This guide explains everything you need to know about choosing, installing, and maintaining an air curtain with heater for your commercial facility. You'll learn how these systems create an invisible barrier to save energy, the different types available, and how to ensure you get the best performance and return on your investment. We'll cover key technical terms in simple language and provide real-world examples relevant to facilities like yours.

The Invisible Door Your Facility Needs

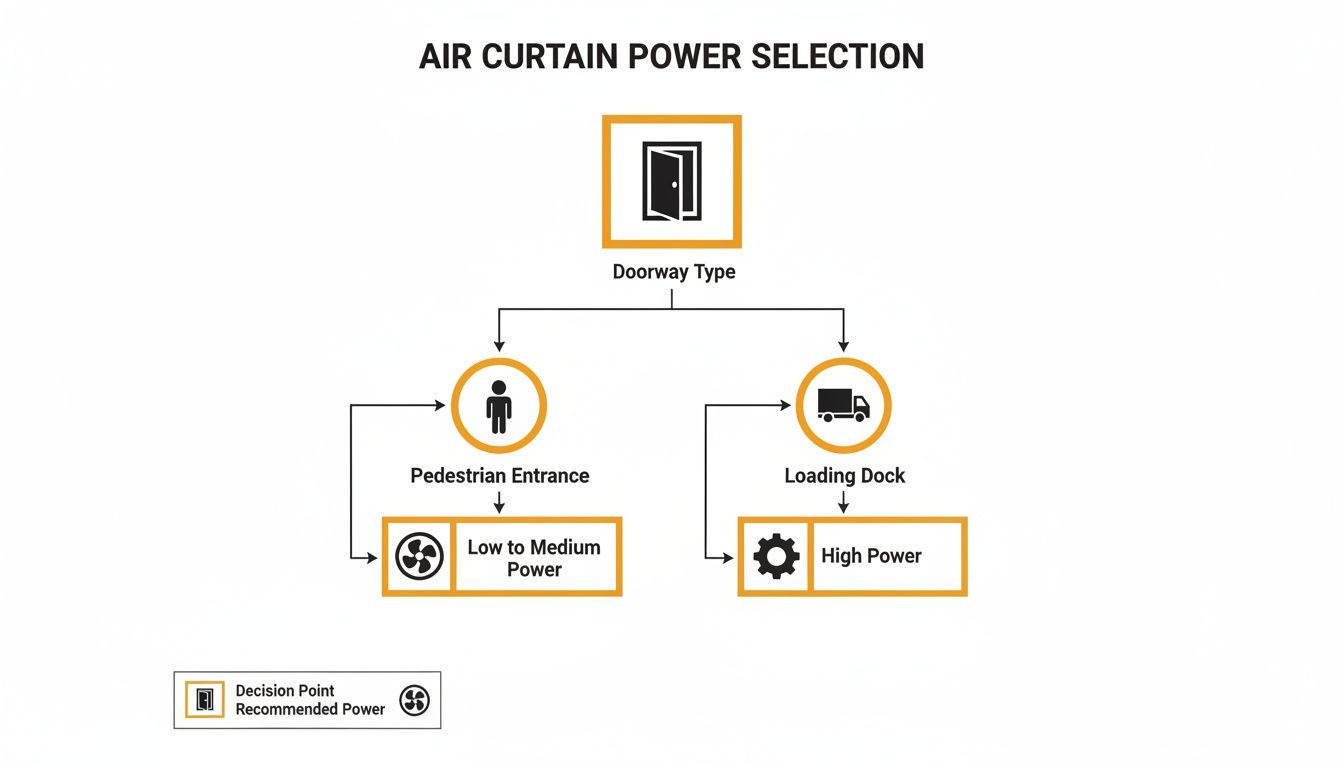

Alt text: Illustration of an air curtain creating a heated barrier at an entrance, protecting people from snow and cold.

An air curtain with heater is a powerful yet simple solution that creates an invisible shield of warm air at an open doorway. This shield effectively separates your controlled indoor climate from the harsh Canadian elements outside. It acts as an invisible door, blocking frigid drafts, insects, and debris while keeping your valuable heated air inside your building. For any Canadian business, this translates directly into significant energy savings and a more comfortable, productive environment.

Imagine a busy loading dock on a frigid January morning. Each time the overhead door opens, a blast of icy air rushes into your workspace, causing the temperature to plummet and forcing your heating system to work overtime. An air curtain with heater, mounted above the doorway, pushes a high-velocity stream of heated air downwards to create a seal that stabilizes your indoor temperature, even with frequent door openings.

This isn't just about comfort; it's about smart, efficient operations. A stable internal environment creates a chain of benefits that positively impacts your bottom line.

Core Benefits of a Heated Air Curtain at a Glance

| Benefit | Impact on Your Facility |

|---|---|

| Drastic Energy Savings | Your primary HVAC system works less to combat temperature drops, leading directly to lower monthly energy bills. |

| Improved Staff Comfort & Safety | Eliminating cold drafts improves morale and productivity. It also prevents ice from forming on floors near doorways, reducing slip-and-fall hazards. |

| Better Environmental Control | The air barrier effectively blocks dust, fumes, and flying insects—essential for sensitive industries like food processing, beverage, or pharmaceuticals. |

The demand for these systems is growing, particularly in regions with severe winters. An unprotected doorway can account for up to 80% of a building's heat loss, but studies show a properly installed heated air curtain can reduce that loss by over 70%.

Of course, an air curtain is most effective as part of a complete door system. For example, ensuring your automatic doors are properly sealed is another key piece of climate control. Learn more in our guide on the importance of automatic door weather stripping. At its core, installing a heated air curtain is a strategic investment in a more controlled, efficient, and safe workspace.

How a Heated Air Curtain Creates an Invisible Barrier

While it may sound like high-tech wizardry, the concept behind a heated air curtain is straightforward. It generates a powerful, invisible waterfall of warm air that covers your entire doorway. This isn't a random blast of heat; it's a precisely directed stream that creates a solid barrier, effectively separating your indoor space from the outdoors.

This effect is achieved through three key components working in unison. Powerful fans draw in ambient air from inside your building. This air is then pushed through a heating element—which can be electric, hot water, or gas—and forced out at high speed through a specialized nozzle. The result is a fast-moving, uniform sheet of warm air that seals the opening. This invisible barrier works by creating a wall of pressure that outside air cannot easily penetrate, physically stopping cold drafts, snow, and dust from entering while keeping your expensive heated air inside.

Understanding the Key Performance Metrics

For this air barrier to be effective, two critical metrics must be correct: CFM and throw distance. Getting these specifications right is the difference between an energy-saving seal and an expensive, glorified fan.

CFM, or Cubic Feet per Minute, is a measure of air volume. It tells you how much air the unit moves. A higher CFM means more air is being pushed down to form the barrier. For example, a small pedestrian doorway requires a lower CFM, but a massive 14-foot high loading dock door at a distribution centre needs a unit with substantial CFM to generate enough air to seal the entire opening from top to bottom.

A classic mistake is selecting an air curtain based only on the door's width. Without sufficient CFM, the airstream will be too weak to reach the floor, leaving a large gap at the bottom for cold air to rush in and rendering the entire system ineffective.

The Importance of Throw Distance

The second essential metric is throw distance (sometimes called projection). This tells you how far the airstream can travel from the unit before it loses its force. Simply put, the throw distance must be greater than the mounting height of the air curtain.

- For a standard 8-foot retail entrance: You need an air curtain with a throw distance of at least 8-10 feet to ensure the air reaches the floor with enough velocity to create a proper seal.

- For a 16-foot high industrial overhead door: A standard unit won't suffice. You'll need a high-velocity industrial model designed for a throw distance of 16-20 feet or more.

If the throw distance is too short, the air will dissipate halfway down, allowing cold air to pour in at floor level. This is why a professional assessment of your specific doorway is critical. A proper evaluation ensures your commercial door solutions are integrated correctly for optimal performance. Our "Respected Partners, Reliable Service" promise is built on delivering tailored solutions that work effectively.

Choosing the Right Heater Type for Your Facility

When selecting an air curtain with heater, the power source is a crucial decision that will impact your operational budget for years. It’s not about finding the "best" heater, but the best fit for your building's existing infrastructure, local climate, and financial goals.

The three primary options are electric, hot water/steam, and gas-fired. Each has its strengths, and the choice involves balancing upfront costs and installation complexity against long-term energy savings. A manager of a new warehouse with easy access to gas lines might choose one option, while a manager retrofitting an older building with a robust boiler system will see benefits in another.

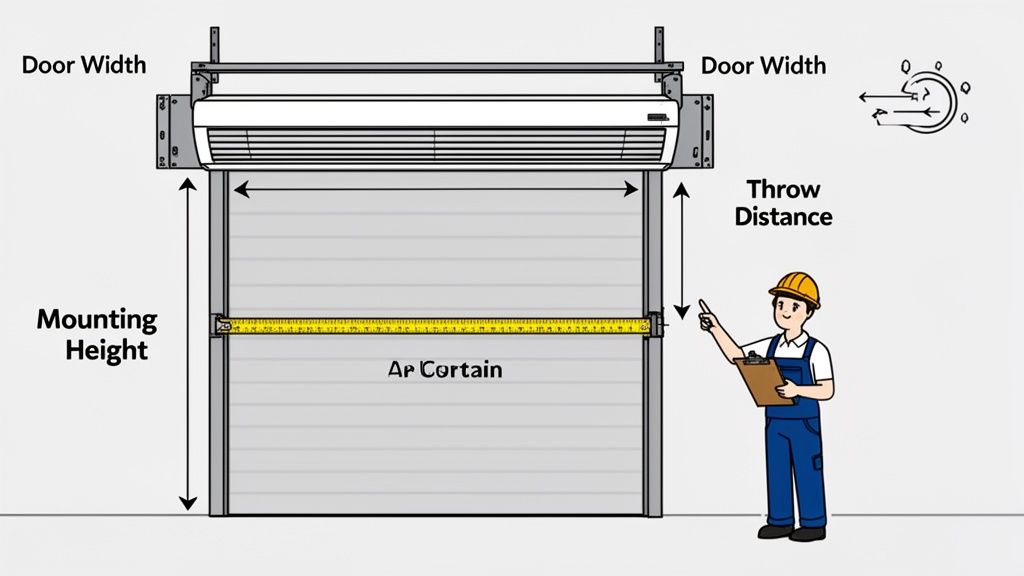

This decision tree helps visualize the initial choice based on your doorway type.

Alt text: Flowchart showing air curtain power selection. Pedestrian door leads to electric or hot water options; loading dock door leads to hot water or gas options.

The needs of a busy loading dock are very different from those of a retail entrance, guiding you toward more powerful and cost-effective heating solutions for heavy-duty industrial applications.

Electric Heaters: Simple and Accessible

Electric heated air curtains are typically the quickest and easiest to install. They don't require complex plumbing or gas lines, making them ideal for retrofits or buildings where other utilities are not readily accessible. For a storefront or office with high foot traffic but smaller openings, the simplicity of wiring a unit directly into the building's electrical supply often makes the most sense. The main consideration is ensuring your electrical panel can handle the additional load. While operating costs can be higher depending on local electricity rates, their installation simplicity is a major advantage.

Hot Water and Steam Heaters: Tapping Into What You’ve Got

If your facility already has a central boiler system, a hot water or steam-powered air curtain can be an incredibly efficient choice. These units function like a radiator, using the hot water or steam already circulating through your building to heat the air. This is a perfect strategy for large industrial plants, hospitals, or schools that rely on hydronic heating. The primary benefit is low operational cost, as you are using an existing heat source. Installation is more involved, requiring a plumber to connect the unit to your boiler, but the long-term energy savings can be substantial, offering an attractive return on investment. This is a key part of our approach to energy-saving facility solutions.

Gas-Fired Heaters: Heavy-Duty Power for Industrial Doors

For massive openings at warehouses, manufacturing plants, and busy loading docks, gas-fired air curtains provide exceptional heating power at a running cost that is typically much lower than electricity. Using natural gas or propane, these units generate a significant amount of heat, making them ideal for combating the large drafts from oversized overhead doors. The upfront investment is higher, as a certified technician must run a gas line and ensure proper ventilation for the exhaust. However, for a facility with tall doors and constant traffic, the power and cost-effectiveness of natural gas usually make these units the clear winner over their lifespan.

Comparing Heated Air Curtain Technologies

| Heater Type | Best For | Installation Complexity | Operating Cost | Key Consideration |

|---|---|---|---|---|

| Electric | Retail, commercial buildings, retrofits where other utilities are unavailable. | Low | High (depending on rates) | Confirm your electrical panel can handle the load. |

| Hot Water/Steam | Facilities with existing central boiler systems (hospitals, schools, large plants). | Medium | Low | Maximizes the efficiency of your existing infrastructure. |

| Gas-Fired | Warehouses, loading docks, large industrial openings with high traffic. | High | Low (typically) | Requires gas line installation and proper exhaust ventilation. |

Choosing the right heater is a balancing act. It’s about weighing the upfront installation cost against the long-term operational savings and aligning the technology with the infrastructure you already have in place.

An expert consultation is the best way to ensure you select a solution that delivers real performance and savings.

Proper Sizing and Installation for Peak Performance

An air curtain with heater is a precision instrument, and its success depends entirely on correct sizing and installation. A "one-size-fits-all" approach leads to wasted energy and poor results. To create that essential invisible wall of warm air, we must move beyond guesswork and consider the unique characteristics of your doorway—its width, height, and exposure to wind.

An undersized air curtain cannot create a complete seal, allowing cold air to pour in at floor level. Conversely, an oversized unit is overkill, consuming more energy than necessary and potentially creating uncomfortable drafts for staff and customers.

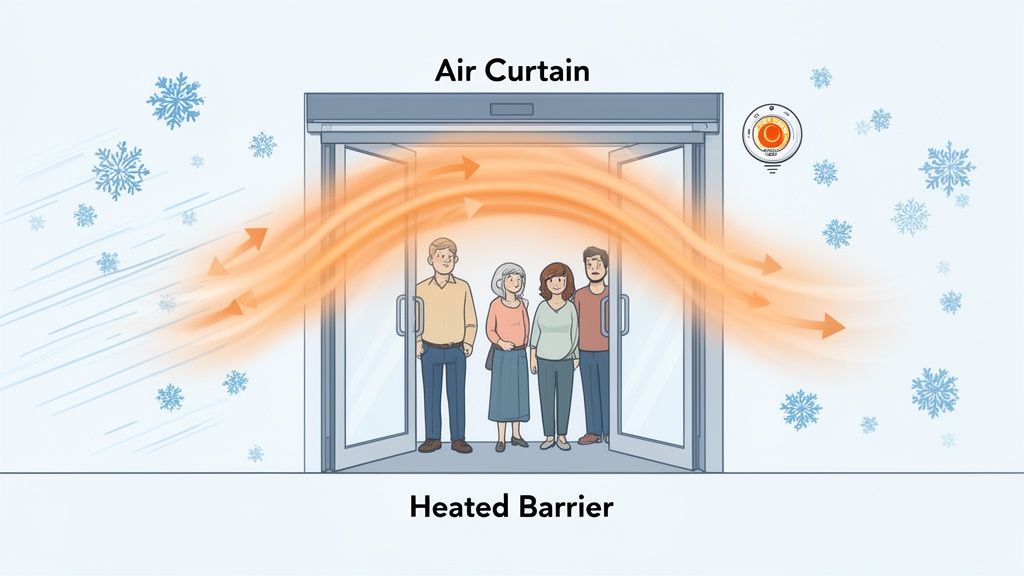

Alt text: Diagram showing an air curtain installation above a commercial door, illustrating measurements for door width, mounting height, and throw distance.

Key Sizing Factors You Cannot Ignore

Properly sizing an air curtain is a technical process that involves balancing several critical variables.

- Door Width is Just the Start: The unit must span the entire width of the door opening, ideally extending slightly beyond the frame on each side to ensure complete coverage and prevent cold air from seeping in at the edges.

- Mounting Height Determines Power: The distance from where the unit is mounted to the floor is perhaps the most critical factor. This measurement directly determines the required throw distance—the unit's ability to project the airstream effectively to the floor.

- Environmental Conditions Matter: Real-world factors like building pressure (whether your building pushes air out or sucks it in) and exposure to strong winds can disrupt the air barrier. A facility in an open, windy area will require a more powerful unit than one in a sheltered urban location.

A common mistake is choosing a unit based only on door width. A 12-foot wide loading dock door that is 16 feet high needs a much more powerful air curtain than a 12-foot wide door that is only 8 feet high. Ignoring the height guarantees failure.

Installation and Integration for Flawless Operation

Once the correct unit is selected, professional installation is essential to unlock its full potential. This involves more than just mounting it on the wall; it's about integrating the air curtain intelligently into your building's operations. The air curtain should activate the instant the door opens and shut down the moment it closes, which requires careful integration with your door's control system.

- Door Switches and Sensors: For high-speed roll-up doors or automatic sliders, the air curtain must be wired directly into the door's activation circuit. This ensures it only runs when needed, maximizing energy savings. See a real-world example in our TNR door and air curtain installation project.

- Proper Mounting: The unit must be installed as close to the top of the door as possible to optimize its throw distance. It also needs to be angled correctly—usually slightly outward—to effectively counter incoming drafts and create a stable air seal.

Correct sizing and professional installation are non-negotiable. They are the difference between achieving your desired energy savings and comfort and simply having an expensive fan on the wall.

Calculating Your Return on Investment

Beyond the technical specifications, the ultimate question for any facility manager is: does an air curtain with heater make financial sense? The answer is a resounding yes. This is not just another operational expense; it's a strategic investment in efficiency that pays for itself over time.

The most significant financial benefit comes from substantial energy savings. Every time a large loading dock door opens in winter, your HVAC system works overtime to combat the influx of cold air. An air curtain with a heater acts as a shield, dramatically reducing that workload and, consequently, your heating bills.

Breaking Down the Financial Gains

To understand the full financial picture, you must consider both direct cost reductions and indirect operational benefits.

A simple way to estimate your ROI involves a few key variables:

- Reduced HVAC Run-Time: How many hours a day are your doors open? What is the average outdoor temperature? These factors help quantify the energy your HVAC system no longer needs to consume.

- Local Energy Rates: The cost of electricity or natural gas in your area significantly impacts how quickly you see a return. Higher rates lead to a faster payback period.

- Door Cycle Frequency: A busy loading dock with doors opening 50 times a day will see a much faster return than a secondary entrance used only a few times daily.

When calculating ROI, it’s important to consider long-term energy efficiency. The high-efficiency electric motors in modern units are a key component that directly lowers your ongoing operational costs.

Looking Beyond Direct Energy Savings

While lower energy bills are the most immediate reward, the indirect benefits often provide equal or greater long-term value.

An air curtain with heater pays you back in multiple ways. The energy savings are immediate and easy to track, but the improvements in employee comfort and workplace safety create long-term value that strengthens your entire operation.

Consider the real-world impact on your facility:

- Improved Employee Morale and Productivity: Eliminating icy drafts near workstations creates a more comfortable and productive environment for your team.

- Enhanced Safety and Reduced Liability: An air curtain helps prevent moisture, snow, and ice from accumulating on floors near entrances, directly reducing the risk of costly slip-and-fall incidents.

- Protection of Goods and Equipment: For facilities with temperature-sensitive products, a stable climate is non-negotiable. An air curtain serves as your first line of defense, protecting valuable inventory from damage.

For a deeper analysis of the numbers, explore our detailed guide on how air curtains save you money. Investing in a heated air curtain is a proactive step toward a more efficient, safer, and cost-effective facility.

Essential Maintenance and Troubleshooting Tips

To ensure years of reliable performance from your air curtain with heater, proactive maintenance is essential. Regular check-ups prevent minor issues from escalating into expensive failures and protect your investment. A simple, consistent maintenance routine extends the unit's lifespan and guarantees it continues to deliver the expected energy savings.

Proactive Maintenance Checklist

A straightforward preventative maintenance plan is your best defense against unexpected downtime. These simple tasks can be performed in-house and make a significant difference. For a broader facility-wide program, consulting a comprehensive commercial kitchen equipment maintenance guide can be a helpful starting point.

Here are the core tasks for your team:

- Inspect and Clean Air Inlet Screens: The inlet grille is like the lungs of your unit. If clogged with dust, it restricts airflow, leading to poor performance and motor strain. A quick vacuum or wipe-down every few months is all it takes.

- Check and Clean Fan Blades: Grime buildup on fan blades can cause them to become unbalanced and reduce efficiency. A visual inspection will determine if they need cleaning.

- Examine Heater Elements: For electric units, inspect heating coils for damage or heavy dust buildup, which can be a fire hazard. For hot water or gas models, check for leaks in the connections.

Think of your air curtain's maintenance schedule like the routine service for a fleet vehicle. Skipping an oil change seems minor at first, but it eventually leads to major engine trouble. Consistent care is the key to long-term reliability.

Common Troubleshooting Steps

Even with proper maintenance, issues can arise. Before calling for service, your team can often identify and sometimes resolve the problem with these quick checks.

Issue 1: Weak Airflow

If the airstream feels weak and isn't reaching the floor:

- Check the Inlet Screen: A clog is the most common cause.

- Inspect the Fan: Ensure the blades are clean and spinning freely.

- Confirm Power Supply: Verify that the unit is receiving full power and that a circuit breaker has not tripped.

Issue 2: Insufficient Heat

If the air is blowing but isn't warm enough:

- For Electric Heaters: Locate the dedicated circuit breaker for the heating element (often separate from the fan's circuit) and ensure it has not tripped.

- For Hot Water/Steam Heaters: Confirm that hot water is reaching the unit. Check that valves are open and the main boiler is functioning correctly.

- For Gas Heaters: Ensure the gas supply is on and check if the pilot light (if applicable) is lit.

These basic steps can resolve many minor issues. For more complex problems or to establish a formal Planned Maintenance Program, our expert technicians are always ready to assist.

Answering Your Questions About Heated Air Curtains

Here are answers to the most common questions we hear from facility managers considering an air curtain with heater.

Can a Heated Air Curtain Replace My Building's Main Heating System?

No. An air curtain with a heater is a supplementary system, not a primary heat source. Its function is to create an air barrier at doorways to prevent the loss of heated air and the entry of cold air. By doing so, it reduces the load on your primary HVAC system, making it much more efficient, but it is not designed to heat your entire building.

How Noisy Are Commercial Air Curtains?

Noise levels vary depending on the model and its power. Manufacturers provide decibel (dBA) ratings for comparison. A heavy-duty industrial unit for a large loading dock will naturally be louder than a sleeker model for a retail entrance. Modern designs incorporate noise-reduction features, and low-noise models are available for sensitive environments. A professional can help you find the right balance between power and quiet operation.

What Is the Typical Lifespan of a Heated Air Curtain?

With proper installation and regular maintenance, a quality commercial air curtain can last 10 to 15 years, or even longer. Consistent preventive care, such as cleaning filters and periodic professional inspections, is key to maximizing its service life.

A planned maintenance program is the best way to extend the unit's service life and ensure it runs at peak efficiency, protecting your investment for the long haul.

Are Government Rebates Available for Installing These Units?

Yes, often they are. Many Canadian federal and provincial programs offer rebates for energy-efficiency upgrades, and a new air curtain with heater frequently qualifies. These incentives are designed to help businesses reduce their carbon footprint and offset the initial investment. Program details can change, so it's best to check with sources like Natural Resources Canada or your provincial energy authority for the latest information.

Ready to enhance your facility’s efficiency and comfort? As your respected partners in reliable service, the team at Wilcox Door Service Inc. has the expertise to help you select, install, and maintain the perfect air curtain solution for your needs.