Pharmaceutical & Healthcare Facility Solutions | Wilcox Door Service Inc.

Fully GMP-, FDA-, and Health Canada-compliant door, dock, and access systems for pharmaceutical and healthcare facilities.

Compliance-Driven Access & Containment Systems for Life-Saving Environments

Pharmaceutical and healthcare environments demand unmatched performance in containment, sanitation, access control, and regulatory compliance. At Wilcox Door Service Inc., we design, install, and maintain specialized commercial doors, dock systems, and safety equipment for mission-critical facilities where uptime, security, and clean environments are non-negotiable.

We partner with life sciences clients, hospitals, labs, pharmacies, and controlled environments to ensure their infrastructure supports GMP, Health Canada, FDA, and CSA standards.

Trusted by Canada’s Life Sciences Leaders

Wilcox Door Service has built trusted partnerships with some of Canada’s leading pharmaceutical companies, medical institutions, and controlled environment operators. We understand the regulatory landscape, urgency, and precision required for this sector — and we deliver.

Our team works with facility managers, engineering consultants, infection control officers, and capital project teams to design and implement solutions that protect product integrity, patient health, and regulatory compliance.

Wilcox supports door and dock systems at facilities across Ontario’s pharma and health sectors, including:

- Pharmaceutical manufacturing & cleanroom facilities

- Biotech and life sciences labs

- Hospitals and private surgical centers

- Long-term care & senior living residences

- Compounding pharmacies

- Medical storage and cold-chain distribution centers

Our solutions align with standards for:

- Good Manufacturing Practices (GMP)

- FDA & Health Canada Regulations

- CSA Z317.13 – Infection control during construction

- CSA Z432 / OHSA – Equipment and worker safety

- ISO 8+ Cleanroom Requirements

Specialized Door & Dock Solutions for Healthcare and Pharma

We offer a wide range of equipment and systems engineered specifically for sterile, high-performance, and compliance-critical environments. Every component we recommend is evaluated for its ability to support contamination control, air pressure retention, and hygienic operation.

We supply and service:

Controlled Access & Containment Doors

- High-speed doors – Reduce air transfer between spaces with high cycle rates, minimal dwell time, and smooth PVC or rubber surfaces for cleanability.

- Hermetic sealing sliding doors – Ideal for labs, surgical suites, and ICU zones where air pressure control and contamination prevention are paramount.

- Specialty cleanroom doors – Stainless or aluminum-framed polycarbonate doors, with seamless edges and easy-clean hardware.

- Fire-rated doors – Rolling or swinging fire-rated closures equipped with drop test and reset functionality for life safety compliance.for cleanroom separation and pressurized spaces

- Hermetic sealing sliding doors for labs and surgical centers

- Aluminum-framed polycarbonate or stainless doors for sterile zones

- Fire-rated doors with drop test & reset capabilities

Hygienic & Non-Contact Entry Systems

- Touch-free activation systems – Reduce touchpoints with wave-to-open sensors, motion detection, and footplate entry controls.

- Antimicrobial surfaces – Hardware and door surfaces with microbial-resistant coatings and easy-clean construction.

- Automation-ready frames and hardware – Support retrofits and automation protocols while meeting hygiene standards.

- Flush or seamless doors – Designed with cleanability in mind, eliminating ledges and gaps where pathogens may collect.wave-to-open, or antimicrobial handles

Loading Dock Containment & Safety

- Air curtains – Reduce air infiltration and airborne contamination during open-door cycles at the dock.

- Vertical dock levelers – Maintain pit cleanliness and eliminate debris collection common in traditional leveler pits.

- Dock sealing systems – Custom foam and inflatable solutions to protect clean corridors and storage areas from external exposure.

- Vehicle restraint systems – Ensure trailer stabilization during loading to reduce accident risk and maintain process flow.and seals to prevent contamination during deliveries

Access Control & Compliance Upgrades

- Interlocking door systems – Prevent simultaneous opening of two doors to maintain pressurization or sterile zoning.

- Observation windows and view panels – Tempered or polycarbonate viewing options with sealed glazing.

- Card access and biometrics – Fully integrated solutions to support secure access tracking and restricted zone management.

- Emergency egress & monitored exit devices – Panic hardware with electronic feedback and alarm interface capabilities.to manage sequencing and cross-contamination

Why Healthcare Facilities Trust Wilcox

Proven Pharma and Healthcare Expertise: Trusted door and dock solutions for leading life-sciences and medical facilities

Cleanroom Certified Technicians: Specialists in gowning protocols and infection control for sterile environments

Union Backed Installation Quality: Durable, code-compliant access systems installed by skilled Ironworkers

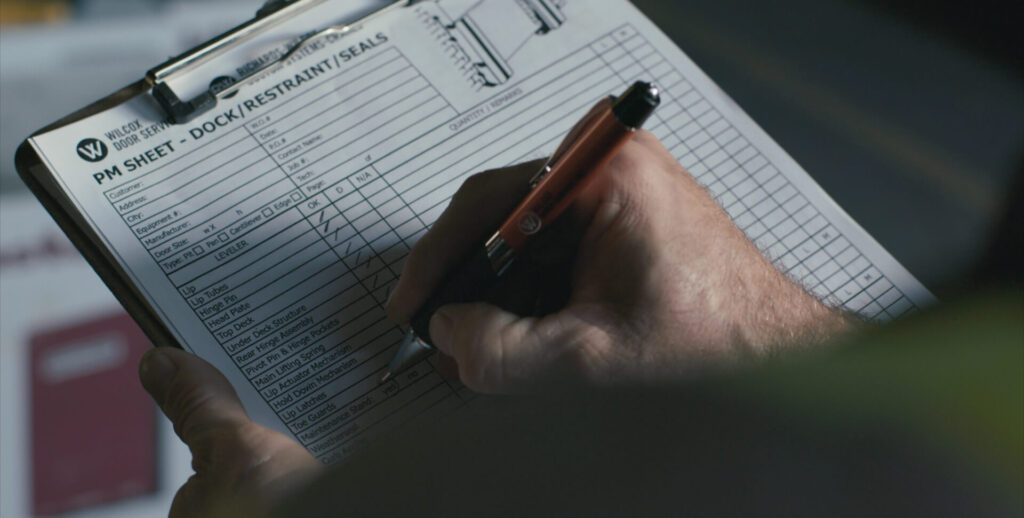

Audit-Ready Compliance Documentation: GMP, FDA and Health Canada submittals with test data and service logs

Proactive Preventive Maintenance: Tailored service plans to maximize uptime and maintain regulatory compliance

Turnkey Project Management: End-to-end design, installation and handover for sterile access infrastructure

Pharmaceutical & Healthcare Door Solutions

Cleanroom-rated, insulated, and fire-rated doors designed for pharmaceutical labs, healthcare facilities, and sterile environments.

Ready to Upgrade or Build a Health-Compliant Access System?

From cleanroom entries to sterile loading zones, Wilcox delivers compliant, reliable, and expertly managed solutions to Canada’s most demanding environments.

Wilcox Door Service — Built for Health, Backed by Compliance.