In this guide, you will learn how to identify the right perimeter weatherstripping for your facility, understand the key differences between materials like vinyl and brush seals, recognize the signs of seal failure, and see why professional installation is critical for protecting your investment. This knowledge will help you improve your building's efficiency, security, and operational bottom line.

When you think about your commercial overhead doors, what comes to mind first? Usually, it's the big, moving parts—the springs, the opener, the tracks. But the garage door seals for top and sides are the unsung heroes of your building's efficiency and protection. These aren't just simple strips of rubber; they are a critical barrier, also known as perimeter weatherstripping, designed to protect your facility from weather, pests, and costly energy loss.

This weatherstripping, whether it’s a durable vinyl flap seal or a flexible brush seal, is a core component for keeping your commercial operations running smoothly and securely.

Why Your Commercial Door Seals Matter More Than You Think

It's easy to overlook the seals around your overhead doors, but their performance directly impacts your daily operations and, ultimately, your bottom line. Think of these seals not as an accessory but as the first line of defence for your building’s entire interior environment. When your perimeter seals are in good shape, they create a formidable barrier, keeping the air you pay to heat or cool in, and contaminants out.

This is absolutely vital in commercial settings where environmental control is non-negotiable.

For example, imagine a food distribution warehouse with gaps in its loading dock door seals. Those small openings are an open invitation for pests and allow temperature fluctuations that could spoil an entire shipment, leading to a failed health inspection. In a manufacturing plant, the same gaps let in dust and debris that can damage sensitive equipment and compromise product quality.

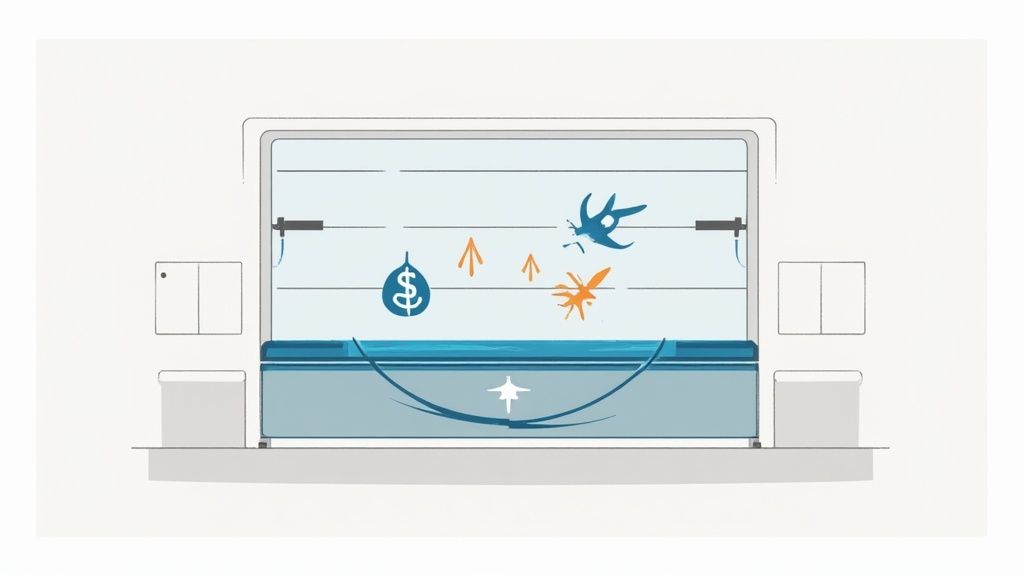

Alt text: Diagram of a commercial garage door showing how garage door seals for top and sides protect the interior from dirt, pests, and energy loss.

The Core Benefits of Proper Sealing

Properly installed and maintained weatherstripping around the perimeter of your commercial doors delivers a host of benefits that go way beyond just blocking a draft. Investing in high-quality commercial door seals helps you:

- Control Energy Costs: A tight seal stops conditioned air from leaking out. This reduces the strain on your HVAC system and can lead to a noticeable drop in your utility bills.

- Prevent Contamination: Seals are your best defence against dust, dirt, pollen, and other airborne particles. This is essential for clean rooms, food processing plants, and pharmaceutical facilities.

- Enhance Pest Control: A fully sealed door frame is one of the most effective, and simple, ways to keep rodents, insects, and other pests from getting inside your facility.

- Improve Workplace Comfort: No more complaints about chilly drafts. A stable, comfortable environment for employees working near loading docks makes a big difference in productivity and morale.

Understanding these benefits is the first step toward optimizing your facility. At Wilcox Door Service, our brand promise is built on being "Respected Partners, Reliable Service." We believe that begins with a deep understanding of your operational needs, and the right seals are a small but powerful part of that equation.

The Hidden Costs of a Poorly Sealed Garage Door

A failing perimeter seal on your commercial overhead door is much more than a minor annoyance. It’s a quiet but constant drain on your resources and a real threat to your facility's integrity. The true cost of worn-out garage door seals for top and sides goes way beyond simple weather protection, often creating a domino effect of expensive and disruptive problems.

Think of your building like a large ship. A small, unchecked leak below the waterline might not seem like a big deal at first, but over time, it compromises the entire vessel. In the same way, the gaps left by old seals—even if they're just a few millimetres wide—act like persistent leaks in your building's protective shell.

The Financial Drain of Energy Loss

The most immediate and obvious cost of bad seals is wasted energy. When outside air creeps into your building, your HVAC system has to work overtime just to maintain the temperature you’ve set. This constant fight against incoming hot or cold air sends your utility bills soaring.

In facilities with large overhead doors, proper seals aren't just a maintenance item; they're a core part of your energy management strategy. A fully sealed perimeter can slash air leakage by up to 90%, making a direct dent in your heating and cooling expenses.

This is especially true in places with harsh or fluctuating climates. It’s no surprise that the demand for better sealing solutions is on the rise, with the North American garage and overhead door market expected to grow by about 5.2% annually. A huge part of that growth is driven by the push for energy conservation, something quality seals directly address.

Compromised Sanitation and Pest Control

For many industries, a tight seal is non-negotiable for sanitation and compliance. Gaps around the top and sides of a loading dock door are basically an open invitation for pests like rodents and insects, not to mention airborne contaminants like dust and pollen.

Here’s a real-world example we’ve seen happen:

- A Food Distribution Warehouse

A food distribution centre was fighting a losing battle with pests, despite having regular extermination services. During an inspection, we found that the vinyl perimeter seals on their main loading dock doors were cracked and warped, creating obvious gaps. These small openings were the main highway for rodents and insects, leading to contaminated products, failed audits, and expensive emergency pest control calls. Replacing the worn weatherstrip for their garage doors with new, properly fitted seals solved the problem almost overnight. It turned out to be a far cheaper solution than endless pest management.

This scenario shows just how a seemingly minor component can have massive operational consequences, affecting everything from inventory loss to your company’s reputation.

The Slow Creep of Water Damage and Decay

Water is another relentless enemy that will exploit any weakness in your door seals. Wind-driven rain can easily push through gaps, kicking off a chain of problems that often stay hidden until serious damage is done.

Water seeping in can cause:

- Rust and Corrosion: Moisture that collects around the door tracks, bottom bar, and hardware will eventually lead to rust. This weakens the components and cuts the lifespan of your entire door system short.

- Structural Damage: Water can soak into the door jambs and the surrounding wall, leading to wood rot, mould growth, and the kind of structural repairs that get very expensive, very fast.

- Slip Hazards: Puddles forming on the floor near doorways create a serious slip-and-fall risk for your team, increasing the chance of workplace injuries and liability claims.

Investing in high-quality perimeter seals is really an investment in the long-term health of your facility. It’s a proactive step that stops small leaks from becoming a flood of costly problems. To get a better sense of how proper sealing ties into your building’s overall performance, this homeowner's guide to energy-efficient garage doors is a great resource that breaks down the benefits.

Choosing The Right Perimeter Seal For Your Operation

Picking the right garage door seals for top and sides isn't a one-size-fits-all job. The best perimeter weatherstrip for your commercial overhead door really comes down to your facility's day-to-day operations, the surrounding environment, and the specific problems you're trying to solve. Making the right call means looking past a simple like-for-like replacement and actually matching the material to the mission.

Think of it like choosing tires for a vehicle. You wouldn't put standard highway tires on a heavy-duty truck that spends its life in a gravel quarry. In the same way, the perfect seal for a climate-controlled pharmaceutical clean room is probably the wrong choice for a high-traffic manufacturing plant with uneven floors. As your Respected Partners, we want to help you make an informed decision by explaining the differences between common commercial seal types.

Vinyl and Rubber Seals: The Climate Control Champions

When your absolute top priority is creating a solid, unyielding barrier against air and moisture, vinyl and rubber seals are the clear winners. These materials are known for their firmness and ability to form an incredibly tight closure against a smooth, even door frame and door face.

- What They Are: Vinyl and rubber seals are typically installed as a stop moulding. This means a rigid PVC or aluminum holder (called a retainer) holds a flexible vinyl or rubber flap that presses firmly against the outside of the overhead door when it's closed, creating a solid wall against the elements.

- Best Applications: These seals are the first choice for any facility where temperature and environmental control are non-negotiable. That includes cold storage warehouses, food processing plants, pharmaceutical facilities, and any building that needs a clean-room environment. Their solid surface is a breeze to clean and stops fine dust, pollen, and moisture in their tracks.

Brush Seals: The Versatile Problem Solvers

Where vinyl is rigid, brush seals offer amazing flexibility. Made of dense but pliable polypropylene bristles held in an aluminum retainer, they are engineered to conform to imperfect surfaces and handle constant movement without wearing down.

- What They Are: While a vinyl flap creates a single line of contact, a brush seal uses thousands of dense filaments to close a gap. This design allows it to seal effectively even on corrugated, textured, or slightly uneven door surfaces, something a rigid vinyl seal struggles with. The bristles bend and flex, maintaining a consistent seal without impeding the door’s movement, even in high-cycle situations.

- Best Applications: Brush seals are the workhorses for warehouses, distribution centres, and manufacturing plants. They are fantastic for pest control, as the dense bristles create a physical barrier that rodents and insects cannot get through. They're also much better at stopping dust and debris from blowing in, which is a huge plus for facilities near open fields or industrial zones.

Alt text: Diagram showing how a gap in commercial garage door seals for top and sides leads to energy loss, pest entry, and water damage.

Head-To-Head Comparison: Vinyl vs. Brush Seals

To help you decide, let's put these two materials side-by-side and compare what matters most to facility managers.

| Feature | Vinyl/Rubber Seals | Brush Seals |

|---|---|---|

| Sealing Effectiveness | Excellent against air and moisture on smooth surfaces. | Excellent against pests, dust, and debris, even on uneven surfaces. |

| Ideal Applications | Climate-controlled facilities, clean rooms, food & beverage, cold storage. | Warehouses, manufacturing, high-traffic docks, pest-prone areas. |

| Durability | Can become brittle in extreme cold and may crack with direct impact. | Highly durable, resistant to friction, and maintains flexibility in all temperatures. |

| Maintenance Needs | Requires regular cleaning to prevent mould and mildew buildup. | Low maintenance; bristles are self-cleaning and resist sticking. |

Ultimately, choosing between these two comes down to what you need your seal to accomplish. If you want to dive deeper into the different ways seals can be configured, our guide on understanding different garage door side seals is a great next step.

How to Spot a Failing Commercial Door Seal

Your door seals can start to undermine your facility's integrity long before a total failure becomes obvious. Learning to spot the early warning signs of failing garage door seals for top and sides is a critical part of proactive facility management. It means you can tackle small issues before they snowball into expensive emergencies like pest infestations or water damage.

A failing seal isn't always as dramatic as a ripped piece of rubber dangling from the door. More often, the signs are subtle. By training your eye to catch these clues, you can act fast and keep your building secure.

Alt text: A technician inspects a commercial garage door with damaged top and side seals, looking for signs of pests and water entry.

Obvious Signs of Seal Degradation

Let's start with the things you can see. A quick walk around your overhead doors can tell you a lot about whether your perimeter weatherstripping is past its prime. During your next facility check, keep an eye out for:

- Visible Cracks and Brittleness: Seals made of vinyl and rubber that are constantly exposed to UV rays and temperature swings will eventually get hard and brittle. Look for fine cracks—they're the first sign the material is losing its flex and can no longer form a tight seal.

- Flattened or Compressed Sections: In busy doorways, seals can get squashed flat over time. A seal that doesn't spring back into shape has lost its ability to close gaps effectively.

- Tears, Gouges, or Missing Pieces: Physical damage from forklifts, pallets, or just daily wear and tear can create major breaches in your building's defenses.

Subtle Clues Your Seals Are Failing

Sometimes, the clues of a failing seal show up in the environment around the door, not on the door itself. These secondary signs are just as important.

Ever hear a whistling sound near a closed overhead door on a windy day? That’s a classic sign of air infiltration—air forcing its way through a tiny, unseen gap in your seal.

Pay attention to these environmental hints:

- Unexpected Puddles: Finding water on the floor near your door after it rains is a huge red flag. It means your side and top seals aren't properly channelling water away from the opening.

- Increased Dust and Debris: If you're noticing more dust, leaves, or dirt piling up just inside your overhead doors, it’s a strong indicator that your brush or vinyl seals are no longer blocking the elements.

- Evidence of Pests: Droppings or chew marks near a doorway are clear signs of an entry point. Rodents and insects can squeeze through surprisingly small gaps left by worn-out seals.

While you're checking your seals, it’s also a good idea to inspect other key parts of your garage door system. For example, if the door is acting up, you might need to troubleshoot garage door sensors to rule out other issues.

The Simple Light Test

One of the easiest and most effective ways to check the integrity of your garage door seals for top and sides is the light test. This quick diagnostic can be done by your own maintenance team and instantly reveals every single gap.

- Wait until it’s dark outside.

- Close the overhead door completely.

- Turn off all the lights inside the area around the door.

- Have one person stand inside while another shines a bright flashlight along the entire perimeter of the door from the outside.

Any spot where you see light bleeding through to the dark interior is a gap. This test takes all the guesswork out of the equation and pinpoints the exact locations where your seals are failing, giving you a clear roadmap for repairs or replacement.

Why Professional Installation Is a Non-Negotiable

While installing garage door seals for top and sides might seem like a straightforward job, getting it right on a commercial overhead door is a game of precision. A DIY approach can quickly turn into a costly mistake, completely defeating the purpose of the new seals.

Think of professional installation less as a service and more as an insurance policy. It guarantees the performance you paid for and protects your entire door system from unnecessary strain.

The Diagnostic Advantage

A true professional doesn’t just show up and start slapping on new weatherstripping. Their first move is a full diagnostic check of your entire overhead door system, because they know the seals are just one piece of a much larger puzzle.

An expert can spot underlying issues that would cause a brand-new seal to fail prematurely:

- Door Imbalance: An unbalanced door puts uneven pressure on the seals, grinding down certain sections much faster than others.

- Track Misalignment: If the tracks are even slightly off, the door won't close squarely. This creates awkward gaps and pinch points that will chew up a new seal.

- Worn Rollers or Hinges: Worn hardware can make the door wobble as it travels, preventing the seal from making the consistent, firm contact needed to do its job.

Fixing these root causes before installing new weatherstripping is what separates a quick patch from a lasting solution.

Precision Fitting for a Perfect Closure

Getting that perfect, airtight closure without interfering with the door's operation takes a level of precision that only comes with experience. The goal is a seal that makes light, even contact along the entire perimeter—anything more or less is a problem.

An improperly fitted seal can be just as bad as a worn-out one. If the seal is too tight, it creates friction that puts immense strain on the door opener, leading to premature motor burnout. If it’s too loose, you still have the drafts, pests, and energy loss you were trying to eliminate.

A professional technician knows how to measure, cut, and fasten seals to account for the subtle imperfections found in every door frame and concrete floor. This meticulous process ensures a gap-free closure that doesn't compromise the door’s safety features or operational health. Our technicians bring years of hands-on experience to every installation, a standard you can learn more about in our approach to commercial door installations in Toronto.

Choosing a professional install isn't an extra cost—it's an investment in the reliability and longevity of your entire overhead door system. It reinforces our promise of being your Respected Partners by ensuring the work is done correctly the first time.

Frequently Asked Questions About Commercial Door Seals

As your partners in keeping your facility running smoothly, we want to provide clear, straightforward answers to the most common questions we hear about garage door seals for top and sides.

How often should commercial door seals be replaced?

There’s no hard-and-fast rule, as the lifespan of a seal depends on usage, material, and environment. However, a quality commercial seal should provide 5 to 10 years of reliable performance. A loading dock door cycling dozens of times a day will wear out seals faster than one used infrequently. We recommend a visual inspection every quarter and a full "light test" annually to catch problems early.

Will new seals actually lower my energy bills?

Absolutely. This is one of the most immediate and tangible benefits. Gaps around your building are a massive source of energy loss, and a poorly sealed overhead door is often the biggest offender. A complete, properly installed perimeter seal can cut air leakage by over 90%, meaning your HVAC system isn’t constantly fighting to maintain temperature. For a climate-controlled facility, this can translate to thousands of dollars in savings each year.

What's the best seal for a food-grade facility?

For any sanitary environment like a food and beverage or pharmaceutical facility, durable vinyl or rubber seals are the required standard. These materials create a non-porous, solid barrier that is critical for preventing contamination. They can be easily cleaned and sanitized, helping you meet health and safety regulations.

While brush seals are excellent for general pest and dust control in many industrial settings, they are not suitable for food-grade applications. The bristles can trap organic material, making them impossible to sanitize properly and creating a compliance risk. A solid vinyl seal provides the complete closure these critical environments demand.

Your Next Step: A Proactive Facility Check

Making sure you have the right garage door seals for top and sides isn't just a minor fix—it’s a crucial investment in your facility's efficiency, cleanliness, and security. Don't wait until drafts, pests, or high energy bills force your hand. The biggest takeaway is to be proactive.

Your next step is simple: walk your facility and take a close look at your overhead doors. If you can see daylight around the edges, notice cracks, or feel that the weatherstrip has gone brittle, it's time to act. Those small gaps add up to significant energy loss and create vulnerabilities. As your Respected Partners committed to Reliable Service, we're here to help you protect your assets and lower your operating costs.

Ensure your facility is sealed, secure, and running at its best. Contact Wilcox Door Service today to schedule a professional assessment and get a quote for your facility.