This guide is designed for facility managers looking to optimize their building’s efficiency and space. You will learn what commercial jackshaft garage door openers are, how they differ from traditional trolley operators, the key advantages for facilities with limited overhead space, and what to consider for installation and maintenance. By the end, you’ll understand if a jackshaft system is the right strategic choice for your commercial or industrial doors.

In any commercial facility, every square foot is prime real estate. That’s where jackshaft garage door openers come in, offering a smart, space-saving alternative to traditional overhead operators. Instead of a long central rail bolted to the ceiling, these units mount neatly on the wall right beside the door. This frees up valuable overhead space for storage, lighting, or even a vehicle lift. It’s a more direct and efficient way to muscle open large, heavy commercial doors.

Understanding Commercial Jackshaft Operators

For any facility manager, the constant challenge is juggling operational space and efficiency. The old-school trolley-style operators, the ones that pull a door along a ceiling track, can be a real headache. They create overhead obstructions that dictate how you can use your own space. This is precisely where jackshaft garage door openers prove their worth in demanding commercial and industrial environments.

Here’s a simple way to think about it: a trolley operator is like a locomotive pulling a train along a fixed track, and that track needs a long, clear path above the door. A jackshaft, on the other hand, acts more like a powerful wrench, turning the door’s torsion bar (the spring-loaded rod above the door) directly. This wall-mounted design delivers all its power right where it’s needed, getting rid of bulky overhead rails and chains altogether. It’s a simple mechanical shift, but one that makes all the difference in the right facility.

Why Facility Managers Choose Jackshaft Systems

The switch to a jackshaft system usually happens when a trolley system just can’t meet the facility’s needs. Think about a loading dock with high-lift doors that need to travel straight up the wall before rolling back. A standard operator would get in the way, but a jackshaft is the perfect hands-off solution. Similarly, an auto repair shop can’t install a two-post vehicle lift near a door bay if a trolley operator rail is blocking the ceiling.

At Wilcox Door Service, we’re all about providing reliable solutions tailored to the unique demands of your operation. Our deep expertise in commercial door systems means you get the right gear for the job, every time. As your “Respected Partners, Reliable Service,” we ensure your facility’s access points are efficient and dependable.

How a Commercial Jackshaft Operator Works

To really get why jackshaft garage door openers are such a game-changer in commercial spaces, you need to understand how they work. Forget the traditional trolley systems that pull a door along an overhead track. A jackshaft operator takes a much more direct, no-nonsense approach. It mounts right on the wall beside the garage door, which means no more bulky rails hogging your ceiling space.

This direct-drive design is the secret to its efficiency. Think of it like this: a trolley operator is like trying to pull a heavy wagon with a long rope from a distance. A jackshaft operator, on the other hand, is like grabbing the wagon’s axle and turning it directly with a powerful, motorized wrench. The force gets applied exactly where it’s needed, giving you incredible torque and rock-solid performance.

What truly sets it apart is this direct connection to the door’s torsion bar—that spring-loaded rod above the door that does all the heavy lifting. The operator simply rotates this bar to lift and lower the door. It’s a simple yet powerful mechanism, perfectly suited for the heavy, high-cycle industrial doors we see every day.

The Core Components and Their Roles

The impressive performance of a commercial jackshaft operator comes down to a few key components working in perfect harmony. Each part is engineered for durability and power, ensuring your facility’s access points stay operational, even under the stress of constant use.

Here’s a breakdown of the primary parts and what they do:

- The Motor: This is the powerhouse of the unit. Commercial-grade motors are built to provide consistent torque (rotational force) without the wear and tear of jerky starts and stops. They’re designed to handle hundreds of cycles a day without breaking a sweat.

- The Gearbox: The motor’s raw power is channelled through a gearbox. This component multiplies the torque, giving the operator the muscle it needs to lift incredibly heavy doors—from insulated sectional doors to heavy-duty rolling steel—smoothly and safely.

- The Drive Shaft and Sprocket: This is where the power meets the door. The operator connects to the door’s torsion bar with a drive shaft and a chain-and-sprocket system. When the motor kicks in, this assembly rotates the torsion bar, which in turn lifts the door along its vertical tracks.

This direct-drive system isn’t just about raw power; it’s about control. Modern jackshaft units feature soft-start and soft-stop technology, which reduces mechanical stress on both the door and the operator. This dramatically extends the lifespan of your equipment and is a critical feature for any facility focused on minimizing maintenance costs.

Freeing Up Valuable Overhead Space

Perhaps the most significant operational benefit of this design is what it gets rid of: the overhead rails. By mounting on the wall, jackshaft garage door openers completely free up the ceiling space above the door bay. This seemingly simple change has a massive impact on how you can use your facility.

For instance, an auto service centre can install vehicle lifts right up to the door, something that’s impossible with a central trolley operator. A warehouse can extend pallet racking higher to maximize every inch of vertical storage. A distribution centre can install high-volume, low-speed (HVLS) fans for better air circulation. It allows for clear, unobstructed placement of sprinkler systems, HVAC ducting, and lighting, giving you total freedom to design your workspace for peak efficiency.

This practical advantage is why we so often recommend these systems during consultations for new construction or major retrofits. When you need to get the most out of every cubic foot of your facility, choosing the right door operator is a strategic decision. To see how these systems could fit into your facility, you can explore our full range of commercial door operators.

Jackshaft Versus Trolley Systems for Commercial Doors

When you’re outfitting a commercial or industrial facility, the choice of door operator often boils down to two main contenders: the modern, wall-mounted jackshaft garage door opener and the traditional, ceiling-mounted trolley system. Both get the job done—lifting and lowering heavy doors—but they go about it in completely different ways. Understanding those differences is key for any facility manager who wants to get the most out of their space, safety, and efficiency.

This isn’t just a matter of preference. It’s a strategic decision that hinges on your building’s unique layout and the daily demands you put on your doors. Trolley systems, which pull a door along an overhead rail, have been the reliable workhorse for decades. But the jackshaft operator, which mounts right beside the door to turn the torsion bar directly, brings some serious advantages to the table, solving common headaches in busy commercial spaces.

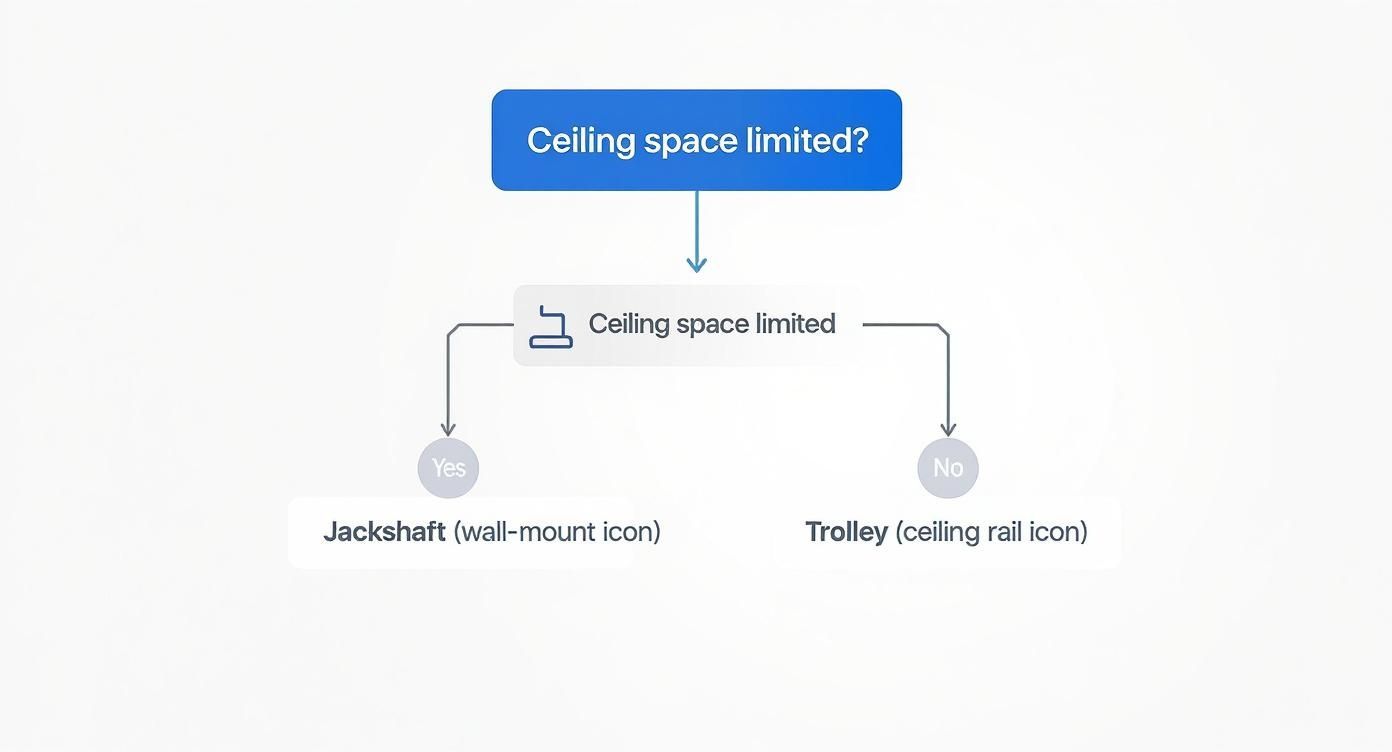

If you’re just starting, this simple decision tree is the best place to begin: is your overhead space already spoken for or needed for other equipment?

As the graphic shows, the amount of clear ceiling space you have is usually the first and most critical factor in picking the right operator for your facility.

Space Utilization and Door Configuration

The single biggest difference between these two systems is how they use your building’s real estate. A trolley operator needs a long, clear runway directly above the door for its rail, chain, and motor. This can get in the way of everything from lighting and sprinkler systems to HVAC ducting or even a vehicle lift in an auto shop.

Jackshaft operators, on the other hand, have a tiny overhead footprint. By mounting neatly on the wall, they leave your ceiling completely open. For many facilities, this is a necessity.

- High-Lift and Vertical-Lift Doors: If your doors travel straight up the wall before rolling back (high-lift) or open entirely vertically without any horizontal tracks (vertical-lift), a trolley is simply out of the question. Jackshafts are the standard solution for these setups, which you’ll often find at loading docks or in buildings with soaring ceilings.

- Maximizing Vertical Storage: In a warehouse where every cubic foot is money, getting rid of those overhead rails means you can stack pallets higher. This directly impacts your storage capacity and, ultimately, your bottom line.

- Accommodating Other Equipment: Think about car washes, auto service bays, or manufacturing plants with overhead cranes. They all depend on clear ceiling space. A jackshaft system ensures the door operator never becomes an obstacle to the real work happening inside.

Performance and Maintenance Demands

Beyond space, the way these operators perform and what they need in terms of upkeep are worlds apart. Because a jackshaft applies force directly to the torsion bar, it delivers a much smoother, more controlled lift. This direct-drive setup has fewer moving parts strung out along a rail, which usually translates to a more reliable system with less wear and tear over the long haul.

A key performance benefit of modern jackshafts is their quiet operation and soft-start/soft-stop functionality. This reduces the mechanical shock and jarring that can stress door panels and hardware, ultimately contributing to a longer lifespan for your entire door assembly and reducing the frequency of costly repairs.

Trolley systems, with their long chains or belts, tend to be noisier and often need more frequent adjustments to keep everything properly tensioned. They’re certainly robust, but that long travel path creates more opportunities for things to go wrong over tens of thousands of cycles. For a deeper dive on how proactive care can extend the life of any system, it’s worth exploring the benefits of a commercial garage door maintenance plan.

Commercial Operator Comparison: Jackshaft vs. Trolley

To help you size up the options for your facility, here’s a straightforward comparison of the two systems, focusing on the factors that matter most to facility managers and operations leaders.

| Feature | Jackshaft Operator | Trolley Operator |

|---|---|---|

| Space Requirement | Minimal overhead footprint; requires adequate side-room next to the door. | Requires significant, clear overhead space for the central rail and motor unit. |

| Best For | High-lift doors, vertical-lift doors, facilities with tall ceilings, or obstructed overheads. | Standard-lift sectional doors in buildings with ample, unobstructed ceiling clearance. |

| Installation | Can be more complex, requiring a solid mounting surface and precise alignment with the torsion bar. | Generally more straightforward for standard door configurations, but rail installation is labour-intensive. |

| Maintenance | Fewer exposed moving parts can lead to less frequent maintenance needs. | Chains or belts may require periodic tensioning and lubrication along the entire rail length. |

| Performance | Quieter, smoother operation with direct-drive torque application. | Can be noisier and may produce more vibration due to the chain/belt drive system. |

| Cost | Typically a higher initial investment due to more advanced technology and components. | Generally a lower upfront cost, making it a budget-friendly option for standard applications. |

In the end, the right choice really does depend on your operational reality. A trolley system might be the perfect, cost-effective solution for a standard warehouse bay with plenty of headroom. But for more specialized or space-crunched facilities, a jackshaft operator offers a level of versatility and space efficiency that’s hard to beat.

Key Installation and Retrofit Considerations

Thinking about installing or upgrading to a commercial jackshaft garage door opener? It’s a fantastic way to free up overhead space, but it’s not a simple plug-and-play swap. Whether you’re planning for a new build or retrofitting an existing bay, getting the planning right from the start is absolutely critical for a safe, reliable, and long-lasting setup.

Success here is about more than just picking a powerful operator. It’s about making sure the entire environment is ready for it. You have to be certain the wall can handle the force, the power supply is correct, and you have all the necessary clearances. If you skip these details, you’re setting yourself up for operational headaches, expensive rework, or even serious safety hazards down the road.

Pre-Installation Technical Checklist

Before you even think about ordering a jackshaft system, a thorough site assessment is non-negotiable. An experienced technician needs to come out and evaluate the entire door assembly and the surrounding structure to confirm everything is compatible. This single step can identify potential showstoppers early on, making the actual installation process go smoothly.

Here are the big questions that need solid answers first:

- Is There Adequate Side-Room? Unlike a trolley operator that lives in the ceiling, a jackshaft needs a home on the wall right next to the door. You’ll need enough clearance not just to mount the unit, but also to give technicians room to perform routine service.

- Does the Wall Have Structural Integrity? This is a big one. The operator generates a lot of rotational force—or torque—right at its mounting points. That wall, whether it’s concrete block or steel, has to be strong enough to take that stress day in and day out without failing.

- Is the Correct Electrical Supply Available? Commercial operators are power-hungry and have specific needs, like three-phase power or a particular voltage (208/230V or 460V). You’ll need an electrician to confirm that a dedicated circuit with the right power is ready and waiting near the installation spot.

- What is the Door’s Condition and Weight? The operator is designed to assist a well-balanced door, not dead-lift a broken or heavy one. The door itself has to be in good working order and properly balanced first.

- Does the Torsion Bar Meet Specifications? The jackshaft operator connects directly to the torsion bar, turning it to lift the door. This bar must be the right diameter (usually 1 inch or larger for commercial doors) and in perfect shape to handle all that direct-drive force.

The Retrofit Scenario: Upgrading from a Trolley System

Swapping out an old, clunky trolley system for a sleek jackshaft opener is one of the most common and beneficial upgrades you can make. It’s a bit more involved than a simple replacement, though.

First, the entire old trolley system has to go—the operator, the long central rail, and all its mounting hardware. This is the step that immediately frees up all that valuable overhead space. Next, a technician will prep the wall area where the new unit will live, ensuring it’s clean, structurally sound, and ready for the mounting bracket.

A huge part of this process is a deep dive into the condition of the existing door components. To get a feel for everything this covers, check out our guide on what a professional jackshaft operator install really involves.

Real-World Example: An auto service garage wanted to install a taller vehicle lift to work on modern trucks. Their old trolley operator rail hung right in the way, making it impossible. By switching to a jackshaft system, they cleared the entire ceiling area. The new lift went in without a hitch, and they were able to instantly expand their service capabilities and increase revenue.

The jump to jackshaft technology has really changed the game in commercial door automation. The technology was popularized for residential use in the early 2000s and has since evolved into the powerful, reliable commercial models we depend on today.

At the end of the day, a successful installation is all about matching the right equipment to the right application. As your “Respected Partners, Reliable Service,” we make sure every single detail is accounted for.

Preventive Maintenance and Troubleshooting Tips

In any commercial facility, uptime is everything. A door that won’t open at a critical loading dock or service bay isn’t just an inconvenience; it can bring your entire operation to a grinding halt. When it comes to jackshaft garage door openers, a proactive maintenance plan is the single best way to guarantee safety, sidestep costly downtime, and get the most out of your investment.

Like any piece of heavy machinery, these operators need regular attention. Ignoring what seems like a small issue—a strange noise or a slight hesitation—can snowball into a catastrophic failure. A structured maintenance schedule helps you spot these red flags early, long before they turn into expensive emergencies.

A Proactive Maintenance Schedule

A consistent inspection routine is the backbone of reliability. By breaking tasks down into daily, monthly, and annual checks, the process becomes simple and ensures nothing falls through the cracks.

Daily Checks (Performed by On-Site Staff)

These are quick visual and auditory inspections that can be done at the start of every shift.

- Visual Scan: Glance over the door, tracks, and the operator itself. Look for any new dings, dents, or obstructions in the door’s path.

- Listen for Unusual Sounds: Pay close attention when the door is moving. Any grinding, squeaking, or banging noises are tell-tale signs of a mechanical problem that needs to be looked at right away.

Monthly Checks (Performed by a Maintenance Supervisor)

These checks are a bit more hands-on and focus on testing the systems that keep your people safe.

- Test Safety Features: Place a soft object (like an empty cardboard box) under the door to make sure the photo-eyes detect it and reverse the door. You should also test the reversing edge on the bottom of the door to confirm it backs up immediately on contact.

- Inspect the Manual Release: Find the emergency disengage handle. It needs to be easy to get to and operate smoothly, just in case of a power outage.

Annual Inspection (Performed by a Certified Technician)

This is the deep dive that should only be handled by a professional. At Wilcox Door Service, our union-certified technicians perform comprehensive checks to keep your equipment running like new.

- Chain and Sprocket Inspection: The technician will check the drive chain for the correct tension and inspect the sprocket teeth for any signs of wear.

- Lubrication: All moving parts, including the gearbox and drive mechanism, get lubricated according to the manufacturer’s exact specifications.

- Motor and Electrical Diagnostics: This involves checking all electrical connections to ensure they’re tight and running diagnostics on the motor to confirm it’s drawing the correct amperage.

- Hardware Tightening: The tech will go over all the mounting bolts for the operator and the door itself, tightening everything to prevent issues caused by constant vibration.

A well-documented maintenance history isn’t just good practice—it’s vital for compliance and can be a lifesaver when diagnosing a tricky recurring issue. Proactive care is always cheaper than reactive repair, a principle we dig into in our guide on the benefits of a commercial garage door maintenance plan.

Common Troubleshooting Guide for Facility Managers

Even with the best maintenance, things can still go wrong. Knowing how to identify the problem helps you decide if it’s a quick fix or if it’s time to call in the experts.

Issue 1: Door Won’t Close and Operator Clicks

This is probably the most common call we get, and it almost always points to an issue with the safety sensors.

- What to do: First, check if anything is blocking the photo-eyes. Next, look at the small LED lights on both sensors—they should be solid, not blinking. If one is blinking, they’re out of alignment. Gently adjust one of the sensors until both lights go solid. The door should now work properly.

Issue 2: The Door Makes a Grinding or Straining Noise

That kind of sound usually signals a more serious mechanical problem.

- What to do: Stop using the door immediately and cut the power to the operator. This could be a sign of a failing gearbox, a damaged sprocket, or an issue with the door itself, like a broken spring. Do not attempt to fix this yourself. It needs a professional diagnosis to avoid causing even more damage.

Knowing how to handle these simple troubleshooting steps can empower your team to resolve minor hiccups on the spot. More importantly, it helps everyone recognize the signs of a serious problem that requires a trained technician.

When your facility’s uptime is on the line, trust the experts. Contact Wilcox Door Service to schedule a professional maintenance inspection for your jackshaft operators.

Choosing the Right Commercial Jackshaft Operator

Picking the right commercial jackshaft operator for your facility isn’t just another item on a checklist—it’s a decision that directly affects your daily efficiency, safety, and long-term repair budget. This is definitely not a one-size-fits-all purchase. The ideal unit has to be perfectly matched to the unique demands of each doorway, because a mismatch can lead to premature wear, frustrating downtime, and even serious safety risks.

Getting this right starts with a solid evaluation of a few key factors to make sure the operator has the right muscle and stamina for the job. Honestly, the best way to nail this is with a professional assessment.

Key Decision Factors

When you’re looking at specifying a jackshaft garage door opener, you need to weigh these variables carefully:

- Door Size and Weight: This is the most obvious one. Heavier, larger doors need operators with more horsepower (HP) and beefier gearboxes. Trying to lift a heavy door with an underpowered motor is a recipe for strain and early failure.

- Duty Cycle: Think about how many times a day that door is going to move. A loading dock door that’s flying up and down 100+ times a day requires a heavy-duty, high-cycle operator built for that kind of punishment. On the other hand, a door that’s only used a few times a week can get by with a standard medium-duty model.

- Environmental Conditions: Where is this door located? A food processing plant, a car wash, or any facility with high moisture needs an operator with a specialized, water-tight enclosure (like a NEMA 4X rating) to fight off corrosion and prevent electrical shorts.

- Power Supply: You have to match the operator to the power you have on-site. Check the available voltage (120V, 208V, 460V, etc.) and confirm if you need single-phase or three-phase power. It’s a simple check, but missing it can bring an installation to a dead stop.

Choosing the correct operator ensures you get the performance and longevity you expect. Our commitment to being “Respected Partners, Reliable Service” means we guide you to the right solution, not just the most expensive one.

Ultimately, the smartest move is to partner with an experienced provider who knows the ins and outs of these systems. Our team’s expertise is backed by industry recognition, as detailed in our announcement about Wilcox achieving Platinum Dealer status. A professional consultation guarantees that your operator won’t just work—it will meet every operational demand and safety code for years to come.

Ready to see if a jackshaft operator is the right fit for your facility? Contact us today for a professional consultation and quote.