Are you a facility manager looking to maximize vertical space and enhance operational safety? This guide explains everything you need to know about a side mounted garage door opener, also known as a jackshaft operator. You will learn how this technology works, its key advantages for commercial doors and loading docks, the technical requirements for installation, and how it delivers a strong return on investment.

Why Facility Managers Choose Side-Mounted Openers

For any commercial facility, from a bustling warehouse to a high-traffic loading dock, maximizing usable space and ensuring operational reliability are top priorities. A side mounted garage door opener offers a superior solution, moving beyond the limitations of traditional ceiling-mounted systems to meet the demands of modern industrial environments.

This system is surprisingly straightforward. A traditional trolley opener uses a long rail hanging from the ceiling to pull the door open, consuming valuable overhead real estate. A side mounted opener, often called a jackshaft operator, works more like a powerful, automated wrench. It mounts on the wall next to the door and applies rotational force directly to the torsion bar—the spring-loaded rod that balances the door’s weight. This direct-drive approach is not just more efficient; it fundamentally changes how you can use your vertical space.

The Strategic Value in Commercial Operations

The decision to install a side mounted garage door opener is almost always driven by clear operational needs. These operators are specifically engineered to solve common pain points found in busy commercial and industrial settings.

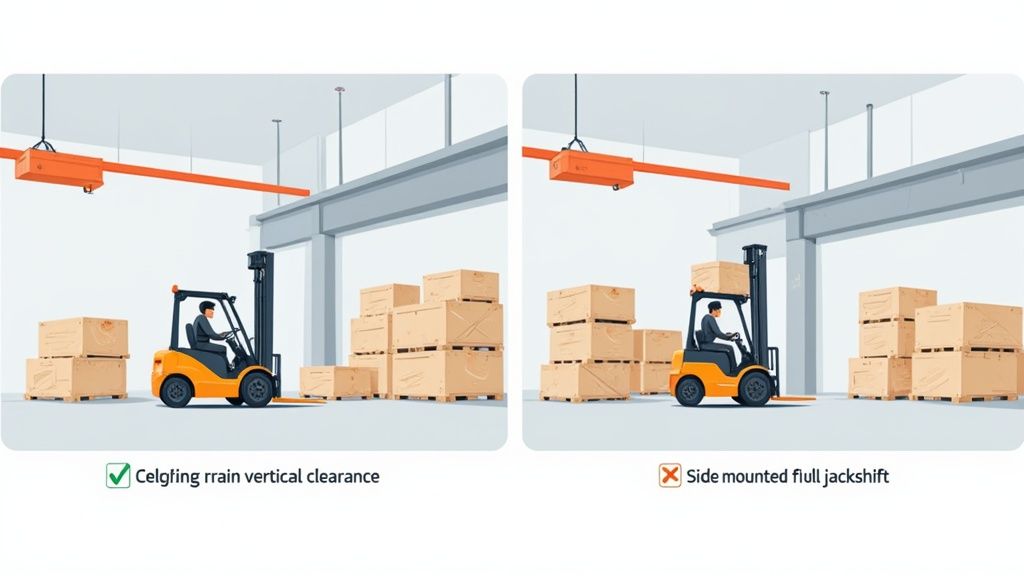

Consider a busy loading dock where forklifts are in constant motion. A ceiling-mounted trolley system can become a low-hanging obstruction, dramatically increasing the risk of costly collisions with tall loads or machinery. By moving the entire operator to the wall, you eliminate that hazard. The result is a safer, more efficient workflow—a critical win for any facility manager focused on reducing downtime and preventing accidents. You can explore our comprehensive commercial door services to see how integrated systems can make your facility even safer.

This space-saving benefit is a game-changer in other commercial applications as well:

- Warehouses with High Ceilings: It allows storage racks and inventory to be stacked right up to the ceiling, letting you maximize every square foot of your facility.

- Auto Repair Bays: Vehicle lifts can operate without any risk of interfering with an overhead opener rail, which greatly improves service bay flexibility and safety.

- Facilities with Overhead Cranes: In manufacturing or heavy industry, a clear ceiling is essential for crane operation. Side mounted openers make this possible.

Ultimately, a side mounted garage door opener is more than just an alternative; it’s a strategic upgrade. It enhances safety, boosts operational efficiency, and unlocks the full potential of your vertical space. For specialized jobs, understanding the installation of a jackshaft operator is key to a successful project.

Our “Respected Partners, Reliable Service” commitment means we deliver solutions that solve real problems. To find out more about how a side-mounted system could benefit your specific operations, contact our team for a professional site assessment.

How a Jackshaft Opener Actually Works

To fully appreciate why a side mounted garage door opener is a game-changer for commercial facilities, it’s important to understand how it operates. Unlike the long, clunky rail hanging from the ceiling in a traditional setup, a jackshaft opener is a compact unit that mounts on the wall, right next to the commercial door.

The easiest way to picture it is as a powerful, automated wrench that directly turns the door’s torsion bar. The torsion bar is the heavy-duty, spring-loaded rod running above your commercial door that does the hard work of balancing the door’s immense weight. By applying rotational force straight to this bar, the jackshaft opener lifts and lowers the door with impressive efficiency and control.

This direct-drive system is the key. It completely eliminates the bulky chains, belts, and tracks that define ceiling-mounted openers. That elegant simplicity is precisely what makes it so durable and space-efficient.

Core Components and Mechanics

At its heart, a side mounted garage door opener has three main parts working in harmony. Each is engineered for durability and direct power transfer—essential features in a high-cycle commercial environment like a loading dock or distribution center.

- The Motor: This is the muscle, providing the raw torque (rotational force) needed to turn the torsion bar. Commercial models feature heavy-duty motors designed for constant use and lifting heavy, insulated, or wind-loaded doors.

- The Gearbox: The motor doesn’t just spin the torsion bar at full speed. A gearbox reduces the motor’s speed while multiplying its torque, giving you the controlled, immense strength needed to move a massive commercial door smoothly and safely.

- The Drive Mechanism: This component creates a direct connection to the torsion bar. A collar from the opener slides right over the end of the bar and is locked down, ensuring every bit of power from the motor goes directly into lifting the door.

This diagram illustrates how the system’s key benefits—space, reliability, and safety—all stem from this fundamental design.

Alt text: Diagram of a side mounted garage door opener system showing core components and features like safety and efficiency for commercial doors.

Connecting directly to the torsion bar not only saves a huge amount of overhead space but also reduces the number of moving parts, which is a massive win for long-term reliability and lower maintenance.

Why Direct Drive Matters in Your Facility

The direct-drive approach is transformative for facilities like auto repair bays with vehicle lifts or warehouses trying to stack inventory to the ceiling. In these environments, every inch of vertical clearance is valuable. By eliminating the overhead rail, you allow forklifts, machinery, and tall vehicles to move without the constant risk of a costly collision.

The real genius of a jackshaft opener isn’t just what it does, but what it doesn’t do. It doesn’t block your ceiling, it doesn’t use long chains that can stretch or snap, and it doesn’t send as much operational vibration through your building’s structure.

This efficiency and space-saving design are major reasons why facility managers are increasingly choosing them for new construction and retrofits alike. For a deeper dive, check out our detailed comparison of jackshaft vs. trolley garage door openers.

The way a side mounted garage door opener works is elegantly simple yet mechanically powerful. By rethinking the entire lifting process, it offers a solution far better suited to the demands of a modern, fast-paced commercial or industrial facility.

Key Advantages in Commercial and Industrial Settings

In the demanding world of commercial operations, a side mounted garage door opener isn’t just a convenience—it’s a strategic asset that solves real-world problems. Its unique design directly translates into measurable improvements in efficiency, safety, and the overall utility of your facility. Let’s explore the key benefits that make this technology a superior choice for industrial environments.

Alt text: A forklift operating in a warehouse, demonstrating the excellent overhead clearance provided by a side mounted garage door opener.

Maximizing Your Overhead Clearance

The most immediate and impactful benefit is reclaiming valuable overhead space. Traditional trolley openers rely on a long rail hanging from the ceiling, creating a low-hanging obstruction that limits your vertical clearance.

A side mounted opener eliminates this entirely. For a busy loading dock, that means forklifts can operate freely without the constant risk of a collision that could damage the opener, the door, or valuable goods. In a warehouse, it allows you to install storage racking right up to the ceiling, maximizing your facility’s storage capacity. This simple change unlocks the full potential of your vertical real estate.

Enhancing Workplace Safety

Removing the overhead rail is a significant safety upgrade. In facilities with complex operations, that rail can interfere with other essential equipment like overhead cranes, vehicle lifts in an auto repair shop, or specialized manufacturing machinery. By moving the operator to the wall, you remove a major potential hazard.

A safer workspace is a more productive one. The design of a side mounted garage door opener inherently reduces collision risks, contributing to a better safety record and minimizing the potential for costly operational downtime.

The safety advantages are so significant that they’ve driven wider adoption across the industry. Removing the overhead trolley and rail can reduce garage ceiling obstruction by up to 100%, which drastically lowers the risk of personnel or equipment accidentally bumping into moving parts. You can learn more about the advantages of side-wall mounted garage openers to see why these systems are becoming the standard.

Quieter and Smoother Operation

Because a jackshaft opener uses a direct-drive mechanism, it operates with far less noise and vibration than traditional chain- or belt-driven systems. There are no long chains clattering along a metal rail, which means a quieter, more pleasant environment for your employees.

This is particularly beneficial in mixed-use facilities where office spaces are located near the warehouse or loading dock. A quieter operation reduces distractions and improves the work environment. This operational smoothness also leads to less wear and tear on the door components over time, contributing to a longer service life. For doors in constant use, a reliable system is crucial, and our commercial door services ensure your equipment is always running smoothly.

Ideal for Specialized Door Systems

Commercial and industrial buildings often feature specialized door configurations that are incompatible with a standard trolley opener. Side mounted openers are the perfect solution for these scenarios.

- High-Lift Doors: These doors rise vertically for a distance before rolling back along the ceiling, requiring significant headroom that a trolley opener would block.

- Vertical-Lift Doors: Found in facilities with very high ceilings, these doors move straight up the wall without turning. A side mounted opener is the only practical way to automate them.

- Doors on Sloped Ceilings: In buildings with angled roofs, installing a horizontal trolley rail can be a logistical nightmare. A side mounted opener bypasses this challenge entirely.

This adaptability makes the side mounted garage door opener an incredibly versatile tool for modern facility design and retrofits. When dealing with these complex systems, a professional installation of a jackshaft operator is essential to guarantee safety and performance.

Technical Requirements for a Successful Installation

Upgrading to a side mounted garage door opener is a smart move for many commercial facilities, but a successful installation depends on meeting a few key technical requirements. Understanding these prerequisites is essential for facility managers to plan for a smooth, efficient installation and ensure the new system delivers long-term reliability.

The most critical requirement relates to your door’s mechanics. A jackshaft opener works by directly turning the door’s torsion bar. This means your commercial door must have a torsion spring system. These openers are not compatible with extension spring systems, which use a different mechanical principle to lift the door.

Alt text: A side mounted garage door opener installed on a commercial door track, illustrating the sideroom and headroom clearance needed.

Sideroom and Headroom Clearances

Physical space is the next major consideration. Unlike overhead units that occupy ceiling space, a jackshaft opener requires clear space on the wall next to the door.

- Minimum Sideroom: You’ll typically need at least 8 to 12 inches of clear, unobstructed wall space on one side of the door tracks. This area is where the opener unit is mounted, so it must be free of pipes, conduits, or structural beams.

- Headroom Above Torsion Bar: A few inches of clearance are also needed directly above the torsion bar. This allows the opener to be properly seated and secured to the wall for a stable and safe connection.

A professional assessment is the best way to confirm your facility meets these spatial requirements. Our technicians can measure your site conditions and identify any potential obstructions before work begins.

Electrical and Power Supply Needs

A reliable power source is non-negotiable for any commercial door operator. For a side mounted opener, this means having a robust electrical setup capable of handling a commercial-grade motor that may cycle hundreds of times a day.

To ensure safety and performance, the installation must adhere to local electrical codes, which often requires a certified electrician. We typically recommend a dedicated circuit to prevent power fluctuations that could interfere with the opener’s performance or damage its sensitive electronic components. For mission-critical facilities like cold storage or emergency services, planning for a commercial-grade battery backup system is also a wise investment.

The Importance of a Professional Assessment

While knowing the basic requirements is helpful, attempting a DIY assessment for a commercial installation is not recommended. A professional technician does more than check clearances; they perform a comprehensive evaluation to guarantee safety, compliance, and flawless functionality.

A successful installation is built on precision. Incorrect alignment or improper tension can lead to premature wear on door components, operational failure, and serious safety hazards for your personnel.

A professional site assessment from Wilcox Door Service includes:

- Verifying Torsion System Compatibility: We confirm your door’s spring system is suitable for a jackshaft opener and is in good condition.

- Precise Space Measurement: Our team measures the sideroom and headroom to ensure a perfect fit for the chosen operator model.

- Door Balance and Weight Assessment: We check that your door is properly balanced. An unbalanced door puts immense strain on the opener, leading to premature failure.

- Safety Sensor Placement Planning: We identify the optimal locations for photo-eye safety sensors to ensure they meet all commercial compliance codes and provide maximum protection.

This thorough process is a core part of our “Respected Partners, Reliable Service” promise. For a detailed look at what a professional setup involves, explore our guide to a successful jackshaft operator install.

Evaluating the True Cost and Return on Investment

For any facility manager, the initial price of new equipment is just the beginning. When considering a side mounted garage door opener, it’s essential to evaluate the total cost of ownership and, more importantly, the long-term return on investment (ROI). This is not just an expense; it’s a strategic upgrade that pays dividends in operational efficiency, safety, and facility value.

Breaking Down the Initial Investment

The upfront cost for a side mounted system typically includes a few key components.

- The Opener Unit: Commercial-grade jackshaft operators are built for high-cycle, demanding environments. They are generally priced higher than standard trolley systems due to their robust construction and direct-drive technology.

- Professional Installation: This is non-negotiable for commercial applications. Proper installation by certified technicians ensures the unit is aligned, secured safely, and compliant with all commercial codes.

- Electrical Work: These operators often require a dedicated power source. This may involve an electrician running a new circuit to protect the opener’s electronics and ensure reliable performance.

Calculating the Long-Term ROI

This is where the business case for a side mounted opener becomes clear. The financial benefits it delivers over its lifespan are significant and often quickly justify the initial investment.

The push for smarter, more efficient facility solutions is driving this trend. Market analyses point to a projected Compound Annual Growth Rate (CAGR) of about 2.9% for the garage door opener market, largely fuelled by a shift toward space-saving and efficient systems like side mounted openers. You can read the full research about these market dynamics to see how these trends are playing out across the industry.

Here’s how the returns add up:

- Reclaimed Vertical Space: By eliminating overhead rails, you unlock valuable cubic footage. For a warehouse, this could mean adding an entire extra tier of pallet racking, directly boosting storage capacity and revenue potential without expanding your footprint.

- Reduced Risk of Damage: In a busy loading dock, overhead trolley systems are vulnerable to forklift collisions. The cost to repair a damaged opener, a bent door track, or the forklift itself—not to mention the operational downtime—can be substantial. A side mounted opener moves this risk out of the way.

- Lower Maintenance Needs: Jackshaft openers have fewer exposed moving parts. There are no long chains or belts to stretch, sag, or snap. This typically translates to fewer service calls, lower lifetime maintenance costs, and more uptime for your most critical access points. Our commercial door services are designed to maximize equipment lifespan through proactive maintenance.

Investing in a side mounted opener is a proactive step toward creating a more efficient and resilient facility. It’s a solution that pays for itself by preventing costly accidents, maximizing usable space, and reducing long-term upkeep.

When you analyze this upgrade through the lens of total cost and long-term gain, you can build a powerful business case for an investment that strengthens both your safety record and your bottom line.

Partnering with Experts for Your Commercial Door System

Choosing the right door opener is a critical decision that impacts your facility’s daily workflow, safety protocols, and overall efficiency. As this guide has shown, a side mounted garage door opener offers significant advantages, especially for demanding commercial environments like busy loading docks or warehouses with high ceilings.

However, the best hardware in the world is only as good as the expertise behind its selection and installation. A successful system isn’t just about the opener; it’s about the entire integrated solution.

That’s where a true partner comes in. Our “Respected Partners, Reliable Service” commitment means we focus on delivering a system engineered for longevity and peak performance in your specific environment. The value of this approach cannot be overstated. To understand why, it’s worth exploring the benefits of hiring a professional installer for any automated system.

Your Path to an Upgraded System

A successful upgrade starts with a clear strategy, and the first step is always a professional site assessment. This is the only way to guarantee the project goes smoothly and delivers the results you expect.

- Comprehensive Site Evaluation: Our technicians will visit your facility to analyze your existing door system, measure clearances, check power availability, and understand your workflow to recommend the ideal operator.

- Customized Solution Design: We avoid “one-size-fits-all” solutions. We will specify a side mounted garage door opener model with the right horsepower and features for your door’s size, weight, and daily cycle count.

- Code-Compliant Installation: Our certified technicians handle every detail of the installation, ensuring that all components, especially critical safety sensors, are installed to meet or exceed commercial compliance standards.

A professional partnership is about more than just the day of installation. It’s about having ongoing support you can count on, from planned maintenance to emergency repairs, making sure your investment pays dividends for years to come.

Our team is ready to walk you through every step of this process. To get to know the dedicated professionals who make it happen, we invite you to read our service department spotlight.

Your Questions Answered: Side Mounted Openers

When evaluating a critical piece of equipment like a side mounted garage door opener, it’s natural to have questions. Here are clear, straightforward answers to the most common inquiries we receive from facility managers.

Can a Side Mounted Opener Be Installed on Any Commercial Door?

Not always. A side mounted garage door opener has one non-negotiable requirement: it must be paired with a torsion spring system. This is because the opener works by directly turning the torsion bar to lift the door. Doors with extension springs are not compatible.

Additionally, an exceptionally heavy or oversized industrial door may require a specialized heavy-duty model. A professional assessment is crucial to ensure the opener’s horsepower is correctly matched to your specific door.

How Does Maintenance for a Jackshaft Opener Compare to a Trolley System?

Maintenance is generally simpler. A jackshaft opener has far fewer exposed moving parts—no long chains or belts stretching across the ceiling. This means fewer components to lubricate, adjust, or replace over time.

However, it is not a “set it and forget it” system.

The simplicity of a side mounted opener’s design reduces certain maintenance tasks, but it places greater importance on the health of the torsion system and the motor itself. Regular professional inspections are crucial for long-term reliability.

Routine service should always include a close inspection of the motor, gearbox, and the entire torsion spring assembly. This ensures the door remains balanced and operates safely. You can see how we handle this proactively by checking out our commercial door services.

Are Side Mounted Openers Secure Enough for a Commercial Facility?

Absolutely. Modern commercial-grade side mounted openers are built with security as a priority. Many models come standard with a power lock or an electronic deadbolt that automatically engages when the door closes, creating a strong physical barrier against forced entry.

These operators can also be integrated with modern access control systems, allowing for electronic monitoring, user logs, and remote operation. This ensures your key entry points are as secure and intelligent as the rest of your facility.

What Happens During a Power Outage?

Business continuity is key, and these systems are designed for power failures. Most commercial side mounted openers include a manual override, typically a chain hoist. This allows your team to safely open or close the door by hand until power is restored.

For facilities where downtime is not an option—such as emergency services or cold storage warehouses—commercial-grade battery backup systems are available. These units keep the door fully operational for a set number of cycles, ensuring uninterrupted access when it matters most. Planning for these contingencies is a core part of a professional jackshaft operator install.

Choosing the right system for your commercial doors requires expert guidance. As your “Respected Partners, Reliable Service,” Wilcox Door Service is here to help you evaluate every option.