Your commercial overhead door is more than just an entry point—it’s one of the hardest-working pieces of equipment in your facility. A massive moving asset, it directly impacts your operational efficiency, security, and energy costs. This guide will walk you through everything you need to know to select the right door for your business, ensuring it becomes a reliable asset, not a source of costly downtime.

In this guide, you will learn how to:

- Understand key technical terms like R-value (insulation) and cycle life (durability) in simple, clear language.

- Match different door types and materials to your specific operational needs, from high-traffic loading docks to climate-controlled environments.

- Navigate Canadian safety standards to ensure your facility is compliant and your team is protected.

- Recognize the long-term value of a high-performance door in reducing energy bills and maintenance costs.

By the end, you’ll have the confidence to choose a commercial overhead door that actively boosts your productivity and security. As “Respected Partners, Reliable Service” is our promise, our goal is to empower you with the knowledge to make an informed investment.

Understanding Your Most Important Moving Asset

For any facility or operations manager, the overhead door is far more than a simple barrier against the Canadian weather. It’s a dynamic part of your workflow, protecting valuable inventory, keeping your team safe, and ensuring trucks can get in and out on schedule.

A door that’s poorly chosen or badly maintained quickly becomes a liability. It can lead to staggering energy loss, create serious security gaps, and trigger operational headaches you just don’t have time for. For example, a slow or malfunctioning door at a busy loading dock can create a bottleneck, delaying shipments and costing your business money. This guide is here to help you cut through the complexity and make a smart, long-term decision for your building. You can learn more about what makes a door system dependable in our article on essential insights on reliable overhead door systems.

By the end of this guide, you’ll have the confidence to select a door that actively improves your productivity and security. You’ll see exactly why partnering with an experienced provider is the cornerstone of reliability.

Matching Door Types and Materials to Your Operation

Picking the right commercial overhead door is a lot like choosing the right tool for a job. You wouldn’t use a slow, heavy-duty door for a fast-paced, climate-controlled warehouse. The door that works perfectly for a low-traffic storage unit is completely wrong for a bustling food processing facility.

Getting a handle on the basic door types and the materials they’re made from is the first step toward a smart investment. Your choice has a direct line to durability, maintenance headaches, security, and your long-term operational costs. Let’s walk through the most common options to help you line up the right door with what your business actually needs.

The Workhorses: Sectional and Rolling Steel Doors

For most facilities in Canada, the sectional steel door is the default, go-to solution. Made of several horizontal panels hinged together, these doors follow tracks up and along the ceiling. They hit that perfect sweet spot between cost, durability, and customization.

- Best For: Warehouses, distribution centres, automotive service bays, and most general industrial applications.

- Why they work: Their design makes it easy to add windows (often called “lites”) for natural light and visibility. Plus, they can be heavily insulated to boost energy efficiency—a must-have for dealing with Canada’s wild climate swings.

Then you have rolling steel doors, sometimes called coiling doors, which bring a different level of toughness to the table. They’re built from interlocking steel slats that coil up into a tight, compact roll above the opening. This design makes them incredibly durable and secure, ready to take a beating in heavy industrial settings.

- Best For: High-security zones, manufacturing plants, and any opening where you don’t have much ceiling space to spare.

- Why they work: Their rugged build is top-notch for fending off impacts and break-ins. For more specialized jobs, fire-rated rolling doors are non-negotiable for creating safety barriers and staying on the right side of building codes.

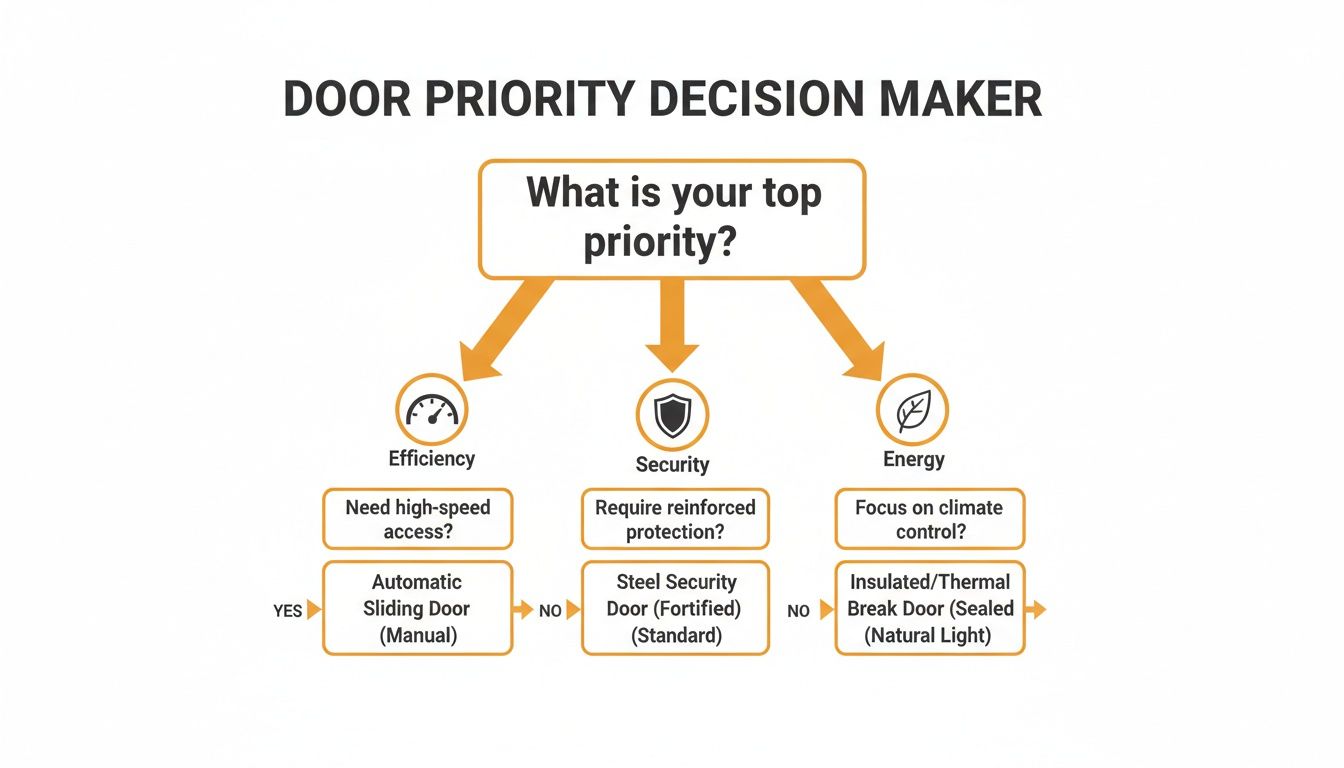

If you’re trying to figure out which door lines up with your main goals, this visual guide can help cut through the noise and clarify your priorities.

This decision tree helps visualize how your number one priority—whether that’s operational speed, protecting your assets, or saving on energy—points you directly to a specific type of door solution.

Specialized Solutions: High-Speed and Security Grilles

When every second counts, high-speed doors are the only real answer. Typically made from tough fabric or vinyl, these doors fly open and shut in just a few seconds. That quick cycle time is absolutely essential for keeping your indoor climate stable and your workflow moving without a hitch.

Picture a food and beverage facility with a high-speed fabric door separating a refrigerated storage area from the packaging line. The door opens and closes in a flash, keeping temperature swings to a minimum. This protects the product’s quality and slashes the energy wasted by the cooling system trying to keep up.

Security grilles give you protection while still allowing for visibility and airflow. You’ve seen them in retail storefronts, parkades, and convention centres. They act as a strong physical barrier to keep people out after hours, but without making your space feel like a fortress. They’re a great deterrent that keeps your property secure while staying visually open.

Why Material Selection Is So Important

The material your door is made of determines its strength, weight, how much maintenance it will need, and its insulating power.

- Steel: This is the crowd favourite for a reason. It’s strong, durable, and won’t break the bank. It comes in different gauges (thicknesses)—remember, a lower gauge number means thicker, tougher steel.

- Aluminum: It’s lighter than steel, which makes it a great pick for extra-wide doors or anywhere weight is a factor. It’s naturally rust-resistant and can be designed with huge glass sections for a clean, modern look. Think car dealerships or new fire stations.

- Advanced Composites & Fabrics: Found in high-performance doors, these modern materials bring unique advantages like incredible speed, resistance to chemicals, and fantastic sealing for tightly controlled environments.

To give you a clearer picture, here’s a quick comparison of the most common commercial overhead door types.

Commercial Overhead Door Comparison

This table compares common door types based on application, materials, and key performance features to help you choose the right solution.

| Door Type | Best For | Common Materials | Key Features |

|---|---|---|---|

| Sectional Doors | General warehouse, distribution, automotive bays | Steel, Aluminum | Versatile, can be insulated, allows for windows |

| Rolling Steel Doors | High security, heavy industry, limited ceiling space | Steel | Extremely durable, secure, fire-rated options available |

| High-Speed Doors | Climate control, high-traffic areas, food processing | Fabric, Vinyl, Rubber | Fast cycle times, superior environmental separation |

| Security Grilles | Retail storefronts, parkades, convention centres | Steel, Aluminum | Provides security with visibility and airflow |

Each door type offers a distinct set of benefits, making it crucial to match the solution to your operational demands for the best long-term results.

The Canadian market is definitely seeing a bigger appetite for these advanced solutions. As logistics and distribution keep booming, the North American overhead door market is expected to climb to USD 2,175.88 million by 2033. This surge is fuelled by the need for efficient, dependable doors that keep downtime to a minimum and support the breakneck pace of modern business. And while thinking about doors, it’s worth noting that other solutions, like durable and practical PVC strip curtains for doors, can also provide excellent environmental control in certain situations.

Getting the combination of door type and material right is the foundation of your facility’s performance. If keeping your building’s temperature stable is a top priority, you can dive deeper into the case for insulated overhead doors in commercial spaces in our detailed guide.

Understanding Key Metrics for Performance and ROI

Making a smart investment in a commercial overhead door means looking far beyond the initial price tag. True value comes from performance—how the door functions day in and day out, how it protects your assets, and how it impacts your bottom line. You need a door that works for you, not one that creates constant headaches.

To get the best return on your investment, you need to understand four key performance metrics. These factors directly influence your long-term costs, from energy bills to maintenance expenses and downtime. Let’s break down what you need to look for to ensure your next door is a lasting asset, not a short-term fix.

Insulation and R-Value

In Canada’s varied climate, controlling your building’s temperature is a major operational cost. That’s where insulation, measured by its R-value, becomes a critical factor. Simply put, the R-value tells you how well a material resists heat flow—the higher the number, the better the insulation.

Think of it like a winter coat for your building. A thin jacket is fine on a cool autumn day, but it’s useless in a January blizzard. Similarly, an uninsulated door at a loading dock in winter lets heated air pour out and cold air rush in, forcing your HVAC system to work overtime.

A well-insulated door with a high R-value, like an R-16 or higher, acts as a powerful thermal barrier. This dramatically reduces energy loss, leading to lower heating and cooling bills every single month. For any temperature-controlled environment, from a food storage facility to a heated manufacturing plant, choosing the right R-value is one of the easiest ways to secure a fast, measurable ROI.

Durability and Cycle Life

How many times a day does your door need to open and close? This simple question determines its required cycle life—one of the most important, and most overlooked, metrics. One “cycle” is a full open-and-close motion. A door’s cycle life rating tells you how many cycles its key components, especially the springs, can handle before they are expected to fail.

A standard commercial overhead door might be rated for 10,000 to 20,000 cycles. For a low-traffic storage area, that could be perfectly fine. But what about a busy distribution centre where a door opens 100 times a day? That standard door would hit its limit in under a year, leading to inevitable downtime and costly emergency repairs.

For high-traffic applications, investing in a high-cycle door rated for 100,000 cycles or more is non-negotiable. While the upfront cost is higher, the long-term value is undeniable. You avoid the constant expense and operational disruption of spring replacements, ensuring your workflow remains smooth and predictable.

Choosing a door based on its cycle life is a strategic decision. It’s the difference between planning for reliability and reacting to constant breakdowns. For a critical access point, durability isn’t a feature—it’s the foundation of your uptime.

Operational Speed

In many modern facilities, speed is money. The faster a door opens and closes, the more efficient your workflow becomes and the better you can control your building’s environment. This is especially true for businesses where temperature or contamination control is a priority.

A conventional sectional door might open at about one foot per second. In contrast, a high-speed fabric door can operate at speeds up to 100 inches per second. This incredible speed offers two huge benefits:

- Improved Productivity: At a busy loading dock, slow doors create bottlenecks, forcing forklifts and staff to wait. High-speed doors eliminate that delay, keeping materials and products moving without interruption.

- Environmental Control: The longer a door stays open, the more energy you lose and the more dust, pests, and humidity can enter. A fast-moving door minimizes air exchange, preserving your internal climate and cutting down on energy waste.

For operations that demand efficiency and environmental stability, the speed of your door is a performance metric you can’t afford to ignore.

Critical Security Features

Finally, your commercial overhead door is a primary line of defence for your facility. Its security features are essential for protecting your inventory, equipment, and people from theft and vandalism. Security is not just about a strong lock; it involves the door’s entire construction.

Key security elements to look for include:

- Material Gauge: Thicker steel (indicated by a lower gauge number) is much harder to breach.

- Locking Mechanisms: Look for heavy-duty internal slide locks, keyed locksets, or integration with your facility’s access control system.

- Impact Resistance: For high-risk areas, doors designed to withstand direct impact provide an added layer of protection.

- Design: Rolling steel doors, with their interlocking slats, are often considered more secure than sectional doors because they lack external hinges that can be targeted by intruders.

By carefully evaluating these four metrics—insulation, cycle life, speed, and security—you can move beyond the sticker price and select a commercial overhead door that delivers true, long-term value. As “Respected Partners, Reliable Service” is our promise, we can help you analyze your operational needs to find the perfect balance of performance and cost.

For a deeper look at how to ensure your doors are always ready for action, learn more about our Planned Maintenance Programs.

Meeting Canadian Safety Standards and Compliance

Here in Canada, making sure your commercial overhead door is up to code isn’t just a good idea—it’s the law. These safety standards are in place for a very good reason: to protect your staff, your customers, and your property from accidents that are entirely preventable. A door that isn’t compliant is a major liability, plain and simple. It’s a risk no facility manager can afford to take.

Getting a handle on all the regulations might seem daunting at first, but it really comes down to a few core ideas. The main goal is to ensure every single door operates safely and predictably, cutting down the risk of injury or damage to equipment. Knowing what’s required empowers you to run a facility that’s not just efficient, but fundamentally safe. That’s the kind of peace of mind you get when you work with experts who live and breathe compliance.

Key Regulations You Need to Know

While specific codes can shift a bit depending on your province or municipality, a few key safety mandates are in effect right across Canada. Getting familiar with these is your first step to making sure your facility is buttoned-up and your team is protected.

Two of the most important areas to focus on are entrapment protection and fire safety. There’s a good reason these standards are so strictly enforced—they tackle the most serious risks that come with large, automated door systems.

- Entrapment Protection: Every modern commercial door operator has to include safety mechanisms that can detect an obstruction. This usually comes in the form of photoelectric sensors (those light beams at the bottom that stop or reverse the door if something breaks the beam) or a sensing edge along the bottom of the door that tells it to reverse direction the moment it touches something.

- Fire Door Compliance: If you have an opening in a fire-rated wall, you absolutely must have a specialized fire door. These doors are designed to close on their own in a fire, containing the blaze and smoke to slow it down. They need to be inspected and tested every year in a process called a “drop test” to prove they’ll work when you need them most.

Think of a fire door like a circuit breaker in your electrical panel. Its job is to automatically shut down a dangerous situation to prevent it from spreading and causing catastrophic damage. A successful drop test confirms this crucial safety feature is ready to perform when it matters most.

The Critical Role of Certified Installation

Meeting these standards all starts with a professional installation. It’s not enough to just buy a compliant commercial overhead door; it has to be installed by technicians who truly understand the ins and outs of national and provincial building codes. This is where bringing in union-certified professionals makes all the difference.

Certified technicians go through rigorous training on proper installation methods, electrical wiring, and how to correctly integrate safety systems. They make sure every single part, from the torsion springs to the safety sensors, is calibrated perfectly for top performance and full code adherence. A shoddy installation can void your warranty, create immediate safety hazards, and leave you legally exposed if an accident happens.

Consequences of Non-Compliance

Cutting corners on safety regulations can lead to some pretty severe consequences that can affect your entire operation. The risks go way beyond a simple slap on the wrist, potentially hitting your finances, your legal standing, and your ability to do business.

Workplace safety regulations have profoundly shaped Canada’s commercial door landscape, with mandates like fire door drop testing driving a 15% rise in demand for certified installations since 2020. Data from Statistics Canada tracks over 2,000 contractors specializing in these setups, which are integral to the nation’s $50 billion annual construction sector. You can explore more data on the role of specialized contractors from Statistics Canada’s official records.

A non-compliant door can result in:

- Hefty Fines: Provincial safety authorities can, and will, issue significant financial penalties for violations.

- Operational Shutdowns: A stop-work order can be issued until the safety issue is fixed, bringing your productivity to a dead stop.

- Legal Liability: If someone gets hurt, your business could be facing lawsuits and a tarnished reputation.

- Denied Insurance Claims: An insurance company might refuse to cover damages if the equipment didn’t meet legal standards.

Making sure your doors are compliant isn’t just about dodging penalties; it’s about building a true culture of safety. You can learn more about fire door ratings in our detailed article to better understand these crucial requirements.

The Value of Professional Installation and Maintenance

Even the best commercial overhead door on the market will fall short if it isn’t installed and maintained by a professional. Think of it like a high-performance engine; all that power is useless without an expert mechanic to install it properly and tune it regularly. Professional installation isn’t just a good idea—it’s an absolute must to guarantee safety, unlock peak performance, and keep your warranty intact.

Just as critical is the ongoing care that comes after. Proactive maintenance is what separates a door that lasts for decades from one that becomes a constant source of expensive headaches. This commitment to professional service is the cornerstone of operational continuity, ensuring your most critical asset remains just that: an asset, not a liability.

Why Professional Installation Is Non-Negotiable

A proper installation is a complex job that goes way beyond just hanging the door. It demands precise measurements, correct spring tensioning, perfect track alignment, and flawless integration of all safety systems. When a certified technician handles every component, you get a door that runs smoothly, safely, and efficiently from day one.

Unfortunately, cutting corners with an inexperienced installer can open the door to a whole host of problems that undermine your entire investment. These issues often don’t show up right away but can lead to significant damage and serious safety risks down the road.

Common problems from improper installation include:

- Premature Wear and Tear: Misaligned tracks or incorrect spring tension forces everything to work harder, causing rapid wear on rollers, cables, and the operator itself.

- Safety System Failures: If safety sensors aren’t wired and calibrated perfectly, they might fail to detect an obstruction, creating a major risk of injury or damage to equipment.

- Voided Manufacturer Warranty: Most manufacturers won’t honour a warranty claim if the door wasn’t installed by a certified professional, leaving you on the hook for the full cost of any defects.

- Poor Sealing and Energy Loss: Gaps around the door from an improper fit can lead to massive energy loss, driving up your heating and cooling bills.

A professional, union-certified installation ensures every single element is perfectly calibrated, safeguarding both your team and your bottom line from the very beginning. It’s the foundation that the door’s entire service life is built on.

The Power of a Planned Maintenance Program

Once your door is installed correctly, the secret to its long life is proactive care. Waiting for a part to break before you call for service is a reactive strategy that almost always ends in unexpected downtime and expensive emergency repairs. A Planned Maintenance Program (PMP) shifts your entire approach from reactive to proactive, turning maintenance from a necessary evil into a strategic investment.

A PMP involves regularly scheduled inspections and tune-ups by a certified technician. This consistent attention catches the small issues—like a fraying cable or a worn-out roller—before they can escalate into a complete system failure.

A proactive maintenance plan is like a regular health check-up for your most critical equipment. It allows you to identify and address potential issues on your own schedule, preventing emergencies that can shut down your entire operation without warning.

This foresight pays off in tangible ways that directly impact your facility’s performance and budget. By preventing breakdowns, you can extend the door’s lifespan by years, get the most out of your initial investment, and maintain a much safer work environment for your team.

Your Proactive Maintenance Checklist

So, how can you tell if your current maintenance strategy is setting you up for success? A solid plan should cover every one of these critical inspection points. Our technicians follow a detailed checklist during every PMP visit to ensure nothing gets missed.

Below is a sample of what a professional inspection covers.

Planned Maintenance Checklist

A sample checklist of key components inspected during a professional planned maintenance visit to ensure door safety and reliability.

| Component | Inspection Point | Benefit of Regular Checks |

|---|---|---|

| Springs & Cables | Check for signs of wear, fraying, or corrosion. Verify proper tension. | Prevents sudden, dangerous spring failure and ensures balanced door operation. |

| Tracks & Rollers | Inspect for alignment, debris, and signs of excessive wear. Lubricate moving parts. | Guarantees smooth, quiet operation and reduces strain on the door operator. |

| Safety Sensors | Test photoelectric eyes and reversing mechanisms to ensure they are functioning correctly. | Confirms compliance with safety standards and protects personnel and equipment. |

| Hardware & Fasteners | Tighten all nuts, bolts, and hinges. Check for loose or damaged components. | Prevents structural failure and ensures the door’s integrity under daily use. |

| Weatherstripping | Examine seals for cracks, gaps, or damage that could compromise the building envelope. | Maintains energy efficiency by preventing air leaks and keeps out pests and debris. |

Regularly addressing these points through a structured PMP is the single most effective way to ensure your commercial overhead door remains a reliable asset for years to come.

To learn more about how a customized maintenance plan can benefit your facility, explore our Planned Maintenance Programs and let our team build a strategy that protects your investment and prevents costly downtime.

Your Commercial Door Questions, Answered

Over the years, we’ve helped countless facility managers across Canada get the right overhead door for their operations. In that time, we’ve noticed the same crucial questions pop up again and again. Getting clarity is key before making a big investment like a new commercial overhead door.

Here are some straightforward answers to the questions we hear most often, designed to give you the confidence to make a decision that will pay off for years to come.

How Do I Know What R-Value I Need?

Think of R-value like choosing the right winter coat. You wouldn’t wear a light windbreaker in a blizzard, and you wouldn’t wear a heavy parka on a mild day. The R-value you need for your door depends entirely on your building’s job and your local climate.

For a temperature-sensitive space like a cold storage warehouse, a high R-value (R-16 or more) is non-negotiable. It acts as a powerful thermal barrier, locking in the cold and keeping your energy bills from skyrocketing. On the other hand, an unheated parkade in a more temperate area can get by just fine with a lower R-value. A door expert can look at your specific needs and energy use to recommend the perfect balance, so you get the performance you need without paying for insulation you don’t.

What Is “Cycle Life” and Why Should I Care?

Cycle life is one of the most important, yet often overlooked, specs on a commercial door. Simply put, it’s the number of times a door is engineered to open and close before its core components, like the torsion springs, will likely need to be replaced. One “cycle” is one full trip up and one full trip down.

Matching the cycle life to your actual usage is critical for avoiding frustrating downtime. A storage unit door that’s only used a few times a week might be perfectly fine with a standard 10,000-cycle rating. But a high-traffic loading dock door that opens 100 times a day? That needs a high-cycle spring rated for 100,000 cycles or even more. Investing in the right cycle life from the start means fewer surprise repairs and keeps your business moving without a hitch.

Should I Repair My Door or Just Replace It?

The “repair vs. replace” question really boils down to three things: safety, cost, and efficiency.

If a door has serious structural damage or fails to meet current safety codes, the conversation ends there—replacement is the only responsible choice. But if it’s less clear-cut, look at the numbers. Are you constantly calling for service? The money you’re spending on frequent, small repairs could quickly add up to more than the cost of a new, reliable door.

Finally, think about what a new door could do for you. A modern, well-insulated, high-speed door isn’t just a replacement; it’s an upgrade. The gains in energy efficiency and productivity can deliver a real return on investment, making a new door a smart, strategic move for your facility’s future.

At Wilcox Door Service Inc., we believe in being “Respected Partners, Reliable Service.” If you have more questions or need help selecting the perfect commercial overhead door for your facility, our expert team is ready to assist. Contact us today to schedule a consultation or request a quote at https://www.wilcoxdoor.com.