That small gap around your commercial garage door isn’t just a minor annoyance—it’s a significant drain on your budget and a weak point in your building’s defence. In this guide, you will learn why a high-quality garage door weather seal for the top and sides is a strategic asset for any facility manager, how to select the right materials for your specific needs, and the correct steps for installation and maintenance. Understanding this critical component is the first step toward enhancing energy efficiency, operational security, and long-term cost savings.

The Unsung Heroes of Your Commercial Facility

Alt text: A modern garage with icons illustrating how a garage door weather seal for top and sides protects against energy loss, pests, and water.

Think of your facility as a sealed container designed to protect everything inside from the outside world. This concept is often called the “building envelope”—essentially, the physical barrier between the conditioned indoor environment and the unconditioned outdoors. Effective weather seals are crucial components of this defence system, directly contributing to the importance of the building envelope for thermal performance and structural longevity. When the perimeter seals on your largest moving wall—the garage door—are compromised, the entire envelope fails.

This guide moves beyond basic tips to show you exactly why investing in the right seals is a direct path to cutting your operational costs and risks. As your “Respected Partners, Reliable Service,” we believe in empowering you with the knowledge to make smart, informed decisions for your facility.

Why Top and Side Seals Are Non-Negotiable

While the bottom seal often gets all the attention, the top and side seals are just as vital for creating a complete barrier. They work together as a system to prevent a whole range of costly issues that can grind your operations to a halt.

Here’s what a robust sealing system protects you from:

- Significant Energy Loss: Unsealed gaps let your heated or cooled air pour right outside, forcing HVAC systems to work overtime. This is especially true in Canada’s harsh winters, where poorly sealed doors at a loading dock can account for up to 30% of a facility’s heat loss.

- Pest and Debris Infiltration: Those small gaps are an open invitation for rodents, insects, dust, and dirt. All of which can contaminate products, damage sensitive equipment, and create an unpleasant work environment.

- Water and Moisture Damage: Wind-driven rain and melting snow can easily seep through perimeter gaps. This leads to rusted door components, damaged inventory, and hazardous, slippery floors right where your team is working.

A complete perimeter seal is the first line of defence for your facility’s interior environment. Neglecting the top and sides is like locking your front door but leaving the windows wide open.

This guide will walk you through everything from material selection to maintenance, ensuring your facility remains secure, efficient, and compliant. For a deeper look into the different types available, you can also explore our detailed breakdown of weatherstrip options for your garage door.

Choosing the Right Seal for Your Application

Picking the right garage door weather seal for the top and sides isn’t a one-size-fits-all job. It’s a calculated choice that hinges on your facility’s environment, day-to-day operations, and the local climate. The seal that works perfectly for a dry storage unit in a mild climate will fail miserably at a food processing plant or a cold storage warehouse in the dead of winter.

Let’s cut through the jargon. We’ll break down the most common materials and profiles to give you the practical knowledge you need to specify the right seal for your exact situation.

Understanding Weather Seal Materials

The material is the heart of your weather seal. It dictates how long it lasts, how flexible it stays, and how well it stands up to the elements. In the commercial world, three materials really dominate the scene, each with its own strengths.

- PVC (Polyvinyl Chloride): This is the workhorse of the industry—cost-effective and a solid choice for general-purpose use. It handles moisture and abrasion well, making it a good fit for standard warehouses or manufacturing facilities where you aren’t dealing with extreme temperatures or harsh chemicals.

- TPE (Thermoplastic Elastomer): Think of TPE as a significant performance upgrade. It blends the toughness of rubber with the versatility of plastic, staying flexible across a much wider temperature range. From scorching summers to freezing winters, it won’t crack or turn brittle like cheaper options.

- Brush Seals: Made of dense nylon or polypropylene bristles, these are brilliant at blocking dust, debris, and pests without needing a perfectly rigid seal. Brush seals are ideal for facilities with uneven floors or high-traffic doors because the bristles conform to imperfections and reduce friction as the door moves.

For a deeper dive into the materials used across different sealing applications, check out our guide on the types of exterior door weatherstripping. It offers extra insights that can help round out your decision.

Comparing Commercial Weather Seal Materials

To make the choice a bit clearer, here’s a practical look at how these materials stack up. Think of this as your cheat sheet for matching the material to your facility’s unique challenges.

| Material Type | Optimal Temperature Range (Celsius) | Key Benefits | Best Suited For (Example Applications) |

|---|---|---|---|

| PVC | -20°C to 65°C | Cost-effective, good moisture resistance, widely available. | General warehouses, light manufacturing, low-traffic storage units. |

| TPE | -50°C to 120°C | Excellent flexibility in extreme cold/heat, durable, chemical resistant. | Cold storage, food processing plants, high-traffic distribution centres. |

| Brush Seal | -40°C to 100°C | Conforms to uneven surfaces, stops pests and dust, low friction. | Hangar doors, facilities with sloped floors, high-dust environments. |

Ultimately, the right material choice comes down to knowing your environment. A quick look at this table can steer you away from a material that’s bound to fail and toward one built to last in your specific conditions.

Matching the Material to the Mission

Let’s put this into context with a few real-world scenarios. Imagine you’re the facility manager for three different sites across Canada, each with its own sealing puzzle to solve.

Scenario 1: The Food Processing Plant in Ontario

Here, your top priorities are hygiene and keeping pests out. A standard PVC seal might do the job, but a TPE seal creates a much denser, more reliable barrier against insects and rodents. A dense brush seal is another excellent choice, as it can stop fine dust from getting in, helping you keep the environment clean and compliant with food safety standards.

Scenario 2: The Heavy Manufacturing Facility in Alberta

At this site, the loading dock doors get hit with chemical splashes and abrasive dust. A standard PVC seal wouldn’t last a season. You absolutely need a durable, chemical-resistant TPE or a heavy-duty brush seal to stand up to that kind of punishment and avoid premature failure.

Scenario 3: The Cold Storage Warehouse in Calgary

This is where material choice is non-negotiable. In a facility chilled to -30°C, a PVC seal would become as brittle as cheap plastic and shatter on impact. The only real option is an arctic-grade TPE seal, specifically engineered to stay flexible in deep-freeze conditions. Anything less will lead to ice buildup and catastrophic energy loss.

Choosing the wrong material isn’t just a minor mistake; it’s a direct threat to your operational efficiency, product integrity, and energy budget. Always match the material’s properties to your facility’s specific environmental stressors.

Decoding Seal Profiles and Retainers

Beyond the material, the shape of the seal—its profile—dictates how it actually meets the door and frame. The seal itself is held in place by an aluminum or PVC retainer, a rigid mounting strip which gets fastened to the door jamb or header.

Common profiles include:

- Single-Blade: A simple, flexible flap that presses against the door. It’s a good, straightforward solution for standard, well-aligned doors.

- Double-Blade or Fin: This profile has two blades, which creates a redundant seal and can trap a pocket of air for better insulation. It’s an excellent upgrade for any energy-conscious facility.

- Reverse Angle: Designed to mount on the face of the jamb, this profile is a problem-solver for doors where a standard straight retainer just won’t fit right.

The retainer itself also comes in different angles (like 45° or 90°) to work with various track setups and jamb configurations. A professional can quickly figure out the exact retainer and profile combination needed for a truly airtight fit on your specific door system. Getting this right is the difference between a seal that just covers a gap and one that truly performs.

When you need a professional assessment to ensure you’ve selected the perfect seal, our team is ready to help. As your respected partners, we provide reliable service to inspect your facility and recommend a solution that meets your operational and budgetary needs.

Mastering the Installation Process

Choosing the right garage door weather seal top and sides is only half the battle. A top-tier seal is useless if it’s not installed correctly—it’ll fail, and your facility will be right back where it started. We’ve seen it all on service calls over the years, so we’ve put together this practical, field-tested guide for in-house maintenance teams to get the job done right the first time.

We’ll walk you through the entire process, from prep and safety to removing the old seals, and finally, fastening the new ones for a perfect, airtight fit.

Preparing the Door and Work Area

Before you even think about picking up a tool, you need to get the area safe and the door prepped. Rushing this first phase is one of the most common mistakes we see, and it often leads to accidents or a shoddy final result.

First things first: always disconnect the power to the garage door operator at the breaker panel. This isn’t optional. It’s a critical safety step to ensure the door can’t be activated while you’re working on it.

With the power off, manually close the door. Engage the slide lock or, for extra security, place a pair of C-clamps securely on the vertical tracks just above the bottom rollers. This physically stops the door from moving. Remember, commercial doors are under immense spring tension and can cause severe injury if they move unexpectedly.

Finally, give the door jambs and header a thorough cleaning. Use a mild solvent or degreaser to get rid of all the dirt, grime, and old adhesive. You need a clean surface for the new retainer to sit flush and create that crucial airtight seal.

Safely Removing Old and Worn Seals

Once the door is secured, you can start taking off the old weather stripping. Most top and side seals are held in an aluminum retainer that’s been screwed or nailed to the door frame.

Grab a pry bar or the claw end of a hammer and gently start lifting the old retainer away from the jamb. Don’t try to rip it all off in one go. Work your way along its length, prying a little at a time to avoid gouging the wood or steel frame underneath.

After the retainer is off, take a good look at the jamb for any damage like rot or rust. Now is the perfect time to make those small repairs. A compromised door frame means the new seal will never fit right, so fixing these issues now will save you a world of headache troubleshooting leaks later on.

Getting Precise Measurements and Cuts

When you’re sealing a door, accuracy is everything. “Close enough” won’t cut it if you want to create a real barrier against the elements. You’ll need a tape measure, a pencil, and a hacksaw with a fine-toothed blade for the aluminum retainer.

Here’s our tried-and-true method for getting it right:

- Measure the Vertical Sides: Measure the height of the door opening from the floor to the header on both the left and right. Don’t trust your memory—write these numbers down.

- Measure the Top: Now, measure the width of the door opening along the header.

- Cut the Retainers: Using your hacksaw, cut your two side retainer pieces to the exact heights you just measured. Then, cut the top retainer piece to match the width.

Pro Tip: For an absolutely perfect cut on an aluminum retainer, use a miter saw with a blade made for non-ferrous metals. You’ll get a clean, burr-free edge that makes fitting the corners a breeze.

This visual guide breaks down the core decisions you need to make before you start the installation.

Alt text: A 3-step infographic for choosing a garage door weather seal: 1) assess needs, 2) select material, and 3) choose a profile.

As the infographic shows, a successful installation begins long before you pick up a drill. It starts with a clear-eyed assessment of your facility’s specific operational and environmental challenges.

Fastening New Seals for a Perfect Fit

It’s time to install the new retainer and seal. This is where your patience and precision will really pay off. You’ll need a drill, the right self-tapping screws for your jamb material (wood or steel), and a level.

Start with the top retainer. Position it along the header and use your level to make sure it’s perfectly straight. If the retainer is crooked, it will put uneven pressure on the seal and leave gaps. Secure it to the header every 12 to 18 inches with self-tapping screws.

Next up are the side retainers. Line them up so they’re flush with the top retainer to create a nice, tight corner. Once again, use a level to ensure they are perfectly vertical before fastening them every 12 to 18 inches.

The Art of the Mitre Cut

The corners where the top and side seals meet are the most common places for leaks to appear. A simple butt joint almost always leaves a small triangular gap. To prevent this, you need to make a clean mitre cut.

This means cutting the ends of the flexible vinyl or rubber seal insert—not the aluminum retainer—at a 45-degree angle where they meet. When the two 45-degree cuts come together, they form a perfect, gap-free 90-degree corner. A sharp utility knife and a mitre box will give you the best results.

With the retainers firmly in place, you can now slide the flexible weather seal insert into the channel. Start at one end and gently feed it through. If it’s a tight squeeze, a quick spray of silicone lubricant will make the job much easier. Once the insert is all the way in, trim any excess with your utility knife for a clean, professional finish.

The final step is a simple visual check. Go inside the garage, turn off the lights, and look for any daylight creeping in around the perimeter. If you see light, the seal isn’t making good contact. You might need to slightly adjust the retainer to apply a bit more pressure against the door. This last check ensures all your hard work pays off with a truly sealed entryway.

We want to empower your team with the knowledge to handle these jobs in-house. But if this process seems a bit much, or if you just want to guarantee a perfect installation, our union-certified technicians are always ready to help.

Contact Wilcox Door Service today for an expert installation quote or to schedule a full facility door inspection.

Building a Proactive Maintenance and Inspection Plan

Putting in a new garage door weather seal for the top and sides is a great start, but it’s definitely not a “set it and forget it” job. The best way to dodge the cost and downtime of an emergency repair is to catch problems before they even begin. Switching from a reactive mindset to proactive asset management is the secret to getting the most life out of your seals and making sure they do their job day in and day out.

This really just means creating a simple, consistent inspection schedule. A little bit of planned effort now will save you from major headaches down the road, keeping your facility secure, efficient, and free from those surprise failures.

What to Look For During Inspections

Regular visual checks are the bedrock of any solid maintenance plan. Your in-house team can easily handle these inspections every quarter or twice a year, depending on how hard your doors work and what your local climate throws at them.

Here’s a practical checklist of what to keep an eye on:

- Brittleness and Cracks: Get your hands on the seal material. It should feel flexible and soft. If it’s hard, stiff, or you can see cracks—especially in the corners—it’s lost its flexibility and is on the verge of failing.

- Visible Gaps or Daylight: This one is impossible to miss. Close the door, turn off the lights inside, and look for any daylight creeping in around the edges. Even the smallest sliver of light is a breach in your building’s defenses.

- Compression Set: Over time, a seal can get squashed flat from constant pressure. In technical terms, we call this compression set. If the material no longer bounces back to its original shape, it can’t create the tight barrier you need to block drafts and water.

- Physical Damage: Be on the lookout for any tears, gouges, or bits that have been pulled away from the retainer. This kind of damage is especially common around loading docks where doors take a lot of abuse.

Common Causes of Premature Seal Failure

If you understand why seals fail, you can get ahead of the problems. It’s rarely just old age; the environment a seal lives in plays a massive role in how fast it breaks down.

Think about a south-facing loading dock door getting blasted by the sun all day. That constant UV radiation will destroy a standard PVC seal way faster than one on a shaded side of the building. Or imagine a chemical plant where airborne solvents cause a seal to swell up, get soft, and lose its shape in just a few months. Identifying these unique stressors at your facility helps you pick the right material from the get-go and know which doors need a closer look more often.

To make sure your entire property benefits from this kind of proactive care, it’s worth consulting a comprehensive seasonal home maintenance checklist; the principles of staying ahead of problems apply just as much to commercial assets.

Real-World Example: A property manager we work with runs several large distribution centres with over 50 loading dock doors. Before winter hits, his team spends about 30 minutes per door applying a silicone-based lubricant to all their PVC perimeter seals. This simple task keeps the material flexible and stops it from freezing to the door, which has cut their emergency calls for torn seals by an estimated 40% during the coldest months.

Seals as a Critical Safety Component

Beyond just saving on energy bills, your garage door weather seal for the top and sides can also be a critical piece of life-safety equipment, especially in certain environments.

In wildfire-prone areas like British Columbia and Alberta, where Wilcox Door Service Inc. provides coast-to-coast solutions, these seals are vital for ember resistance at industrial sites and airports. Building codes are catching on. The 2020 California Building Code, which has influenced Canada’s regional codes like the one in BC, now requires exterior garage doors to have no gaps at the top and sides to block ember intrusion. Post-wildfire assessments, like those after the 2021 Lytton fire, showed that unsealed doors were a factor in 40% of commercial building losses.

A proactive maintenance plan isn’t just about protecting your budget. It’s about protecting your people, your assets, and your ability to stay open for business.

If you need a hand setting up a planned maintenance program for your facility’s doors, our team is here to help. We provide the reliable service that respected partners depend on.

How to Troubleshoot Common Seal Failures

Even the best garage door weather seal top and sides will eventually run into issues, especially in a busy commercial facility. When you spot a problem, figuring it out quickly saves time, stops further damage, and keeps your building secure. Think of this section as your field guide for diagnosing and fixing the most common seal failures we see every day.

We’ll go beyond just pointing out what’s wrong and give you clear steps to make it right. It’s a practical guide for your maintenance team to pinpoint the root cause and get your doors sealed up fast.

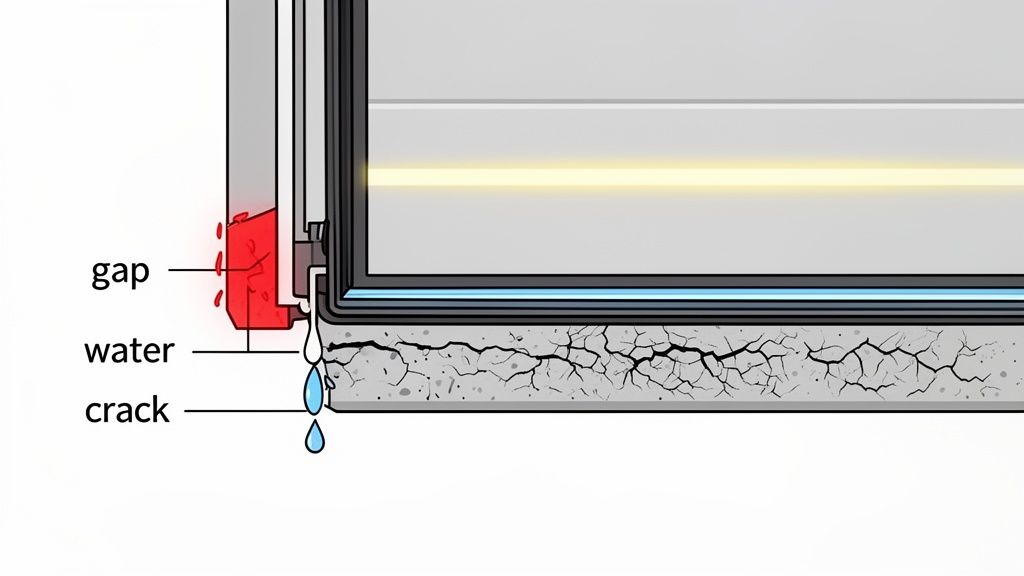

Alt text: Diagram showing water entering under a garage door, highlighting why a comprehensive top and side weather seal is crucial.

Problem One: Persistent Drafts or Visible Daylight

One of the first calls we get is about seeing daylight peeking around the edges or feeling a draft even when the door is shut tight. That’s a dead giveaway that the seal isn’t making solid contact with the door anymore.

Likely Causes:

- Compression Set: Over time, the seal material has been squashed flat and has lost its bounce. It can’t spring back into shape to fill the gap.

- Improper Retainer Placement: The aluminum retainer holding the seal might be set too far back from the door, so it isn’t creating enough pressure for a tight seal.

- Shrinkage: We often see this with lower-quality PVC seals. When the temperature drops, the material shrinks and pulls away from the corners, leaving you with obvious gaps.

Actionable Solutions:

Go out and give the seal a squeeze. If it feels hard, brittle, or just stays flat, the material has given up. It’s time for a replacement.

If the seal itself feels fine, take a look at the retainer’s position. Sometimes, you can get away with a slight adjustment, moving it closer to the door to increase the pressure. For those stubborn gaps right in the corners, a specialized corner seal block can often be a quick and effective fix. If the alignment is more complicated, a professional adjustment from a crew like our 24/7 emergency repair team is your best bet.

Problem Two: Water Seeping In at the Bottom Corners

Finding puddles inside the facility after it rains is more than just an annoyance—it’s a serious slip hazard that can ruin inventory. This problem almost always points to a breakdown at the critical spot where the side seals and the bottom seal are supposed to meet.

Don’t underestimate small water intrusions. Over time, they can lead to concrete damage, rust on the door tracks, and costly product spoilage, especially in food-grade or pharmaceutical facilities.

Likely Causes:

- Poor Mitre Cuts: The 45-degree angle cuts on the side seals might not have been done correctly during the initial installation. This leaves a small but pesky triangular gap that water loves to find.

- Worn or Damaged Bottom Seal: The bottom seal itself could be torn, cracked, or completely compressed, letting water sneak past and pool up near the corners.

- Uneven Concrete Floor: Over years of use, the floor right at the doorway can settle or crack, creating low spots where water collects and eventually seeps under the seal.

Actionable Solutions:

Start by inspecting the corner cuts. If they’re just pushed together (a butt joint) instead of being properly mitred, they need to be replaced and cut correctly. Next, get a good look at the bottom seal for any obvious damage.

If the floor is the real culprit, installing a threshold seal directly on the concrete can create a raised barrier, effectively damming the water out. Keeping your facility properly sealed is a huge part of our comprehensive planned maintenance programs, designed to catch these issues early.

If your troubleshooting points to a bigger problem with the door’s alignment or structure, don’t hesitate to reach out. As your “Respected Partners, Reliable Service,” we’re here to help diagnose and solve the problem for good.

The Real ROI of a Properly Sealed Garage Door

Thinking of a high-quality garage door weather seal for the top and sides as just another maintenance expense is a mistake. It’s actually a strategic investment with a real, tangible return. The financial upside goes way beyond just knocking a few dollars off your utility bill. When you properly seal your building’s biggest moving wall, you directly impact your operational costs, the lifespan of your equipment, and even your ability to stay compliant.

It’s pretty easy to connect the dots between a simple rubber seal and your bottom line. The most immediate payback comes from energy savings. Every gap around that massive door is a constant drain on your HVAC system, forcing it to work longer and harder just to hold the temperature. Sealing those gaps puts a direct, measurable stop to that energy waste.

Quantifying the Financial Impact

These savings aren’t just theoretical. A 2022 Natural Resources Canada study of 1,000 industrial facilities in Quebec and Ontario found that simply optimizing perimeter seals slashed overall building energy use by a staggering 12-22%.

Digging deeper, they found top and side seals specifically curbed 15% of all garage-related energy losses. For a typical 10,000 sq ft distribution centre, that translated to an average annual savings of $10,200. You can see how these numbers add up when industry experts champion these kinds of upgrades.

But the return on investment (ROI) is about more than just your hydro bill. Think about these other financial wins:

- Reduced HVAC Strain: When your heating and cooling units aren’t running constantly, they get less wear and tear. That means you can delay expensive repairs or, even better, the premature replacement of major capital equipment.

- Asset Protection: Keeping moisture, dust, and debris out is huge. It protects valuable inventory from damage, stops sensitive equipment from failing, and prevents your concrete floors from spalling and cracking.

- Pest Control Savings: A tight seal is your best—and cheapest—line of defence against rodents and insects. It dramatically cuts down the need for expensive, ongoing pest control services.

Beyond the Balance Sheet: Compliance and Safety

For a lot of Canadian industries, proper sealing isn’t just a good idea—it’s the law. If you’re in the food and beverage or pharmaceutical sectors, you have to maintain a pristine environment to meet strict health and safety regulations. A single compromised seal can lead to contamination, failed audits, and serious headaches.

A complete and properly installed weather seal system is not merely a component of the door; it is a critical element of your facility’s operational integrity, safety protocol, and regulatory compliance framework.

It gets even more serious with fire-rated doors. These require specialized intumescent seals that are mandatory for preventing the spread of smoke and flames. Ignoring this isn’t just a compliance issue; it’s a major life safety risk with severe legal and financial consequences. Taking these simple steps now can have a massive impact, and you can learn more about how to save energy and money with Wilcox and Enbridge through these kinds of strategic partnerships.

Ultimately, a well-sealed door pays for itself many times over. The combination of lower energy costs, less downtime, protected assets, and guaranteed compliance makes it a foundational investment in a more efficient, resilient, and profitable facility.

Your facility’s performance depends on the reliability of every component. At Wilcox Door Service Inc., we provide the expert audits, professional installations, and planned maintenance programs you need to realize the full ROI of your access points. Partner with us for service that keeps your operations secure and efficient.

Contact Wilcox Door Service today to schedule a service inspection and eliminate your seal problems.