A side garage door seal is the weatherstripping that runs along the vertical edges of a commercial garage door frame. In simple terms, it’s the barrier that closes the gap between the door and the jamb, protecting your facility from drafts, moisture, pests, and debris. This guide will walk you through everything you need to know about this critical component—from selecting the right materials and installing them correctly to understanding their financial impact and performing routine maintenance. By the end, you’ll see how a well-maintained seal is an essential asset for a secure and efficient operation.

Why the Side Garage Door Seal Is Your Facility’s Unsung Hero

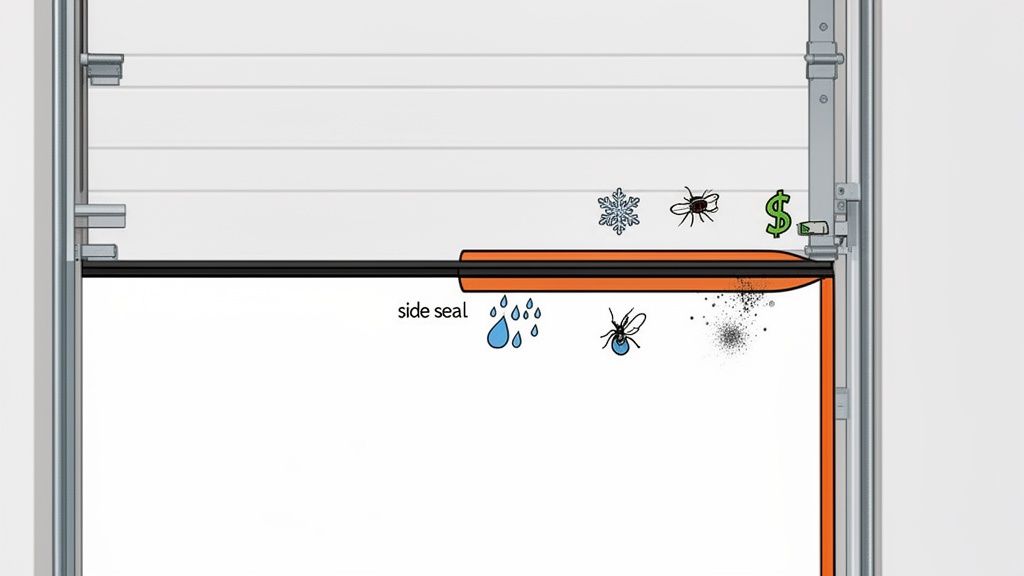

Alt text: Diagram of a commercial side garage door seal showing how it blocks water, insects, and snow, leading to significant energy savings.

That simple strip of rubber or vinyl running down the side of your commercial garage door? It’s doing more heavy lifting than you might think. A high-quality side garage door seal is one of the hardest-working components of your building envelope, acting as a crucial barrier that directly impacts operational efficiency, safety, and your bottom line.

For busy facility managers and maintenance teams, it’s an easy detail to overlook. But ignoring worn or damaged side seals can lead to surprisingly large consequences, from spiking energy bills and compromised inventory to potential compliance issues. The integrity of these seals is directly tied to your operational success.

The Real-World Impact of a Failing Seal

Consider a food processing facility in the midst of a harsh Canadian winter. A small, unnoticed tear in the side seal of a main loading dock door allows moisture to seep in during a storm. That tiny gap creates just enough condensation inside to spoil a pallet of goods, leading to a rejected shipment due to unsanitary conditions.

The cost isn’t just the lost product. It includes the emergency cleanup crew, the urgent service call for the door, and a mark against their compliance record. This practical example highlights a critical point: a functional side garage door seal isn’t just a “nice-to-have”—it’s an essential asset for maintaining a controlled and secure environment.

More Than Just Weatherproofing

While blocking drafts is the most obvious function, the benefits of a well-maintained side garage door seal extend much further. It’s a comprehensive solution that contributes to a safer, cleaner, and more cost-effective operation.

A robust seal delivers on multiple fronts:

- Significant Energy Savings: By stopping drafts, your HVAC system isn’t fighting a losing battle to maintain a stable indoor temperature. This means lower utility bills. Unsealed commercial doors are a massive source of air leakage, with some facilities seeing heating costs jump by as much as 28%.

- Enhanced Pest and Debris Control: Gaps are an open invitation for rodents, insects, dust, and pollen. An effective seal creates a solid barrier that helps you maintain a clean and hygienic interior—a non-negotiable for industries like food and beverage or pharmaceuticals.

- Improved Employee Comfort and Safety: No one wants to work in a constant cold draft, especially at a busy loading dock. A good seal creates a more comfortable and productive environment. It also prevents slippery puddles from forming inside from rain or snowmelt, reducing a major safety hazard.

- Protection for Stored Goods: By keeping moisture out and helping regulate temperature, a quality side seal protects your valuable inventory, equipment, and vehicles from damage caused by the elements.

“Thinking of a side seal as just weatherstripping is like thinking of a lock as just a piece of metal. Both are essential for protecting what’s inside. A failing seal compromises your entire building envelope, impacting everything from energy costs to product integrity.”

This guide will explain everything you need to know about selecting, installing, and maintaining the right side garage door seal for your facility. As your respected partners, we’re committed to providing reliable service and expertise to turn a routine maintenance task into a strategic operational advantage. For a broader look at how different seals work together, check out our guide on weatherstripping for your garage door.

Choosing the Right Materials for Your Commercial Side Seals

Picking the right material for your side garage door seal isn’t just about grabbing something off the shelf. It’s a critical decision with a direct impact on your facility’s energy bills, security, and future maintenance costs. The material you choose must stand up to your unique environment—from the brutal Canadian cold to the daily wear and tear of a busy loading dock.

Make the wrong choice, and you’ll find yourself dealing with the same drafts, pests, and energy loss all over again. A standard vinyl seal might become brittle and crack in a deep freeze, while a less robust option could degrade under constant UV exposure. Let’s break down the most common materials so you can make an informed decision.

EPDM Rubber: A Flexible and Resilient Choice

EPDM (ethylene propylene diene monomer) is a type of synthetic rubber that has become a go-to for one primary reason: its incredible flexibility across a wide temperature range. For any facility battling severe winters, this is a game-changer. While other materials can become stiff and fail when the temperature plummets, EPDM stays pliable, ensuring a solid seal year-round.

Its resilience makes it a perfect fit for:

- Cold Storage Facilities: Where maintaining a constant low temperature is non-negotiable, EPDM seals prevent thermal leaks without becoming brittle.

- Warehouses in Northern Climates: Doors exposed to snow, ice, and sub-zero temperatures need a seal that remains flexible and effective. EPDM delivers exactly that.

Additionally, EPDM offers solid resistance to UV rays and general weathering, making it a durable, long-lasting solution for most commercial applications.

PVC and Vinyl: Versatile and Cost-Effective

PVC (polyvinyl chloride) and vinyl seals are widely used, primarily because they are affordable and effective in many situations. They are often part of a two-piece system, where a flexible vinyl seal is held in place by a rigid retainer (typically aluminum or PVC). This design is practical because when the seal wears out, you can simply slide out the old insert and install a new one.

However, it’s important to understand their limitations. Standard PVC can lose flexibility in extreme cold, which may compromise the seal’s performance. It’s best suited for moderate climates or interior doors where temperatures are more stable. That said, these materials offer good durability against physical impacts and scrapes in high-traffic areas.

A 2024 facility audit in Manitoba’s distribution centres revealed that aluminum side supports outperformed PVC by 44% in areas with heavy UV exposure, significantly reducing the warping that creates gaps and invites moisture damage.

Brush Seals: The Ultimate Debris Blocker

When your primary concerns are dust, dirt, and pests, brush seals provide an incredible line of defense. They consist of dense polypropylene bristles locked into an aluminum retainer, creating a tough barrier that flexes and conforms to uneven surfaces like floors and walls.

Consider brush seals for:

- Manufacturing Plants: To keep production areas clean and free of contaminants.

- Agricultural Buildings: An excellent way to prevent pests and debris from entering storage areas.

- Loading Docks near Unpaved Areas: They effectively block blowing dirt and sand.

While brush seals excel at blocking particles, they don’t create the airtight and watertight barrier that solid rubber or vinyl can. For this reason, they are often used in combination with other types of weatherstripping to achieve comprehensive protection. Getting familiar with the different types of weatherstripping for exterior doors can help you build a complete sealing strategy.

Aluminum Retainers: The Backbone of a Strong Seal

The retainer is the track that holds the flexible seal insert securely against the door jamb. While single-piece seals exist, most high-performance commercial systems use a two-piece design with an aluminum retainer. Aluminum is the preferred material for its strength, corrosion resistance, and longevity.

It won’t rust, warp, or crack under pressure, ensuring the seal insert stays exactly where it needs to be for years. In a busy commercial environment, that durability is crucial. Industry data confirms that reliable side seals are essential for reducing downtime. At Wilcox Door Service, our own records show a 65% increase in side seal service calls between 2015 and 2025, driven largely by climate volatility, which underscores the need for robust materials.

Commercial Side Garage Door Seal Material Comparison

Choosing the right material from the start saves headaches later. This table breaks down the key options to help you match the material to the real-world demands of your facility.

| Material Type | Best For Climate | Durability | Typical Application | Key Advantage |

|---|---|---|---|---|

| EPDM Rubber | Extreme cold & heat | High | Cold storage, northern warehouses, exterior doors | Maintains flexibility in all temperatures |

| PVC / Vinyl | Moderate climates | Medium | High-traffic interior doors, general warehouses | Cost-effective and easily replaceable inserts |

| Brush Seal | All climates | High | Manufacturing, agriculture, dusty environments | Excellent barrier against pests and debris |

| Aluminum Retainer | All climates | Very High | Paired with insert seals for commercial/industrial doors | Corrosion-resistant, provides structural integrity |

By carefully matching the material to your facility’s specific needs, you’re not just installing a part—you’re investing in the reliable, long-term performance of your side garage door seal. As your partners in the field, we are always here to offer reliable service and expert advice on the best solutions for your doors.

Installing Your Side Garage Door Seal Like a Pro

Equipping your in-house team to install a side garage door seal can be a smart, cost-saving move. However, a successful installation depends on attention to detail. A professional-grade result requires more than just attaching new weatherstripping; it demands precision, thorough preparation, and an understanding of how these materials perform over time.

This guide provides practical, field-tested advice from our technicians to help your crew achieve a tight, long-lasting seal. We’ll cover the entire process, from accurate measurement to final fastening, so you can avoid common mistakes that lead to premature failure.

Accurate Measurement is Non-Negotiable

You’ve heard the saying: “measure twice, cut once.” For seal installation, this is the golden rule. An incorrect measurement is one of the most common and costly mistakes, leading to wasted material and frustrating gaps that defeat the purpose of the seal.

Before you begin, gather the right tools:

- A reliable tape measure

- A pry bar or putty knife for removing the old seal

- A miter saw or a sharp utility knife for clean cuts

- A drill or hammer with appropriate fasteners (use galvanized nails or exterior-grade screws)

- A cleaning solvent like isopropyl alcohol or a degreaser

To get it right, measure the entire height of the vertical door jamb on both sides, from the header down to the concrete floor. Never assume both sides are identical—buildings settle and frames can shift. You also need to measure the width of the door stop moulding to determine the correct retainer size.

Surface Preparation for Maximum Adhesion

A new seal is only as solid as the surface it’s mounted on. Leftover adhesive, old caulk, dirt, or grime will create weak points, causing the new seal to pull away from the jamb over time. This is a significant issue in facilities with high-pressure wash-downs or exposure to grease and oil.

First, carefully pry off the old seal. Next, meticulously scrape away any remaining residue. The final preparation step is critical: use a solvent to thoroughly clean the entire door jamb surface. This ensures the new seal or retainer has a clean, solid base to adhere to. Allow the surface to dry completely before proceeding.

“We often see installation failures that have nothing to do with the seal itself but everything to do with poor surface prep. Taking an extra ten minutes to properly clean the jamb is the single best thing you can do to guarantee a professional, long-lasting result.”

This chart breaks down how to pick the right side garage door seal material based on your facility’s real-world conditions.

Alt text: Flowchart showing how climate, usage, and durability needs influence the choice of a side garage door seal material.

As you can see, matching the material to your climate, use intensity, and durability requirements is the foundation of a successful, long-lasting installation.

Cutting and Fastening With Precision

With accurate measurements and a prepared surface, it’s time to cut the new side garage door seal. For rigid retainers, a miter saw is ideal for achieving a clean, 45-degree angle where the side meets the header. For the flexible vinyl or rubber insert, a sharp utility knife is sufficient.

Start fastening the new seal at the top and work your way down, placing fasteners every 12 to 16 inches. Here’s a pro tip: do not overtighten the fasteners. This is especially important with vinyl or PVC seals, as these materials need room to expand and contract with temperature changes. Overtightening can cause the seal to warp or buckle, creating new gaps.

The goal is for the flexible flap of the seal to press gently but consistently against the face of the closed door. You want light contact along the entire length—not so much pressure that it causes friction or impedes door operation. Once installed, operate the door a few times, watching carefully to ensure it moves smoothly and the seal isn’t catching or bunching up.

While most installations are straightforward, some situations—like dealing with a warped door frame or installing seals on specialized high-speed doors—are best left to professionals. For these complex scenarios, our team is always ready to provide reliable service.

How a High-Performance Seal Impacts Your Bottom Line

Think of a high-performance side garage door seal as more than just a maintenance part. It’s a strategic investment with a clear return. For facility managers, justifying an upgrade often comes down to demonstrating financial impact, and the connection here is direct: a better seal leads to lower operating costs, easier compliance, and better-protected assets.

The most immediate benefit is a reduction in energy consumption. Gaps around commercial doors force your HVAC system into a constant battle, with conditioned air escaping and outside air infiltrating. This is a significant source of energy waste, particularly in Canada’s demanding climate.

Slashing Energy Costs Through Airtight Efficiency

By eliminating drafts, a properly installed side seal allows your heating and cooling systems to operate efficiently instead of running constantly. The result is lower utility bills, month after month. These savings are not trivial; they represent a tangible reduction in your facility’s operating budget.

Data from the Canadian market supports this. Commercial side garage door seals are now a key component of energy-saving retrofits, with the market projected to grow at a 7.7% CAGR through 2030. A 2023 audit by Natural Resources Canada in Quebec’s food and beverage sector found that worn-out side seals on sectional doors were responsible for a staggering 43% of conditioned air loss. For a typical 10,000 sq. ft. cold storage unit, this translated to approximately $3,800 in extra cooling costs annually. You can explore these industry trends in this comprehensive industry report.

Moving Beyond Energy Savings to Compliance and Uptime

While energy savings are compelling, the financial benefits of a quality side garage door seal don’t end there. A solid seal is often a critical requirement for meeting strict industry standards and building codes.

- Regulatory Compliance: In sectors like pharmaceuticals or food processing, maintaining a controlled, contaminant-free environment is paramount. An airtight seal is your first line of defense against dust, pests, and moisture, helping you comply with Health Canada regulations and avoid costly fines or shutdowns.

- Operational Uptime: The right seal can literally keep your operations running. For example, some pharmaceutical plants have achieved a 52% reduction in air infiltration by upgrading to low-leakage seals with integrated polyurethane. This stability prevents equipment malfunctions due to temperature fluctuations and protects sensitive, high-value inventory.

- Asset Protection: A secure seal also acts as a barrier against the elements. Water damage from rain or snowmelt can be devastating. To understand the importance of these barriers, consider how other seals function, such as water stops in showers and preventing leaks, which serve the same fundamental purpose: preventing costly damage.

A well-sealed door isn’t just an energy-saving measure; it’s a foundational element of your facility’s risk management strategy. It protects your inventory, ensures regulatory adherence, and supports uninterrupted operations.

Justifying the Investment in Your Facility

Frame a seal upgrade as a capital investment, not just a repair cost. The initial outlay is often quickly recovered through the combined savings from lower energy bills, avoided compliance penalties, and protected products.

For example, airport authorities are investing in high-performance seals to meet Transport Canada’s 2025 air curtain integration mandates. A quality seal can reduce dust ingress by up to 40%, improving air quality while also cutting cleaning costs and protecting sensitive equipment. When you invest in a quality side garage door seal, you are making a proactive choice that strengthens your entire operation.

These figures provide the hard financial justification needed when building a case for your maintenance budget. Working with a trusted partner like Wilcox ensures you get a solution designed to maximize those returns. For more on setting up a proactive care schedule, check out our insights on the benefits of a planned garage door maintenance program.

A Practical Maintenance and Troubleshooting Checklist

Alt text: A maintenance checklist for a side garage door seal, featuring inspection tools and examples of healthy vs. damaged seals.

A proactive approach is the best way to maximize the life and performance of your side garage door seal. A regularly inspected seal is unlikely to fail unexpectedly during a critical time, like a winter storm.

Providing your maintenance team with a simple, repeatable checklist transforms this task into a routine part of your facility’s upkeep. This simple step helps prevent minor issues from escalating into costly operational disruptions and keeps your facility secure and efficient.

Your Routine Seal Inspection Checklist

Integrate these checks into your team’s regular maintenance schedule. Catching a problem early is far less disruptive than dealing with a complete seal failure when you least expect it.

- Monthly Visual Check: A quick walk-around is often sufficient. Look for obvious damage like tears, rips, or sections that are hanging loose. Pay close attention to the bottom of the seal, as this area is most susceptible to impacts from forklifts or pallet jacks.

- Quarterly Physical Inspection: This is a more hands-on check. Gently press along the length of the seal. Does it feel pliable and spring back, or has it become hard and brittle? Look for signs of compression wear—where the seal has flattened and lost its ability to rebound—which inevitably creates gaps.

- Annual Deep Dive: At least once a year, conduct a thorough inspection of the entire sealing system. Check all fasteners to ensure they are tight and not corroding. This is also a good time to clean the seal with a mild detergent to remove grime that can accelerate deterioration, especially in harsh industrial environments.

A structured inspection process not only extends the life of your seals but also forms a key part of a broader preventative maintenance strategy. To see how this fits into your overall facility care, explore the benefits of a planned garage door maintenance program in our detailed guide.

Common Problems and How to Fix Them

Even with diligent maintenance, issues can arise. Here’s a practical troubleshooting guide to help your team diagnose and address the most common side seal problems.

Problem: The seal is pulling away from the frame.

- Likely Cause: This typically indicates adhesive failure or improper surface preparation during installation. It could also mean the wrong fasteners were used and have since corroded or loosened.

- Solution: Remove the loose section and thoroughly clean both the seal and the door jamb to remove old adhesive and debris. Re-secure it using a high-quality, exterior-grade adhesive and ensure your fasteners are appropriate for the jamb material.

Problem: The seal freezes to the door in winter.

- Likely Cause: Moisture is becoming trapped between the seal’s flap and the door face, then freezing. This is common with older seals that have lost their flexibility.

- Solution: Applying a light coat of silicone lubricant spray to the seal can prevent moisture from sticking and freezing. If the problem persists, the seal material may no longer be suitable and may need to be replaced with a more cold-resilient option like EPDM rubber.

In Canada’s harsh winters, a functional side garage door seal is a critical component for operational stability. Research from Statistics Canada highlighted that unmaintained side seals in warehouses accounted for 28% of total air leakage, increasing annual heating costs by up to $4,200 per 9,000 sq ft facility.

“A seal that appears fine from a distance might be hiding critical failures up close. Brittleness, compression set, and micro-cracks are the early warning signs that tell you a seal is on its last legs. Don’t wait for a complete failure.”

Problem: You can see visible gaps or light shining through when the door is closed.

- Likely Cause: The seal has either shrunk over time or has become permanently compressed and no longer makes proper contact. This could also indicate that the door itself is out of alignment.

- Solution: First, check the door’s alignment. If the door is tracking correctly, the seal has reached the end of its service life and needs to be replaced. There is no effective repair for a seal that has lost its shape and memory.

By following this checklist, your team can confidently manage the upkeep of your side seals, ensuring they continue to protect your facility. When a problem goes beyond a simple fix, remember that our team of experts is always ready to provide reliable service.

Knowing When to Call in a Professional

Even the most capable in-house maintenance teams have their limits. While your crew can handle routine upkeep, sometimes a problem with your side garage door seal is a symptom of a larger, more complex issue. Recognizing these red flags is crucial to preventing a minor annoyance from escalating into costly downtime and a major repair.

A failing seal isn’t always the root cause—it’s often just the messenger. Knowing when to call for an expert protects your assets, keeps your team safe, and ensures your facility continues to run smoothly.

When the Problem Is More Than Just the Seal

Some issues extend beyond the weatherstripping and point to underlying structural or mechanical failures. If your team encounters any of these scenarios, it’s a clear signal that you need a professional to diagnose and resolve the core problem.

- Damaged or Rotted Door Jambs: A seal is only as effective as the surface it’s attached to. If the wood or metal jamb is corroded, rotted, or warped, installing a new seal is a temporary fix at best. It will never adhere properly and will fail quickly. This structural weakness must be addressed by a professional before any new weatherstripping is installed.

- A Misaligned or Unbalanced Door: Do you see uneven gaps along the door? Is the seal crushed in one area but barely making contact in another? This is a classic sign that the door itself is out of alignment, which could be caused by worn rollers, loose tracks, or serious issues with the torsion springs. Replacing the seal without addressing the door’s mechanical problem ignores a significant safety hazard.

- Signs of Building Settlement: Large, irregular gaps between the door and the frame that have appeared over time can indicate that the building itself has shifted. In these cases, a standard seal won’t suffice. A professional is needed to assess the situation and recommend a specialized solution to accommodate the structural change.

“A persistent gap after a new seal installation is a classic sign of a deeper issue. It’s often the door telling you it needs more than just new weatherstripping—it needs a professional adjustment to ensure it operates safely and efficiently.”

Specialized Doors Require Expert Knowledge

Not all commercial doors are the same. Certain types require specific seals and installation techniques that are beyond the scope of general maintenance. Attempting a DIY installation on these doors can void warranties, violate safety codes, and compromise their critical functions.

Calling a professional is non-negotiable for these specialized doors:

- High-Speed Doors: These doors operate under intense speed and pressure, and their seals are engineered for those demanding conditions. An incorrect installation can impair their performance and create dangerous operating hazards.

- Fire-Rated Doors: The seals on fire-rated doors are not just for weather protection—they are a critical part of a life-safety system. They must be certified, installed, and tested according to strict fire codes to ensure they perform during an emergency. An improper seal can render a fire door non-compliant, putting your facility and its occupants at risk.

Your facility’s doors are vital assets that must perform reliably every day. While proactive in-house maintenance is a cornerstone of smart facility management, understanding your team’s limitations is equally important. When you spot these warning signs, bringing in a professional isn’t an admission of failure—it’s a strategic decision to protect your investment and ensure the job is done right.

At Wilcox Door Service Inc., we are your respected partners in maintaining a safe, compliant, and efficient facility. If you’ve identified any of these complex issues, don’t wait for them to become emergencies. Our union-certified technicians are available 24/7 to provide expert diagnostics and reliable service.

Schedule a professional inspection today to keep your facility secure and fully operational.