When a critical commercial door fails, your immediate actions are crucial for safety, security, and minimizing operational downtime. This guide will walk you through the essential first steps to take, how to identify the likely cause of the failure, what to look for in a professional emergency door fixer, and how proactive maintenance can prevent future crises. By the end, you'll have a clear plan for managing any door emergency with confidence.

Your First Moves During a Commercial Door Emergency

A sudden door failure can bring your entire operation to a halt. Imagine a sectional door at a busy loading dock stuck open, or a security grille that won’t close at the end of the day. How you react in those initial moments makes all the difference.

Your absolute first priority is safety. A malfunctioning commercial door, especially one with high-tension components like springs or live electrical parts, is a serious hazard. Your job is to protect your people, products, and property from any further risk.

Secure The Area Immediately

The moment you identify a door failure, you must create a safe zone. This isn't just a suggestion—it's a critical safety protocol.

Use whatever is available—safety cones, caution tape, or even a forklift—to block off the entire area around the broken door. For a real-world example, if a rolling steel door at a distribution centre suddenly crashes halfway down, the correct response is to clear all personnel and equipment from both sides in case it drops completely.

Assess Without Intervention

Once the area is clear, you can observe the situation from a safe distance. Your goal isn't to fix anything; it's to gather information for the professional technicians.

Look for obvious clues:

- Visible Damage: Can you see dented panels, bent tracks, or cables that look frayed or snapped?

- Unusual Noises: Did you hear a loud bang? This is the classic sound of a broken torsion spring—the powerful springs that do the heavy lifting. Is the motor just humming or grinding without any door movement?

- Positional Problems: Is the door sitting crooked in its opening? Has it come completely off its tracks?

This is strictly a visual check. Do not allow anyone to touch broken cables, try to force the door, or tamper with the springs. These components are under extreme tension and can cause severe injury. For more detail on what qualifies as a true crisis, our guide on what constitutes an emergency garage door repair is a helpful resource.

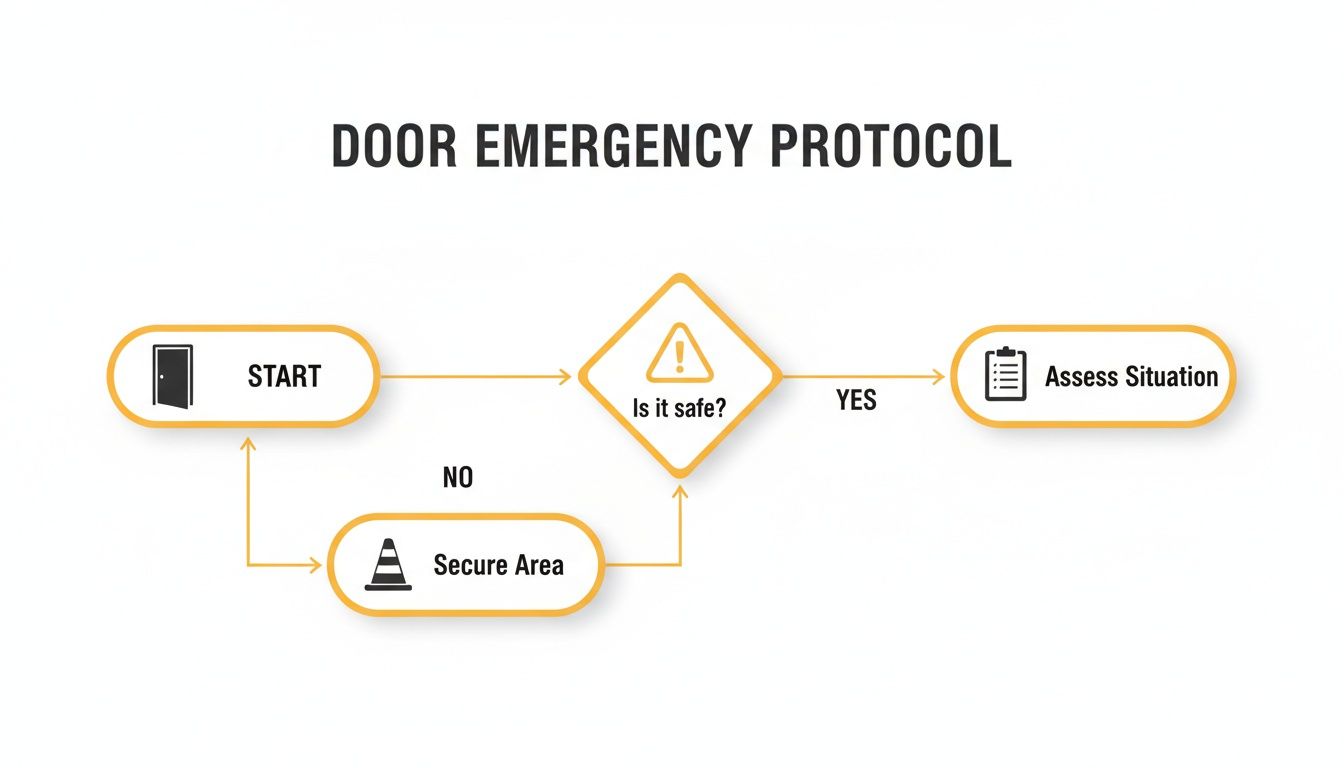

This simple decision tree helps visualize the immediate protocol when facing a door emergency.

Alt text: A flowchart outlining a door emergency protocol, emphasizing securing the area before assessing the situation to ensure safety.

The flowchart reinforces a safety-first approach: secure the area before trying to figure out what’s wrong. This prevents accidents and helps you provide clear, accurate information to the repair team when you call.

With the area cordoned off and a quick assessment completed, your next step is to call a professional emergency door fixer. The details you've gathered will help them arrive with the right tools and parts to get you operational again, fast.

Identifying the Cause of Your Door Failure

Understanding what went wrong is the first step toward a proper fix. When you call for an emergency door fixer, being able to clearly describe the problem helps the technician arrive prepared, which significantly speeds up the repair process. This quick guide will help you diagnose common commercial door failures without needing an engineering degree.

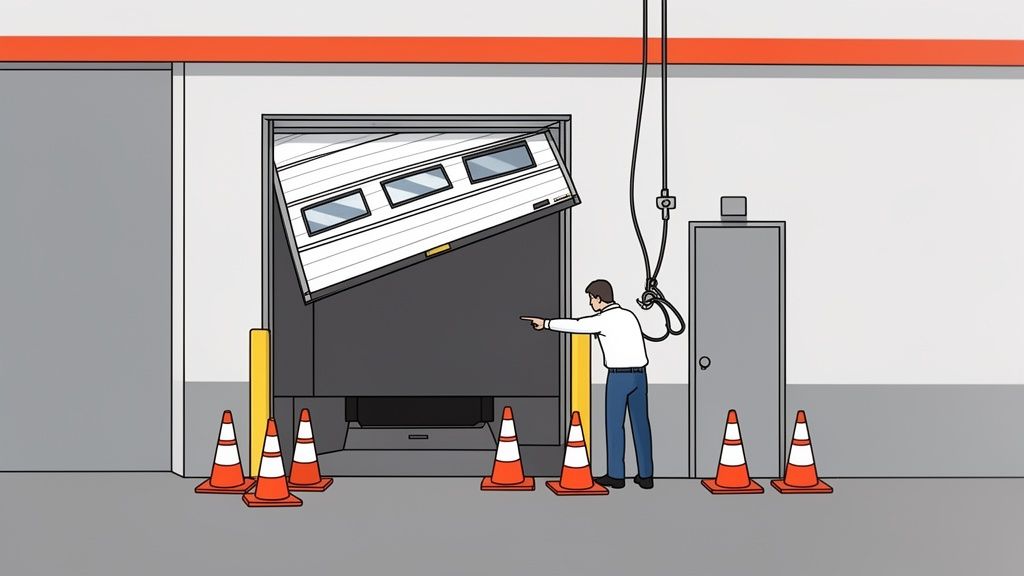

Alt text: A facility manager points at a damaged industrial garage door, with safety cones in place, while waiting for an emergency door fixer.

You don’t need to be a technician to spot the signs. Listening for specific sounds or looking for clear physical damage can give you critical clues about the cause of the failure.

Common Mechanical Failures

Mechanical issues are often the easiest to spot and account for a large number of emergency calls. They almost always involve the physical parts that move the door.

A classic example is a broken torsion spring. These are the large, tightly wound springs typically located above the door opening. When one breaks, it usually makes an incredibly loud bang or snap. The door will then feel extremely heavy and become nearly impossible to lift, because the springs are what counterbalance the door's weight.

Another common problem is a door that has come off its tracks. You'll see the rollers have popped out of the guide rails, often leaving the door hanging at a crooked angle. This is a very hazardous situation, as the door is unstable and could fall.

Electrical and Operator Issues

If the door's mechanical parts look fine but it still won't move, the problem is likely with the electrical system or the door operator—the motor that powers the door. An operator that just hums or makes a grinding noise without moving the door is a strong indicator of a stripped gear or a disconnected drive chain.

Think of it like a car with the engine running but a broken transmission; power isn't getting to the wheels. In a logistics hub like the Greater Toronto Area where warehouses run 24/7, an operator failure can halt shipments. It’s no surprise that the Sheet Metal, Window & Door Manufacturing sector in Canada is projected to hit a $13.0 billion market size by 2025, highlighting how much businesses rely on both new installations and urgent repairs.

Key Takeaway: A loud bang almost always means a broken spring, while a humming motor with no movement points to an operator failure. Knowing the difference helps our technicians arrive with the right parts for the job.

Sensor and Safety Device Malfunctions

Sometimes, the door itself is mechanically sound, but its own safety features are preventing it from working. These issues can be frustrating because the cause isn't always visible.

The usual suspects include:

- Misaligned Photo-Eye Sensors: These are the small sensors near the bottom of the door tracks that shoot an invisible beam across the opening to detect obstructions. If they get bumped, the door will refuse to close.

- Faulty Reversing Edge: This is the sensitive strip along the bottom of the door. If it's damaged or has a wiring issue, it can make the door think it's hitting something, causing it to reverse immediately after starting to close.

These problems, while less dramatic than a snapped spring, can bring your operations to a standstill. For a deeper dive into troubleshooting, check out our guide on troubleshooting overhead door repairs. By pinpointing the likely cause, you help us restore safety and function to your facility that much faster.

What to Look for in an Emergency Door Fixer

When a critical door fails, the pressure is on. You don't just need a repair service; you need an emergency door fixer who performs reliably under pressure. The choice you make determines how quickly you can get back to business and how safely the job is completed.

In a crisis, the last thing you want is a voicemail or a service that can't dispatch a technician until the next business day. True 24/7/365 availability is non-negotiable. This means a live person answers your call—day or night—and provides a specific response window.

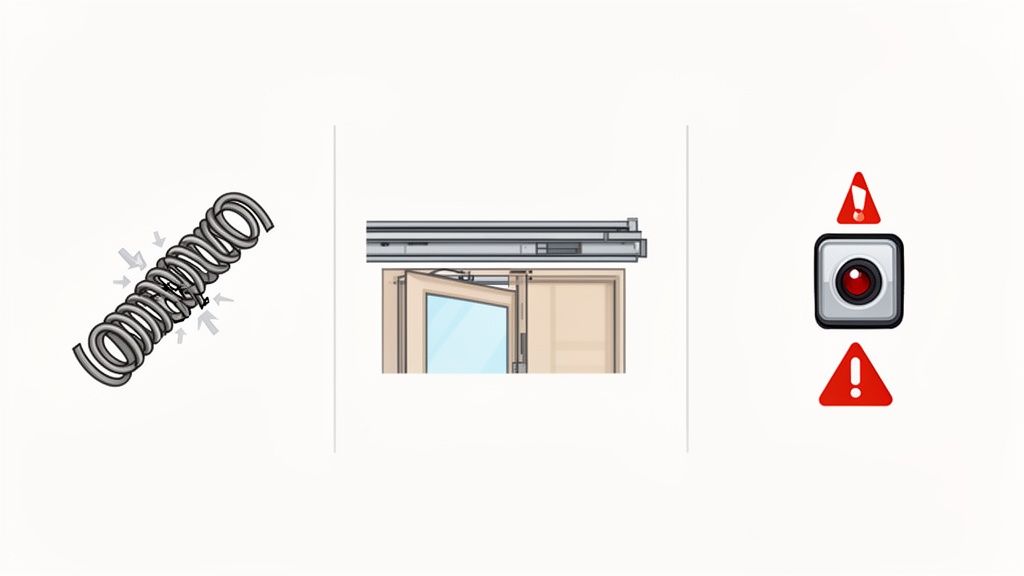

Alt text: An illustration showing critical commercial door components an emergency door fixer might repair, including a spring, closer, and safety sensor.

This level of readiness is absolutely critical. A 2014 Statistics Canada survey found that while most people have an emergency plan, only 60% had established household emergency exit plans. This preparedness gap often extends to commercial facilities, where functional exits are vital for safety. A professional understands this urgency. You can read more about these emergency preparedness findings from Statistics Canada.

Verifying Credentials and Specialised Experience

Beyond availability, genuine expertise is paramount. You wouldn’t call a general handyman to fix a complex server, and the same logic applies here. Commercial doors are specialized equipment.

When you call, ask specific questions about their experience with your type of door:

- High-Speed Doors: Have they worked on the complex electronics in brands like Rytec or Albany?

- Fire-Rated Doors: Are their technicians certified to perform annual inspections and ensure compliance with NFPA 80 fire codes?

- Loading Dock Doors: Do they understand the entire integrated system, including dock levelers, seals, and vehicle restraints? This is a key factor when comparing top loading dock repair companies.

A company that employs union-certified technicians often indicates a higher caliber of training, stricter safety protocols, and consistent quality. This ensures the repair is a lasting, code-compliant solution, not just a temporary patch.

Respected Partners, Reliable Service: A true professional won't just fix the immediate problem. They'll also inspect the entire system to identify underlying issues that could cause another failure, saving you from repeat emergencies.

The Importance of Proper Insurance and Quality Parts

Finally, there are a couple of non-negotiables. Always confirm that any contractor you hire carries comprehensive liability insurance and WSIB coverage. This protects your business from any accidents that might occur on your property during the repair and is a hallmark of professionalism.

The quality of the repair is also directly tied to the parts used. Inquire about their suppliers and ensure they source high-quality door hardware. Using cheap, generic components may save a few dollars upfront but often leads to premature failure and another emergency call.

Choosing the right emergency door fixer is about finding a reliable partner who restores safety and functionality with speed and expertise. At Wilcox, we combine 24/7 availability with certified technical skill to deliver solutions you can trust.

Breaking Down Emergency Repair Costs and Timelines

When a critical door fails, safety and security are top of mind. But two other questions quickly follow: "How much will this cost?" and "How soon can it be fixed?" An experienced emergency door fixer knows that transparency is crucial. Let's pull back the curtain on what shapes the final bill and repair schedule.

Understanding these variables helps you set realistic expectations and manage your budget, turning a chaotic situation into a predictable process. The goal is always a professional, durable solution without surprises.

Factors Influencing Repair Costs

The final invoice for an emergency repair is a reflection of a few key factors. The time of your call is significant; a service request at 2 PM on a Tuesday will cost less than one at 2 AM on a holiday due to overtime and after-hours rates.

The type and severity of the damage also play a huge part:

- Minor Fixes: A simple task like realigning a photo-eye sensor may only involve a standard labor charge.

- Major Repairs: A snapped torsion spring or a door panel damaged by a forklift involves significant labor and expensive replacement parts.

- Custom Components: If your facility has a specialized or oversized door, sourcing a custom panel or a specific operator part can add to both the cost and the lead time.

Delaying repairs can end up costing more. In Canada, trends in residential repairs often provide insight into commercial needs, showing that ignoring urgent problems is a costly mistake. Postponing a fix for an issue like a jumped track can inflate the final bill by as much as 300%. For a closer look, you can explore these findings on household repair needs from Statistics Canada.

Realistic Timelines for Common Fixes

Just like costs, repair timelines vary. A straightforward problem, such as a door that has popped off its track, can often be resolved by a skilled technician within a couple of hours. A reputable service partner will aim to get you operational on the first visit.

However, complex situations take longer. For example, if a custom-sized rolling steel door needs a completely new curtain (the main body of the door), that part must be ordered, manufactured, and shipped. In such scenarios, the immediate job of your emergency door fixer is to secure the opening with a temporary solution, keeping your building safe while waiting for permanent parts to arrive. For context on emergency service pricing, this guide on Decoding Emergency Locksmith Cost offers a useful, though lock-focused, financial breakdown.

Our Commitment: We believe in clear, upfront communication about both costs and timelines. If a part needs to be ordered, you’ll know right away, and we'll provide a solid plan to secure your facility in the meantime.

When you understand these dynamics, you're better positioned to make smart decisions under stress. Knowing what to expect lets you focus on what matters most—getting your operations back on track safely and efficiently.

Shifting from Reactive Repairs to Proactive Care

The best way to handle a door emergency is to prevent it from happening in the first place. Once the immediate crisis is resolved and the door is operational, you have a valuable opportunity. That emergency repair provides data on your equipment’s health, highlighting weaknesses that can be addressed before they cause another expensive shutdown. This is the perfect moment to shift from reacting to problems to proactively managing your facility's assets.

By applying the lessons learned from an unexpected failure, you can build a strategy that prioritizes uptime, safety, and long-term stability. It’s about turning a short-term fix into a long-term advantage.

The Power of a Planned Maintenance Program

A Planned Maintenance Program (PMP) is your most effective tool for preventing future emergencies. This isn't just a checklist; it's a strategic approach to asset management where a qualified technician performs routine inspections, lubrication, and adjustments on a set schedule. Think of it like regular oil changes for your company vehicles—you do it to prevent a breakdown, not just after one occurs.

For commercial doors, a PMP addresses the common causes of failure before they become critical:

- Lubrication and Cleaning: Technicians clean tracks and lubricate all moving parts—rollers, hinges, and springs. This simple step reduces friction, a leading cause of premature wear and motor strain.

- Component Inspection: They check for signs of fatigue in high-stress parts like cables, springs, and fasteners, allowing you to replace them before they snap.

- Balance and Alignment Checks: An unbalanced door puts immense strain on the operator. Ensuring proper balance and alignment can significantly extend the life of your motor and other components.

Turning Recurring Costs into Smart Investments

Consider this real-world example: A food distribution centre was constantly dealing with stuck loading dock doors during harsh Canadian winters. Each failure required an emergency door fixer call, leading to operational delays and unplanned expenses.

By implementing a PMP, they not only stopped the emergency calls but also identified that worn-out weather seals were letting ice build up in the tracks. As part of their new proactive approach to commercial door solutions, they upgraded to energy-efficient seals.

The Result: They eliminated winter downtime at their docks. Better yet, they improved the thermal efficiency of their loading bay, which cut their heating costs. A recurring repair expense was transformed into a smart, long-term investment in both reliability and energy savings.

This proactive approach, guided by our principle of being Respected Partners, Reliable Service, ensures your facility runs smoothly. A PMP is more than just maintenance; it's a partnership aimed at maximizing the life and performance of your critical door and dock equipment. Our approach to planned maintenance is designed to catch small issues before they become major disruptions.

Common Questions About Emergency Door Repair

When a critical door fails, you need answers fast. As a facility manager, you're likely juggling the same urgent questions every time an emergency strikes. This section provides direct, clear information to help you make the right calls under pressure.

We've gathered the most common questions we hear to give you the clarity you need. Understanding these points helps ensure the entire repair process, from your first call to the final fix, goes smoothly.

Alt text: A technician performing routine lubrication on a commercial door hinge, a key part of preventative maintenance to avoid needing an emergency door fixer.

How Quickly Can an Emergency Door Fixer Arrive?

In a true emergency, response time is everything. A top-tier service provider should offer a clear, guaranteed arrival window as part of their commitment.

For instance, a two to four-hour response window is a solid industry benchmark for urgent calls within a primary service area. That speed is vital for securing your facility and reducing the costly downtime impacting your operations.

Should My Team Attempt a Temporary Fix?

While it may be tempting to try a temporary fix to get things moving, we strongly advise against it. Commercial doors are heavy-duty systems operating under extreme tension from powerful springs and are often tied into complex electrical networks.

An attempted DIY fix by an untrained person is one of the quickest ways to turn a minor problem into a catastrophic failure. The safest and smartest move is always to secure the area and wait for a certified technician.

Professionals have the correct tools, training, and safety protocols to handle the equipment, preventing serious injury and avoiding further damage to the door.

What Information Should I Have Ready When I Call?

Being prepared when you call can significantly impact how quickly service arrives and how efficient the repair is. If possible, have these details ready:

- Your exact location, including a specific entry point or door number.

- The type of door (e.g., sectional overhead, rolling steel, high-speed).

- A brief description of the problem (e.g., "it's stuck halfway open," "we heard a loud bang," or "a forklift hit the track").

- Any visible damage you can safely observe from a distance.

If you can find the manufacturer's name or a model number on the door or its operator (the motor), that's a huge help. This information allows the dispatcher to send a technician with the right tools and parts on their truck, potentially turning a long repair into a quick one. For more on how to stay ahead of these issues, you can explore our full range of commercial door solutions.

When an emergency strikes, you need a partner who answers the call. Wilcox Door Service Inc. delivers 24/7 emergency repairs with the expertise to get your facility back up and running safely. Contact Wilcox Door Service now for immediate assistance or to schedule a facility assessment.