As a facility manager for a commercial or industrial building, you know the importance of durable and reliable entryways. This guide will walk you through everything you need to know about the hollow metal door—the industry standard for pedestrian doors in demanding environments. You will learn about their construction, the benefits they offer for commercial and industrial settings, how to select the right one for your needs, and why professional installation and maintenance are critical for safety and longevity.

Don’t let the name fool you. While “hollow,” these doors are anything but weak; their layered construction is precisely what makes them so strong and versatile. A hollow metal door is an engineered assembly, built with two layers of steel sandwiching an inner core, creating a solution prized for its durability, security, and performance.

Why a Hollow Metal Door is a Commercial Facility Standard

When you need a pedestrian door that can withstand the daily grind of a high-traffic area, a hollow metal door is the default choice. Unlike wood or fibreglass doors that can warp, crack, or dent easily, these steel doors are engineered to last for decades, delivering a superior return on your investment.

Imagine a busy loading dock entrance or a service door connecting a warehouse floor to an office. These doorways endure constant use, occasional bumps from carts, and fluctuating temperatures. A standard residential door would fail within months, but a Wilcox hollow metal door assembly is designed specifically for that kind of punishment. Our doors are built for the commercial and industrial world, ensuring they stand up to the unique pressures of your environment.

Built for Strength and Security

The core strength of a hollow metal door lies in its steel construction. The steel face sheets, combined with a reinforced frame, create a formidable barrier against forced entry, vandalism, and accidental impact. This inherent security is why they are specified for exterior access points, secure storage rooms, and any area requiring controlled access.

This robust build provides facility managers with peace of mind when it comes to protecting assets and ensuring personnel safety. For a deeper look at securing your facility, explore our insights on commercial metal doors.

Versatility in Performance

Beyond raw strength, the true advantage of a hollow metal door is its customizable performance. The “hollow” space between the steel panels is filled with different core materials to handle specific jobs.

- Fire Safety: Filled with specialized cores like mineral wool, these doors can achieve fire ratings of up to three hours. This makes them an essential component of a building’s life safety system, crucial for containing fires and protecting escape routes.

- Energy Efficiency: A polyurethane foam core transforms the door into an excellent insulator. In technical terms, it provides a high R-value, which simply means it’s very effective at stopping heat transfer. This helps lower HVAC costs—a significant benefit for exterior doors in Canada’s variable climate.

- Sound Control: In facilities like hospitals, schools, or offices, acoustical cores can be used to dampen sound transmission, creating quieter and more productive environments.

This adaptability makes the hollow metal door the perfect solution for nearly any application within a commercial or industrial building. At Wilcox Door Service, our “Respected Partners, Reliable Service” philosophy means we guide you to the exact door configuration that solves your facility’s unique challenges.

Ready to find the right door solution for your facility? Contact us for a professional consultation or quote.

Exploring the Anatomy of a Hollow Metal Door

To fully appreciate the strength of a hollow metal door, it helps to look beyond its tough exterior and understand its internal construction. While they may look simple, these doors are engineered systems where every component serves a purpose. The design is a masterclass in balancing strength, weight, and performance.

It all starts with the steel face sheets—the two layers of steel forming the front and back of the door. These provide the initial defense against impacts, weather, and unauthorized entry. But what truly defines the door’s performance is the material sandwiched between those sheets.

The Critical Role of the Door Core

That “hollow” space isn’t empty; it’s filled with a specific core material. This choice transforms a basic steel door into a high-performance solution tailored to a specific environment. Think of it like choosing the right insulation for a building—the material dictates how it performs.

Each core type offers a distinct advantage, allowing facility managers to specify a door that meets precise needs, whether for thermal efficiency, sound control, or fire safety.

A hollow metal door isn’t just a slab of steel; it’s an engineered assembly. The core material is the hidden hero that defines its performance, turning a simple barrier into a tool for energy savings, fire safety, or acoustic privacy.

The demand for these versatile doors is strong. North America’s steel door market, which includes hollow metal types, was valued at USD 4.4 billion in 2023 and is projected to grow. In Canada, this growth is partly driven by commercial construction, where security and durability are top priorities. You can learn more about steel door market trends from this detailed report.

Common Core Types and Their Applications

Understanding the primary core options clarifies how a hollow metal door can be adapted for virtually any commercial setting. Let’s break down the most common types and their ideal applications.

- Honeycomb Core: This is the standard, most common core. It consists of a kraft paper honeycomb structure treated for moisture resistance. It provides excellent rigidity and flatness at a low weight and cost, making it ideal for interior doors in offices, retail spaces, and light industrial areas where fire or temperature control isn’t the main concern.

- Polystyrene Core: When you need thermal insulation, a polystyrene slab is bonded to the steel face sheets. This core acts like a high-performance cooler, significantly reducing heat or cold transfer. It’s a perfect choice for exterior doors or those separating heated and unheated zones, like a warehouse and an office.

- Polyurethane Core: A step up from polystyrene, polyurethane foam offers even better insulating properties (a higher R-value) and adds superior structural strength. The foam is injected into the door cavity, where it expands and bonds to every surface, creating an exceptionally tough and energy-efficient unit.

- Mineral Wool Core: When fire safety is the top priority, a mineral wool core is the solution. This dense, fibrous material is inherently fire-resistant and is key to achieving high fire ratings—often up to three hours. It also provides excellent sound-dampening qualities, making it a great choice for stairwells, electrical rooms, and anywhere you need to contain fire and noise. For more on this critical topic, explore our guide to understanding fire-rated doors.

To help visualize these differences, here’s a quick comparison of the common core materials to help you match the right door to your facility’s needs.

Comparing Hollow Metal Door Core Types

| Core Type | Primary Benefit | Best Use Case Example | Typical Performance Rating |

|---|---|---|---|

| Honeycomb | Lightweight & Economical | Interior office or retail storeroom doors | Standard structural, minimal thermal/fire |

| Polystyrene | Good Thermal Insulation (R-Value) | Exterior doors, separating heated/unheated spaces | Good thermal, moderate structural |

| Polyurethane | Excellent Thermal & Structural | Cold storage, high-traffic exterior doors, high-security | Excellent thermal, superior structural |

| Mineral Wool | Fire Resistance & Acoustics | Stairwells, electrical rooms, building separations | Fire ratings up to 3 hours, excellent sound control |

As you can see, selecting the right core is a crucial decision that directly impacts your facility’s safety, energy efficiency, and occupant comfort.

Partnering with experts ensures you get the right anatomy for your application. At Wilcox Door Service, our “Respected Partners, Reliable Service” commitment means we help you specify the exact components your facility needs. Contact us to discuss your project requirements today.

Decoding Steel Gauge and Material Strength

When evaluating a hollow metal door, its toughness and longevity often come down to one critical number: the steel gauge. This number indicates the thickness of the steel face sheets and is the foundation of the door’s ability to withstand daily wear and tear.

Understanding gauge can seem counterintuitive at first. With steel gauge, a lower number means thicker, stronger, and more durable steel. A lower gauge number signifies a more robust and resilient door.

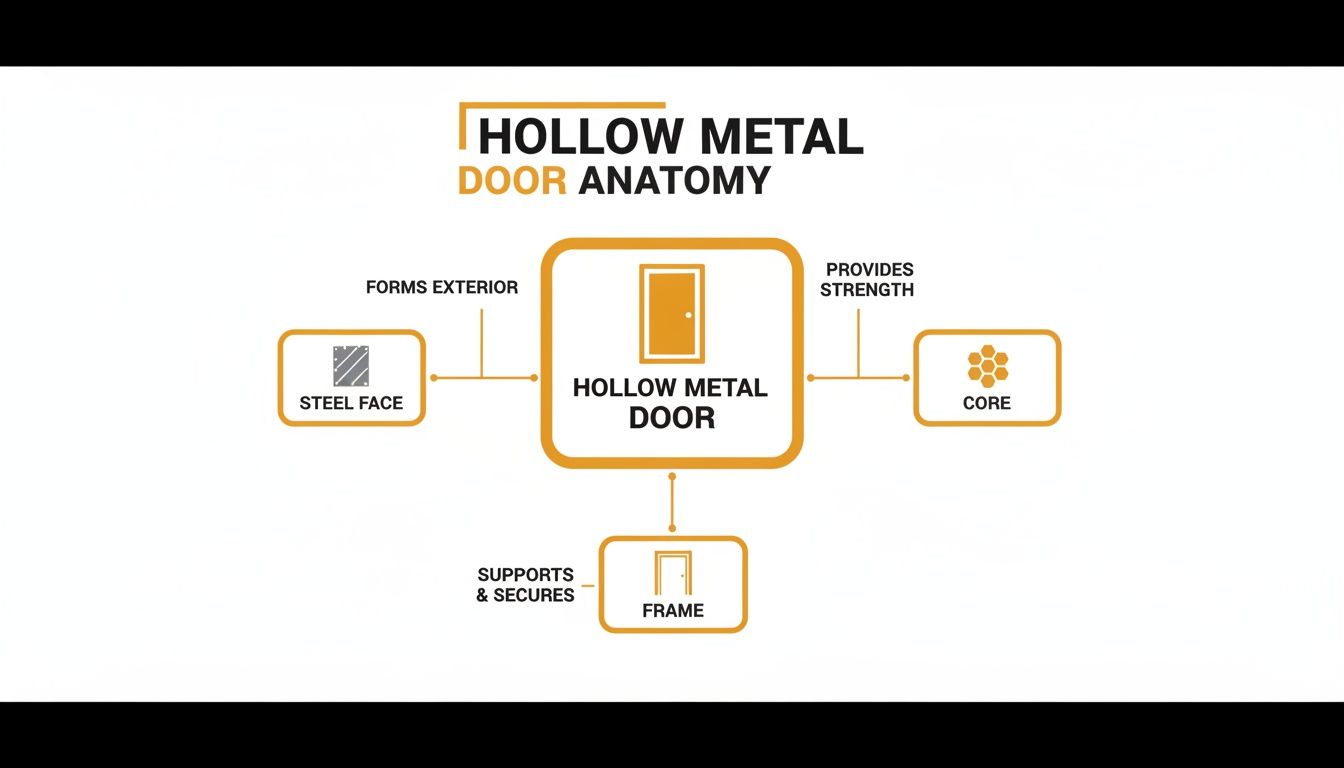

This diagram breaks down the key parts that give the door its overall strength and performance.

As you can see, the steel face, the inner core, and the frame all work together as a complete system to deliver the performance you need.

Matching Gauge to Application

Choosing the right gauge isn’t about simply selecting the thickest option available; it’s about matching the door’s strength to its environment. Over-specifying means spending unnecessarily, while under-specifying leads to premature failures and replacements. It’s a strategic decision that directly impacts your facility’s budget and security.

Here are a few real-world examples to illustrate:

- 20-Gauge (Light-Duty): The thinnest standard option, perfect for low-traffic interior locations like electrical closets or small office supply rooms where security isn’t a top priority.

- 18-Gauge (Standard-Duty): A versatile and common choice, 18-gauge steel provides a great balance of durability and cost. It’s well-suited for most interior doors with moderate traffic, such as in offices, apartment entries, and hotel rooms.

- 16-Gauge (Heavy-Duty): When a door needs to endure significant abuse, 16-gauge is the answer. Its thicker steel is built for high-traffic or high-impact zones like school entrances, hospital corridors, and warehouse personnel doors.

- 14-Gauge (Extra Heavy-Duty): This is one of the toughest doors available, reserved for applications requiring maximum security and durability. You’ll find 14-gauge doors in high-security government facilities, detention centers, or exterior doors in areas prone to vandalism.

Protecting Steel from the Elements

The base steel is just one part of the equation. For exterior doors or those in damp environments like loading docks, the steel requires protection from rust and corrosion. Specialized treatments are essential for a long service life.

The most robust hollow metal door assembly will fail if its steel succumbs to corrosion. Material treatment isn’t an add-on; it’s a fundamental requirement for any door exposed to the elements, protecting your investment for years to come.

The industry standard for superior corrosion resistance is A60 galvannealed steel. In this process, the base steel is coated with zinc and then heat-treated. This creates a durable, rust-resistant surface that is also excellent for painting.

This type of treated steel is especially popular in Canada’s varied and often wet climates. In fact, galvanized hollow metal doors saw a regional market value of USD 3.2 billion in 2023, offering 50% better corrosion resistance than untreated mild steel. This superior performance is a key reason they are so common in commercial and multi-family residential buildings across the country. Explore more statistics on the North American steel door market.

Making the right choice in gauge and material treatment is fundamental. As your respected partner in facility management, Wilcox Door Service provides the reliable expertise to help you select a solution built to last.

To ensure your doors are specified correctly for your environment, schedule a consultation with our door experts today.

Understanding Fire Ratings and Code Compliance

In any commercial or industrial building, fire safety is non-negotiable. A critical part of your facility’s life safety system is the fire-rated hollow metal door, which is engineered to contain a fire and protect vital escape routes. Understanding these ratings and the codes behind them is a core responsibility for any facility manager.

A fire-rated door assembly will have a label indicating its rating, such as “90-minute” or “3-hour.” This number specifies how long the entire door assembly is designed to withstand intense heat and flames, preventing a fire from spreading. This containment provides precious time for occupants to evacuate safely and for first responders to manage the situation.

More Than Just a Door

A common misconception is that the fire rating applies only to the door slab itself. In reality, a fire rating certifies the entire opening assembly. This includes the door, the frame, and all hardware—hinges, latches, and the closer—which must all be fire-rated and work together as a tested system.

If even one component is not rated correctly—for example, installing a non-rated lock on a 90-minute door—the entire assembly loses its official fire rating. This is why professional specification and installation are crucial. It’s the only way to ensure every part of the assembly meets strict safety standards and will perform as designed when needed most.

Real-World Application and Code Requirements

Consider a fire separation wall between a busy production floor and the main office area. Building codes mandate a specific fire rating for any door in that wall to create an effective barrier. If a fire were to start on the production side, that fire-rated hollow metal door would contain it, preventing it from spreading to the offices and allowing for an orderly evacuation.

When dealing with fire ratings, it’s essential to understand the broader commercial building permit requirements that govern construction and safety. These codes are legal mandates designed to protect lives and property, and non-compliance can result in serious penalties.

The fire label on a hollow metal door is a promise of performance. It certifies that the entire opening, when installed correctly, will act as a barrier to fire, smoke, and heat for a specific duration, protecting both people and the continuity of your business.

These critical safety components are a significant part of the construction industry. In California, the Sheet Metal, Window & Door Manufacturing sector has seen healthy growth, with an average annual increase of 5.8% from 2020 to 2025. Hollow metal doors, valued for their durability and fire ratings of up to 3 hours, are a key contributor to this trend.

For a deeper dive into the specifics of these assemblies, our guide on what you need to know about fire-rated doors offers more detailed information.

At Wilcox Door Service, our “Respected Partners, Reliable Service” philosophy means we ensure your facility’s doors are not just installed, but are fully compliant and ready to perform when it matters most.

To ensure your facility meets all fire code requirements, schedule a professional door and frame inspection with our certified technicians today.

Selecting the Right Door for Your Application

Now that we’ve covered the fundamentals—core types, steel gauge, and fire ratings—it’s time to apply that knowledge to your facility. Choosing the right hollow metal door is not about picking the strongest or most expensive option; it’s about making a smart match between the door’s features and its intended environment. A successful match results in a door that performs reliably for years without overpaying for unnecessary features.

The selection process begins by asking key questions about each opening. Is it an exterior door exposed to harsh weather? A busy hallway in a school? Or is it guarding a server room holding critical company data? Each scenario requires a different combination of materials and features.

Matching Door Specifications to Commercial Environments

Let’s look at a few common commercial settings to see how different specifications create the ideal door for the job.

- Hospital Corridor: Durability and hygiene are paramount here. A heavy-duty 16-gauge galvannealed steel door is ideal to withstand constant impacts from gurneys and carts. A seamless edge design and a smooth, painted finish are also critical for easy cleaning and disinfection.

- School Main Entrance: This opening demands maximum security and resilience. An extra heavy-duty 14-gauge door is often the standard, paired with high-security hardware. A polyurethane foam core adds significant structural strength and provides excellent thermal insulation against the Canadian climate.

- Data Centre or IT Closet: Security and fire safety are non-negotiable. A 16-gauge door with a 90-minute or 3-hour fire rating is essential. It must also be equipped with controlled access hardware to ensure only authorized personnel can enter, protecting valuable technology.

- Warehouse Personnel Door: This door needs to be tough yet practical. An 18-gauge door is usually sufficient, but if it opens to the exterior, a polystyrene or polyurethane core is vital for energy efficiency. It must be durable enough for daily staff use while keeping conditioned air in and pests out.

This targeted approach ensures every door in your building is truly fit for its purpose. You can explore more about how different metal doors for commercial use are selected in our detailed guide.

Key Questions for Your Facility

To streamline your selection process, start with these core questions for every opening you are evaluating.

The right hollow metal door is the one you don’t have to think about after it’s installed. By matching the specs to the application from the start, you invest in reliability, safety, and long-term operational peace of mind.

Canada is a major player in this market, holding a 15.4% share of North American demand, driven by strong commercial and institutional construction. Globally, the commercial sector is the powerhouse, representing a market valued at US$1,442.8 million that is poised for significant growth. You can discover more insights about the hollow metal door market here.

Answering these questions will guide you to a solution that fits your facility’s daily needs and your budget.

As your trusted partner, Wilcox Door Service brings decades of hands-on expertise to help you navigate these choices. Our “Respected Partners, Reliable Service” promise means we make sure you get the right door, every single time.

To get a professional assessment and quote for your facility’s door needs, contact our team of experts today.

Proper Installation and Long-Term Maintenance

You can purchase the best hollow metal door on the market, but its performance depends entirely on correct installation. Professional installation is not just the final step; it is the foundation for the door’s entire service life, ensuring you receive the security, fire safety, and durability you invested in.

True expertise makes all the difference. We’ve seen frames that aren’t perfectly square, causing the door to bind or sag over time. We’ve seen misaligned hardware that prevents a fire door from latching securely, completely defeating its safety function. These seemingly small errors lead to premature wear, operational headaches, and costly emergency repairs.

Shifting from Reactive Repairs to Proactive Care

While a flawless installation is the starting point, the key to decades of reliable service is planned maintenance. This is not an expense but a strategic investment in your facility’s operational continuity. A proactive approach protects you from unexpected downtime and keeps your doors functioning reliably.

For facility managers, a comprehensive commercial building maintenance checklist should always include critical components like doors. Regular inspections are the best way to catch minor issues before they escalate into major failures.

A well-maintained hollow metal door is an asset that quietly performs its duty. Proactive care ensures it remains a reliable component of your building’s safety and security, preventing the disruptive and expensive chaos of an unexpected failure.

This consistent attention to detail is what distinguishes a door that lasts a decade from one that is still performing after thirty years.

A Practical Maintenance Checklist for Facility Managers

A simple but consistent inspection routine is the most effective way to ensure longevity and reliable performance. Here’s a practical checklist to get your team started:

- Hinges and Pivots: Look for signs of excessive wear, listen for grinding noises, and check for loose screws. Lubricate hinges twice a year with a manufacturer-recommended product to keep them operating smoothly.

- Door Closers and Latching Hardware: This is critical. Ensure the door closes and fully latches on its own every time. Adjust the closer’s speed and power as needed to prevent slamming or failure to secure. For fire-rated doors, this is non-negotiable.

- Weather Seals and Gaskets: Inspect the perimeter seals for cracking, peeling, or flattened spots. Intact seals are your defense against drafts, pests, and moisture, and they play a significant role in controlling energy costs.

- Surface Condition: Scan the door’s surface for rust spots, dents, or damage. Addressing minor corrosion or chipped paint early prevents rust from spreading and compromising the door’s structural integrity.

Regularly performing these checks will keep your doors functioning at their best while maintaining safety. For a deeper dive into professional service options, take a look at our guide on top-quality commercial door repairs and maintenance services.

This proactive approach is at the heart of our “Respected Partners, Reliable Service” philosophy. We are committed to helping you protect your investment and maintain a safe, efficient facility.

Contact Wilcox Door Service today to schedule a professional maintenance inspection or to discuss establishing a planned maintenance program for your facility.

Your Top Questions Answered

To conclude, let’s address some of the most common questions facility managers have about hollow metal doors. This quick reference will help you feel confident in your decisions by reinforcing the key concepts we’ve discussed.

How Long Does a Typical Hollow Metal Door Last?

A properly installed and maintained hollow metal door in a commercial setting can easily last for 30 years or more. Its lifespan depends on several factors: the steel gauge, the volume of daily traffic, and its exposure to weather or corrosive elements. Consistent, planned maintenance is the secret to maximizing this impressive service life.

Can You Paint a Hollow Metal Door?

Absolutely. Most hollow metal doors are delivered with a factory-applied primer, making them ready for painting. The key is to use paint specifically formulated for metal surfaces to ensure proper adhesion and long-term durability. For exterior doors, we highly recommend an industrial-grade, weather-resistant paint to protect against rust and environmental wear.

Are Hollow Metal Doors Insulated?

Yes, many models are insulated to meet specific performance requirements. While the standard core is often a honeycomb material, you can specify cores like polystyrene or polyurethane foam for excellent thermal insulation (R-value). This is particularly important for exterior doors, as it significantly improves a building’s energy efficiency.

What Is the Difference Between a Hollow Metal Door and a Steel Door?

The terms are often used interchangeably, but “hollow metal door” is the more precise industry term for a commercial-grade product. It specifically refers to a door constructed with steel face sheets over a reinforced, hollow interior that is filled with a specific core material.

“Steel door” is a broader term that can also include residential-grade doors, which are typically made with thinner steel and have a much less robust construction. For any commercial or industrial application, “hollow metal” is the standard you should be looking for.

At Wilcox Door Service Inc., we believe in being respected partners who deliver reliable service. Our expertise ensures you get the right door solution that meets your facility’s safety, security, and operational needs.

Ready to enhance your facility’s performance? Learn more about our comprehensive door and dock solutions at https://www.wilcoxdoor.com.