Choosing the right weatherstripping is a critical decision for any facility manager, one that directly impacts energy efficiency, pest control, and operational safety. This guide will walk you through the essential types of exterior door weatherstripping, explaining the key differences between materials and profiles. You will learn how to select the best seals for your specific industry—from standard A/V weatherstrip for warehouses to custom brush seals for food and pharmaceutical facilities—ensuring you can make a smart, cost-effective choice to protect your building.

Your Guide to Commercial Door Seals

Alt text: Three loading dock bays on a commercial building, illustrating the need for effective exterior door weatherstripping.

On a commercial or industrial door, weatherstripping is much more than a simple draft blocker; it’s a core part of your building’s operational integrity. A failing seal can lead to surprisingly high energy bills, pest problems that compromise your inventory, and an uncomfortable—or even unsafe—environment for your team. This guide will break down the essential types of exterior door weatherstripping to help you make an informed decision for your facility.

We’ll explore how different materials and designs hold up in demanding, real-world scenarios. By the end, you’ll have a clear picture of which options can handle heavy forklift traffic at a loading dock, extreme temperatures in a cold storage facility, and the strict regulatory standards of the food and pharma industries.

Why Prioritize the Right Weatherstripping

Picking the right seal for your facility isn’t just a maintenance chore—it’s a strategic move with real, tangible benefits. A proper seal actively works to protect your assets and lower your operating costs. Think of it as reinforcing a secure and efficient operational environment.

- Energy Efficiency: Gaps around large overhead or loading dock doors can bleed a shocking amount of energy, forcing your HVAC systems to work overtime. A tight seal is your first and best defence against that waste.

- Pest and Debris Control: In industries like food processing or pharmaceuticals, keeping pests and contaminants out is non-negotiable. Specialized seals, like brush or rodent-proof options, create a formidable barrier.

- Operational Safety: Poorly sealed doors can let rain and snow creep onto loading dock floors. That creates hazardous slip-and-fall conditions for your employees.

A Facility Manager’s Guide to Commercial Door Seals often extends beyond immediate security and energy efficiency, delving into broader building health. Understanding various strategies for improving indoor air quality is crucial for maintaining a healthy and productive environment.

Understanding the Basics of Door Seals

Before diving into specific materials, it helps to know the fundamental parts of a complete sealing system. For a great overview of how these elements work together, our guide on garage door seals for top and sides provides excellent foundational knowledge. Essentially, a complete system has to address the entire perimeter of the door opening—the top (header), the sides (jambs), and the bottom.

This holistic approach makes sure no gaps are left vulnerable. As we continue, you’ll see how to select the right components for each part of your door, from standard vinyl weatherstrip to custom brush seals, ensuring your facility is protected on all fronts. As your respected partners, Wilcox Door Service is here to provide reliable service and expert guidance.

Decoding Weatherstripping Materials From Vinyl to Silicone

Picking the right material for your weatherstripping is the most important decision you’ll make for its performance and lifespan. It’s a lot like choosing tires for a commercial vehicle—the ones on a city delivery van wouldn’t last a day on a heavy-duty truck in a gravel pit. The material is what determines how well a seal fights off weather, handles physical abuse, and stays flexible after thousands of open-and-close cycles.

For any facility manager, getting this right from the start is crucial. It’s the difference between investing in a reliable, long-term solution and a quick fix that’s guaranteed to fail, costing you more in frequent replacements down the road.

The Workhorse Materials of Commercial Doors

When you look at the world of commercial and industrial doors, four materials really do most of the heavy lifting. Each one brings a unique mix of durability, flexibility, and environmental resistance to the table. This makes them suitable for very different jobs, from a high-traffic loading dock to a climate-controlled cleanroom.

Let’s break down the most common players:

- Vinyl (PVC): As the go-to budget-friendly option, vinyl gives you a good initial seal and stands up well to moisture and scuffs. You’ll often see it in standard A/V (Aluminum/Vinyl) perimeter seals on many commercial overhead doors. The downside? Vinyl gets stiff and brittle in the cold and can lose its shape in high heat, so it’s not the best choice for places with big temperature swings.

- EPDM Rubber: Ethylene Propylene Diene Monomer—or EPDM for short—is the true workhorse for tough jobs. This synthetic rubber is a beast when it comes to resisting UV radiation, ozone, and extreme weather. It stays flexible across a huge temperature range, making it the top choice for exterior loading dock doors that take a beating all year long.

- Silicone: When you’re dealing with serious temperature extremes, silicone is the undisputed champion. It stays incredibly flexible in both deep freezes and scorching heat, blowing vinyl completely out of the water. This makes it the perfect material for freezer and cold storage doors, where a lesser seal would just crack and fail.

- Nylon Brush: Unlike solid seals, brush seals use thousands of dense nylon bristles to form a flexible barrier. This design is fantastic for sealing against uneven surfaces, like a pitted or rough concrete floor. Brush seals are also a secret weapon for pest control in food and pharma facilities, as the dense bristles create a wall that rodents and insects find nearly impossible to get through.

Durability and Performance in the Real World

The environment your door lives in will quickly expose the strengths and weaknesses of its weatherstripping. A vinyl seal on a south-facing steel door in a hot climate might warp and become useless in just a couple of seasons. Put an EPDM rubber seal in that same spot, and it will hold its own for years.

In regions with tough, variable climates, your material choice becomes even more critical. Industry data shows that EPDM rubber and silicone maintain their sealing performance for decades. Some manufacturers even report a useful life of 10–20 years under typical outdoor exposure. That kind of longevity drastically cuts down on how often you need to replace them compared to less durable materials. You can find more details about how materials perform in varied climates in this comprehensive guide about the best types of weatherstripping for exterior doors on doorsforpros.com.

Matching Materials to Your Facility’s Needs

Choosing the right material from the many types of exterior door weatherstripping available isn’t just a maintenance task; it’s a strategic decision. For a high-volume distribution centre, the sheer durability of EPDM rubber is a smart investment that can handle the daily grind. But for a pharmaceutical cleanroom, the superior seal and pest-blocking power of a nylon brush seal are non-negotiable for compliance.

At Wilcox Door Service, we help you sort through these choices. Our team of respected partners provides reliable service by first understanding your specific operational needs, whether you need standard perimeter seals or a custom brush solution. We make sure you get a durable, effective seal that’s built for your unique environment.

Ready to find the perfect sealing solution for your facility? Contact Wilcox Door Service today for an expert consultation.

How Different Seal Profiles Create a Perfect Fit

Choosing the right material for your weatherstripping is only half the battle. The other, equally important half is picking the correct shape, or profile. The profile is what dictates exactly how the seal makes contact with the door and frame to create that impenetrable barrier. It’s the smart engineering behind the seal that makes it work—or fail—in real-world conditions.

Think of it like this: you can seal a container with a simple flat lid, or you can use a screw-on cap. Both are meant to seal, but the threaded profile of the screw-on cap creates a far more secure and reliable barrier. It’s the same idea with weatherstripping. Different profiles are engineered to solve specific problems, from creating a perfectly airtight seal to conforming to a bumpy, uneven loading dock floor.

Perimeter Seals: The First Line of Defence

The absolute foundation of any effective sealing system is the perimeter seals. These are the strips running along the top (header) and sides (jambs) of the door opening, creating a complete frame of protection. They’re your primary defence against drafts, dust, and rain.

Most commercial overhead doors rely on a standard A/V weatherstrip. This design cleverly combines a rigid aluminum retainer with a flexible vinyl or EPDM rubber insert. This gives you a firm, consistent point of contact against the door, effectively shutting down airflow when the door is closed. For a closer look at sealing the sides of your door, checking out different garage door side seal options can offer great insights for a complete solution.

Compression Seals Versus Brush Seals

When you get down to how a seal actually works, two main profiles dominate the commercial world: compression seals and brush seals. Each one has a completely different way of blocking gaps and is suited for very different jobs.

- Compression Seals: These work by getting squeezed between the door and the frame. The classic example is a bulb seal, which is basically a hollow tube of a flexible material like rubber or silicone. Just like the gasket on your refrigerator door, it flattens out when the door closes, filling the gap entirely to stop air and moisture in their tracks. This profile is fantastic for creating a super-tight, energy-efficient barrier on doors that are well-aligned.

- Brush Seals: Instead of a solid barrier, a brush seal uses thousands of dense, flexible nylon bristles to fill the gap. Because the bristles can move and conform, they’re perfect for irregular surfaces, like a worn or pitted concrete floor at a loading dock. This makes them exceptionally good at stopping pests, dust, and debris that a more rigid seal might miss.

The key takeaway here is that the choice between compression and brush seals really boils down to your main goal. If maximum energy efficiency and thermal control are what you’re after, a compression seal is usually the better bet. But for robust pest control and sealing up uneven surfaces, a brush seal is the undisputed champion.

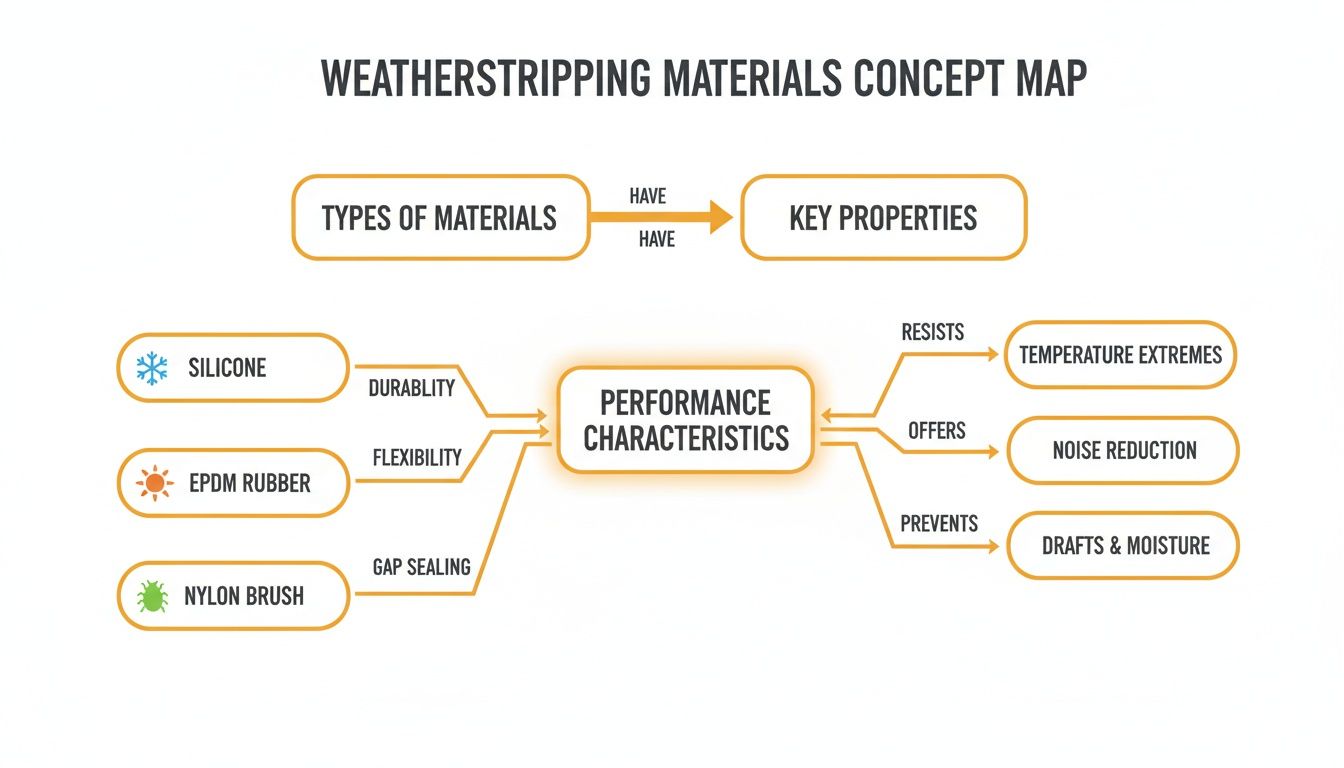

This infographic gives you a quick visual rundown of key weatherstripping materials, highlighting where each one shines.

Alt text: Infographic showing types of weatherstripping materials like silicone, EPDM, and nylon brush with their benefits.

As you can see, materials like silicone are stars in cold environments, EPDM rubber is a pro at handling sun exposure, and nylon brush seals are top-tier performers for pest control.

Sealing the Bottom Gap: Sweeps, Shoes, and Astragals

The gap at the bottom of a commercial door is often the toughest spot to seal effectively. It takes the most abuse from traffic and has to deal with floors that are rarely perfectly level. Luckily, several profiles are designed specifically to tackle this challenge.

A door sweep is a simple flat strip of material—often a brush or a flexible fin held in an aluminum retainer—that’s attached to the face of the door. When the door closes, the sweep brushes against the threshold to close off the gap.

For more demanding, heavy-duty situations, you’ll see a door shoe. This is a U-shaped channel that actually wraps around the very bottom of the door, providing both a seal and a layer of protection for the door itself. The seal insert can be anything from a vinyl fin to a bulb seal or even a brush.

Finally, when you have two doors that meet in the middle, like in a double-door setup, you need an astragal. This is a vertical molding strip attached to one of the doors. When the doors are closed, it covers the gap between them, stopping drafts and adding a layer of security.

Getting a handle on these different profiles is crucial for creating a complete and effective seal around your commercial doors. As your trusted partners in facility maintenance, we make sure every solution—from a simple perimeter seal to a custom-configured brush seal—delivers the reliable performance your operation needs.

Matching the Right Seal to Your Industry’s Demands

Picking the right weatherstripping isn’t a simple off-the-shelf decision. A pharmaceutical cleanroom and a high-traffic distribution centre play by completely different rules, and their door seals have to match those unique demands. Choosing the correct exterior door weatherstripping is a strategic decision that directly impacts your compliance, safety, and bottom line.

Think of it like picking the right tires for a vehicle. You wouldn’t put racing slicks on a heavy-duty dump truck. The same logic applies here. The standard perimeter seal that does a fine job on a typical warehouse door would fail spectacularly in a food processing facility where sanitation and pest control are non-negotiable.

Food and Pharmaceutical Facilities

In tightly regulated industries like food processing and pharmaceuticals, the stakes couldn’t be higher. A single breach allowing in pests, dust, or airborne contaminants can ruin entire batches of inventory, trigger audits, and lead to costly shutdowns. In these environments, door seals aren’t just for weather—they’re a critical line of defence in your quality control plan.

The priorities here are crystal clear:

- Pest Prevention: Seals need to create an absolutely impenetrable barrier. This is where brush seals really shine. Their thousands of flexible bristles conform to every tiny dip and imperfection in the floor and frame, slamming the door shut on rodents and insects.

- Sanitation: Materials must be non-porous and a breeze to clean. Seals should be FDA-compliant and built to handle frequent, aggressive cleaning protocols without breaking down.

- Airtight Control: Cleanrooms often rely on maintaining specific positive or negative air pressure to control contamination. High-quality compression seals, typically made from durable EPDM rubber, are essential for creating that perfect airtight barrier needed to manage the environment.

Manufacturing and Logistics Hubs

For busy manufacturing plants, warehouses, and loading docks, the biggest enemy is wear and tear. These doors are in constant motion, and their weatherstripping gets beat up by forklifts, pallet jacks, and the relentless cycle of daily operations.

Here, the focus shifts to tough, heavy-duty solutions built to last:

- Impact Resistance: Seals have to be tough enough to take a hit. Heavy-duty EPDM rubber seals protected by sturdy aluminum retainers can shrug off incidental impacts that would shred standard vinyl seals.

- Longevity: Constant use grinds seals down. Opting for a material like EPDM rubber, known for its long service life and resistance to UV damage, means you aren’t replacing seals every single year. A quality seal minimizes downtime and maintenance headaches.

- Effective Sealing: Even in a rugged setting, energy efficiency still counts. Well-kept perimeter and bottom seals are key to keeping conditioned air in and the elements out. Our guide on enhancing commercial door energy efficiency has practical tips for plugging those costly gaps.

Climate-Controlled and Cold Storage Warehouses

In facilities where temperature control is everything, even a tiny gap in a door seal can cause a cascade of problems. It leads to massive energy waste, forces refrigeration equipment to work overtime, and can create dangerous condensation or ice buildup—a serious safety hazard.

For a cold storage facility, a failing door seal is more than just an energy leak; it’s a direct threat to product integrity and employee safety. The resulting ice buildup can create slip hazards and even prevent the door from closing properly, compounding the problem.

The right seal is absolutely vital for operational stability:

- Extreme Temperature Flexibility: Materials like silicone are the undisputed champion here. Silicone stays soft and effective in deep-freeze conditions where vinyl would turn brittle and crack.

- Complete Thermal Break: The entire system—seals, retainers, and even the fasteners—needs to be designed to prevent thermal bridging. That’s when cold transfers right through the material, leading to condensation and frost.

- Airtight Compression: A perfect, uninterrupted compression seal is non-negotiable. It’s the only way to stop warm, moist air from sneaking into the cold space and forming ice around the doorway.

Weatherstripping Solutions by Industry

To make the selection process easier, here’s a quick-reference guide matching common industry challenges with the most effective weatherstripping solutions.

| Industry | Primary Challenge | Recommended Solution(s) |

|---|---|---|

| Food & Pharmaceutical | Pest control, sanitation, and maintaining air pressure | Brush seals for pest prevention; FDA-compliant EPDM or silicone for sanitation and airtightness. |

| Manufacturing & Logistics | High traffic, impact damage, and operational longevity | Heavy-duty EPDM rubber seals in durable aluminum retainers; reinforced bottom seals. |

| Cold Storage & Freezers | Extreme cold, preventing ice buildup, energy loss | Silicone seals for flexibility at low temps; systems designed for a complete thermal break. |

| Retail & Commercial | Energy efficiency, comfort, and noise reduction | Compression seals (EPDM or vinyl) for general-purpose sealing; door sweeps for acoustics. |

This table provides a starting point, but every facility is unique. The key is to analyze your specific operational needs to find a solution that delivers real value.

By matching the seal to your industry’s specific challenges, you ensure the solution works as intended and provides a maximum return on investment. As your partners in facility management, Wilcox Door Service has the expertise needed to identify and install the perfect sealing system for your unique operational demands.

Getting the Most Out of Your Seals: Installation and Replacement

Even the best types of exterior door weatherstripping will let you down if they’re installed poorly or left to degrade. A top-of-the-line seal is only as good as its installation and upkeep. Proper installation creates a lasting bond and a truly effective barrier, while a little proactive maintenance can add years to a seal’s life, protecting your investment and preventing future headaches.

Alt text: Technician installing exterior door weatherstripping, demonstrating the importance of professional installation.

Here, we’ll walk through what facility managers need to know on both fronts. We’ll explain why surface preparation is the non-negotiable first step for a secure seal and how a simple maintenance checklist can save you from costly emergency repairs. Knowing what to look for is the first step in maintaining a secure and efficient building.

The Critical First Step: Proper Installation

You can buy the best EPDM rubber or silicone seal on the market, but if it’s slapped onto a dirty, rusty, or uneven surface, it’s destined to fail. The strength of the bond comes down to one thing: meticulous surface preparation. This means the door frame and threshold have to be spotless—free of all dirt, grease, old adhesive, and rust—before the new weatherstripping even comes out of the box.

For screw-on retainers, you have to ensure they are perfectly straight and fastened securely. Any warping will just create new gaps you didn’t have before. With adhesive-backed seals, a clean, dry surface is the only way to guarantee the seal stays put through thousands of door cycles and harsh seasonal temperature swings. Cutting corners here is a surefire recipe for premature failure.

Tell-Tale Signs Your Weatherstripping is Failing

A seal rarely fails all at once. It usually whispers before it shouts, giving off warning signs that, if caught early, can prevent bigger problems like sky-high energy bills, pest infestations, or water damage. A regular walk-through of your facility’s access points is all it takes to spot these issues before they get out of hand.

Keep an eye out for these clear indicators:

- Visible Daylight: This is the most obvious one. If you can see light peeking around the edges of a closed door, you’ve got a breach that’s letting in air, dust, and pests.

- Audible Drafts or Whistling: On a windy day, stand near your loading dock or personnel doors. That whistling or hissing sound is air being forced through a gap in the seal.

- Water Pooling or Stains: Check for water seeping under the door after it rains. This points to a failing bottom seal and can create dangerous slip hazards or ruin your flooring.

- Increased Pest Sightings: If you’re suddenly seeing more insects or signs of rodents inside, compromised door seals are one of the most common entry points.

- Brittle or Cracked Material: Get hands-on and inspect the seals. If the rubber or vinyl is cracked, stiff, or has pieces flaking off, it’s lost its flexibility and isn’t creating an effective barrier anymore.

Knowing when to act is crucial. A small gap today can become a major expense tomorrow, leading to spoiled inventory in a food facility or shocking energy bills in a climate-controlled warehouse. Proactive replacement is always more cost-effective than reactive repair.

When DIY Isn’t Enough: The Case for Professional Service

While sticking a simple adhesive-backed seal on a personnel door might seem like a straightforward weekend task, commercial and industrial doors are a different beast entirely. A professional assessment often uncovers underlying issues that a simple seal replacement won’t fix. For instance, a misaligned overhead door or a damaged track can prevent even the best weatherstripping from making proper contact.

Trying to fix these complex systems without the right tools or experience can lead to an ineffective seal or, even worse, create a serious safety hazard. Partnering with a professional service like Wilcox Door Service ensures the job is done right the first time. Our certified technicians have the expert eye needed to diagnose the root cause of a seal failure—not just the symptom—and implement a solution that lasts.

For a comprehensive evaluation of your facility’s door seals, schedule a service inspection with our expert team today.

Securing Your Facility with the Right Partner

Choosing the right commercial weatherstripping is a smart investment in your facility’s efficiency and bottom line. We’ve walked through the different types of exterior door weatherstripping, from standard perimeter seals to the specialized brush seals needed for sensitive areas like food processing plants. It’s clear that a good seal is much more than a strip of rubber—it’s your first line of defence in energy management, sanitation, and operational safety.

But picking the right product is only half the battle. You can have the best seal on the market, but if there are bigger issues at play, it won’t do you much good.

Why You Can’t Just Slap on a New Seal

This is where a professional assessment becomes invaluable. An experienced technician sees more than just worn-out rubber. They can spot hidden problems—a slightly misaligned door, a warped frame, or an uneven concrete floor—that will prevent any new seal from working properly.

Simply replacing old weatherstripping without fixing these root causes is a recipe for frustration. A facility manager might just see the failing seal, but the real culprit could be the door’s alignment. That’s where expertise makes all the difference, ensuring the new seal lasts and performs as it should.

Partnering with an expert means you get a solution that fits your unique operation. You move beyond a temporary patch to a long-term strategy that truly protects your facility.

At Wilcox Door Service, we’re not just in the business of selling parts; we deliver complete, effective sealing solutions that secure every access point. As your respected partners, we provide the reliable service needed to identify the real challenges at your loading docks and overhead doors and find the ideal weatherstripping system to solve them.

Ready to stop air leaks and fortify your building for good? Contact Wilcox Door Service today to schedule an expert consultation and finally get that perfect seal.

Got Questions About Commercial Weatherstripping? We’ve Got Answers.

Even after getting familiar with the different types of exterior door weatherstripping, facility managers usually have a few lingering questions. We get it. Theory is one thing, but your facility has unique challenges. Here are a few of the most common questions we hear, with practical answers to help you keep your building envelope tight, efficient, and secure.

How Often Should I Replace My Commercial Door Weatherstripping?

This really comes down to the material, how busy your facility is, and the environment it’s in. That budget-friendly vinyl seal on a high-traffic loading dock might give you a few years at best. On the other hand, a high-performance EPDM rubber or silicone seal could easily last a decade or more.

But honestly, it’s better to inspect your seals than to just go by their age. If you can see cracks, feel a draft, or notice the material has gone brittle and flat, it’s time for a replacement. Being proactive here will save you a ton of money on energy loss and prevent other headaches down the road.

Can New Weatherstripping Really Lower My Energy Bills?

Absolutely. Gaps around a big commercial door are like leaving a window wide open while your HVAC system is running full blast. A solid seal is essential for keeping your conditioned air in and the outside temperatures out.

This takes a huge amount of strain off your heating and cooling equipment, which you’ll definitely see on your utility bills. For specialized places like cold storage warehouses, the ROI on professional-grade weatherstripping is often incredibly fast thanks to the immediate and sustained energy savings.

What Is the Best Weatherstripping for Pest Control?

For keeping pests out—especially in sensitive places like food processing or pharmaceutical facilities—brush seals are the clear winner. The bristles are dense but flexible, so they conform perfectly to uneven floors and frames. This creates a tough barrier that’s incredibly difficult for rodents and insects to get through.

For a top-tier defence, pair a heavy-duty brush seal with a solid rubber bottom seal. This two-layer system is one of the most effective strategies out there for maintaining compliance and protecting your products.

How Can I Seal a Door with an Uneven Floor?

This is a classic problem, especially at loading docks and in older buildings. The good news is, there are weatherstripping profiles designed specifically for this. An adjustable bottom seal with a large, flexible rubber loop is engineered to press down and mould itself to the floor’s contours.

Brush seals are also fantastic in these situations. The individual bristles can fill in gaps and dips that a rigid seal would just skim over. A professional can take a look at how uneven your floor is and recommend the right combination of products to get you a complete, effective seal.

Your facility’s doors are critical access points that demand a reliable sealing solution. For a professional assessment that addresses all your operational needs, trust Wilcox Door Service. Explore our commercial and industrial door services to find the perfect fit.