In this guide, you’ll learn everything you need to know about the table scissor lift, a critical piece of equipment for any modern facility. We’ll cover what a table scissor lift is, the different types available, how to choose the right one for your needs, and the essential safety and maintenance practices to ensure reliable operation. By the end, you’ll be equipped to make an informed decision that boosts both safety and efficiency in your workplace.

At its heart, a table scissor lift is a powerhouse platform, built to adjust its height and safely lift heavy loads. It’s the tool that bridges those dangerous gaps between different work levels. Think of it as your secret weapon for both ergonomics and efficiency, taking risky manual lifting and turning it into a controlled, mechanical process.

Understanding the Table Scissor Lift

A table scissor lift is so much more than a piece of machinery; it’s a direct solution to the common bottlenecks you see in warehouses, manufacturing plants, and loading docks every day. Its main job is to raise or lower materials—and sometimes people—to the perfect, ergonomic height. Ergonomics is simply the science of designing the workplace to fit the worker, reducing strain and preventing injury. This simple function dramatically cuts down on the physical strain your team faces and helps workflows run a whole lot smoother.

Picture your loading dock for a second. A delivery truck pulls in, but its bed is just a few inches higher or lower than your dock floor. That height difference creates a gap that’s both dangerous and a massive time-waster. A table scissor lift installed right at the dock acts as an adjustable bridge, creating a perfectly level surface so forklifts or pallet jacks can move goods without a hitch. It’s a straightforward fix that prevents injuries, protects products from damage, and keeps your shipping and receiving operations from grinding to a halt.

Alt text: Two warehouse workers use a mobile table scissor lift to safely transfer boxes from a loading dock to a truck, highlighting its role in logistics.

The Core Mechanics Explained

The name “scissor lift” is pretty self-explanatory once you see it in action. The platform is supported by a series of crossed supports that look and act like a pair of scissors. This design is sometimes called a pantograph. When power is applied, these supports extend and push the platform straight up.

That lifting action is usually driven by one of three power sources:

- Hydraulic: This is the most common type, using pressurized fluid to generate immense lifting force. It’s the go-to for most heavy-duty applications.

- Pneumatic: Instead of fluid, this one uses compressed air. It offers a clean and quiet operation, which is perfect for sensitive environments like food processing or pharmaceuticals.

- Electric: An electric motor and a screw mechanism provide incredibly precise, repeatable positioning, which is ideal for assembly lines and detailed manufacturing work.

To give you a clearer picture, let’s quickly break down the key advantages these lifts bring to the table.

Table Scissor Lift Key Benefits at a Glance

This table offers a quick summary of how a table scissor lift can positively impact facility operations.

| Benefit Category | Impact on Facility Operations | Real-World Example |

|---|---|---|

| Ergonomic Safety | Reduces musculoskeletal injuries from manual lifting, bending, and reaching. | An employee on an assembly line can adjust the lift to keep their work at waist height, eliminating the need to stoop over. |

| Operational Efficiency | Speeds up material handling by creating level, accessible work surfaces. | A scissor lift at a loading dock allows a single operator to unload a pallet from a truck in minutes, instead of needing multiple people to manually transfer boxes. |

| Product Protection | Minimizes the risk of dropping or damaging goods during transfer between levels. | A lift table gently raises a pallet of fragile electronics to the height of a conveyor belt, preventing jarring movements that could cause damage. |

| Space Optimization | Provides vertical lifting capability in a small, fixed footprint. | A stationary lift installed in a tight workspace can serve multiple levels of shelving without requiring a bulky ramp or conveyor system. |

Essentially, integrating a scissor lift isn’t just about lifting things—it’s about making your entire workflow safer, faster, and more reliable.

A Cornerstone of Modern Logistics

In Canada’s fast-paced logistics and warehousing sector, a table scissor lift has become an indispensable tool for keeping operations safe and efficient. The numbers back it up. Industry analyses show that facilities using these lifts for pallet positioning can see downtime from dock height mismatches drop by as much as 30%. That’s a massive win for maintaining the constant throughput needed in major distribution centres.

Even more critically, they are proven to reduce manual handling injuries by up to 45%. You can discover more insights about the scissor lift market’s growth and impact in recent industry reports. This data makes it clear: investing in this equipment is a direct investment in your facility’s safety and bottom line. Here at Wilcox Door Service, we bring our “Respected Partners, Reliable Service” approach to help you integrate these systems seamlessly into your operations.

Navigating the Different Types of Table Scissor Lifts

Choosing the right table scissor lift isn’t a one-size-fits-all decision; picking the wrong one is like using a screwdriver when you need a wrench. It might work, but it won’t be efficient or safe. To get it right, you need to understand the key differences that ensure you invest in a solution that fits your facility’s daily rhythm like a glove. The first big fork in the road is deciding between a stationary and a portable lift.

Stationary vs Portable Lifts

A stationary scissor lift is exactly what it sounds like: a permanent fixture in a specific spot. You’ll find them bolted to the floor, becoming an integral part of a dedicated workstation, loading dock, or assembly line. These are the heavy lifters in high-volume areas where the task is repetitive and always happens in the same place.

For instance, picture a stationary lift at the end of a conveyor in a busy packaging facility. It provides a stable, ergonomic platform for an employee to build out pallets without the constant strain of bending and reaching. Its fixed position is its greatest strength, guaranteeing stability and making it easy to integrate with other permanent machinery.

On the other side, a portable table scissor lift brings the power to you. Built on casters or wheels, these handy units can be moved across your facility to wherever they’re needed most. This kind of flexibility is a game-changer in dynamic environments where workflows are always shifting.

Think of a maintenance team that needs to lift heavy motors for repair in different corners of a plant. A portable lift lets them bring the muscle directly to the job, then wheel it away when they’re done, keeping precious floor space clear.

Here’s a simple way to figure out what you need. Ask yourself: “Does the work come to the lift, or does the lift need to go to the work?” Your answer will point you straight to either a stationary or portable solution.

Understanding Power Sources

Once you’ve settled the stationary versus portable question, the next choice is the power source. How the lift actually goes up and down has a massive impact on its performance, where it can be used, and how much attention it will need from your maintenance crew.

Hydraulic Lifts: The Heavy-Duty Standard

You’ll find hydraulic lifts in almost every industrial setting, and for good reason. They use pressurized fluid to generate incredible lifting force, making them the undisputed champions for heavy-duty jobs.

- High Load Capacity: Hydraulic systems can handle massive loads, often pushing past 10,000 lbs. This makes them perfect for lifting everything from pallets and machinery to vehicle components.

- Durability and Simplicity: Their design is straightforward and tough. This translates to robust equipment that can take a beating in rugged places like loading docks and fabrication shops with relatively simple maintenance.

- Cost-Effective: Typically, hydraulic lifts come with a lower price tag than their electric counterparts, offering a solid return on investment from day one.

A busy distribution centre moving thousands of kilograms of goods every hour depends on stationary hydraulic scissor lifts at its dock bays. Their raw power and durability are crucial for keeping up with the pace and avoiding downtime.

Pneumatic Lifts: The Clean and Quiet Option

Pneumatic lifts swap hydraulic fluid for compressed air. This one change makes them the go-to choice for environments where cleanliness and quiet operation are top priorities.

Because there’s no hydraulic fluid, the risk of a messy, contaminating leak is zero. This makes them ideal for industries with strict hygiene standards, like food and beverage processing, pharmaceutical manufacturing, or clean-room assembly. They also run noticeably quieter than a hydraulic system, which can make a big difference for your team.

Electric Lifts: For Precision and Speed

Electric scissor lifts use a motor to drive a screw mechanism that raises and lowers the platform. This design gives you a level of control over movement that other types just can’t match, making it the top choice for tasks that demand absolute accuracy.

A great example is an assembly line for sensitive electronics. An electric lift can be programmed for precise, repeatable positioning, ensuring every component is presented to the operator at the exact same height, every single time. They also tend to be faster than hydraulic models, which can give you a real efficiency boost in fast-paced production cycles.

Your choice ultimately comes down to balancing the need for raw power, pinpoint precision, and compatibility with your work environment. For a deeper dive into improving your facility’s vertical material handling, you can explore our comprehensive guide on up and down lifting solutions.

No matter the type, the goal remains the same: to find a reliable partner in your daily operations. The team at Wilcox Door Service is here to help you navigate these options.

How to Select the Perfect Table Scissor Lift for Your Needs

Choosing the right table scissor lift can feel like a complex puzzle, but it really just boils down to matching the machine to the job you need it to do. Get this decision right, and you’re not just buying equipment; you’re making a smart investment in your facility’s safety, productivity, and long-term efficiency.

This guide will give you a clear roadmap. We’ll walk through the key factors—from load weight to how often you’ll use it—turning a complicated choice into a straightforward, confident decision. Think of it as investing in a reliable workhorse that will serve your team well for years.

Calculating Your Load Capacity Requirements

First things first: what is the absolute heaviest load this lift will ever need to handle? This is its load capacity, and it’s the most critical number to get right. It’s a common mistake to think only about the average weight of your products.

To avoid dangerous overloading and give yourself a crucial safety margin, always base your calculation on the heaviest pallet, component, or machine part you’ll be lifting. A solid rule of thumb is to add a 20-25% buffer to that maximum weight. This accounts for things like unevenly distributed loads or future changes in your inventory.

For example, if the heaviest pallet in your loading dock weighs in at 1,800 kg, you should be looking for a lift with a capacity of at least 2,250 kg. This simple step ensures you’re never pushing the equipment to its breaking point, which extends its lifespan and, most importantly, protects your team.

Matching Lift Height and Platform Size to the Task

Next up, let’s think about the physical space. The lift height you need is determined by the highest point the platform has to reach. Get out the measuring tape and find the distance from the floor to the highest surface it will serve, whether that’s a truck bed, a conveyor belt, or a mezzanine level.

The platform size is just as important. Your platform has to be big enough to support your largest load comfortably, with no overhang. An overhanging load is an unstable load, and that’s a major safety hazard. If you’re working with standard pallets, make sure the platform dimensions give you solid support on all sides. An undersized platform is a risk you can’t afford to take.

Comparing Power Sources for Your Environment

As we’ve covered, the power source—hydraulic, pneumatic, or electric—is a huge factor in how the lift performs. Here’s a quick breakdown to help you decide:

- Hydraulic Lifts: These are the heavy lifters. Built for raw power, they are the go-to choice for tough environments like loading docks and manufacturing plants where lifting capacity is king.

- Pneumatic Lifts: This is your clean-air option. Because they don’t use hydraulic fluids, they are perfect for industries where hygiene is non-negotiable, like food processing or pharmaceuticals.

- Electric Lifts: These are the precision specialists. If you need exact, repeatable positioning for tasks on an assembly line or in a technical workshop, an electric lift offers the control and speed you need.

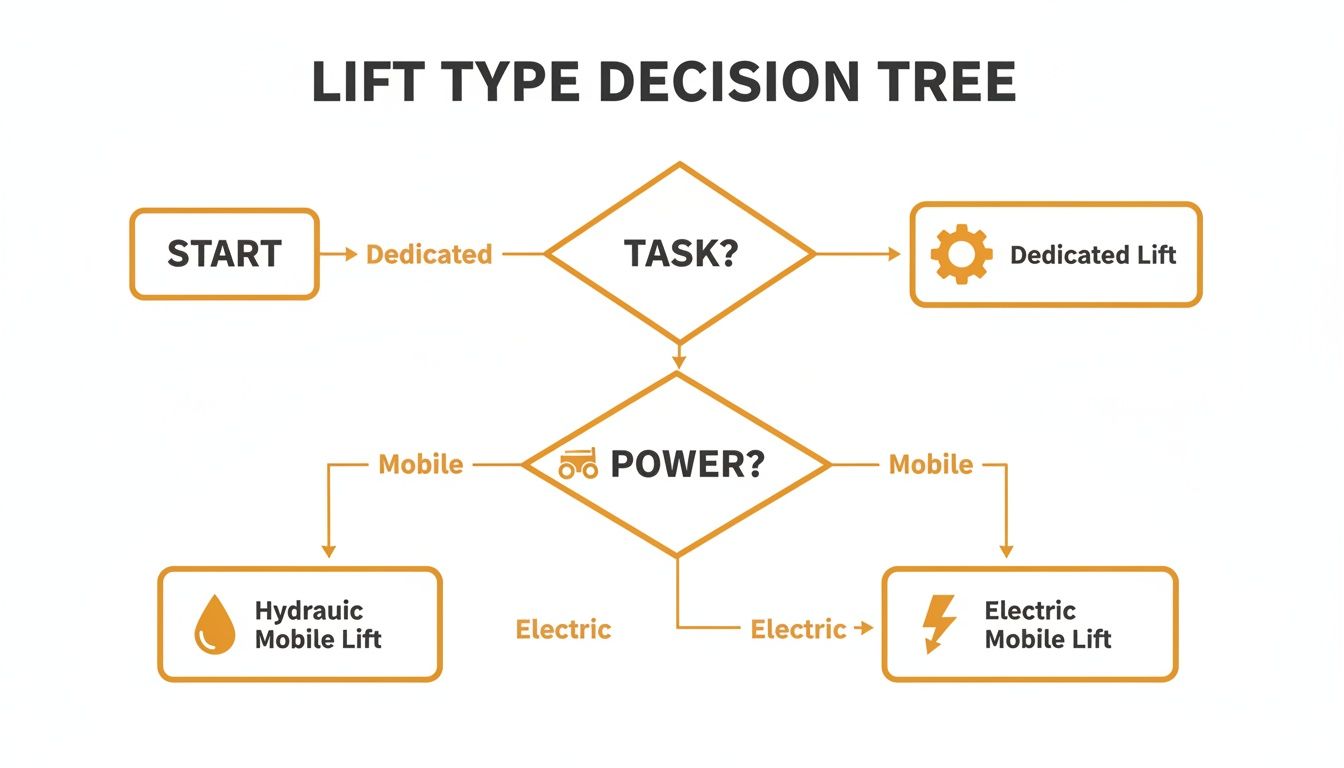

Choosing the right power source often comes down to the primary task at hand. This decision tree helps visualize how your specific needs point you toward the best type of lift.

Alt text: A decision tree diagram to help select the right table scissor lift based on task, mobility, and power source requirements.

As the diagram shows, the path to the right lift starts with a simple question about where the work happens, leading you logically to the ideal power source for that job.

Assessing the Duty Cycle for Your Operational Tempo

How often will this lift be in motion? The duty cycle is a technical term that tells you how many times a lift can be raised and lowered per hour or shift without being overworked. A lift destined for occasional use in a maintenance shop has a very different duty cycle rating than one needed for a fast-paced, 24/7 distribution centre.

Be realistic about your operational tempo. Choosing a lift with a duty cycle that’s too low for your needs will lead to premature wear and unexpected downtime. It’s always better to invest in a model that can comfortably handle your peak workflow.

Evaluating Critical Safety Features

Finally, and most importantly, never compromise on safety. Any table scissor lift you consider should be equipped with fundamental safety features to protect your operators. When you’re looking at spec sheets, make sure these are on the list:

- Toe Guards: These are safety skirts or metal plates around the platform’s edge. They’re simple but essential for preventing feet or equipment from getting caught under the lift as it descends.

- Emergency Stop Button: A big, obvious button that cuts all power to the lift instantly. It needs to be easy to see and reach in an emergency.

- Velocity Fuses: This is a crucial safety feature in hydraulic systems. If a hose were to fail, these fuses prevent the platform from crashing down, controlling its descent instead.

These features are non-negotiable. They are the foundation of a safe work environment. The logic of matching equipment to the job applies across your entire facility; for more on this, take a look at our insights on how to choose the right dock leveler. By carefully thinking through each of these factors, you can invest with confidence, knowing you’ve picked a solution that is both reliable and safe.

Putting Safety and Compliance First

Getting the job done efficiently is important, but it’s nothing without a solid foundation of safety. When you’re dealing with powerful equipment like a table scissor lift, following safety and compliance standards isn’t just about ticking a box—it’s a fundamental part of running a productive, responsible operation. Here in Canada, these standards are in place to protect your team and ensure your equipment runs reliably, keeping your facility humming without any costly incidents.

Diving into these regulations might seem a little daunting at first, but it all comes down to one simple goal: preventing accidents. Once you get a handle on the mandatory safety features, operator training protocols, and the critical role of regular check-ups, compliance stops feeling like a chore and starts becoming a real strategic advantage for your facility.

Key Canadian Safety Regulations

In Canada, the safety of a table scissor lift is governed by a mix of national standards and provincial Occupational Health and Safety (OHS) acts. While the specific rules can differ slightly from province to province, the core principles are always the same.

Here are the key players and regulations you should know:

- CSA Group Standards: The Canadian Standards Association (CSA) sets the bar with standards like CSA B354 for elevating work platforms. These documents get into the nitty-gritty technical details for design, manufacturing, inspection, and safe operation.

- Provincial OHS Acts: Every province has its own OHS legislation that clearly lays out an employer’s duty to provide a safe workplace. This includes making sure equipment is kept in good shape and that operators have the right training.

- Manufacturer’s Guidelines: This one’s a biggie. Always follow the specific instructions from the lift’s manufacturer for operation and maintenance. It’s not just crucial for safety; it’s also essential for keeping your warranty valid.

“Safety is not a feature; it’s a prerequisite. A compliant table scissor lift is one that has been designed, tested, and maintained to prevent failure, protecting both the operator and the valuable assets being handled.”

This entire framework is designed to make sure every aspect of the lift, from its first blueprint to its daily use, is laser-focused on minimizing risk.

Must-Have Safety Features Explained

Modern scissor lifts are kitted out with several safety features that are absolutely non-negotiable. As a facility manager, knowing what they are and why they’re there is essential.

- Guardrails: For any lift designed to carry people, sturdy guardrails are a must. They’re your first line of defence against falls, a leading cause of workplace injuries.

- Emergency Stop Button: You can’t miss it—a big, obvious button that cuts all power to the lift instantly. It’s a critical failsafe.

- Velocity Fuses: This is an unsung hero in hydraulic lifts. If a hydraulic line ever bursts, this valve automatically slows the platform’s descent, preventing a catastrophic free-fall.

- Toe Guards: These are the plates or skirts around the base of the platform. They’re there to stop feet or other objects from getting caught in the scissor mechanism as it lowers.

Safety regulations have truly changed the game for table scissor lift use in Canadian industrial settings. In line with Canada’s Occupational Health and Safety Act, these lifts are instrumental in cutting down fall risks that once accounted for a staggering 25% of workplace incidents in logistics. Facilities are now reporting far fewer access-related claims, proving just how much compliance makes a worksite safer.

The Critical Role of Operator Training

Even the most advanced, safety-packed machine can be a hazard in untrained hands. Proper operator training isn’t just a good idea; it’s a legal requirement and a practical necessity. Certified training makes sure your team knows the lift’s capacity limits inside and out, understands how to operate the controls confidently, and knows exactly what to do in an emergency. For more guidance on fostering a safer environment during equipment operation, have a look at our article on heavy equipment installation safety tips.

At Wilcox Door Service, we believe in being proactive about safety. Our “Respected Partners, Reliable Service” promise means we don’t just supply compliant equipment; we help you understand the standards that keep your facility and your team secure.

Implementing a Proactive Maintenance and Inspection Plan

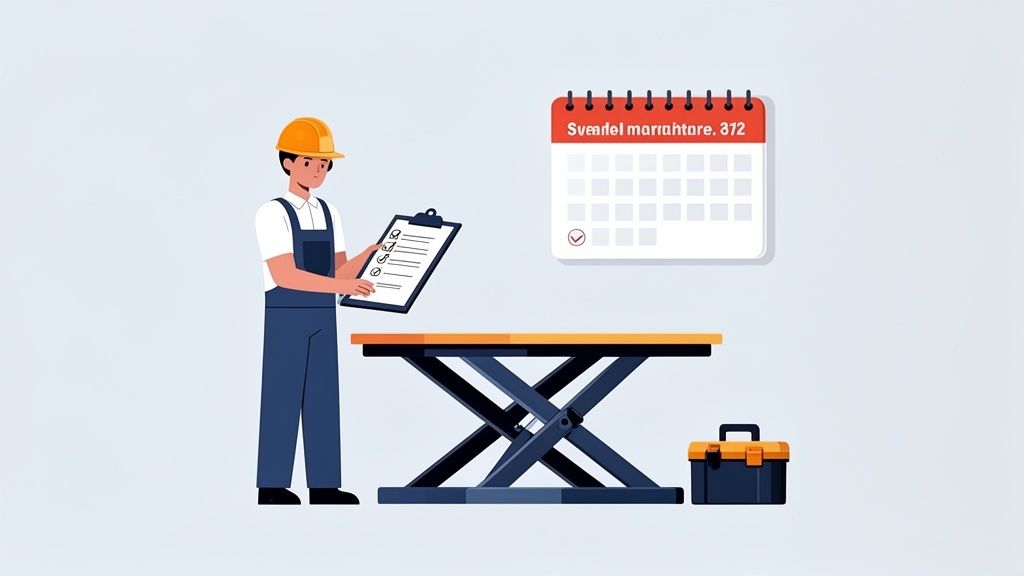

A well-maintained table scissor lift is a safe and reliable one. It’s easy to see maintenance as just another cost, but the smart move is to treat it like a strategic investment. Being proactive is the key to preventing unexpected downtime, getting more years out of your equipment, and keeping your facility running without a hitch.

A solid plan isn’t complicated. It’s really about setting up simple, consistent checks that catch small issues before they snowball into major, production-halting headaches. Think of it this way: a facility manager who schedules a technician to fix a minor hydraulic hose leak today spends a fraction of what they would on a full system failure and the associated downtime tomorrow. By building a routine of daily, weekly, and monthly inspections, you give your team the power to keep your lifts in peak condition and protect your investment.

Alt text: A maintenance technician in a hard hat inspects a table scissor lift, following a preventative maintenance checklist.

Building Your Daily Inspection Checklist

The daily check is your first line of defence. It’s a quick, visual once-over that the operator should do before every single shift. This simple habit takes just a few minutes but is incredibly effective at catching common operational hazards before they cause trouble.

Your team’s daily checklist should cover the basics:

- Visual Scan: A quick walk-around to spot any obvious damage, like dents, cracked welds, or loose parts.

- Work Area Check: Make sure the area around the lift is clear of debris, obstructions, or spills that could turn into a safety risk.

- Controls Test: A quick function test to confirm the up/down controls and, most importantly, the emergency stop button are responding exactly as they should.

This simple routine ensures the equipment is safe to use right from the start of the day.

Establishing Weekly and Monthly Routines

While daily checks are all about immediate safety, your weekly and monthly inspections need to dig a bit deeper. These are where you get into the lift’s mechanical and electrical systems, which is essential for long-term reliability.

Weekly Inspection Tasks:

- Check Hydraulic Fluid Levels: For any hydraulic lift, make sure the fluid is at the manufacturer-recommended level. Low fluid can lead to sluggish performance and cause real damage to the pump.

- Inspect Hoses and Fittings: Look closely for any signs of leaks, cracks, or abrasion on hydraulic hoses and electrical cables. Even a tiny leak is a clear warning sign that something needs attention.

- Lubricate Moving Parts: Get the grease gun out and hit all the pivot points, including rollers and pins, just as the manufacturer specifies. This keeps everything moving smoothly and quietly.

Monthly Inspection Tasks:

- Structural Integrity Check: Examine the scissor arms, platform, and base frame for any signs of stress fractures, bending, or excessive wear.

- Test Safety Features: Go beyond the emergency stop. Verify that features like toe guards and velocity fuses are in place and working correctly.

- Review Fasteners: Check that all nuts, bolts, and anchoring hardware are tight and secure. The vibrations from normal operation can easily cause them to loosen over time.

This structured approach helps you systematically monitor the health of your table scissor lift.

A proactive maintenance schedule isn’t just about preventing breakdowns; it’s about maximizing asset utilization. Consistent care ensures your equipment is always ready, supporting the high-tempo demands of modern facilities.

The rental market for this equipment has seen massive growth. In Canada, the rental ecosystem for table scissor lifts exploded post-2020, now mirroring North America’s 857,000-unit rental fleet. Wilcox Door Service supports this by offering 24/7 repairs and preventive programs that can extend the life of these assets by up to 30%—a vital service for facility managers who count on 95%+ utilization rates. To learn more about these market trends, you can read the full research on the scissor lift market.

A formal maintenance plan keeps your operations dependable. When more complex issues pop up, relying on union-certified technicians ensures the job is done right. For expert help building out your maintenance program, check out our commercial and industrial door repair services. Partnering with our team means you have a reliable resource dedicated to keeping your facility’s equipment in peak condition.

Troubleshooting Common Table Scissor Lift Issues

Even the most dependable piece of equipment has an off day. When your table scissor lift starts acting up, having a solid troubleshooting plan can mean the difference between a quick fix and a major workflow disruption. We’ve laid out a simple ‘Problem, Cause, Solution’ guide to help your team safely diagnose and handle the small stuff.

Just as important, this guide will help you spot the signs that it’s time to call in a pro. Knowing when to pick up the phone is just as critical as knowing which fuse to check, ensuring complex repairs are handled correctly and your team stays out of harm’s way.

Problem One: The Lift Won’t Raise

It’s a common headache: you hit the button, and nothing happens. Before you start thinking the worst, the culprit is often something simple that your team can safely investigate.

- Potential Cause 1: Power Supply Issue. The first and most obvious thing to check is the power. It sounds basic, but a disconnected cord, a tripped circuit breaker, or a loose air line on a pneumatic lift is behind more service calls than you’d think.

- Solution: Take a moment to safely check all power connections. Is the unit plugged in securely? Is the breaker in the ‘on’ position? Are all the necessary power switches on the lift itself activated? For pneumatic models, double-check that the air supply is connected and properly pressurized.

- Potential Cause 2: Overload Condition. Most modern lifts are built with safety systems that will stop them from operating if they’re overloaded. It’s a smart feature designed to protect the motor and hydraulic components from getting fried.

- Solution: Carefully remove the load from the lift’s platform and try operating it again. If it suddenly works, the answer is simple: you need to lighten the load to stay within the manufacturer’s specified capacity.

Problem Two: Jerky or Unstable Movement

A scissor lift should move with a smooth, predictable motion. If you notice the platform jerking, shuddering, or seeming wobbly on its way up or down, that’s a red flag telling you something isn’t right.

- Potential Cause: Air in the Hydraulic System. On hydraulic lifts, trapped air bubbles in the fluid are a common cause of that erratic, jerky motion. This can happen if the hydraulic fluid has dropped too low or right after a hose has been replaced.

- Solution: The system likely needs to be “bled” to get the air out. This usually involves cycling the lift all the way up and down a few times, which helps work the air bubbles out of the lines. Always check your owner’s manual for the specific procedure for your model.

When to Call for Service: If the jerky movement doesn’t stop, or if it’s paired with loud grinding or whining noises, stop using the lift immediately. This could point to a much bigger problem with the pump, motor, or the scissor leg rollers. For expert diagnostics, trust our 24/7 emergency repair service.

Problem Three: The Platform Drifts Downward

You get the lift to the perfect height, only to watch it slowly sink back down over the next few minutes. This issue, known as “drifting,” is almost always a sign that the hydraulic system is losing pressure.

- Potential Cause: Leaking Hydraulic Fluid or Faulty Valve. The most likely reason is either a slow leak from a hose or fitting, or an internal issue with a cylinder or control valve that’s letting fluid bypass where it shouldn’t.

- Solution: Start with a careful visual inspection. Look over all the hydraulic lines and connection points for any tell-tale signs of fluid. If you spot a leak, that component needs to be replaced. If everything looks dry on the outside, the problem is likely internal to the valve or cylinder.

Because tinkering with hydraulic systems requires specialized tools and knowledge to be done safely, this is a job best left to a professional. Our team at Wilcox Door Service has the expertise to pinpoint and fix these issues, getting your equipment back to safe and reliable operation. Our “Respected Partners, Reliable Service” promise means we’re always here to help.

Ready to Elevate Your Facility’s Safety and Productivity?

Choosing the right table scissor lift isn’t just a purchase—it’s a smart investment in your facility’s safety, efficiency, and bottom line. We’ve walked through everything from selecting the best equipment for your unique workflow to understanding the safety standards that protect your team and the maintenance routines that keep things running smoothly. You now have the foundational knowledge to make a great decision. The next step is putting it into practice.

A well-chosen lift does more than just move materials; it protects your team from physical strain, prevents product damage, and keeps your entire operation flowing without a hitch. Whether you’re finally replacing that old, unreliable unit or outfitting a brand-new workstation, the right solution is within your grasp.

Work With People Who Know Their Stuff

Let our team of union-certified experts help you take that next step with confidence. We can come in and provide a detailed assessment of your facility’s needs, recommend the perfect table scissor lift from our lineup, or schedule a thorough service inspection for your current equipment. Our goal isn’t just to sell you a machine, but to provide a solution that works for you today and supports your growth for years to come.

Take action today and see the difference it makes. When you work with a team that’s serious about reliable service, you get more than just equipment. You get a trusted partner dedicated to making sure your facility’s material handling systems are safe, efficient, and always ready for the job.

Your facility’s efficiency and your team’s safety are two sides of the same coin. A properly specified and maintained table scissor lift is not just a tool—it’s a core component of a modern, productive, and safe industrial environment. Let us help you get it right.

Ready to enhance your facility’s safety and efficiency? Contact Wilcox Door Service Inc. to discuss your needs with our experts and get a personalized quote. Visit us online at https://www.wilcoxdoor.com to learn more.