In this guide, you'll learn everything a facility manager needs to know about the roll up steel door. We'll cover how they work, what key performance ratings like R-value and fire ratings mean for your operations, and provide a clear framework for choosing, installing, and maintaining the right door to enhance your facility's security and efficiency.

When you hear roll up steel door, what comes to mind? For many facility managers, it’s the sound of reliability. It’s a tough, secure barrier that practically vanishes into a compact coil above the opening, giving you back every inch of your valuable floor and ceiling space.

Think of it like a heavy-duty metal window shade. This simple but incredibly robust design is what makes it a true workhorse in commercial and industrial settings, a principle we stand by as your Respected Partners in delivering Reliable Service.

Understanding the Roll Up Steel Door

A roll up steel door gives you serious security and access control without the bulky overhead tracks that traditional sectional doors demand. This is a huge advantage in busy environments like loading docks, warehouses, and manufacturing plants where clear ceiling space is a must for high-stacked pallets or overhead equipment.

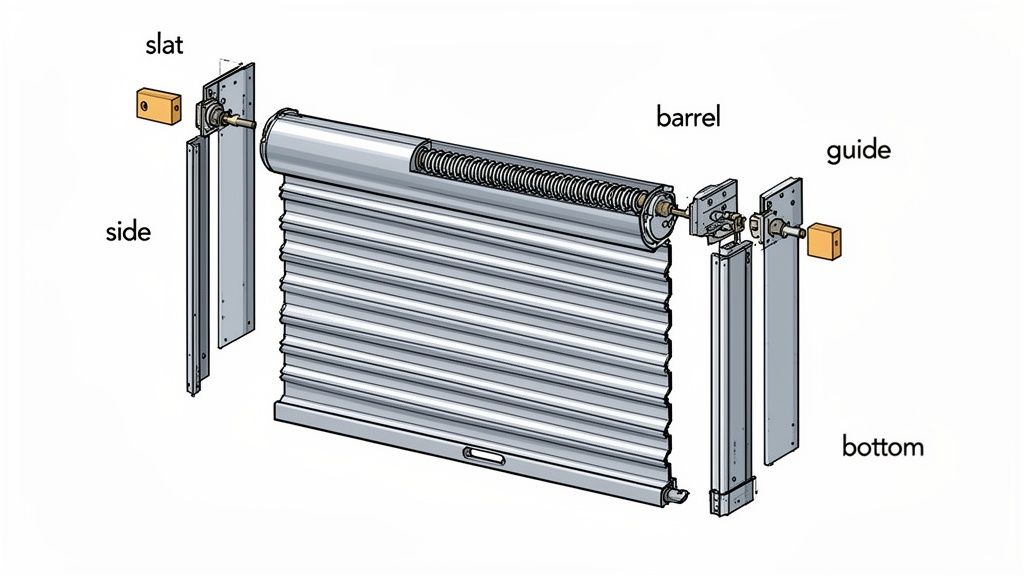

The door itself is a curtain made of tough, interlocking steel slats, forming a formidable barrier when it's closed. But the real magic happens in the mechanics hidden above the opening.

- The Curtain: This is the visible barrier of the door. It's built from strong, interlocking steel panels (slats) that create a continuous shield.

- The Barrel: This is a large, hollow tube that acts as the core of the system. The curtain wraps neatly around it when the door opens.

- The Springs: Tucked inside the barrel are powerful torsion springs. These are expertly tensioned to perfectly counterbalance the weight of the steel curtain. This brilliant engineering makes lifting a door that weighs hundreds—or even thousands—of pounds feel almost effortless, whether you're doing it by hand or with a motor.

- The Guides: These are the vertical tracks on each side of the doorway. They ensure the curtain travels smoothly and securely up and down, preventing any wobble or jamming.

Alt text: A detailed illustration of a partially opened roll up steel door, showing its internal mechanism and coiling barrel.

Why This Design Matters for Your Facility

That efficient coiling action is a game-changer for high-traffic areas. Picture a busy loading dock with forklifts buzzing around. The overhead tracks from a sectional door could easily get in the way of high-stacked inventory, lighting, or even crucial sprinkler systems.

A roll up door eliminates that conflict entirely, leaving your ceiling area completely open and unobstructed. You can learn more about finding the best overhead coiling door solutions for your business needs in our detailed guide.

To give you a clearer picture, here's a quick rundown of what these features mean for your day-to-day operations.

Roll Up Steel Door at a Glance

| Feature | Key Consideration | Best Application |

|---|---|---|

| Coiling Design | Maximizes vertical and horizontal clearance. | Warehouses, loading docks, and facilities where ceiling space is needed for lighting, sprinklers, or high-stacking. |

| Interlocking Slats | Provides a strong, continuous barrier against intrusion and weather. | Any facility requiring high security, from storefronts to industrial plants. |

| Counterbalance Springs | Ensures smooth, easy, and reliable operation, even for very heavy doors. | High-cycle environments where doors are opened and closed frequently throughout the day. |

| Durable Steel | Offers long-term resilience against impact, heavy use, and harsh environmental conditions. | Manufacturing facilities, auto service bays, and any area exposed to tough operational wear and tear. |

Ultimately, it’s the blend of space-saving design, tough construction, and reliable mechanics that makes the roll up steel door an essential asset for any modern commercial operation. As your partners in facility maintenance, we know that a dependable door is the starting point for a smooth, secure, and productive workflow.

Anatomy of a Durable Roll Up Steel Door

Not all roll-up doors are built the same. Understanding their construction is the key to choosing one that will actually last. Here, we'll take you inside the door’s anatomy, breaking down the components that really define its strength, security, and longevity. Think of it like looking under the hood of a car—what’s inside is what determines its performance on the road.

At the heart of any roll-up steel door is the curtain, which is the visible barrier that secures your opening. The quality and type of this curtain are the first indicators of the door's intended purpose and how much abuse it can handle.

Alt text: Exploded view of a commercial roll up steel door showing its main components: slat, side, barrel, guide, and bottom bar.

The Curtain Construction: Slatted vs. Sheet Doors

The most significant difference in construction lies in how that curtain is made. You'll primarily encounter two types: sheet doors and slatted doors. Each one is engineered for very different environments.

- Sheet Doors: These are made from a single, continuous sheet of corrugated steel. They’re lightweight and economical, making them a common sight on self-storage units or small agricultural sheds where security needs are moderate and the door isn't opened and closed all day long.

- Slatted Doors: These are the true industrial workhorses. They are built from individual, interlocking horizontal slats that form an incredibly strong and resilient curtain. This design is the standard for warehouses, loading docks, and manufacturing plants because it can withstand heavy use and provides far superior security.

A practical, real-world advantage of slatted doors is repairability. If a forklift accidentally clips a section, you can often replace just the damaged slats instead of the entire door curtain. For any busy facility, that’s a massive practical benefit that minimizes both downtime and repair costs.

The Backbone: Materials of a Roll-Up Door

The material used for the slats and guides is your first line of defence against weather, impacts, and daily wear and tear. Choosing the right material isn't really about preference; it's about matching the door to its operational environment.

Galvanized Steel is the most common and practical choice for the vast majority of commercial applications. The galvanization process involves applying a protective zinc coating to the steel, which acts as a tough barrier against rust and corrosion.

This makes it exceptionally well-suited for exterior loading docks or any facility exposed to Canada’s tough weather conditions. The demand for durable materials like this is clear; steel roll-up doors are gaining significant traction in Canada's commercial and industrial landscapes. This trend mirrors the broader North American steel door market, valued at USD 4.4 billion in 2023, where galvanized steel doors alone accounted for a whopping USD 3.2 billion. Projections show this segment growing, which just underscores its reputation for superior corrosion resistance.

For more specialized environments, other materials come into play:

- Stainless Steel: This is the go-to for facilities requiring strict hygiene, like food processing plants, pharmaceutical labs, or clean rooms. Its non-porous surface is easy to sanitize and is highly resistant to rust and harsh cleaning chemicals.

- Aluminum: Lighter than steel, aluminum is often used for security grilles in retail spaces or for smaller doors where weight is a concern. It offers good corrosion resistance but just doesn't have the same impact strength as steel.

Key Takeaway: The construction of your roll-up steel door—from its slatted design to its material—isn't just a technical detail. It's a direct indicator of its expected lifespan, security level, and suitability for your specific operational demands.

Ultimately, understanding these core components helps you see beyond the surface. A well-built door from the right materials is a long-term asset, while a mismatched one can quickly become a source of frustration and unexpected expense. You can explore a deeper comparison and find more insights in our guide to choosing commercial steel doors.

Getting to Grips with Key Performance Ratings

A roll up steel door is more than just a way to close an opening; it’s a critical piece of your building's operational machinery. Getting familiar with its key performance ratings is essential because these numbers directly affect your facility's safety, security, and even your bottom line. Once you know what they mean, you can make smarter choices that protect both your assets and your people.

Think of these ratings like the specs on a new vehicle—you want to know about its safety features and fuel efficiency before you buy. We'll break down the technical jargon around security, fire ratings, insulation, and wind resistance into practical, real-world terms you can actually use.

Security and Durability

The first line of defence for any commercial property is its physical security, and that starts with how the door is built. A key factor here is the steel gauge, which is simply a measure of the steel's thickness. Here’s the trick: a lower gauge number means thicker, stronger steel. For example, a heavy-duty 20-gauge door provides far more resistance against forced entry than a lighter 26-gauge door you might see in less demanding situations.

Of course, a thick door isn't much good without solid locks.

- Slide Bolts: These are the straightforward, manually operated locks you’ll find on the interior side of the bottom bar. They're simple, effective, and perfect for securing a facility overnight.

- Cylinder Locks: If you need key access from the outside, cylinder locks can be built right into the bottom bar.

- Chain Hoist Locks: For manually operated doors, these devices lock the chain hoist in place, adding another layer of security by preventing someone from simply cranking the door open.

A tough door with the right locking system sends a clear message: this facility is secure.

Fire Ratings and Life Safety

In many industrial and commercial buildings, certain walls are designated as fire barriers to contain a fire and give everyone time to evacuate safely. If your roll up steel door is installed in one of these walls, it absolutely must be a fire-rated door. These aren't just regular doors; they are engineered to close automatically when a fire is detected, sealing off the area to stop the spread of flames and smoke.

Fire ratings aren’t suggestions—they are life-safety requirements mandated by building codes. An incorrect or poorly maintained fire door can lead to serious fines and, more critically, fail to protect your team in an emergency.

These ratings are measured in hours (like 90-minute or 3-hour) and tell you exactly how long the door can hold back a fire. A professional partner like Wilcox Door Service can make sure your fire doors meet all National Fire Protection Association (NFPA) 80 standards, which includes the mandatory annual fire door drop testing and inspection.

Insulation and Energy Efficiency

For any climate-controlled space, whether it's a cold storage warehouse or a heated manufacturing plant, an uninsulated door is like leaving a window wide open. This is where the R-value comes in. The R-value measures how well a material resists heat flow—the higher the R-value, the better the insulation.

Insulated roll up doors have a core of polyurethane or polystyrene foam injected between the steel slats. For instance, keeping a consistent temperature in a food distribution centre isn't just a preference, it's a requirement. A well-insulated door with a high R-value eases the burden on your HVAC system, which translates directly into lower energy bills over the door's lifetime.

Wind Load Resistance

If your facility is in an area exposed to high winds, a wind load rating is not optional. This rating tells you how much wind pressure, measured in pounds per square foot (psf), a door can handle without failing. Wind-rated doors are built differently—they use heavier gauge steel, have reinforced guides, and feature special wind locks that engage to hold the door curtain securely in its tracks during a storm.

Imagine a large distribution centre with a row of loading dock doors facing an open field. Those doors need to stand up to powerful gusts. A failure could lead to catastrophic building damage and bring operations to a grinding halt. Making sure your door meets local building code requirements for wind resistance is crucial for both safety and business continuity. For expert guidance on all your commercial door needs, contact our team for a consultation.

To make things a bit clearer, we've put together a simple table breaking down what these performance ratings really mean for your day-to-day operations.

Comparing Performance Ratings for Roll Up Doors

Here’s a clear comparison to help you match door specifications with your facility’s unique operational demands.

| Performance Metric | What It Really Means | Why It Matters to Your Operations |

|---|---|---|

| Steel Gauge | The thickness of the steel slats. A lower number (e.g., 20-gauge) means thicker, stronger steel. | A lower gauge provides superior defence against forced entry, protecting your inventory, equipment, and property from theft and vandalism. |

| Fire Rating | The length of time (e.g., 90 minutes, 3 hours) a door can withstand a fire and contain flames/smoke. | This is a non-negotiable life-safety feature. It compartmentalizes a fire, protecting personnel and limiting property damage. It’s also a building code requirement. |

| R-Value | A measure of thermal resistance. The higher the R-value, the better the door's insulating properties. | A high R-value reduces heat transfer, significantly lowering your heating and cooling costs and helping maintain stable indoor temperatures for sensitive products. |

| Wind Load Rating | The amount of wind pressure (in psf) the door can safely resist without failing or getting blown out of its tracks. | Essential for facilities in high-wind areas. It prevents catastrophic door failure during storms, protecting your building, assets, and people inside. |

By understanding these four key metrics, you’re no longer just buying a door; you’re investing in a solution that actively contributes to your facility’s security, safety, and efficiency.

How to Select the Right Door for Your Needs

Choosing the right roll up steel door is a big decision. It’s a strategic move that will impact your day-to-day workflow, your energy bills, and even the security of your entire building. This isn't just about plugging a hole in a wall; it's an investment in a critical piece of equipment that needs to support your operations for years to come. So, let's walk through a practical framework for making a smart choice, covering the critical factors that will ensure your new door is the perfect fit.

Assess Your Operational Intensity

First things first: how hard is this door going to work? The answer to that question dictates the kind of durability you'll need from every single component, from the springs right down to the operator.

We're talking about cycle frequency—a straightforward way of saying how many times the door opens and closes each day. A door at a local self-storage facility might only get used a handful of times. But a busy loading dock door at a 24/7 distribution centre? That could see hundreds of cycles, day in and day out.

- Low-Cycle Applications: For lighter use, a standard door with springs rated for 20,000 to 50,000 cycles is usually more than enough.

- High-Cycle Applications: For constant, heavy use, you need a heavy-duty door equipped with high-cycle springs, often rated for 100,000 cycles or more. Trying to get by with a standard door in a high-traffic spot is just a recipe for premature failure and expensive downtime.

Match the Door to Its Environment

Where your facility is located and what happens inside it plays a massive role in what kind of door you need. A one-size-fits-all approach simply doesn't cut it when you start factoring in climate and interior conditions.

For example, a facility near the coast dealing with corrosive salt air absolutely requires a door with a specialized, rust-resistant finish or even stainless steel construction to fend off rapid deterioration. In the same way, putting an uninsulated door on a heated warehouse in a cold climate is like leaving a window wide open—it's a constant drain on your energy budget.

Key Insight: The environment dictates the materials. Picking a door that can stand up to your specific conditions—whether that’s corrosive chemicals, extreme temperatures, or high winds—is fundamental to getting a long service life and a solid return on your investment.

Align Specifications with Your Facility’s Mission

Beyond basic durability, your door’s performance specs have to line up with its specific job. This is where you connect all the features we've discussed to your real-world needs.

Is the door for a high-traffic loading dock? A high-speed roll up steel door might be the perfect solution. These doors open and close in a flash, minimizing how long the opening is exposed to the elements. That means lower climate control costs and better productivity. On the other hand, for a pharmaceutical clean room, a stainless steel door with smooth surfaces and tight seals is non-negotiable for maintaining hygiene.

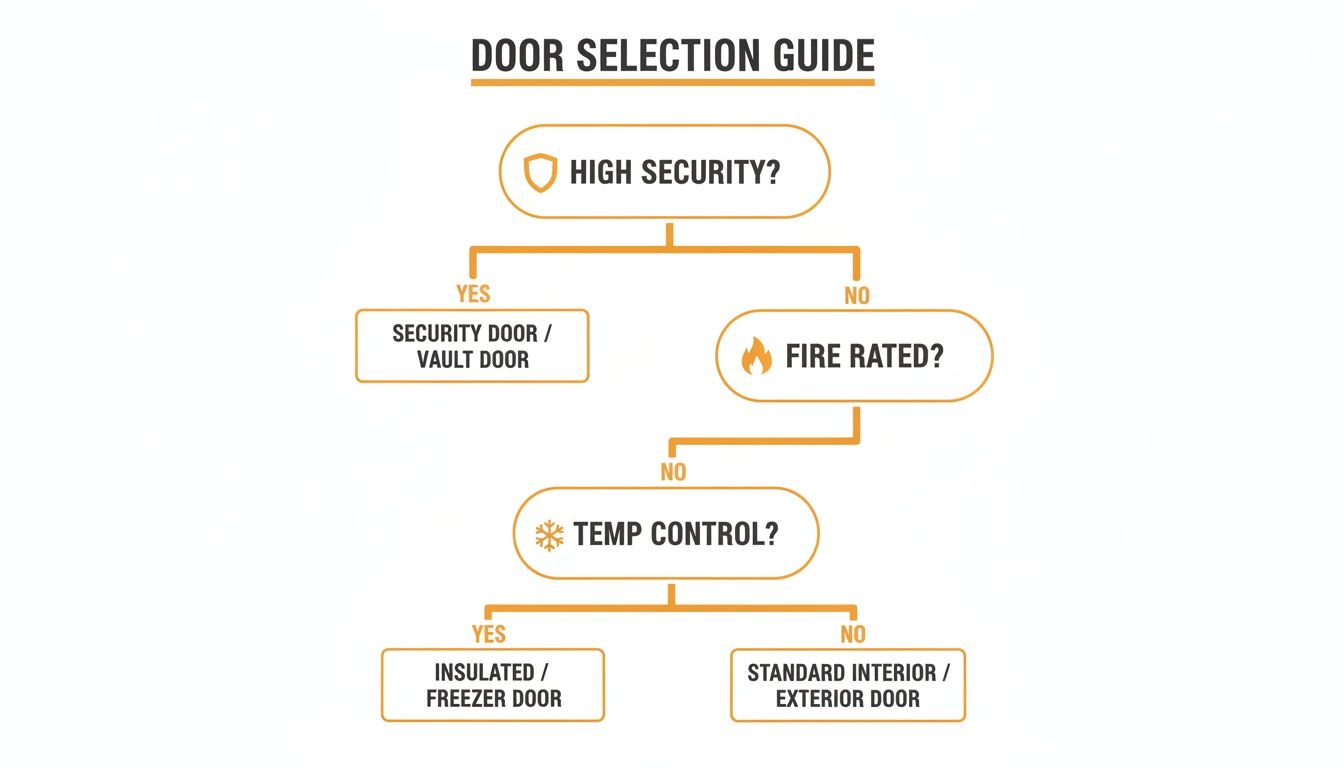

This handy decision tree can help you quickly zero in on your core needs based on security, fire safety, and temperature control.

Alt text: Flowchart selection guide for roll up steel doors based on security, fire rating, and temperature control requirements.

This visual guide really drives home the point that specialized requirements like fire ratings or insulation aren't afterthoughts—they should be primary drivers in your decision.

Consider the Total Cost of Ownership

Finally, it's absolutely crucial to look past the initial price tag and think about the total cost of ownership (TCO). A cheaper, lighter-duty door might save you some money upfront, but it will almost certainly lead to higher repair bills and a shorter lifespan in a demanding setting. Investing in a durable, properly specified door is always the smarter financial decision in the long run.

The demand for these robust solutions is only growing, especially with the boom in commercial construction across Canada. Market forecasts point to significant growth in the roll-up door sector through 2032, with commercial applications leading the charge as more warehouses and industrial facilities are built. For these applications, the durability of steel is paramount. You can read more about these commercial door market trends.

Making the right choice comes down to a clear-eyed assessment of your needs. When you partner with experts, you get a solution that's built for reliability from day one.

Ready to find the perfect door for your facility? Contact the Wilcox Door Service team to discuss your specific operational needs.

Mastering Installation, Maintenance, and Repair

A top-tier roll up steel door performs only as well as its installation and the maintenance plan that follows. Investing in a quality door is just the first step; maximizing its life, safety, and reliability really comes down to professional setup and proactive care. This section is your guide to protecting that investment.

We’ll outline what a professional installation should involve, emphasizing the importance of site preparation and safety protocols that prevent future headaches. Then, we'll dive into a practical maintenance checklist your facility team can use to catch small issues before they become major operational disruptions.

Alt text: A service technician performs maintenance on a roll up steel door's spring mechanism, with tools and a checklist nearby.

The Foundation of Reliability: Professional Installation

A flawless installation is the bedrock of a long-lasting door. Rushing this stage or cutting corners is a direct path to premature wear, operational failures, and serious safety hazards. A certified technician doesn’t just hang a door; they ensure every component works in perfect harmony from day one.

A professional installation process always includes:

- Thorough Site Assessment: Before any work begins, the opening must be measured precisely. The surrounding structure—walls, floor, and header—is inspected to ensure it can support the door’s weight and operational forces.

- Proper Assembly and Alignment: The barrel, springs, guides, and curtain must be assembled and aligned with extreme precision. Even a slight misalignment can cause scraping, binding, and excessive strain on the motor and other parts.

- Correct Spring Tensioning: This is a critical—and dangerous—step. The torsion springs have to be perfectly tensioned to balance the door's weight. Incorrect tension makes the door difficult to operate and can burn out the motor.

- Safety System Integration: All safety devices, like photo-eye sensors or reversing edges, must be installed correctly and rigorously tested to ensure they function as intended to protect people and equipment.

Proactive Maintenance: A Facility Checklist

Once installed, routine maintenance is the absolute key to preventing unexpected downtime. A simple, consistent inspection routine can extend the life of your door by years and help you avoid costly emergency repairs.

Here’s a practical checklist to keep your doors in peak condition:

- Look and Listen (Weekly): Operate the door and just watch its movement. Does it travel smoothly? Do you hear any unusual grinding, scraping, or popping sounds? These noises are early warnings of issues like debris in the tracks or worn-out parts.

- Inspect the Tracks (Monthly): Check the vertical guides for any dirt, debris, or damage. Clean them out with a simple brush and cloth to ensure the curtain can move freely. Remember, misaligned or bent tracks are a serious issue that requires immediate professional attention.

- Check Hardware (Quarterly): Visually inspect the nuts, bolts, and fasteners. A door's constant vibration can cause hardware to loosen over time, so a quick check can prevent bigger problems.

- Test Safety Features (Monthly): For motorized doors, test the auto-reverse function. Just place a non-damaging object (like a roll of paper towels) in the door's path to make sure it stops and reverses upon contact.

Expert Insight: Never apply grease to the door tracks. While it seems logical, grease attracts dirt and grime, creating a thick, abrasive paste that actually accelerates wear. A clean track is a happy track.

For a more detailed breakdown, our guide on maintaining a rolling steel door offers what you need to know.

Recognizing Common Problems and When to Call for Help

Even with great maintenance, issues can pop up. Knowing the difference between a minor hiccup and a serious problem can save you a ton of time and money.

Watch for these warning signs:

- The Door Struggles or Moves Unevenly: This could signal incorrect spring tension, a motor malfunction, or an alignment issue. If the door seems unusually heavy or moves in a jerky motion, stop using it immediately.

- Loud, Unusual Noises: A sudden loud "bang" often means a broken torsion spring. This is an extremely dangerous situation, as those springs hold the door’s full weight under immense tension.

- Visible Damage: Dented slats, bent guides, or frayed cables compromise the door’s structural integrity and safety. These issues rarely fix themselves and typically get worse over time.

While a simple track cleaning is a fine DIY task, most other problems—especially those involving springs, cables, or the motor—require professional expertise. Attempting to repair high-tension components without the right training and tools can result in severe injury.

As your trusted partners, we provide reliable service to keep your operations running. For complex issues or urgent failures, our 24/7 emergency repair team is always ready to restore safety and functionality to your facility.

If your roll up steel door shows any signs of significant wear or failure, don’t wait for a complete breakdown. Contact Wilcox Door Service to schedule a professional inspection or repair.

The Real Cost and ROI of Your Door

When you're looking at investing in a quality roll up steel door, it's easy to get fixated on the initial quote. But that sticker price is just the beginning of the story. The real financial picture comes into focus when you look at the total cost of ownership and the value that door delivers over its entire life.

Think of it this way: a well-chosen door isn't just another line item on an expense report. It's a workhorse asset that pulls its weight by boosting your facility's efficiency, security, and bottom line.

A few key things will shape that initial investment, of course. The door's size and the gauge of the steel are the big ones, but specialized features are just as important. Adding insulation for climate control, getting a fire-rated model for safety compliance, or installing a high-speed operator to keep traffic moving will all factor into the upfront cost.

Calculating Your Return on Investment

But the upfront cost is only half the equation. The real story is the return you get over the long haul. A durable, efficient door is a powerful tool for cutting costs right across your operations, and those savings add up faster than you might think.

A properly specified door starts paying you back almost immediately by minimizing ongoing expenses:

- Fewer Repair Bills: It’s simple, really. Higher quality components paired with a professional installation mean fewer breakdowns. That translates directly to less money spent on emergency service calls and replacement parts.

- Tighter Security: A tough steel door is a serious deterrent against theft. It protects your valuable inventory and equipment from being stolen, preventing not just the cost of replacement but also the massive headache of operational disruptions.

- Lower Energy Bills: An insulated door with a solid R-value can make a huge difference in your heating and cooling costs. This is especially true for facilities with large openings or climate-controlled spaces where every bit of lost air is money out the door.

A cheap door often ends up being the most expensive one you'll ever own. What you save upfront gets quickly wiped out by constant downtime, endless repairs, and security weak spots. A quality door is just a smarter financial decision.

The Financial Side of Compliance and Safety

Beyond the day-to-day savings, staying compliant with safety standards delivers its own financial return by helping you sidestep hefty penalties. This is especially true for facilities with fire-rated doors, where meeting legal requirements isn't optional.

The National Fire Protection Association (NFPA) 80 standards, for instance, require annual inspections and drop tests for all fire doors. These tests aren't just a suggestion; they're the law, and they must be done by a certified technician to ensure the door will actually work in a fire. Failing to comply can lead to steep fines—and far worse, it puts your people and property in serious danger.

Partnering with a trusted provider for a solid maintenance plan ensures your doors stay safe, compliant, and efficient. It's a proactive investment in reliability that protects your assets and your bottom line.

When you look at the whole picture, it becomes crystal clear: investing in a dependable roll up steel door and a robust service plan delivers measurable returns for years to come.

If you’re ready to talk about a door solution that provides lasting value, contact Wilcox Door Service today. We’ll help you build a plan that works for your budget and your business.

Frequently Asked Questions

When it comes to a roll up steel door, it’s easy to get bogged down in the details. We get it. That's why we've put together clear answers to some of the most practical questions we hear from facility managers every day.

Our goal here is to give you straightforward, actionable information that comes from decades of being in the trenches, reflecting our commitment to being Respected Partners providing Reliable Service.

How Often Should a Commercial Roll Up Steel Door Be Serviced?

The industry standard for most doors is a professional tune-up at least once a year. This keeps everything running smoothly and safely.

However, if your door is a real workhorse—like those in busy distribution centres or non-stop manufacturing plants—you’ll want to step that up. For these high-cycle doors, a semi-annual or even quarterly planned maintenance schedule is the smart move.

A real-world example is a cold storage facility where a door cycles hundreds of times a day. For them, quarterly service isn't just a good idea; it's essential to prevent a failure that could compromise thousands of dollars in temperature-sensitive inventory. Proactive maintenance from a certified technician catches small issues like spring fatigue or operator wear before they turn into a full-blown shutdown.

What Is the Difference Between a Sheet Door and a Slatted Door?

The main difference boils down to how they're built and what they're built for.

A roll up sheet door is exactly what it sounds like: it’s made from a single, continuous curtain of corrugated steel. These are lighter-duty and generally more budget-friendly, which makes them a decent fit for places like self-storage units or small commercial sheds where they won’t be opened and closed all day.

A slatted roll up door, on the other hand, is the heavy-hitter. It’s constructed from individual, interlocking horizontal slats. This design is significantly more robust and durable, making it the go-to choice for almost all industrial, warehouse, and high-security applications. Another big plus for slatted doors is repairability—if a forklift dings a section, you can just replace a few slats instead of the entire door curtain. They can also be built to handle massive openings and meet higher performance specs.

Key Takeaway: For light-duty, low-use spots, a sheet door can work. But for any job that demands durability, security, and frequent operation, a slatted door is the right long-term investment.

Can I Add a Motor to My Manual Roll Up Door?

Absolutely. In most situations, you can retrofit a manual roll up steel door with a commercial door operator. Making the switch from a manual chain hoist to a motor is a huge upgrade for efficiency, safety, and convenience—especially for those big, heavy doors that get used all the time.

The process involves fitting a motor that’s properly sized for your door’s weight and expected usage, along with controls like a simple push-button station or remote transmitters. It’s critical to have a professional handle this, though. They’ll make sure the operator is the right match for your door and that the installation is done safely and meets all building codes.

Your doors are the gateway to your business. For expert advice, professional installation, or to schedule a maintenance inspection for your roll up steel door, you can count on the team at Wilcox Door Service Inc.