Picking the right metal door for your business can feel like a huge task, but it really boils down to matching the material to your daily operations. This guide is here to simplify the process, explaining the real-world differences between various metal doors commercial facilities use, like steel, stainless steel, and aluminum. We’ll translate technical terms—such as fire ratings and insulation values—into practical knowledge you can use to protect your building, lower energy costs, and make a smart, long-term investment.

Understanding the Materials: Steel, Stainless Steel, and Aluminum

When you’re looking at new or replacement doors for your facility, the first big decision is the material. This choice is the foundation for everything else—security, durability, and what you’ll spend on maintenance down the road.

While there are a few options out there, steel is the undisputed champion in most commercial settings, and for good reason. Its raw strength is a massive deterrent against forced entry, and it’s built to handle the daily abuse of a busy environment, from a bustling warehouse dock to a high-traffic main entrance.

The numbers back this up. Steel doors are on track to command a massive 45.6% market share in the metal door world by 2025. A huge chunk of that comes from hollow metal doors, which have become a staple in commercial construction thanks to their incredible fire resistance and ability to meet strict safety codes. You can learn more about the metal doors market outlook to see the trends for yourself.

Alt text: A pair of industrial grey metal doors with windows, illustrating common commercial metal door options.

What to Know About Each Material

Getting a feel for the core strengths of each metal will help you line up your choice with what your business actually needs.

- Steel Doors: Think of these as the industry standard for tough security and sheer durability. They’re perfect for exterior entrances, warehouses, and any spot that needs serious protection. They’re also incredibly versatile and can be filled with different cores, like insulation, to boost thermal performance.

- Stainless Steel Doors: These are prized for their ability to resist corrosion (rust) and for their hygienic properties. You’ll find them in environments where cleanliness is non-negotiable—think commercial kitchens, food processing plants, hospitals, and labs where harsh chemicals are a daily reality.

- Aluminum Doors: Lightweight and naturally rust-resistant, aluminum is a great fit for places like retail storefronts and interior offices where looks and ease of use are key. While they aren’t as tough as steel, they offer a clean, modern aesthetic and are often used in glass-and-aluminum storefront systems.

To make the right choice, you have to look past the upfront price tag and think about the door’s entire lifecycle. A well-chosen door doesn’t just secure your building; it supports your operational efficiency day in and day out.

Quick Comparison of Commercial Metal Door Materials

This table summarizes the main characteristics of each common commercial metal door material to help you make a quick, informed decision.

| Material Type | Primary Benefit | Best For Environments Like | Consideration |

|---|---|---|---|

| Steel | Unmatched strength and security | Exterior entryways, warehouses, industrial facilities, schools | Can rust if the protective coating is compromised; requires painting/finishing. |

| Stainless Steel | Superior corrosion resistance and hygiene | Commercial kitchens, hospitals, laboratories, food processing plants | Higher initial cost compared to standard steel. |

| Aluminum | Lightweight, rust-proof, and aesthetically versatile | Retail storefronts, office interiors, curtain wall systems | Less durable and secure than steel; not ideal for high-impact areas. |

Ultimately, a door is a long-term investment. At Wilcox Door Service, we believe in providing solutions that deliver lasting value, embodying our promise of “Respected Partners, Reliable Service.”

Ready to find the perfect door for your facility? Contact our team for a professional consultation and quote.

Exploring Different Types of Metal Doors

Choosing the right type of metal doors commercial properties need is all about matching the door to the specific demands of its environment. From the everyday workhorse you see in offices to highly specialized fire-rated assemblies, each option brings something different to the table. Getting this choice right is the key to a smart, long-lasting investment in your facility’s security, safety, and efficiency.

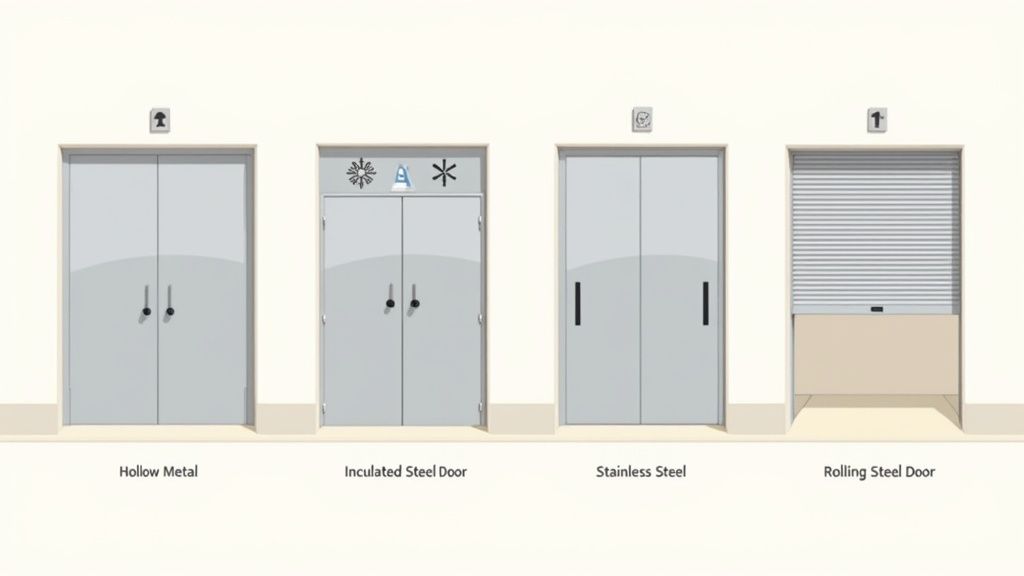

In this section, we’ll walk through the most common types of commercial metal doors you’ll encounter. We’ll start with the industry-standard hollow metal door, move on to insulated and stainless steel options for specific needs, and then look at the clever, space-saving rolling steel doors that solve unique layout challenges. You’ll get a clear picture of where each door shines and see exactly where they fit best in the real world.

Alt text: Four distinct commercial metal doors: Hollow Metal, Insulated Steel, Stainless Steel, and Rolling Steel.

The Industry Workhorse: Hollow Metal Doors

When you picture a typical commercial entry, you’re probably thinking of a hollow metal door. There’s a good reason they’re everywhere in schools, offices, and industrial settings: they deliver a fantastic balance of strength, fire resistance, and overall value.

Now, the term “hollow” can be a bit deceiving. While the core isn’t a solid slab of steel, it’s typically reinforced with steel stiffeners or filled with materials like honeycomb cardboard to add rigidity. This construction makes them tough enough for high-traffic areas without being excessively heavy or expensive.

Insulated and Stainless Steel Doors

Going beyond the standard, insulated steel doors are a must-have for any business that needs to control its climate. These doors have a core of polyurethane foam, which pretty much works like the insulation in your building’s walls. This core prevents heat transfer, keeping the cool air in during the summer and the warm air in during the winter.

- Real-World Example: Picture a food distribution centre with a large refrigerated section. They’ll use insulated steel doors to separate the cold storage area from the ambient-temperature warehouse. This simple choice drastically cuts down on energy consumption and stops condensation from building up.

Stainless steel doors, on the other hand, serve a more specialized role. Their biggest advantages are incredible corrosion resistance and a hygienic, easy-to-clean surface. This makes them the only real option in certain environments:

- Commercial Kitchens: They stand up to constant cleaning with harsh chemicals.

- Hospitals and Labs: Their non-porous surface is key to preventing bacterial growth.

- Marine Environments: They won’t rust, even when exposed to salt spray.

Space-Saving Rolling Steel Doors

For areas with limited overhead space, a rolling steel door is an ideal solution. Unlike a traditional sectional door that needs a large track system running along the ceiling, a rolling steel door coils up neatly into a compact roll right above the opening. This is a game-changer for facilities where ceiling space is at a premium.

For example, in a busy warehouse used for zone separation, the ceiling might be crowded with sprinklers, lighting, and HVAC ducts. A sectional door’s tracks would interfere, but a rolling steel door fits perfectly, maximizing vertical clearance. This minimal headroom requirement makes them perfect for loading docks, service counters, and any application where you can’t afford to lose overhead space.

Critical-Use Doors: Fire-Rated and Acoustic

Finally, we have metal doors designed for life safety and very specific performance needs. Fire-rated doors are not just an option—they are a legal requirement in many commercial buildings. They are built and rigorously tested to contain a fire for a specific amount of time, like 90 minutes or 3 hours. This containment prevents flames and smoke from spreading, giving people crucial time to evacuate safely.

Acoustic doors, sometimes called sound-dampening doors, are engineered to block noise. You’ll find them in places like recording studios, boardrooms, or industrial plants where you need to isolate loud machinery from office areas. Their construction involves multiple dense layers and specialized seals to achieve a high Sound Transmission Class (STC) rating, effectively turning down the volume between two spaces.

Understanding these different types ensures you can pick a door that does more than just open and close—it actively contributes to your facility’s safety, efficiency, and compliance.

Decoding Key Performance and Safety Ratings

Choosing the right type of metal door for your commercial building is only half the story. The other, arguably more critical, half is understanding the performance ratings on the spec sheet. These numbers and codes aren’t just technical jargon—they’re direct indicators of how a door will perform in the real world, affecting everything from your energy bills to the safety of everyone inside.

Think of this section as your guide to turning complex specifications into confident decisions. We’ll break down the most important metrics in simple terms, covering thermal ratings that impact your heating and cooling, acoustic ratings that control noise, and the non-negotiable fire ratings essential for life safety.

Thermal Performance: U-Values and R-Values

When it comes to controlling your facility’s temperature and, more importantly, your energy costs, two ratings matter most: U-value and R-value. They both measure how well a door resists heat flow, just from opposite perspectives.

- U-Value: This tells you how much heat passes through the door. For U-values, lower is always better. A low number means less heat is escaping in the winter or creeping in during the summer. For an exterior door on a climate-controlled warehouse, a low U-value is a top priority.

- R-Value: This measures the door’s ability to resist heat flow. In this case, a higher R-value is better, indicating superior insulation. An insulated steel door with a high R-value acts like a thermal barrier, much like the insulation in your walls.

It’s like this: a low U-value is a well-sealed thermos that keeps your coffee hot, while a high R-value is a thick winter coat. Both achieve the same goal—preventing heat transfer.

Sound Transmission Class (STC) Ratings

Noise control is a huge deal in many commercial environments, from corporate offices to manufacturing plants. The Sound Transmission Class (STC) rating tells you exactly how good a door is at blocking sound.

An STC rating is basically a volume knob for your door. The higher the number, the more sound the entire door assembly—door, frame, and seals—blocks. A standard hollow metal door might have an STC rating around 20-25, which is fine for general use. But for a private boardroom or a quiet room next to a noisy factory floor, you’ll want a door with an STC rating of 45 or higher to keep conversations private and distractions out.

Fire Safety Ratings

Of all the performance ratings, fire ratings are the most critical. They aren’t optional; they’re about life safety and code compliance. A fire-rated door is part of a complete fire-rated assembly—including the frame and hardware—that is tested and certified to contain a fire for a specific amount of time.

A fire rating is a measure of time. It tells you how long a door can withstand a fire, preventing the spread of flames and smoke. Common ratings include 20-minute, 45-minute, 90-minute (1.5-hour), and 3-hour ratings.

For instance, a 90-minute rated door in a stairwell is designed to hold back a fire for at least an hour and a half, giving people crucial time to evacuate. For a deeper dive, check out our guide on understanding fire-rated doors and inspections.

At Wilcox Door Service, our “Respected Partners, Reliable Service” philosophy means we help you navigate these critical ratings. We make sure the doors you choose not only meet your day-to-day needs but also stick to every safety code, protecting your people and your property.

If you need help selecting a door with the right performance ratings for your facility, schedule a consultation with our experts today.

How to Choose the Right Door for Your Application

Choosing the right metal doors commercial buildings need isn’t about finding the single “best” door on the market. It’s about finding the right door for your facility’s unique rhythm and daily demands. The perfect choice for a high-traffic warehouse loading dock will be worlds apart from what a quiet hospital corridor requires.

Think about a busy distribution centre for a moment. Its loading dock doors might slam open and shut hundreds of times a day. In that environment, extreme durability and high-cycle performance are completely non-negotiable. A heavy-duty rolling steel door is often the go-to solution because it’s built like a tank and coils up neatly, leaving precious overhead space for lights and sprinklers. This is a huge advantage over sectional doors, which need a whole network of ceiling tracks.

Now, picture a healthcare facility. Here, hygiene, sanitation, and ease of cleaning are the top priorities. A stainless steel door is the clear winner. Its non-porous surface stands up to harsh cleaning chemicals without corroding and helps stop bacteria from finding a place to hide, making it a must-have for operating rooms and labs.

Matching the Door to the Daily Grind

To land on the right door, you have to ask the right questions. Put on your facility manager hat and think about the day-to-day life of that specific opening. A quick checklist can focus your thinking and help you zero in on the features that genuinely matter.

Start by asking yourself:

- How often will it be used? An emergency exit that’s rarely touched has different requirements than a main entrance with a constant flow of people.

- What’s the security risk? Is the door in a vulnerable area prone to break-ins? This dictates the need for reinforced steel, heavy-gauge construction, and advanced locking hardware.

- What is it up against? Will it face brutal weather, corrosive chemicals, or extreme temperatures? An exterior door on the coast needs top-tier rust resistance, while a freezer door needs a high R-value to keep the cold in.

- How does it affect workflow? Does it need to open in a flash to keep production moving, like a high-speed door in a factory? Or does it need to muffle sound for a corporate boardroom?

Answering these questions helps you build a detailed profile of your ideal door, ensuring your investment boosts both security and operational efficiency.

Visualizing Key Performance Ratings

Not sure where to start? This visual breaks down how to prioritize door ratings based on your primary concern—whether that’s managing climate, controlling noise, or ensuring fire safety.

Alt text: Graphic illustrating key commercial metal door ratings for insulation (thermometer), sound (speaker), and fire (flame).

This simple guide helps cut through the noise. The selection process really begins by identifying the single most critical performance factor for that specific spot in your building.

A Practical Guide: Doors for Different Facilities

Choosing the right door becomes much easier when you match it to the building’s purpose. A retail storefront needs a different solution than a pharmaceutical lab. Below is a quick guide to connect common facility types with the door features that matter most.

| Facility Type | Recommended Door Type | Key Feature to Prioritize | Common Wilcox Solution |

|---|---|---|---|

| Warehouse/Distribution | Rolling Steel or Sectional Door | High-Cycle Durability, Speed | High-performance rolling or sectional doors built for thousands of cycles. |

| Healthcare/Hospital | Stainless Steel Pedestrian Door | Hygiene, Corrosion Resistance | Easy-to-clean stainless steel doors that withstand harsh sanitizers. |

| Manufacturing Plant | High-Speed Fabric or Rubber Door | Operational Speed, Durability | Rapid-open doors that keep production lines moving without interruption. |

| Office Building Stairwell | Fire-Rated Hollow Metal Door | Life Safety, Fire Code Compliance | 90-minute fire-rated doors that meet or exceed building codes. |

| Retail Storefront | Aluminum & Glass Door, Security Grille | Security & Aesthetics | A combination of inviting glass entryways and robust after-hours security. |

| Cold Storage/Food Plant | Insulated Sectional Door | High R-Value, Thermal Seal | Doors with superior insulation (high R-value) to maintain temperature control. |

This table illustrates how the function of the space directly points to the right door solution. It’s all about aligning the product’s strengths with your operational needs. For highly specialized areas, like those needing precise environmental controls, the requirements get even more specific. For anyone working in such fields, resources on laboratory in-plant modular cleanroom solutions offer a deeper dive into their unique door needs.

Our Approach: At Wilcox Door Service, we always start by getting to know your operations. We don’t just sell doors; we deliver solutions that solve your facility’s unique challenges. It’s the core of our “Respected Partners, Reliable Service” commitment.

Whether you need a tough, high-cycle solution from our lineup of commercial rolling steel doors for your loading dock or a durable, insulated option from our sectional door collection for your main bays, we’re here to help you navigate the options.

Ready to find the perfect door for your application? Contact our team today to discuss your facility’s needs and get a tailored recommendation.

Ensuring Longevity with Proper Installation and Maintenance

Investing in a high-quality commercial metal door is a great first step, but that investment is only truly protected by what comes next: expert installation and consistent maintenance. A flawless installation is the foundation for a long-lasting, trouble-free door. It ensures perfect alignment, a proper seal, and smooth operation right from day one, heading off a whole host of future problems like frustrating alignment issues or costly energy loss.

But the job isn’t done once the door is installed. Proactive maintenance is what guarantees your doors will perform safely and efficiently for years to come. Think of it as our “Respected Partners, Reliable Service” philosophy in action. A simple, structured maintenance plan empowers you to catch small issues before they snowball into major, expensive breakdowns.

Alt text: A service technician in an orange vest inspects a light blue commercial metal door, highlighting the importance of maintenance.

The Critical Role of Professional Installation

Think of professional installation as setting the stage for peak performance. When a door is put in correctly, every single component works in harmony. The frame is perfectly plumb and square, the door hangs with perfect balance, and the seals create an airtight barrier against the elements. This kind of precision is crucial. Improper installation can lead to failed inspections, project delays, and costly rework. It’s a foundational step you just can’t afford to get wrong.

A Proactive Maintenance Plan for Facility Managers

Consistent care is the secret to getting the maximum lifespan out of your commercial doors. A proactive maintenance schedule helps you stay ahead of normal wear and tear, which is the key to ensuring both reliability and safety.

Here’s a simple plan that combines your team’s eyes on the ground with expert service:

- Monthly Visual Inspections: Get your team into the habit of doing quick monthly walk-throughs. They should look for obvious signs of trouble—things like frayed cables, damaged weather seals, visible rust on steel doors, or any grinding sounds during operation.

- Quarterly Lubrication: Moving parts like rollers, hinges, and springs need regular lubrication. This simple step reduces friction and helps prevent parts from failing prematurely.

- Annual Professional Servicing: Once a year, it’s time to call in a certified technician for a comprehensive inspection and tune-up. This is absolutely essential for complex tasks that require specialized knowledge and tools.

Key Takeaway: A planned maintenance program isn’t an expense; it’s an investment in uptime and safety. It prevents the kind of unexpected downtime that can halt your operations and helps you meet safety compliance standards, which is especially critical for systems like fire doors.

When to Call in the Experts

While quick visual checks are great, some jobs should always be left to trained professionals. Their expertise is non-negotiable for any task that impacts safety and compliance.

You should always schedule a professional service call for:

- Hardware Adjustments and Spring Tensioning: The springs on large commercial doors are under extreme tension. Trying to adjust them without the right tools and training is incredibly dangerous.

- Fire Door Drop Testing: NFPA 80 standards mandate that fire-rated doors must be tested annually by a qualified person to ensure they will close and latch properly in an emergency.

- Automated Operator Servicing: The motors and electronics that power your automated doors require an expert touch to diagnose issues and keep them running safely and efficiently.

This balanced approach—combining your team’s vigilance with professional oversight—is the most effective way to protect your investment. To see how this works in practice, you can learn more about the benefits of a planned garage door maintenance program in our detailed guide.

By partnering with experts for both installation and ongoing care, you ensure your commercial doors remain a reliable asset rather than becoming a potential liability.

Your Partner in Commercial Door Solutions

Figuring out the world of commercial metal doors doesn’t have to be a headache. As this guide has shown, once you get a handle on the different door types, learn to decode the performance ratings, and make professional service a priority, you can make confident choices that directly help your facility run better every single day.

We’ve walked through the essentials to help you land on a solution that boosts safety, keeps you compliant, and improves your overall efficiency. The right door isn’t just a way in and out; it’s an active part of your building’s security and productivity.

From Selection to Service

At Wilcox Door Service, we don’t just sell and install doors. We see ourselves as your expert partners through the entire journey, from the first conversation about your needs to long-term maintenance and middle-of-the-night emergency calls. Our commitment is simple: provide guidance you can trust and work that you can depend on.

This is the very heart of our brand message: “Respected Partners, Reliable Service.” We build relationships that last by making sure your equipment performs exactly how it should—safely and efficiently—for its entire lifespan. Whether you need an insulated door to get energy costs under control or a high-cycle rolling steel door for a loading dock that never stops, our team has been there and done that.

We see ourselves as an extension of your facility management team. Our goal is to provide solutions that solve your immediate needs while also contributing to your long-term operational success and asset longevity.

Your Next Step

When you’re ready to get a handle on your facility’s access points, our team is here to help. We give clear, practical advice that fits your specific environment and budget. We get the challenges you’re up against and are dedicated to providing solid solutions that just plain work.

Take the next step toward a safer, more efficient facility. Contact the Wilcox team today to schedule your professional consultation.

A Few Common Questions About Commercial Metal Doors

Even with a good handle on the basics, facility managers almost always have a few specific questions when it comes to choosing or maintaining the right metal doors commercial buildings rely on. We get these questions all the time, so we’ve put together some straight, clear answers to help you make smart decisions without the guesswork.

What Is the Difference Between a Hollow Metal Door and an Insulated Steel Door?

On the surface, they can look pretty similar, but the key difference is what’s on the inside. A hollow metal door is essentially a steel frame and panels with a hollow core, though it’s usually reinforced with steel stiffeners to keep it rigid. Its main strengths are brute force and fire resistance, which is why it’s a go-to for so many interior and exterior doorways.

An insulated steel door, on the other hand, is filled with a dense polyurethane foam core. This core gives it a high R-value, which is just a technical way of saying it’s great at resisting heat flow.

Think of it like this: both doors are tough and secure, but the insulated one acts like a good winter jacket for your building. It helps keep your facility’s temperature stable, and that can make a real dent in your energy bills.

How Often Should Commercial Metal Doors Be Inspected?

For most commercial doors, getting a professional inspection done once a year is a solid rule of thumb. It’s the best way to make sure everything is working safely and correctly. But honestly, how often you inspect really comes down to usage.

- High-Use Doors: If you’re talking about a door on a busy loading dock or a main entrance that never stops moving, inspecting it twice a year is a much smarter move. This lets you catch wear and tear before it turns into a full-blown breakdown.

- Fire-Rated Doors: These are in a class of their own. The National Fire Protection Association (NFPA) requires that all fire-rated door assemblies be professionally tested and certified at least once a year. This isn’t just a suggestion; it’s a critical life-safety requirement to ensure they’ll do their job in a fire.

Can an Existing Commercial Door Be Upgraded?

Absolutely. In many cases, you can boost the performance of an existing door without needing a full replacement. It all depends on what you’re trying to achieve.

Looking for better security? You could add reinforced locks, swap in stronger commercial hardware, or even tie it into an access control system. To improve energy efficiency, a simple but effective upgrade is replacing worn-out weatherstripping and seals around the frame to stop drafts in their tracks.

That said, you have to weigh the cost against the benefit. If your goal is a major leap in thermal performance, trying to patch up an old, non-insulated door might not be worth it. In the long run, replacing it with a modern insulated model is often the more cost-effective move. The return you get from energy savings and better reliability usually justifies the upfront cost.

Ready to improve your facility’s safety and efficiency? Contact our team for a professional consultation or to schedule a service inspection.