When overhead space is at a premium and every minute of operational uptime counts, jackshaft door openers are the powerful, wall-mounted answer to traditional ceiling-mounted operators. This guide will walk you through exactly what these systems are, how they work, and why they are becoming the go-to solution for modern warehouses, automotive shops, and other commercial facilities. You'll learn how they maximize vertical space, enhance safety, and what to consider before installation.

Why Facility Managers are Making the Switch to Jackshaft Door Openers

If you're managing a busy commercial facility, you know every square foot—and every cubic foot—is valuable. Traditional trolley-style operators, with their long rails and chains hanging from the ceiling, can be a major operational obstacle. They interfere with high-lift equipment, limit how high you can stack inventory, and are often impractical for buildings with sloped ceilings or other architectural quirks. This is where jackshaft door openers provide a definitive solution.

Instead of hanging from the ceiling, these operators mount directly on the wall next to the overhead door. They function by turning the door's torsion bar—a simple term for the spring-loaded shaft that does the heavy lifting. Think of it like turning a car's axle directly instead of pulling the car with a rope from above. It's a more direct and efficient application of force.

Maximize Every Inch of Your Vertical Space

The most immediate and impactful benefit is reclaiming all that overhead real estate. This is more than a minor improvement; it directly enhances your daily operations.

- Warehouses and Distribution Centres: A real-world example is a warehouse manager who eliminates ceiling rails to stack pallets one level higher. This small change can increase inventory capacity by 20% or more without the cost of a building expansion.

- Automotive Service Bays: For mechanics, this means vehicle lifts can be raised to their full, ergonomic height without the risk of colliding with a garage door operator. This improves both safety and service speed.

- Facilities with High Ceilings or Cranes: In manufacturing plants or facilities that use overhead cranes, unobstructed ceiling space isn't just a convenience—it's a necessity for safe and efficient material handling.

A significant reason facility managers are embracing jackshaft openers is their reliability. With fewer exposed moving parts compared to a chain-driven trolley system, they are less susceptible to wear and environmental damage. For a facility manager, that translates to fewer service calls and a longer, more predictable operational life for the equipment.

A Growing Trend in Canadian Facilities

This shift toward wall-mounted solutions is a clear and measurable trend. In the Canadian market, jackshaft door openers have become a game-changer, especially for warehouses and distribution centres. We're seeing this particularly in Prairie provinces like Alberta and Saskatchewan, where the resource economy is driving warehouse expansion. In these areas, jackshaft installations recently jumped by 28%.

This growth is driven by their space-saving design, which unlocks critical overhead storage. Data also shows that these openers can reduce maintenance calls by up to 40% compared to traditional models—a huge advantage for any operation facing harsh Canadian winters.

At Wilcox Door Service, we've seen firsthand how installing the right commercial door operator can transform a facility's efficiency and safety. As your Respected Partners, we provide Reliable Service by helping you select the best solution for your unique operational needs, ensuring your facility runs without interruption.

How Jackshaft Openers Get the Job Done

To truly understand why jackshaft door openers are such a game-changer, it’s helpful to look at their mechanics. They operate on a completely different principle than the trolley operators most people are familiar with—the ones hanging from the ceiling on a long rail.

Instead of pulling the door from above, a jackshaft unit mounts directly on the wall, adjacent to the door opening. This clever design allows the motor to connect straight to the door's torsion bar—the heavy-duty shaft with springs that counterbalances the door's weight.

By rotating the torsion bar itself, the opener lifts and lowers the door with exceptional control and efficiency. To put it in practical terms: a trolley operator is like trying to pull a heavy cart with a long rope from a distance. A jackshaft is like standing right next to the cart, grabbing the axle, and turning it directly. All the power is applied precisely where it's needed, with no wasted energy or extra moving parts.

This diagram breaks down the key benefits that come from this direct-drive approach.

alt="Flowchart showing the benefits of a jackshaft door opener: space optimization, quiet efficiency, enhanced safety, and reduced maintenance."

This simplified design directly reduces maintenance needs. For any busy facility where downtime is not an option, this is a massive operational win, reinforcing our promise of being your Respected Partners, Reliable Service.

Top Commercial Applications for Jackshaft Systems

So, where do jackshaft door openers truly excel in the real world? Their unique wall-mounted design makes them powerful problem-solvers in specific commercial environments where a traditional, ceiling-mounted operator simply isn't feasible or efficient. Across the industries we serve, these systems deliver practical solutions that improve workflow, bolster safety, and maximize usable space.

Let’s look at some of the most common applications where jackshaft systems turn operational challenges into efficiency gains.

alt="Illustration of a warehouse, auto repair bay, and cold storage unit, all ideal applications for a commercial jackshaft door opener."

Warehouses and Distribution Centres

In a modern warehouse, vertical space is just as valuable as floor space. A facility manager at a loading dock knows that stacking inventory higher is the key to boosting capacity without the massive cost of expanding the building’s footprint. This is precisely where trolley operators, with their low-hanging rails, become a serious obstacle, creating a risk of collision for forklifts.

A jackshaft door opener eliminates that barrier completely. By mounting neatly on the wall, it leaves the entire ceiling area above the door wide open. This allows forklifts and other high-reach equipment to move freely, maximizing vertical storage and preventing costly, dangerous collisions with the door mechanism.

Automotive Service and Repair Bays

Imagine an auto repair shop where a vehicle is on a lift, but the mechanic can't raise it to a comfortable working height because a bulky garage door operator is in the way. It's a common frustration that directly slows down technicians and can even create safety issues.

Jackshaft openers solve this by freeing up all that overhead space, giving vehicle lifts the clearance they need to extend fully. Technicians can work more ergonomically and efficiently, which improves turnaround times and creates a safer, more productive shop. It’s a simple change that makes a significant difference in the daily operations of any service bay.

The core benefit in these settings is unobstructed clearance. Whether it's for a forklift, a vehicle lift, or an overhead crane, the jackshaft design ensures that the door system never interferes with the critical work happening below it.

Facilities with Unique Ceilings

Not all commercial buildings have flat, standard-height ceilings. Many facilities, from architecturally unique buildings to older industrial plants, have sloped roofs, cathedral ceilings, or are cluttered with overhead obstructions like HVAC ducts and sprinkler systems.

In these cases, installing a central trolley operator is often impossible. A jackshaft system bypasses this problem entirely, as it only requires a small patch of wall space next to the door. This makes it the perfect solution for retrofitting older buildings or for new constructions with non-standard rooflines.

Cold Storage and Food Processing

Temperature-controlled environments demand precision. In cold storage facilities, achieving a tight seal is non-negotiable for energy efficiency and product integrity. Jackshaft operators apply consistent, even force on the door, ensuring it closes securely every time to minimize thermal loss.

Their reliability is critical here. There’s a reason jackshaft door openers are the fastest-growing segment in Canada's garage door market. Field data from installations in the Prairies shows that in cold-storage applications, jackshafts can slash failure rates by 35% during harsh -20°C operations. Even better, related energy-saving upgrades can lead to 18-25% in utility savings—a huge factor for any facility manager. You can learn more by exploring the garage door openers market report.

High-Cycle Parking Garages

The constant flow of vehicles in a parking garage puts immense strain on door operators. Here, reliability and durability are essential. Jackshaft systems, with their direct-drive mechanism and fewer moving parts, are built to handle this punishing high-cycle demand. A breakdown at a loading dock is an inconvenience; a breakdown in a parking garage can cause gridlock. The robust design means less wear and tear, reducing maintenance needs and the risk of unexpected failures.

For any of these applications, choosing the right operator is key. As your Respected Partners, we provide Reliable Service by helping you identify the best solution for your facility’s unique challenges.

If your facility faces any of these operational hurdles, contact Wilcox Door Service today to learn how a jackshaft door opener can optimize your space.

Key Considerations for Installation and Retrofitting

Successfully installing a jackshaft door opener is about more than picking the right model; it requires careful planning and preparation. Whether you're installing a new system or upgrading from an old one, a thorough pre-installation assessment is the key to safe, reliable, and long-term performance.

This is the stage where you prevent potential problems before they happen, ensuring the operator functions flawlessly from day one. Skipping these steps can lead to premature wear, frustrating breakdowns, and even serious safety hazards.

Pre-Installation Site Assessment

Before any installation work begins, a detailed site assessment is essential. This is a methodical inspection of the door and its surrounding environment to confirm compatibility. Since a jackshaft operator connects directly to the door's mechanical system, the entire assembly must be in excellent condition.

Here are the non-negotiables for your pre-installation checklist:

- Side-Room Clearance: Unlike ceiling-mounted operators, jackshaft units are installed on the wall beside the door. You must carefully measure to ensure there's enough space for the operator without obstructing walkways or other equipment.

- Electrical Specifications: It's critical to confirm the available power supply matches the operator's requirements. This means checking the voltage (120V, 240V, or 480V) and ensuring a dedicated circuit is available to prevent electrical issues.

- Torsion Bar and Spring Condition: The operator’s entire function is to turn the torsion bar, so that bar and its springs must be in excellent condition. Any signs of rust, wear, or damage are red flags that a professional technician must address first.

- Door Balance and Condition: A jackshaft opener is designed to work with a properly balanced door. A simple manual test reveals its condition: lift the door halfway and let go. It should remain stationary. If it slams down or flies up, the springs require professional adjustment. This is a crucial safety and performance check.

Retrofitting From an Old System

Swapping an outdated trolley operator for a modern jackshaft system is a popular upgrade that immediately boosts a facility's efficiency. However, the job is more than a simple motor exchange; it requires preparing the space for a completely different mounting style.

The first step is always the careful removal of the old trolley rail, motor, and chain assembly from the ceiling. This action alone clears up significant overhead space, which is often the primary motivation for the upgrade. A real-world example is a facility maintenance manager who, after retrofitting, can finally install new, taller shelving units, instantly increasing storage.

Next, the wall area beside the door is closely inspected. The wall must be structurally sound enough to support the operator's weight and withstand the rotational force (torque) it generates. If the wall structure is weak, reinforcement may be necessary to ensure a stable, safe installation.

A key part of any retrofit is ensuring seamless integration. This means connecting the new jackshaft opener to existing safety and access control systems, like photo-eyes, reversing edges, and keypads. A professional installation guarantees these components communicate correctly, maintaining your facility's safety standards without a hitch.

Matching Torque to Door Specifications

One of the most critical technical calculations is matching the operator’s torque—the twisting force the motor applies—to the door's size and weight. If the torque is too low, the operator will struggle to lift the door, leading to motor strain and a shortened lifespan.

Conversely, if the torque is too high, it can apply excessive force, potentially damaging door panels, springs, or the torsion bar itself. This mismatch not only accelerates wear but also creates serious safety risks. A certified technician will calculate the precise torque your door requires, ensuring the system is both powerful and safe.

This is where having an expert partner makes all the difference. As your Respected Partners, we deliver Reliable Service by ensuring every installation is perfectly matched to your facility's unique needs.

Ready to upgrade your facility? Schedule a consultation with a Wilcox Door Service expert to assess your site and get a detailed quote.

Weaving in Modern Safety and Access Controls

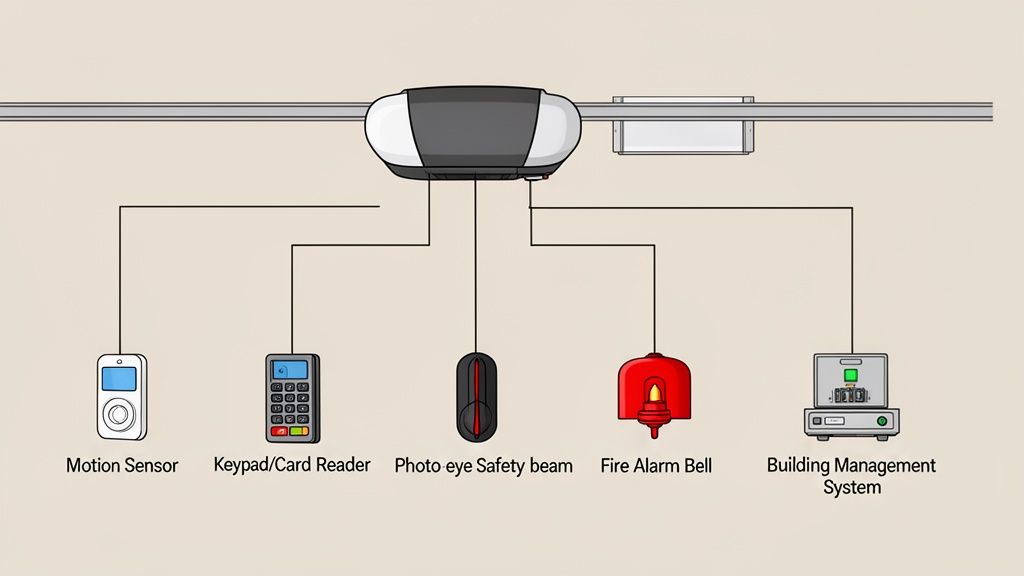

A modern jackshaft door opener is more than just a motor; it’s the command centre for your facility's entryway, integrating safety protocols and access control into a single, intelligent system. These operators are designed to communicate with a wide range of devices, transforming a simple door into a smart, secure, and responsive access point.

Proper integration is key to creating an environment that is not only efficient but also compliant with today's strict safety standards. For a facility manager, this means the door system can react intelligently—opening for an authorized vehicle, reversing instantly upon sensing an obstruction, and even reporting its status to a central building management system.

alt="Diagram of a jackshaft door opener system integrated with safety photo-eyes, a reversing edge, and a keypad for access control."

Connecting to Advanced Access Controls

Controlling who enters and exits is fundamental to facility security. Jackshaft door openers are built with simple input terminals that make it easy to connect them to various access control systems, allowing you to fine-tune access permissions.

Common real-world examples include:

- Keypads and Card Readers: An effective security layer ensuring only authorized personnel can operate the door. This is standard for employee entrances or secure storage areas.

- Motion Detectors: In high-traffic zones like a busy loading dock, motion sensors can trigger the door to open automatically as a forklift approaches, streamlining workflow and reducing manual interaction.

- Ground Loop Detectors: A wire embedded in the pavement detects the metal mass of a vehicle. This is ideal for automating the door cycle as trucks arrive and depart, keeping operations fluid.

Putting Safety and Compliance First

In any commercial or industrial setting, safety is non-negotiable. Modern jackshaft door openers integrate with multiple layers of monitored safety devices to protect people and equipment. These are not optional add-ons; they are essential for meeting safety regulations.

A modern jackshaft operator creates a "safety network" around the door opening. When all these devices are correctly wired, they work in concert to prevent accidents before they happen. It’s a core part of our commitment to providing Reliable Service that protects your people and your assets.

Key safety integrations include:

- Monitored Photo-Eyes: These sensors project an invisible beam of light across the door opening. If anything—a person, pallet, or forklift—breaks that beam while the door is closing, the operator instantly reverses direction.

- Pneumatic Reversing Edges: This is a pressure-sensitive tube on the bottom edge of the door. If it contacts an obstruction, the air pressure change signals the operator to immediately reverse.

- Light Curtains: For the highest level of protection, a light curtain creates a dense grid of infrared beams across the entire door opening. If even one beam is interrupted, the door will not close, or it will reverse if already in motion.

Tying into Centralized Control and Fire Systems

For larger facilities, monitoring and controlling all doors from a central location is a significant advantage. Many jackshaft door openers can be linked to a Building Management System (BMS), allowing facility managers to see the live status of every door, receive alerts, and operate them remotely. To see how different brands handle this, it's worth exploring options like the popular side-mount LiftMaster operators.

Even more critical is integration with a building's fire alarm system. This is a life-safety feature that cannot be overlooked. When connected, the system can be programmed to automatically close fire-rated doors when an alarm is triggered, helping to contain smoke and fire while protecting escape routes.

If you’re ready to bring this level of safety and control to your facility, contact Wilcox Door Service today to talk about integrating a modern jackshaft door opener system.

Keeping Your Jackshaft Opener Running Strong

A hard-working jackshaft door opener is an unsung hero in many facilities, but its reliability depends on consistent care, not chance. To keep your system operating smoothly and prevent unexpected breakdowns that disrupt your day, a simple preventive maintenance plan is essential. A proactive approach protects your investment, reduces downtime, and ensures your door operates safely every time.

Think of it like any other critical piece of equipment in your facility. For a maintenance manager, regular attention is non-negotiable. By implementing a straightforward checklist of daily, monthly, and annual tasks, you can catch minor issues before they escalate into costly emergency service calls. This philosophy is at the heart of our Reliable Service promise.

Your Go-To Maintenance Checklist

Most routine checks are simple enough for your facility team to handle. The key is to break the schedule into manageable steps that fit into your existing maintenance workflow.

Here’s a practical schedule:

- Daily Once-Over: Take a quick walk-around. Are the wall mount bolts tight? Do you hear any unusual grinding or squeaking? Is the area around the opener clear of obstructions? A 30-second visual inspection can prevent major problems.

- Monthly Systems Check: Once a month, test the safety features. Place an object under the door to ensure the photo-eyes reverse it, and press the reversing edge to confirm it retracts immediately. This is also a good time to check the chain tension—it should have slight slack but not be drooping.

- Annual Pro Tune-Up: This is crucial. At least once a year, have a certified technician from a company like Wilcox Door Service perform a comprehensive inspection. Our professionals will lubricate critical parts, test motor performance, and ensure all electrical connections are secure.

Proactive maintenance is a mindset shift. Instead of reacting when a door fails—usually during a critical shipment or right before closing—you identify and solve potential problems on your own schedule. It saves time, money, and significant stress.

A Quick Troubleshooting Guide

Even with excellent maintenance, issues can arise. Knowing how to identify common problems can help you determine if it's a quick fix or if it's time to call in a professional.

- Problem: The door operates intermittently.

- Possible Fix: Start with the basics. Check the power source and ensure a breaker hasn't tripped. Next, inspect the photo-eye sensors. If they are dirty or misaligned, the door won't close. A simple wipe of the lenses often resolves the issue.

- Problem: The opener is making loud grinding or screeching noises.

- Possible Fix: Grinding or squealing can indicate a need for lubrication or that the chain tension is off. However, if the noise is severe, it could point to a more significant internal issue with the motor's gears, which requires a professional technician.

Looking beyond just your opener, solid facility-wide general maintenance practices can extend the life of all your equipment.

Ultimately, knowing your limits is key. For anything more complex than these simple checks, it is always safer and more cost-effective to trust a certified expert.

If your jackshaft door opener is overdue for an inspection or is showing signs of trouble, contact Wilcox Door Service today to schedule a visit from one of our union-certified technicians.

Your Questions About Jackshaft Door Openers, Answered

When evaluating specifications for commercial door operators, many questions can arise. To help you make a clear and confident decision, we’ve compiled straightforward answers to the queries we hear most often from facility managers about jackshaft door openers.

Can I Put a Jackshaft Opener on Any Overhead Door?

Not quite. A jackshaft opener has one critical requirement: a torsion bar. This means it is only compatible with sectional overhead doors that use a torsion bar and spring system for lifting. It will not work on doors that operate with extension springs (the type that run alongside the horizontal tracks).

Another key factor is proper door balance. If the door is not correctly balanced, it places excessive strain on the operator's motor, leading to premature failure. A simple manual test can confirm this.

Do Jackshaft Openers Need a Lot of Special Maintenance?

While their design is simpler than a trolley system, they still require routine care to perform reliably. Key maintenance tasks are straightforward:

- Regularly checking chain tension.

- Lubricating moving parts like the chain and sprockets.

- Verifying that safety devices like photo-eyes and reversing edges are functional.

- Ensuring the wall mount remains secure.

We always recommend an annual professional inspection from a certified technician to ensure long-term reliability and safety.

How Much Side-Room Do I Need for an Installation?

This is a critical measurement to take early on. The exact amount of side-room clearance can vary slightly between models, but a general rule of thumb is to have at least 20 cm (about 8 inches) of clear wall space on one side of the door. This space is necessary for mounting the operator and allowing it to properly engage with the torsion bar.

Are Jackshaft Openers Noisy?

Jackshaft door openers are known for being significantly quieter than their chain-driven trolley counterparts. Because the motor is mounted on the wall and directly rotates the torsion bar, you avoid the rattling noise of a chain traveling along a long metal rail. This makes them an excellent choice for any facility where noise reduction is a priority.

Choosing the right door operator is a major decision that impacts your facility's efficiency, safety, and bottom line. As your Respected Partners providing Reliable Service, the team at Wilcox Door Service Inc. is here to help you navigate the options and find the perfect fit.

Explore our commercial door operator services to learn more.