As a facility manager, you're responsible for keeping your property both secure and accessible. This guide will walk you through everything you need to know about mag locks for doors, from how these powerful electromagnetic devices work to choosing the right one for your building. You'll learn the critical difference between fail-safe and fail-secure systems, how to integrate them with your existing access control, and how to stay compliant with Canadian fire codes.

How Mag Locks Work and Why They’re a Go-To for Facility Security

Magnetic locks, or "mag locks," are a cornerstone of modern security for commercial and industrial buildings. Unlike a traditional lock with keys and bolts that can wear out, a mag lock uses the simple, powerful force of electromagnetism to secure a door. Their design has no moving parts, making them incredibly durable and a perfect solution for high-traffic areas where reliability is key.

At its core, the system consists of two main components:

- The Electromagnet: This is a powerful magnet that is mounted directly onto the door frame and connected to a low-voltage power source.

- The Armature Plate: This is a simple, flat steel plate mounted on the door itself, positioned to line up perfectly with the electromagnet.

When electricity is supplied to the electromagnet, it creates a strong magnetic field that pulls the armature plate tight, locking the door with hundreds or even thousands of pounds of force. To open the door, an access control device like a keypad or card reader temporarily cuts the power. The magnetic field instantly disappears, releasing the plate and allowing the door to open.

alt="A magnetic lock for a glass door, illustrating a high-security mag lock system."

The genius of mag locks lies in their simplicity. With no mechanical parts like springs or bolts to wear down, they offer an exceptionally long service life with minimal maintenance—a major benefit for any busy facility.

Understanding this principle is essential for any facility manager. Consider a main employee entrance at a busy warehouse that's used hundreds of times each day. A standard mechanical lock would wear out quickly under that strain, but a mag lock handles the high traffic effortlessly. Similarly, for securing a server room, the immense holding force of a mag lock provides robust protection that can't be picked or bypassed mechanically.

From standard office doors to heavy-duty hollow metal door applications, these locks deliver reliable performance. They also integrate seamlessly with systems like automatic door operators to create a secure, accessible, and user-friendly entryway.

Fail-Safe vs. Fail-Secure: The Critical Difference

For any facility manager, understanding the difference between fail-safe and fail-secure locking systems is not just a technical detail—it's a critical decision impacting both life safety and asset protection. This distinction defines how a lock behaves during a power outage, with significant implications for your building's compliance and security strategy.

The choice between fail-safe and fail-secure is a fundamental part of responsible facility management, balancing the need to protect people in an emergency with the need to secure valuable assets.

A fail-safe system is designed to unlock when power is lost. All magnetic locks are inherently fail-safe because the electromagnet requires a constant electrical current to remain locked. If the power is cut, the magnetic field collapses, and the door releases. This function is essential for emergency exits, ensuring people can always evacuate safely, even during a building-wide power failure.

A fail-secure system, on the other hand, remains locked when power is lost. This is typical of electric strikes, where power is required to unlock the door. Without power, the bolt stays in place, keeping the area secure.

Real-World Example: A Distribution Centre Fire Exit

Imagine a fire exit at a busy loading dock. On a typical day, this door must remain securely locked to prevent theft and unauthorized entry. However, in an emergency, it must allow employees to exit immediately and without obstruction.

This is the perfect application for a fail-safe magnetic lock.

- During Normal Operation: The mag lock is powered, securing the door with over 1,200 lbs of holding force. Staff can exit using a push-to-exit button or enter with a keycard.

- During an Emergency: The moment the fire alarm is triggered, power to the mag lock is automatically cut. The door instantly unlocks, allowing staff to push it open and evacuate safely, often via integrated panic bar hardware.

This fail-safe functionality is a non-negotiable life-safety requirement under Canadian building codes. Installing the wrong type of lock on an egress path can have severe consequences, which is why partnering with an experienced team like Wilcox Door Service is crucial. We ensure every access point is designed for both security and full compliance.

Choosing the Right Mag Lock for Your Facility

Selecting the right mag lock involves more than just picking a model from a catalogue. It requires balancing your security objectives, the type of door, and relevant building codes. The most important factor in this decision is the lock's holding force.

Holding force is the amount of direct pressure, measured in pounds (lbs), a lock can withstand before being forced open.

A higher holding force indicates a stronger lock designed to resist more significant forced entry attempts. Matching the lock's strength to the security requirements of each specific doorway ensures you are not overspending on a high-power lock for a low-risk interior door or, more critically, under-protecting a key entry point.

For instance, an internal office door might only require a lock with 600 lbs of holding force. But for a high-security exterior entrance on a commercial building, especially a heavy-duty hollow metal doors, you would need a much more robust solution, typically rated for 1200 lbs or more.

Matching Holding Force to Your Application

The right holding force depends on the door's location, its purpose, and the assets it protects. A one-size-fits-all approach is ineffective in a commercial setting where security needs can vary dramatically from one area to another.

Here is a quick reference to help facility managers match holding force to common commercial door applications.

Matching Mag Lock Holding Force to Commercial Doors

| Holding Force (lbs) | Typical Application | Example Use Case |

|---|---|---|

| 300 – 600 lbs | Low-Security Interior Doors | An office door, a small supply closet, or a staff room with minimal security risk. |

| 600 – 800 lbs | Medium-Security Interior & Low-Traffic Exterior | A server room, a pharmaceutical storage area, or a secondary employee entrance. |

| 1200 lbs | High-Security & Main Entrances | A primary building entrance, a shipping and receiving door, or access to a restricted area. |

| 1500+ lbs | Maximum Security & High-Risk Areas | A government facility entrance, a bank vault anteroom, or a critical infrastructure control room. |

This table serves as a starting point. A professional security assessment would also consider factors like foot traffic, door construction, and environmental exposure.

This careful approach to security is driving significant growth in the market. In Canada, mag locks have become an essential component of modern access control. The Canadian magnetic door lock market was valued at USD 85.6 million in 2024 and is projected to reach USD 251.3 million by 2032. This growth, representing a compound annual growth rate (CAGR) of over 16%, is largely driven by strict safety standards within the National Building Code of Canada (NBC).

Single vs. Double Door Mag Locks

Beyond holding force, you must consider the door configuration. The main options are single and double-door mag locks.

- Single Door Mag Locks: This is the most common configuration, consisting of one electromagnet and one armature plate for a standard single door.

- Double Door Mag Locks: Required for a pair of doors that meet in the middle without a central vertical support (a mullion). This setup typically includes two electromagnets in a single housing that spans the top of the frame, with one armature plate on each door.

The choice is dictated entirely by the door's design. A double-door lock ensures both doors are secured equally and, more importantly for emergency exits, release simultaneously when power is cut.

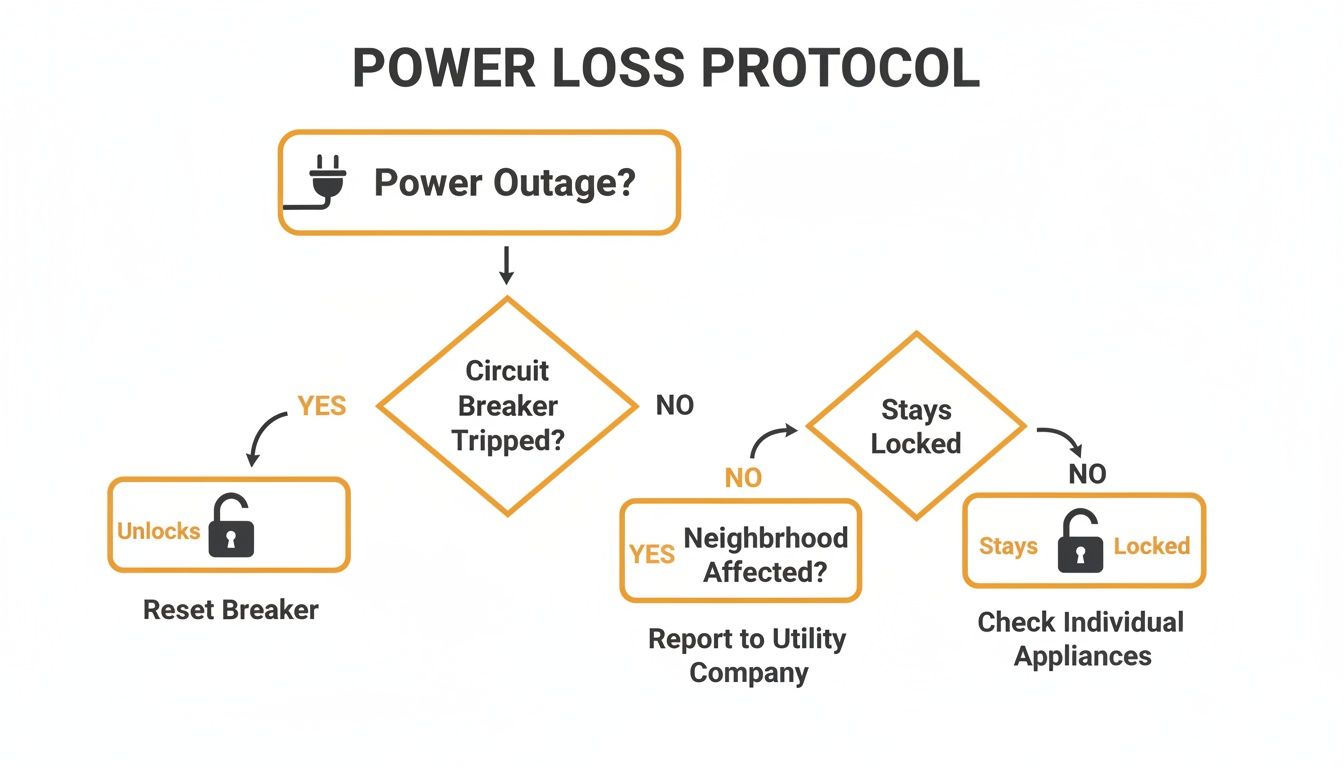

This flowchart illustrates how mag locks behave during a power failure.

alt="Flowchart showing the fail-safe protocol for mag locks for doors during a power outage."

It reinforces a key principle: mag locks are fail-safe, unlocking without power. This is a critical consideration for emergency exits that must comply with fire codes. As your "Respected Partners, Reliable Service," Wilcox Door Service has the expertise to assess your facility and recommend the ideal mag lock solution.

Installation and Access Control Integration

A powerful mag lock is only effective if installed and integrated correctly. Proper installation is the crucial step that transforms a piece of hardware into a reliable part of your facility's security ecosystem. This process requires precision alignment, clean wiring, and seamless integration with your existing access control system.

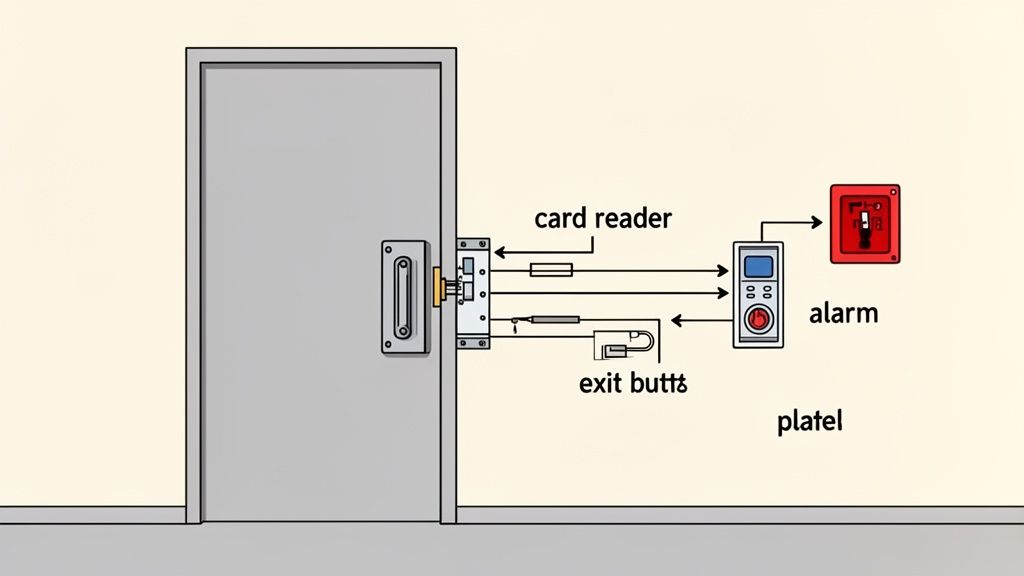

alt="Diagram showing how mag locks for doors integrate with an access control system."

The physical mounting demands perfect alignment. The electromagnet on the frame and the armature plate on the door must meet flush, without any gaps. Even a slight misalignment can significantly reduce the lock's holding force, creating a security vulnerability.

Connecting to Your Access Control System

To function, mag locks for doors must be wired into an access control network. They don't operate independently; they receive commands from various input devices that manage access permissions.

A typical integrated setup includes several key components:

- Access Control Reader: This device, such as a keycard scanner, fob reader, or keypad, verifies credentials before sending an unlock signal to the control panel.

- Control Panel: This is the "brain" of the system. It processes the signal from the reader and instructs the power supply to cut electricity to the mag lock for a brief period.

- Push-to-Exit Button: Installed on the secure side of the door, this button allows for immediate and easy exit by directly cutting power to the lock.

- Motion Sensors (REX): In some high-traffic areas, a Request-to-Exit (REX) motion sensor detects a person approaching from the inside and automatically unlocks the door, often used in conjunction with automatic door operators.

A properly integrated mag lock system perfectly balances robust security with safe, convenient egress. This balance is the hallmark of a professionally designed access solution.

A Real-World Integration Example

Consider a high-security data centre. When an authorized technician approaches, they swipe their keycard. The control panel verifies their access level and the time, then cuts power to the mag lock. Inside, a clearly marked push-to-exit button allows for a quick departure.

Crucially, the system is also tied into the building’s fire alarm. If an alarm is triggered, the panel sends an override signal that instantly cuts power to the mag lock, ensuring it fails safe and allows for emergency evacuation. This seamless integration addresses both asset protection and life safety.

The Importance of Professional Installation

Due to the complexities of low-voltage wiring, system programming, and fire code compliance, installing mag locks for doors is not a DIY task. A minor wiring error could lead to intermittent failures, false alarms, or a lock that fails to release in an emergency.

Certified technicians, like the union-certified team at Wilcox Door Service, possess the specialized expertise to handle these installations correctly. They ensure every component is wired properly, the lock achieves its maximum holding force, and the entire system operates flawlessly. This professional touch is the difference between a security risk and a reliable, code-compliant access point. As your "Respected Partners, Reliable Service," we deliver installations you can trust.

Navigating Canadian Fire Codes and Egress Rules

For facility managers in Canada, installing mag locks for doors is governed by strict fire and building codes. These regulations are not just guidelines; they are life-saving requirements designed to ensure everyone can exit a building safely during an emergency.

The National Building Code of Canada (NBC) sets the national standard, though provinces may have additional requirements. The fundamental rule for any door on a designated egress path is that it must allow for free and immediate exit without requiring a key, special knowledge, or excessive effort.

Core Principles of Egress Compliance

When a mag lock secures an exit door, it must be configured to release instantly under specific emergency conditions. The fail-safe nature of magnetic locks is a critical safety feature in these applications.

Your installation must meet these three non-negotiable criteria:

- Release Upon Fire Alarm: The lock must be wired into the building's fire alarm system. When an alarm is triggered, power to the mag lock must be cut automatically.

- Release Upon Power Failure: As a fail-safe device, the lock must unlock the moment it loses power, ensuring an escape route is available even if the building's power supply is compromised.

- Manual Release: A clearly marked manual release device, typically a green "push to exit" button, must be installed near the door. This button must directly interrupt power to the lock, overriding all other system commands.

Understanding and implementing these release mechanisms is not just about avoiding fines; it's a fundamental responsibility for protecting the people inside your facility. A non-compliant exit door can turn a manageable emergency into a tragedy.

The Importance of Certified Hardware

Beyond installation, the hardware itself must meet Canadian standards. Look for certifications like ULC/ORD-C1000, which indicates the equipment has been tested and approved for use in fire alarm and life safety systems. Using uncertified hardware creates a significant liability risk and may void your insurance coverage.

These safety regulations have a proven track record. Following amendments to the NBC after 1995, mag locks were installed in 72% of new industrial buildings by 2000. Additionally, facilities using UL-listed mag locks reported 55% fewer forced-entry claims, according to property crime data.

Maintenance and Troubleshooting Common Issues

While mag locks for doors are known for their durability, a simple and consistent maintenance routine is essential for ensuring long-term reliability. Proactive checks can extend their lifespan and prevent sudden failures, keeping your access points secure, compliant, and dependable.

Think of it like any other critical piece of facility equipment. A few minutes of preventative care can save you hours of downtime and major headaches.

Your Practical Maintenance Checklist

A proactive approach to maintenance is always better than a reactive one. This process can be easily integrated into your existing facility maintenance schedules, much like an ultimate rental property maintenance checklist.

- Check for Secure Mountings: Regular use and door vibrations can loosen mounting hardware over time. Physically check that both the electromagnet and the armature plate are securely fastened. Any movement can cause misalignment and reduce holding force.

- Clean Magnet and Plate Surfaces: Dirt, dust, and residue can accumulate on the contact surfaces, creating a small gap that weakens the magnetic bond. Wipe both components with a clean, soft cloth to ensure full contact.

- Test Release Functions: Regularly test all exit mechanisms. This includes the manual push-to-exit button, the access control reader, and the crucial integration with your fire alarm system. The lock must release instantly when the alarm is triggered.

Troubleshooting Common Mag Lock Problems

Even with proper maintenance, issues can arise. Fortunately, the simple design of mag locks makes troubleshooting straightforward.

A Door That Won’t Lock: This is almost always a power or alignment issue. First, verify the power supply and wiring. If power is flowing correctly, inspect the alignment between the magnet and the armature plate. Even a slight shift can prevent a solid magnetic bond.

A Buzzing or Humming Sound: A buzzing noise is a clear indicator of a poor connection. It means the magnet and plate are not sitting perfectly flush, causing vibration. This significantly reduces the lock's holding force and should be addressed immediately by cleaning the surfaces and checking alignment.

If these troubleshooting steps don’t resolve the issue, it’s time to call in the professionals. As your "Respected Partners, Reliable Service," Wilcox Door Service provides expert support to ensure total reliability.

Common Questions We Hear About Mag Locks

As you consider your security options, some practical questions are bound to come up. Here are answers to some of the most common inquiries we receive from facility managers about mag locks for doors.

Can a Mag Lock Actually Be Forced Open?

While no lock is completely immune to extreme force, high-quality mag locks are exceptionally difficult to defeat. Their strength lies in their powerful electromagnetic holding force—often exceeding 1,200 lbs—and a design with no moving parts to pick or manipulate. The security of the door depends entirely on this magnetic bond, which is why a precise, professional installation is so crucial to achieving maximum strength.

What Happens to a Mag Lock When the Power Goes Out?

This is one of the most important concepts to understand. How a mag lock behaves during a power outage depends on its application.

- For Emergency Exits: The lock must be 'fail-safe'. This means it releases the moment power is cut, a mandatory fire code requirement that guarantees a clear path for evacuation.

- For High-Security Areas: For locations like a server room where security is the top priority, the system can be connected to a battery backup or an Uninterruptible Power Supply (UPS). This ensures the lock remains engaged and the area stays secure even during a power outage.

How Do Mag Locks Work with Other Building Systems?

A mag lock is a component within a larger access control ecosystem. It is wired to a central controller that serves as the brain, telling it when to lock and unlock based on signals from various inputs.

For instance, when an employee swipes a keycard, the reader sends a signal to the controller, which then briefly cuts power to the mag lock to grant access. In an emergency, the building's fire alarm panel is programmed to send an override signal that cuts power to all designated egress doors simultaneously. This seamless integration makes mag locks a flexible and powerful tool for any modern facility.

Your facility's security and the safety of its occupants depend on expertly designed and installed access control solutions. At Wilcox Door Service, we provide the deep expertise and reliable service needed to ensure your mag lock systems are effective, compliant, and dependable.

For a professional security assessment or to learn more about our Planned Maintenance Programs, Contact us today and discover the Wilcox difference: Respected Partners, Reliable Service.