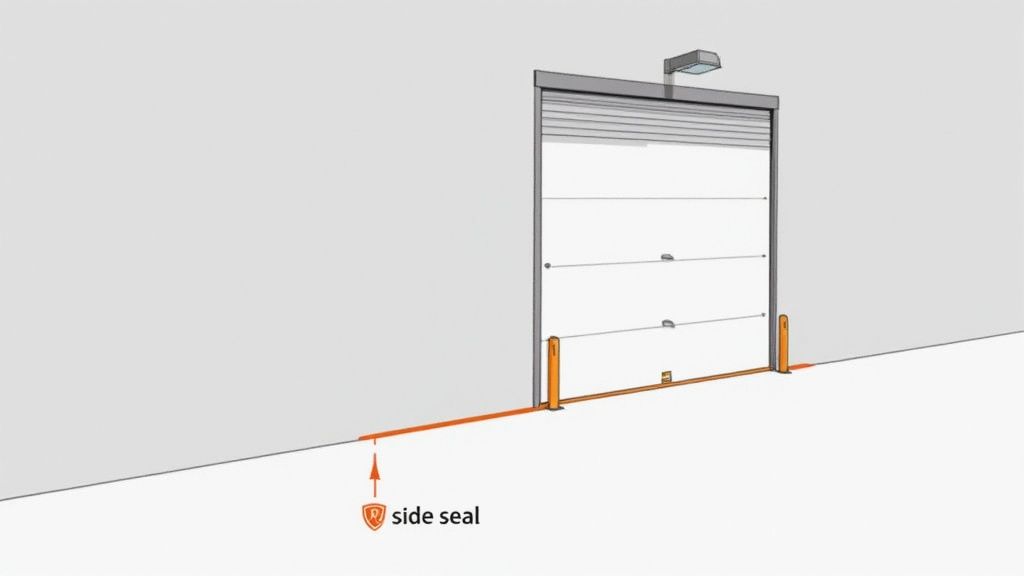

A commercial overhead door is your facility's primary shield against the outside world. To make that shield truly effective, you need a complete perimeter weatherstripping system, and the garage door side seal is a critical component. This guide explains how side, top, and bottom seals work together to protect your building, control your environment, and enhance operational efficiency, especially for commercial doors in demanding industries.

As your Respected Partners in facility maintenance, Wilcox Door Service believes that Reliable Service starts with expert knowledge. We'll break down everything you need to know about perimeter seals to make informed decisions for your business.

What You Will Learn in This Guide

This article provides a comprehensive overview of commercial overhead door perimeter weatherstripping. By the end, you will understand:

- The Complete Sealing System: How the garage door side seal works in tandem with top and bottom seals to create a complete barrier.

- Material Options: The key differences between vinyl, brush, and rubber seals and their ideal applications in commercial settings.

- Industry-Specific Requirements: Why specialized seals are non-negotiable for regulated industries like food processing and pharmaceuticals.

- Benefits and ROI: How proper sealing directly impacts energy costs, pest control, and regulatory compliance.

Why Complete Perimeter Sealing Is a Commercial Necessity

Small gaps around a commercial overhead door are more than a minor inconvenience; they are direct threats to your operational integrity. A complete perimeter weatherstripping system—which includes side seals, a top seal, and a bottom seal—is a foundational component of a high-performing door. It's not just an accessory; it's essential for climate control, cleanliness, and security.

Think of an unsealed door as a constant leak in your budget. Every gap allows conditioned air (heated or cooled) to escape, forcing your HVAC systems to work harder and driving up utility bills. Beyond energy waste, these gaps invite dust, rain, debris, and pests into your facility, compromising your inventory and work environment.

Real-World Example: In a large distribution centre, even a quarter-inch gap along the sides of ten loading dock doors can be equivalent to leaving a window wide open 24/7. The resulting energy loss and potential for contamination can cost thousands annually.

A complete seal acts as a formidable barrier, protecting your assets and maintaining a stable internal environment. For more insights on this, explore our guide on enhancing commercial door energy efficiency.

Climate Control and Product Integrity

For industries where temperature and environmental stability are critical, a perfect seal is paramount.

Consider a pharmaceutical storage facility. Product efficacy often depends on maintaining a precise temperature range. A compromised garage door side seal can create a "thermal breach"—a weak point where outside air infiltrates the controlled space. This can lead to temperature fluctuations that spoil entire batches of valuable inventory, resulting in catastrophic financial loss and regulatory non-compliance. The integrity of a temperature-sensitive supply chain is only as strong as its weakest seal.

A Critical Defense Against Pests and Contaminants

For any commercial facility, especially in the food and beverage sector, pest management is a top priority. A properly sealed overhead door is one of your most effective defenses.

Rodents can squeeze through gaps as small as a dime, and insects require even less space. A complete perimeter seal, particularly a well-fitted garage door side seal and bottom weatherstrip, physically blocks their entry.

- Pest Prevention: A tight seal denies rodents and insects an easy way into your facility.

- Debris Blocking: It prevents dust, dirt, leaves, and wind-driven rain from contaminating your workspace.

- Compliance: Meeting strict standards from bodies like the Canadian Food Inspection Agency (CFIA) requires a demonstrably pest-proof and clean facility.

Investing in quality weatherstripping is a proactive measure that helps you avoid the high costs of extermination, product loss, and operational shutdowns. It works hand-in-hand with other protective elements, like those discussed in our essential guide to choosing the right dock seal.

Choosing the Right Seal: Vinyl, Brush, and Rubber Options

Selecting the right perimeter weatherstripping involves matching the material's properties to your facility’s specific operational challenges. Just as you'd choose different tires for different vehicles, you need to select the right seal for the job. The three primary options for commercial doors are vinyl, brush, and heavy-duty rubber.

Vinyl Stop Moulding: The Versatile Standard

Vinyl weatherstripping is the most common type used on commercial doors. It consists of a rigid retainer (typically aluminum or PVC) that holds a flexible vinyl flap. This flap presses against the face of the door, creating a seal.

- What it is: A simple, effective, and cost-efficient solution for creating a barrier against drafts and moisture.

- Best For: Standard warehouses, automotive bays, and retail facilities with smooth, even door surfaces and frames.

- Consideration: In extreme cold, vinyl can become stiff and brittle, and prolonged UV exposure can cause it to crack over time, reducing its effectiveness.

Dense Brush Seals: The Conforming Protector

Brush seals are made from dense polypropylene bristles tightly packed into an aluminum retainer. Unlike a rigid vinyl flap, the thousands of flexible bristles can conform to uneven surfaces.

- What it is: A flexible wall of bristles that adapts to irregularities in the door or floor.

- Best For: Food processing plants, agricultural facilities, and older buildings where surfaces may not be perfectly smooth. Brush seals excel at blocking fine dust and are a powerful deterrent against insects.

- Real-World Example: At a grain processing facility, fine airborne dust is a constant issue. A standard vinyl seal would let particles seep through minor gaps, but a dense garage door side seal made of brush material effectively traps the dust, maintaining a cleaner environment and protecting equipment.

Heavy-Duty Rubber Seals: The Durable Defender

In high-traffic, demanding environments like busy loading docks, durability is paramount. Heavy-duty seals made from EPDM (ethylene propylene diene monomer) rubber are engineered for this challenge.

- What it is: A robust, thick synthetic rubber seal known for its exceptional resistance to impact, abrasion, and extreme weather.

- Best For: Manufacturing plants, distribution centres, and any high-cycle loading dock where accidental contact from forklifts or pallets is common.

- Consideration: EPDM rubber typically has a higher upfront cost, but its superior longevity in harsh conditions makes it a smart long-term investment.

Choosing the right material is a strategic decision that impacts your operational costs and facility integrity. For more on maintaining your loading bay seals, see our guide on dock seal replacement.

Specialized Seals for Regulated Industries: Food & Pharma

For facilities in food processing, pharmaceuticals, or cleanroom environments, a standard garage door side seal is insufficient. These industries operate under strict regulations where hygiene and contamination control are non-negotiable. A generic seal can fail to meet standards set by bodies like Health Canada or the CFIA, putting the entire operation at risk.

Meeting standards like NSF certification for equipment demonstrates the level of detail required, and your door seals are no exception.

Key Features for Compliant Sealing Solutions

- FDA-Compliant Materials: Seals must be made from materials certified as safe for food contact, ensuring no harmful chemicals can leach into the controlled environment.

- Wash-Down Rated Construction: In food plants, daily high-pressure, high-temperature wash-downs are common. Seals must be made of non-porous materials that withstand caustic cleaning agents without degrading or harbouring bacteria.

- Complete Barrier for Pest Control: A seamless perimeter seal is a core requirement of any Hazard Analysis Critical Control Point (HACCP) plan, as it provides a physical barrier against pests.

Real-World Example: In a pharmaceutical cleanroom, maintaining precise air pressure is critical to prevent cross-contamination. An improperly fitted or worn garage door side seal can cause an air leak, compromising the pressure differential. This can lead to a failed audit, contaminated product batches, and costly production halts.

A complete and robust perimeter sealing system—integrating side, top, and bottom seals—is essential for ensuring compliance, product safety, and operational continuity in these sensitive industries.

How to Spot a Failing Seal and When to Replace It

A garage door side seal rarely fails suddenly. It provides clear warning signs, and proactive inspection allows facility managers to schedule replacements before a minor issue becomes a major problem. Regular checks can prevent emergency downtime, energy loss, and pest infestations.

Telltale Signs of a Worn-Out Seal

Perform this quick visual check on your overhead doors regularly:

- Visible Daylight: The most obvious sign. With the door closed, stand inside and look along the edges. If you see light, your seal has failed.

- Cracked or Brittle Material: Healthy vinyl or rubber should be flexible. If the seal is stiff, cracked, or crumbling, it has lost its effectiveness.

- Permanent Compression: A seal that looks permanently flattened, even when the door is open, has lost its ability to spring back and create a tight barrier. This is known as "compression set."

- Physical Damage: Look for tears, rips, or sections that have been pulled away from the door frame, often caused by operational impacts.

A proactive inspection schedule is a facility manager's best tool for cost control. Identifying a failing seal early prevents the cascading problems of energy loss and contamination, saving significant money down the line.

Knowing when to replace other critical seals is also important. For more information, read our blog on when to consider a dock seal replacement.

If you spot any of these red flags, it’s time to consult a professional. As your Respected Partners, Wilcox Door Service provides the Reliable Service needed to keep your facility perfectly sealed.

Professional Installation: The Key to a Perfect Seal

Even the highest-quality garage door side seal will fail if not installed correctly. Professional installation is not just about attaching the seal; it's about ensuring a precise, airtight fit that delivers maximum performance and longevity. A small misalignment on a large commercial door can create a significant gap, defeating the purpose of the new seal.

Our union-certified technicians understand the nuances of a proper installation, from selecting the correct fasteners for steel or concrete jambs to ensuring the seal makes perfect contact along the entire length of the door.

A Comprehensive System Assessment

When our team arrives on-site, they do more than just replace a part. They conduct a holistic assessment of the entire door system to identify underlying issues that could compromise the new seal's effectiveness. These issues can include:

- Warped Door Panels: Damaged sections that prevent the seal from sitting flush.

- Misaligned Tracks: Door tracks that have shifted, creating an uneven gap.

- Damaged Door Jambs: A compromised frame that cannot securely hold the seal retainer.

By identifying and addressing these root causes, we deliver a long-term solution, not just a temporary fix. This is central to our promise: Respected Partners, Reliable Service.

In specialized facilities, a comprehensive approach to safety and efficiency is key. For a broader look at facility health, learning about services like occupational hygiene consulting can highlight the importance of controlling all environmental factors.

Partner with Wilcox Door Service to ensure your facility is sealed correctly and completely.

A properly sealed commercial door is a cornerstone of an efficient, compliant, and secure facility. From reducing energy costs to preventing contamination, the benefits of a complete perimeter weatherstripping system are clear.

Ready to enhance your facility's performance? Schedule a comprehensive service inspection with our experts today.