A damaged commercial garage door panel is more than just an eyesore—it’s a direct threat to your security, operational efficiency, and team safety. A single bent or cracked panel can halt your logistics flow, create a security breach, and compromise your building’s climate control, impacting your bottom line. This guide will walk you through the entire commercial garage door panels replacement process, from assessing the damage and understanding the costs to seeing how our professional team handles the replacement safely and efficiently.

Unpacking the Risks of a Damaged Commercial Door

When a garage door panel gets compromised at a busy loading dock, it’s not just a cosmetic problem; it’s an active liability. Picture a common scenario: a forklift operator accidentally clips the bottom section of a roll-up door. The immediate issue is a door that won’t close right, but the ripple effects are far more severe.

Immediate Operational and Security Concerns

First off, your security is instantly weakened. A door that can’t fully seal becomes an open invitation for theft or unauthorized entry after hours. From an operational standpoint, a malfunctioning door means an entire loading bay is out of commission. This creates bottlenecks in your supply chain and can lead to costly shipment delays.

On top of that, a bent panel can throw the entire door system out of alignment. This puts immense stress on the rollers, tracks, and the operator motor. What starts as a seemingly minor issue can quickly snowball into a catastrophic failure, resulting in expensive emergency repairs and extended downtime. The best way to sidestep these headaches is with proactive maintenance, which we cover in our guide to effective garage door maintenance.

Safety and Environmental Impact

The safety risks here are significant. A damaged door can become unpredictable and jerky, posing a direct hazard to your employees. Dealing with potential hazards is non-negotiable for any business. Just as maintaining your door panels prevents physical risks, clearly communicating dangers with the right signage is crucial. You can find practical guidance on this in this resource for custom warning signs.

A damaged panel also compromises your building’s envelope—the physical barrier between your conditioned indoor space and the outside world. This breach leads to massive energy loss, forcing your HVAC system to work overtime and driving up utility costs. For climate-controlled facilities like cold storage or food processing plants, this is a critical concern.

We’re seeing a growing trend of businesses having to address aging infrastructure. Across California, service providers are reporting a spike in demand for repairs tied to older building stock. This has prompted many to expand their service fleets just to keep up with panel replacements and other essential maintenance. As “Respected Partners, Reliable Service,” we understand these pressures intimately and always prioritize swift, expert solutions to get you back up and running.

How to Assess Panel Damage: Repair or Replace?

When a forklift clips a door or a truck backs in a little too far, knowing how to size up the damage is the first step toward a smart, cost-effective decision for your facility’s garage door panels replacement. A quick evaluation can be the difference between a simple fix and a critical failure, giving you the clarity to act fast.

The best place to start is with a visual inspection. From a safe distance, take a good look at the door. Look for obvious signs of damage, paying close attention to how the panel sits within the frame and how it lines up with the other sections.

Distinguishing Cosmetic from Structural Damage

Not all damage is created equal, and it’s critical to know whether you’re dealing with a surface-level issue or a problem that has compromised the door’s integrity.

- Cosmetic Damage: This category includes minor scratches, scuffs from pallet jacks, or small, shallow dents. While they might look bad, these issues typically don’t affect how the door operates or its security. A small ding from a hand truck is a perfect example of something that probably doesn’t need immediate attention.

- Structural Damage: This is the serious stuff. We’re talking deep creases, significant bends, or cracks, especially near hinges and rollers. Any warping that stops the panel from sitting flush is a major red flag. This kind of damage, often caused by a vehicle impact, can throw the entire door out of alignment, put a massive strain on the lifting mechanism, and create a real safety hazard.

If you spot any structural issues, that door needs to be taken out of service right away. Continuing to use it can lead to further damage or a serious accident, as it puts immense stress on other components. You can learn more about these related issues in our guide to common overhead door repairs.

Damage Assessment Guide: Repair vs. Replace

Use this quick reference to understand the likely course of action based on the type and severity of your commercial door panel damage.

| Type of Damage | Typical Cause | Recommended Action | Why It Matters |

|---|---|---|---|

| Minor Scratches/Scuffs | Everyday wear, pallet jacks, hand trucks | Monitor / Repair | Primarily cosmetic. Repair is optional and often involves simple touch-up paint. |

| Small, Shallow Dents | Light impact from equipment or tools | Repair (if necessary) | Unlikely to affect function. Can often be pushed out or left alone if not compromising the seal. |

| Deep Dents or Creases | Significant impact from forklifts or vehicles | Replace Panel | A deep crease weakens the panel’s structural integrity and can impede smooth travel in the tracks. |

| Cracks (especially near hardware) | Stress, age, or impact | Replace Panel | Cracks compromise the panel’s strength and can lead to catastrophic failure, especially around hinges or rollers. |

| Warping or Bending | Vehicle impact, improper operation | Replace Panel | A bent panel will not seal properly, leading to energy loss, and puts extreme strain on the opener, springs, and cables. |

| Widespread Corrosion/Rot | Age, moisture exposure | Replace Panel / Full Door | Indicates the material has failed. A single panel replacement might be a temporary fix if other panels are also deteriorating. |

This table should help you quickly triage the problem, but a professional assessment is always the best way to confirm the right solution for your facility.

Key Indicators for Panel Replacement

Sometimes, the decision to replace is pretty clear-cut. If you notice any of the following, a garage door panels replacement is almost certainly on the cards.

A significant bend from a delivery truck, for instance, doesn’t just weaken the panel itself—it can damage the vertical tracks it runs in. This compromises the door’s stability and its weather seal, hitting both your security and energy efficiency. Likewise, widespread corrosion or rot on older steel or wood panels tells you the material has simply reached the end of its life.

When a panel is warped or bent, it disrupts the precise balance of the door system. This forces the opener to work harder and can cause the high-tension springs and cables to wear out prematurely, leading to a much more expensive and dangerous failure down the line.

Finally, think about the age of the door and the availability of parts. For older or discontinued models, finding an exact match for a single panel can be a real headache, if not impossible. In those situations, replacing the entire door is often the more practical long-term solution to ensure everything works correctly and looks uniform. Our team can quickly identify your door’s make and model to check on parts availability for you.

As your “Respected Partners, Reliable Service,” we’re here to give you a transparent, honest assessment. We’ll help you choose the right solution—one that restores safety and gets your operations back to normal with minimal disruption.

Our Professional Panel Replacement Process

Replacing a commercial garage door panel isn’t a simple swap-out. It’s a precise, technical job that demands expertise, specialized tools, and a serious commitment to safety. At Wilcox Door Service, we’ve refined our entire process around one core goal: minimizing your downtime while maximizing safety and long-term reliability.

Let’s walk you through how our pros handle a commercial garage door panels replacement, so you know exactly what to expect when our technicians arrive at your facility.

Safety First: Securing the Door and Releasing Tension

Our process kicks off with a thorough on-site safety assessment. Before a single tool comes out, our union-certified technicians secure the entire area around the door to protect your staff and property. The first critical step is to safely release the immense tension from the door’s torsion springs. These heavy-duty springs are under extreme load and can cause severe injury if mishandled—a task only a trained professional should perform.

Meticulous Identification and Sourcing

With the door secured, we meticulously document the manufacturer, model, colour, and insulation value (R-value). The R-value is a measure of thermal resistance—how well the panel prevents heat transfer. For a temperature-controlled facility like a food distribution centre, matching the R-value is essential to maintaining your building’s thermal efficiency and preventing energy loss. We then use our extensive supplier network to source an exact-match replacement, ensuring the new section fits perfectly and preserves the door’s appearance and structural integrity.

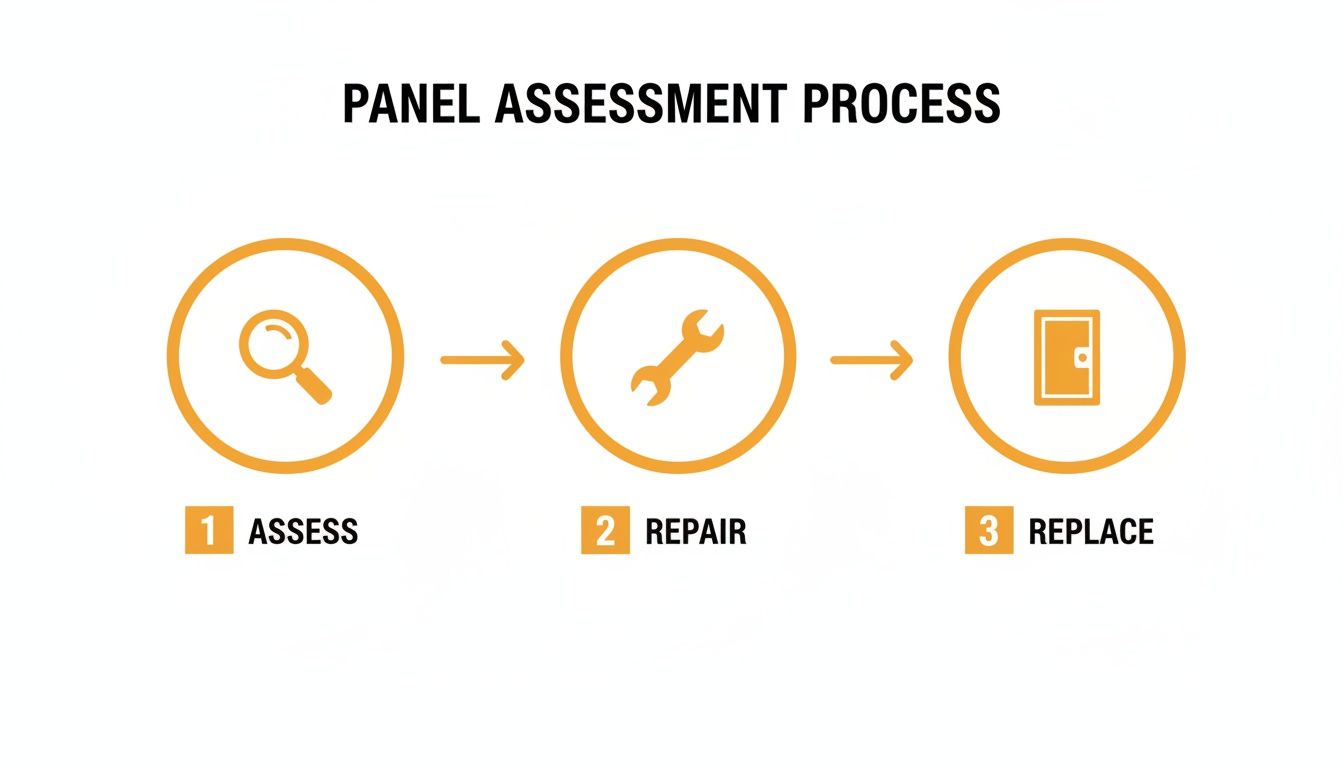

This visual guide breaks down our initial approach to every service call, ensuring we land on the most effective and economical solution for your facility.

The key takeaway here is that our process is diagnostic. We never default to a full replacement if a professional repair can safely and effectively solve the problem.

Precise Removal and Installation

Once the correct panel is on-site, our technicians carefully unbolt and remove the damaged section, properly supporting the weight of the remaining door. This prevents any warping of the tracks, which is especially important for heavy-duty industrial doors. For a closer look at the safety measures involved, particularly when working with the bottom section, check out our resources on bottom section replacement safety.

The new panel is then expertly fitted, ensuring every hinge and roller is aligned and torqued to manufacturer specifications. This precision is what guarantees smooth, quiet, and reliable operation for years to come.

Final Tensioning and Rigorous Testing

Finally, our technicians re-engage and re-tension the spring system, balancing it perfectly to the door’s weight. An imbalanced door puts a huge strain on the electric operator, leading to premature failure. We then run the door through multiple open-and-close cycles, rigorously testing its alignment, safety features (like photo eyes and reversing edges), and overall performance.

This final testing phase is our guarantee. When we leave your facility, your door isn’t just repaired—it’s operating safely and reliably. Our commitment to being “Respected Partners, Reliable Service” means we deliver a complete solution that gets your business back online with minimal disruption.

Diving Into the Cost and ROI of New Door Panels

When a commercial garage door panel gets damaged, the first question is always about cost. It’s a valid concern, but focusing only on the initial price tag misses the bigger picture. Think of a strategic panel replacement less as an expense and more as an investment in your facility’s security, efficiency, and day-to-day operations.

The final bill for a new panel is influenced by a few key things. Each one plays a part in the total investment needed to get your loading dock or service bay back up and running.

What Goes Into the Price Tag?

Several variables directly shape the cost of a replacement panel:

- Panel Material: Steel is the workhorse of the industry for a reason—it’s tough. But you might also consider lighter aluminum or specialized composite panels, each with its own price point.

- Size and Thickness: It stands to reason that larger panels or those made from thicker gauge steel, which are common in heavy industrial settings, will cost more than smaller, standard-duty sections.

- Insulation R-Value: If your facility is climate-controlled, a higher R-value (which measures thermal resistance) is non-negotiable. Panels with better insulation cost more upfront but can lead to serious energy savings down the line.

- Special Features: Need vision lite windows for visibility? Or high-cycle components for a door that’s constantly in motion? These kinds of customizations will also factor into the final price.

These elements determine the material cost, but the true value lies in what that new panel protects.

The Real Return on Your Investment

Just looking at a garage door panel replacement as a line-item expense is short-sighted. The return on investment (ROI) really clicks when you think about all the costly headaches a professional repair helps you avoid.

A new panel isn’t just a piece of metal; it’s an investment in uptime. It restores your building’s security, prevents a catastrophic door failure that could halt operations for days, and improves energy efficiency by properly sealing your building envelope.

Costs can also shift depending on where you are. In California, for example, a single-panel replacement can average around $300–$460 because of regional labour rates and material costs. You can find a more detailed breakdown of California garage door replacement costs here to get a better sense of these dynamics.

Once you’ve replaced the damaged sections, it’s smart to think about protecting your investment. Looking into durable and flexible coatings can add an extra layer of defence against future bumps, scrapes, and environmental wear. When you focus on the long-term value—avoiding downtime, securing your assets, and keeping up a professional appearance—it’s clear that a quality repair pays for itself.

As your “Respected Partners, Reliable Service,” we believe in transparent pricing that reflects the real value of a job done right. We make sure you understand both the cost and the significant benefits of getting your door back into perfect working order.

Why a Professional Partner Is Non-Negotiable

Tackling a minor fix on your own can feel rewarding, but a commercial garage door panels replacement is a whole different ball game. This isn’t a simple weekend project—it’s a complex job that should be left exclusively to certified professionals. The stakes are just too high for guesswork.

The biggest reason, hands down, is safety. The torsion springs on a commercial door are under an incredible amount of tension. If mishandled, they can cause serious injury or significant property damage in an instant. Our union-certified technicians have the specialized training and equipment to safely de-tension the system before any work begins, taking that critical risk completely off the table.

The Wilcox Advantage: Precision and Access

Choosing Wilcox Door Service for your panel replacement means prioritizing safety, precision, and operational continuity. Our technicians are union-certified, bringing a level of expertise and accountability that ensures every job is done right the first time. We use specialized equipment to guarantee a perfect fit, which is crucial for maintaining the door’s structural integrity and weather seal.

Furthermore, our long-standing relationships with top manufacturers give us access to a massive inventory of panels. This allows us to find an exact match for your door’s make, model, and colour, preserving both its function and its professional look. It’s a key part of our promise as “Respected Partners, Reliable Service.”

Real-World Impact: A Cold Storage Scenario

Think about a cold storage facility we recently helped. A damaged panel on their main loading dock door was compromising their climate control, putting thousands of dollars of inventory at risk of spoilage every minute the door was compromised.

Our rapid-response team was on-site within hours. We didn’t just patch up the door; we sourced and installed a perfectly matched, high-R-value insulated panel that completely restored the facility’s thermal envelope. Our efficiency directly protected their assets and prevented a huge financial loss.

This situation shows how an expert garage door panels replacement is about more than just a mechanical fix—it’s about protecting your bottom line. Partnering with professionals also delivers a strong return on investment. In some high-value California markets, for example, a new garage door can yield a resale benefit of up to 194%, driven by improved curb appeal and perceived security. You can dig deeper into repair costs and ROI in California on Angi.com.

Choosing a professional ensures the job is done safely, correctly, and efficiently, minimizing downtime and safeguarding your operations. For a reliable solution that protects your facility, contact Wilcox Door Service to schedule a service inspection today.

Answering Your Top Questions About Panel Replacement

When a commercial garage door panel gets damaged, facility managers need practical answers—fast. You’re thinking about downtime, costs, and what the final result will look like. Getting clear information upfront helps you make the right call before you even pick up the phone. Here are the most common questions we get from partners like you.

Can I Just Replace the One Damaged Panel?

Absolutely. In most cases, swapping out just the damaged panel is the smartest and most budget-friendly move. This is our go-to solution as long as the rest of the door is structurally sound and we can get a matching panel from the original manufacturer.

That said, there are exceptions. If the door is particularly old, the model has been discontinued, or the impact has knocked the tracks and frame out of alignment, we might recommend a full door replacement. It’s all about ensuring long-term safety and performance.

How Long Will My Loading Bay Be Out of Commission?

Our number one priority is keeping your operations moving. For a standard sectional commercial door, our union-certified technicians can typically complete a panel replacement in just a few hours.

We follow a meticulous process: secure the area, perform the replacement, and then run a full battery of tests to make sure everything is perfect. The goal is always to get your bay back online the very same day. If we’re dealing with a more complex job, like a specialty door or extensive frame damage, we’ll give you a clear, realistic timeline right from the start.

Will the New Panel Match My Existing Door?

We work hard to make the replacement as seamless as possible. The first step is to identify the door’s original manufacturer, model, and colour code, which lets us source a panel that’s a near-perfect match. If you want to dive deeper into how we track down specific components, our guide to overhead door repairs is a great place to start.

Keep in mind that on older doors, you might see slight colour variations due to years of weathering and sun exposure. The final look is usually very consistent. However, for businesses where appearance is everything—like storefronts or high-visibility entryways—we can also discuss painting the entire door for a flawless finish.

Key Takeaway: A professional panel match isn’t just about function; it’s about maintaining your facility’s professional appearance. It’s a small detail that protects your brand image.

Is It Cheaper to Replace Panels or the Whole Door?

Nine times out of ten, replacing a single panel is far more affordable than a full door replacement. The real question, though, isn’t just about the initial cost—it’s about making the most sensible long-term investment.

If you have multiple damaged panels, or if the impact was severe enough to affect the tracks and structural frame, a full replacement often becomes the more economical and safer choice down the road. Our technicians will give you a detailed assessment comparing both options, so you can see the costs and benefits side-by-side and make the best decision for your facility.

Your facility can’t afford to be down for long. As “Respected Partners, Reliable Service,” Wilcox Door Service Inc. delivers the prompt, expert solutions you need to restore safety and get back to business. Contact us today for a professional assessment and quote.