door itself, the professional installation, and what it costs to own and operate it over its entire life.

It’s tempting to go for the cheaper option upfront, but that can often lead to bigger headaches down the road. Think higher energy bills from poor insulation, frustrating downtime from mechanical failures, and expensive emergency repairs that disrupt your operations.

This is where the concept of total cost of ownership (TCO) becomes so important. TCO is a simple idea: it’s the total cost of the door over its entire life, not just the purchase price. For example, a well-insulated door for a climate-controlled warehouse might cost 20-50% more at the start. But it can quickly pay for itself by slashing your heating and cooling bills. In a real-world scenario, a busy loading dock that invests a bit more in a durable, high-cycle door prevents operational bottlenecks that could cost far more in lost productivity than the initial price difference.

To help you put together a realistic budget, we’ll break down:

- Core Components: How the door’s type, materials, and size create the baseline price.

- Installation Variables: Why a professional setup is a non-negotiable investment in safety and long-term performance.

- Operational Costs: The price of operators, safety features, and automation.

- Long-Term Expenses: The difference between reacting to breakdowns and proactively maintaining your equipment.

A commercial door isn’t just a barrier; it’s a critical piece of equipment that impacts your facility’s efficiency, security, and energy consumption. A smart investment balances upfront cost with long-term value and reliability.

By understanding these pieces, you can make a decision that truly benefits your facility. For a closer look at specific models and their features, our guide to commercial overhead doors is a great resource.

Now, let’s dive into each of these cost factors, starting with the core components of the door itself.

Dissecting the Core Cost Components

When you’re trying to understand the total cost of a new commercial garage door, it’s best to start by breaking the price down into its core parts. Yes, installation and long-term ownership are big pieces of the puzzle, but the door itself is the foundation of your budget. Its final price tag is a direct reflection of its design, materials, and features—all chosen to handle the specific demands of your operation.

The journey begins with the door’s fundamental type. A standard insulated sectional door for a warehouse loading dock, for instance, has a completely different engineering and cost structure than a high-speed fabric door designed for a busy interior corridor. Similarly, a rolling steel fire door, which has to meet strict life-safety codes, carries a price that reflects its specialized construction and compliance testing. Each model is priced based on its complexity and what it’s built to do.

This visual breaks down the total cost of ownership into three main buckets.

Alt text: A flowchart breaking down the total garage door cost into purchase price, installation fees, and long-term ownership costs.

As you can see, the sticker price is just the beginning. The total cost also includes the critical installation phase and all the ongoing expenses tied to ownership and maintenance over the door’s lifespan.

The Role of Door Materials

The material you choose has a huge impact on both the initial cost and the door’s long-term performance. Think of it as a balancing act between your budget, durability needs, and the environment your door will live in. For most industrial applications, steel is the workhorse, offering a great mix of strength and cost-effectiveness.

But different situations call for different solutions:

- Steel: The most common choice, steel offers excellent durability and comes in a wide range of gauges (a term for its thickness). Thicker, lower-gauge steel costs more but gives you superior impact resistance—a must-have for busy loading docks where accidental bumps are common.

- Aluminum: Lighter and more corrosion-resistant than steel, aluminum is often used for full-view doors with large glass sections or in facilities with high moisture, like a wash-down bay in a food processing plant.

- Specialized Composites: These materials are engineered to solve unique problems. Fiberglass doors, for example, resist rust and dents, making them perfect for coastal areas or chemical plants where corrosion is a constant battle.

Insulation and Its Impact on Your Budget

Insulation is one of the biggest variables affecting both your upfront cost and your long-term operational savings. We measure its effectiveness with an R-value—a simple term for how well it resists heat flow. The higher the R-value, the better the insulation and the more stable your building’s internal temperature will be.

While an insulated door costs more at the outset, it often delivers a strong return on investment. In a climate-controlled facility like a cold storage warehouse or a pharmaceutical plant, a door with a high R-value can slash your energy consumption, paying for itself over time through lower heating and cooling bills. It also helps protect product integrity and creates a more comfortable, productive environment for your team.

Investing in proper insulation isn’t just an expense; it’s a strategic decision to lower your facility’s long-term operating costs and boost your energy efficiency.

How Size and Custom Features Adjust the Price

It’s no surprise that the bigger the door, the higher the material and manufacturing costs. A door for a standard loading dock bay will be significantly less expensive than a massive one needed for an oversized opening built for large machinery or aircraft.

Beyond sheer size, custom features will add to the final price, but they are often essential for operational efficiency and safety. These can include:

- Vision Lites (Windows): Adding windows increases natural light and visibility, which is a great safety boost, but it also adds to the cost of each panel.

- Pass Doors: A built-in pedestrian door allows people to walk through without cycling the main overhead door. This saves a surprising amount of energy and reduces wear and tear on the operator.

- Specialized Hardware: In high-moisture or corrosive environments, upgrading to stainless steel tracks and hardware is a smart move. It prevents rust and can dramatically extend the door’s service life.

Pricing can swing quite a bit based on regional factors and specific requirements. For instance, replacing a standard two-car steel door in some markets might average around $4,190, but that figure can move up or down dramatically based on the materials and features you choose. For facility managers, this really highlights the importance of understanding what separates a basic door from a reliable, long-lasting one built for commercial demands. You can learn more about how door features impact regional pricing from this insightful analysis.

Why Professional Installation Is a Critical Investment

A high-performance commercial door is only as good as its installation. It’s easy to get focused on the door materials and hardware, but the labour portion of your budget is a critical investment in your facility’s safety, compliance, and long-term operational continuity.

Think of it like a high-performance engine; even the best components will fail if they aren’t assembled with precision by a trained expert.

Cutting corners with inexperienced installers introduces huge risks. An improperly balanced door puts immense strain on the operator, leading to premature burnout. Worse, faulty safety sensor alignment or incorrect spring tensioning can create serious, life-threatening hazards for your team and equipment. This is why professional, union-certified installation is non-negotiable for protecting your warranty and ensuring flawless, safe operation from day one.

Factors That Influence Installation Costs

The labour line item on your quote isn’t just a flat fee. It’s a carefully calculated figure based on the complexity and specific requirements of the job. Understanding the variables helps you build a much more accurate budget.

Here’s what our estimators look at:

- Job Complexity: A standard install in a new construction build is pretty straightforward. Retrofitting a door into an older, uneven opening? That takes more skill. Installing a high-lift track system to accommodate vehicle lifts in an auto shop? That requires more time, specialized knowledge, and equipment, all of which drive up labour costs.

- Site Accessibility: Can our technicians easily bring their truck, equipment, and the door sections right to the opening? A loading dock with clear, ground-level access will have a lower labour cost than a job requiring scissor lifts or cranes to reach an elevated or obstructed installation point.

- Specialized Equipment Needs: Installing large, heavy industrial doors often means bringing in the big guns—scissor lifts, forklifts, or other heavy machinery. Those rental and operating costs are naturally part of the overall project budget.

- Removal and Disposal: If there’s an old door that needs to be dismantled and hauled away, this service will be factored into the installation quote.

For a commercial operation, a faulty installation doesn’t just mean a broken door; it means a broken workflow.

A distribution centre that saves a few hundred dollars on installation only to suffer a critical door failure during peak season can lose thousands in delayed shipments and emergency repair fees. Investing in quality installation is an investment in uptime.

The Impact of Regional Economics and Compliance

Where your facility is located plays a surprisingly large role in the overall garage door cost. Labour rates, permitting fees, and local building codes can vary significantly from one municipality to another, and that directly impacts your budget.

For instance, a garage door replacement in a major metropolitan area will almost always have higher installation costs due to elevated labour rates and more stringent building standards. In Los Angeles, professional installation can add $300–$800 to the final bill, a number that reflects the region’s rigorous codes. This is a key reason why operations leaders in multi-site facilities must account for regional price differences when forecasting their budgets. You can discover more about how location impacts garage door costs with this detailed breakdown.

Our union-certified technicians aren’t just masters of their craft; they’re also deeply knowledgeable about local and national safety codes, including fire regulations. Working with an expert partner like Wilcox Door Service ensures your installation is done right and is fully compliant. That saves you from the headache of potential fines and the high cost of future retrofits. We make sure every installation reflects our commitment: Respected Partners, Reliable Service.

When you partner with us for your next project, you’re not just buying a door. You’re investing in a safe, compliant, and durable access solution that will serve your business for years to come.

Budgeting for Operators and Automation

A modern commercial door is much more than a slab of steel; it’s an integrated system. At the heart of that system is the operator—the motor that drives the door—and all the accessories that make it safe, efficient, and secure. Factoring these components into your garage door budget is critical because they directly dictate how your door performs day in and day out.

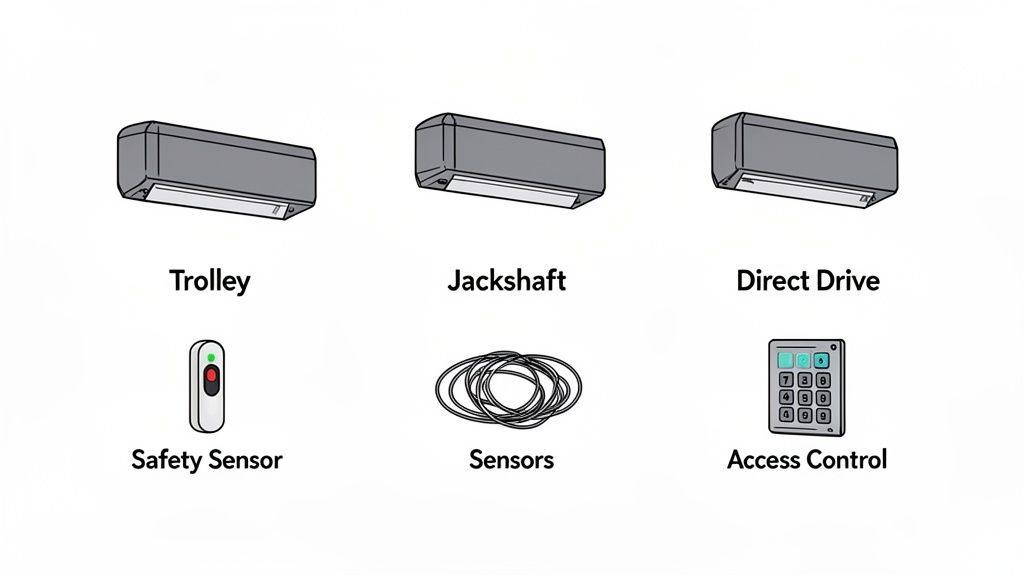

Alt text: Diagram showing different commercial garage door operator parts, including trolley, jackshaft, and safety sensors, which affect overall cost.

Think of the operator as the engine. You wouldn’t put a small car engine in a transport truck, and the same logic applies here. You have to match the operator’s power and design to your door’s size, weight, and how many times it needs to open and close each day. This turns budgeting from a simple line item into a strategic exercise—balancing the upfront cost with long-term reliability.

Comparing Commercial Operator Costs

Commercial operators are built tough for high-cycle use, and their prices reflect that robust engineering. The final cost will hinge on the type of operator, its horsepower, and any special features it includes.

Here’s a quick look at the most common commercial operators and how they stack up:

- Trolley Operators: These are the workhorses you’ll find in most standard warehouses. They use a rail system to pull the door open and push it closed. For most sectional doors, they’re a reliable and cost-effective choice, but they do require a good amount of overhead space to install.

- Jackshaft Operators: Instead of being mounted overhead, these operators sit on the wall right beside the door, turning the torsion bar (the spring-loaded rod) directly. This makes them perfect for facilities with high or obstructed ceilings, like auto repair shops with car lifts. That space-saving design usually means they cost a bit more than trolley models.

- Direct-Drive Operators: You’ll often see these on high-speed doors. They are advanced systems with fewer moving parts, which translates to less wear and tear and lower maintenance costs over the long haul. While they carry a higher initial price tag, their speed and durability deliver a strong return in high-traffic environments where every second of downtime hurts the bottom line.

Getting to know the differences between these systems is a big first step. If you’re weighing repair vs. replacement, our guide on garage door opener replacement offers some great insights for planning your budget.

Factoring in Essential Accessories and Controls

Beyond the motor, a big chunk of your automation budget will go towards the accessories that make your door safe and easy to use. These aren’t just bells and whistles; they’re essential components for any compliant and efficient access point.

Investing in the right activation and safety devices is not an optional expense. It’s a foundational part of protecting your personnel, safeguarding your equipment, and ensuring your operations run without costly interruptions.

Picture a busy distribution centre where forklifts are zipping through a loading dock all day. A simple wall-mounted push-button isn’t going to cut it. In that scenario, a more advanced activation system is a necessity, not a luxury.

Here are the key accessories you’ll need to budget for:

- Safety Sensors: Photo-eyes (beams that detect an object breaking the light path) and reversing edges (pressure-sensitive strips on the bottom of the door) are non-negotiable. They detect obstructions and automatically reverse the door to prevent crushing accidents.

- Activation Devices: The cost here varies based on how you need the door to function. In-floor loop detectors that sense vehicles, motion sensors, or simple pull cords all come with different price points. Picking the right one helps optimize traffic flow and even save on energy costs.

- Access Controls: If the door leads to a secure area, you’ll need to budget for keypads, card readers, or remote transmitters. These systems can be integrated with your facility’s main security protocols to control and track who comes and goes.

While a handy guide for smart garage door opener installation might be useful for a simple home setup, commercial systems are a different beast and demand professional expertise.

By carefully planning for both the operator and the necessary controls, you can build a complete and accurate budget. This ensures your new door system isn’t just powerful, but also smart, safe, and perfectly suited to your facility’s unique demands—a perfect reflection of our promise of Respected Partners, Reliable Service.

Planning for Maintenance and Long-Term Ownership Costs

The sticker price is just the beginning of your garage door cost. A smart budget looks past day one to account for the entire life of the door. To really understand your return on investment, you have to factor in everything from routine upkeep to those middle-of-the-night emergency calls. Planning for this avoids nasty surprises and keeps your operations running without a hitch.

Let’s be realistic—every commercial door will need service eventually. The real question is whether you’ll pay for it reactively, in the middle of a high-stress breakdown, or proactively, with a predictable, structured plan. The path you choose makes a world of difference to your budget and your facility’s uptime.

Alt text: An illustration showing how proactive garage door repair and maintenance impacts the long-term cost.

Reactive Repairs vs. Proactive Care

Reactive maintenance is the “wait until it breaks” approach. While it might feel like you’re saving money by not paying for service you don’t immediately need, it almost always leads to bigger bills and bigger headaches down the road.

When a door fails, it’s never at a convenient time. These emergency calls usually involve:

- Broken Torsion Springs: These are the powerful springs that do the heavy lifting. When one snaps, the door is dead in the water, trapping vehicles and grinding your workflow to a halt until a technician arrives.

- Damaged Panels: A moment’s inattention with a forklift can lead to a bent or broken door section. This isn’t just cosmetic—it’s a security risk and an energy efficiency nightmare. An emergency panel replacement costs far more than a scheduled one.

- Operator Malfunctions: A burnt-out motor or a fried logic board (the operator’s “brain”) can shut down a key access point without any warning, causing serious delays for shipments and staff.

These reactive service calls come with premium labour rates, and you’re often stuck with extended downtime waiting for parts to be sourced. An emergency spring replacement alone can average $292.48 in some regions. When you have multiple doors or more complex failures, the unplanned expenses can spiral out of control fast.

The Value of a Planned Maintenance Program

A much smarter, more cost-effective strategy is a Planned Maintenance Program (PMP). Instead of waiting for a disaster, a PMP involves regularly scheduled visits from a certified technician who keeps your doors and loading dock equipment in peak condition.

A Planned Maintenance Program shifts your budget from unpredictable, high-cost emergency repairs to predictable, manageable operational expenses. It is the single best way to maximize asset life and minimize downtime.

A comprehensive PMP is a lot more than a quick look-over. It’s a detailed inspection and tune-up that catches major problems before they can start. A typical program from Wilcox Door Service includes:

- Lubrication: We lubricate all moving parts—rollers, hinges, bearings—to cut down on friction and wear.

- Balancing and Adjustments: Our technicians check and adjust spring tension to make sure the door is perfectly balanced, which takes a huge amount of strain off the operator.

- Safety Inspections: Critical safety gear like photo-eyes and reversing edges are tested to ensure they’re working correctly and keeping you compliant.

- Fire Door Drop Testing: For facilities with fire-rated doors, we perform the required annual drop tests to verify they function in an emergency and provide the official documentation you need.

Investing in proactive care extends the life of your equipment, prevents expensive breakdowns, and makes your facility safer for your team. You can dive deeper into the specific financial and operational upsides in our guide on the benefits of a planned garage door maintenance program.

To see just how different these two approaches are, let’s compare the costs side-by-side.

Reactive Repair vs. Proactive Maintenance Cost Comparison

| Expense Category | Reactive Repair (Emergency Call) | Planned Maintenance Program (Scheduled Visit) | Long-Term Financial Impact |

|---|---|---|---|

| Labour Rates | Premium rates for after-hours or emergency dispatch (25-50% higher). | Standard, predictable rates included in the program fee. | Significant savings on labour over the asset’s lifespan. |

| Downtime Costs | High. Operations stop until the door is fixed, leading to lost productivity and revenue. | Minimal to none. Service is scheduled during off-peak hours to avoid disrupting workflow. | Improved productivity and revenue protection. Avoids costly operational bottlenecks. |

| Part Replacement | Often requires rush orders for parts at a premium. A major failure can damage multiple components. | Worn parts are identified and replaced early with standard pricing, preventing catastrophic failure. | Lower overall parts cost. Prevents the “domino effect” where one failing part destroys others. |

| Asset Lifespan | Shortened due to excessive wear and tear between major failures. | Extended significantly. Proper care reduces stress on all components, maximizing the door’s life. | Higher ROI on your initial investment by delaying the need for a full door replacement. |

| Budgeting | Unpredictable and chaotic. Large, unplanned expenses can wreck your quarterly budget. | Predictable, fixed cost that can be easily budgeted as an operational expense. | Stable and predictable finances. Eliminates budget shocks and allows for better financial planning. |

As the table shows, the choice is clear. While reactive repairs address an immediate problem, a planned maintenance program is a strategic investment that saves money, reduces stress, and boosts your bottom line over the long run.

For commercial properties, keeping a close watch on these long-term expenses is crucial. You can streamline the management of assets like your garage doors by exploring the best property management apps for 2025 to see how modern tools help track these critical investments.

Ultimately, planning for maintenance isn’t just an expense—it’s an investment in reliability.

Making an Informed Final Decision

Choosing the right commercial door is a strategic move that goes straight to your bottom line. To get it right, you need to look past the initial price tag and think about the total return on investment (ROI). It’s all about understanding how a high-performance door system contributes to your facility’s efficiency, safety, and energy savings over its entire life.

A well-chosen door isn’t just an expense; it’s an asset that pays you back. When you start thinking in terms of ROI, you can confidently justify investing in a quality solution that truly supports your operational goals. This approach ensures you end up with a door that delivers lasting value, not just a low upfront cost.

Calculating Your Return on Investment

Figuring out the ROI for your new door system doesn’t require a complicated financial spreadsheet. It’s more about quantifying the real, tangible benefits a better door brings to your facility. Just think about where a superior door will save you money or make your team more productive.

Here’s a simple way to frame it:

- Energy Savings: If you’re upgrading to an insulated door in a climate-controlled space like a food processing plant or cold storage facility, you can estimate your potential energy savings. A properly insulated door can cut heating and cooling costs by 15-25%, which adds up to a significant amount year after year.

- Reduced Downtime: In a busy logistics centre, a broken door can bring operations to a dead stop, causing costly delays. You know what an hour of downtime costs your business. A durable, high-cycle door that prevents even one major breakdown can easily pay for itself by keeping your shipments moving and your revenue flowing.

- Productivity Gains: High-speed doors, for example, can dramatically shorten cycle times. This lets forklifts move between zones faster, smoothing out workflow and increasing throughput. Even shaving a few seconds off each cycle can translate into hours of recovered productivity over the course of a year.

How to Compare Different Quotes

When you’ve got a few quotes in hand, it’s tempting to let the bottom-line number make the decision for you. But a truly smart choice means looking a lot deeper. The cheapest quote today can quickly become your most expensive problem tomorrow if it leads to constant repairs or simply fails to meet your performance needs.

A quote is more than just a price; it’s a reflection of the provider’s understanding of your needs and their commitment to quality. Analyze it as a complete solution, not just a number.

As you compare proposals, make sure you evaluate these critical factors:

- Long-Term Value: Does the quote specify high-quality materials and components actually designed for commercial use? Cheaper, residential-grade parts will wear out fast under the strain of industrial demands.

- Warranty Coverage: A strong warranty on both parts and labour is a clear sign of confidence from the provider. Think of it as your protection against defects and premature failures.

- Provider Reputation: Look for a partner with a proven track record. Our union-certified technicians and over 100 years of experience are your assurance of a safe, compliant, and reliable installation—a core part of our Respected Partners, Reliable Service promise.

Making the right decision means balancing your initial budget with the need for long-term performance. The final step is to work with an expert partner who can help you weigh these variables and design a solution that’s perfectly matched to your operational needs.

Frequently Asked Questions

When you’re trying to nail down the total garage door cost, you’ll find that it’s about a lot more than just the door itself. To help you see the full picture, we’ve put together answers to the questions we hear most often from facility managers and project leaders.

How Much More Does an Insulated Commercial Door Cost?

You can expect an insulated commercial door to cost roughly 20% to 50% more than a non-insulated version of the same model. It’s a higher upfront number, for sure, but that cost is often earned back over time through significant energy savings.

This is especially true in any climate-controlled space, like a cold storage facility, food processing plant, or pharmaceutical warehouse. The ROI doesn’t just come from lower heating and cooling bills; it also shows up in better product integrity and a much more comfortable—and productive—work environment for your team. The final price difference really hinges on the R-value of the insulation. A higher R-value means more thermal resistance, and naturally, a higher initial investment.

What Is the Biggest Hidden Cost When Buying a New Industrial Door?

The single biggest—and most frequently overlooked—cost is unplanned downtime. It’s easy to focus on the line items of a quote, but a cheap door that breaks down constantly can bleed your budget dry with lost productivity, delayed shipments, and steep emergency repair fees. A single day of a loading dock being out of commission can cost thousands.

Choosing a reliable provider with union-certified technicians is your best defense against this risk. Another sneaky cost can be failing to meet local building or fire codes, which can lead to fines and expensive, mandatory retrofits later on. A proper, thorough quote from a reputable company like ours will factor in all compliance needs from day one, so there are no surprises.

Are High-Speed Doors Worth the Extra Cost?

For the right application, absolutely. High-speed doors come with a much higher price tag than standard sectional doors, but they can deliver a surprisingly fast return on investment in the right environment. Think about a busy distribution centre—their fast cycle times keep the workflow moving and dramatically reduce the risk of forklift collisions.

In climate-controlled facilities, they’re a game-changer. By minimizing how long the door is open, they slash the amount of air exchange, which in turn cuts energy costs. It all comes down to a simple calculation: does the value of boosted productivity and energy efficiency outweigh the upfront investment for your operation?

How Often Should a Commercial Garage Door Be Professionally Serviced?

Our general rule of thumb is that every commercial garage door needs a professional inspection and service at least once a year. But for doors in high-cycle environments—we’re talking loading docks or parking garages where doors open and close hundreds of times a day—we strongly recommend quarterly servicing.

A Planned Maintenance Program (PMP) is easily the most cost-effective way to stay on top of this. Regular servicing ensures all your safety mechanisms are working correctly and lets us spot wear on critical parts before they fail, keeping your operations compliant, safe, and running without a hitch. Take a look at our commercial door services to see how we help facilities perform at their best.

Ready to invest in an access solution built for lasting performance? Contact Wilcox Door Service today to get a comprehensive quote that balances cost with long-term reliability.