Choosing the right entry doors for garage and loading bay areas is far more than a simple purchase—it’s a critical decision impacting your facility’s security, energy costs, and daily operations. These aren’t just standard doors; they are engineered assets vital to your building’s performance. This guide will walk you through everything you need to know, from selecting the right materials and understanding custom solutions like integrated man doors, to navigating security, safety compliance, and energy efficiency. You’ll gain practical insights to make an informed investment that protects your people and your bottom line.

Why Your Garage Entry Door Is a Critical Facility Asset

In any commercial or industrial setting, a pedestrian door—often called a ‘man door’ or pass-through door—is much more than just a way for people to get in and out. Think of it less like a simple door and more like a key component in your operational ecosystem. Its performance touches everything from employee safety and workflow efficiency to your monthly energy bills. A poorly chosen door can quickly become a security weak point, a source of major heat loss, and a constant maintenance headache.

On the other hand, a well-specified pedestrian door becomes a strategic asset. It gives your team secure, controlled access while keeping the massive overhead door sealed shut—a must for maintaining climate control and reducing wear and tear on your larger, more expensive systems.

Understanding the Role of Pedestrian Doors

At its core, the main job of an entry door in a garage bay is to separate people from vehicle traffic. This simple separation is fundamental to creating a safer workplace. Every single time an employee can use a man door instead of cycling a huge overhead door, you unlock a host of benefits:

- Enhanced Safety: It drastically cuts down the risk of accidents between people and moving vehicles or the large doors themselves.

- Operational Efficiency: Staff can move in and out quickly without having to wait for a slow-moving overhead door. For example, a loading dock worker needing to grab paperwork doesn’t need to open a 12-foot bay door to do it.

- Energy Conservation: Keeping the main door closed prevents massive exchanges of heated or cooled air with the outdoors. In Canada’s varied climate, this translates directly into lower utility costs.

- Reduced Wear and Tear: Fewer cycles on your main overhead door and its operator means a longer service life and fewer calls for costly repairs down the road.

A Special Case: Man Doors in Sectional Doors

Sometimes, space is a luxury, and installing a separate pedestrian door next to the main bay isn’t an option. This is where clever, custom solutions for commercial facilities come into play. It is entirely possible to install a fully functional man door directly within a larger sectional overhead door.

This integrated ‘pass-through door’ is a specialized commercial solution that provides personnel access without sacrificing the functionality of the main bay door. It requires expert installation to maintain structural integrity and must include safety interlocks—a mechanism that prevents the overhead door from operating while the man door is open—to ensure safety and prevent damage.

As a long-standing partner in facility management, our message of “Respected Partners, Reliable Service” means we understand that every access point is critical. When you start viewing your entry doors as integral parts of your building’s security, efficiency, and safety systems, you can make smarter investments that deliver real, long-term value. To ensure your doors are assets, not liabilities, it’s worth considering a professional service and maintenance plan.

Exploring Your Commercial Pedestrian Door Options

When you’re outfitting a commercial garage or loading bay, choosing the right pedestrian door isn’t a one-size-fits-all decision. The best entry doors for garage bays are the ones that perfectly match your day-to-day operational needs. A door that’s a champion in a high-traffic warehouse, for instance, would be completely out of place in a retail showroom.

Let’s break down the most common and effective options you’ll find in commercial and industrial settings. Think of your door choice as more than just creating an entryway. It’s a strategic decision that ripples through your facility’s security, operational flow, and energy efficiency.

Alt text: Diagram of a commercial entry door for a garage showing how it functions as a critical asset for security, operational efficiency, and energy savings.

As you can see, this single piece of equipment is tied directly to core business functions. Making the right call here really matters.

Hollow Metal Doors: The Industrial Workhorse

If you were asked to picture a tough, no-nonsense commercial door, you’d probably imagine a hollow metal door. For good reason. They are the undisputed workhorses in demanding industrial environments like manufacturing plants, distribution centres, and workshops. Their construction—steel panels wrapped around a honeycomb or insulated core—gives them incredible durability and impact resistance. That kind of strength is essential in a busy loading dock where forklifts, pallet jacks, and heavy carts are always on the move.

Better yet, many hollow metal doors come with a fire rating. This means they’ve been tested and certified to contain a fire for a specific duration (like 45, 60, or 90 minutes). It’s a critical life-safety feature that’s often mandated by building codes.

Insulated Steel Doors: Your Guard Against the Elements

In any facility where climate control is a priority, insulated steel doors are the clear winner. They act as a thermal shield for your building, keeping the outside out and the inside in. These doors have a core of high-density polyurethane foam sandwiched between two steel skins. This design delivers a high R-value, which is simply a measure of how well the door resists heat flow. The higher the R-value, the better the insulation.

For a cold-storage facility or a heated warehouse battling a Canadian winter, an insulated pedestrian door is non-negotiable. It stops energy from bleeding out, which can slash heating and cooling costs while ensuring a stable environment for temperature-sensitive products.

Aluminum and Glass Doors: Where Security Meets Style

Sometimes, looks matter just as much as toughness. For applications like auto dealerships, modern fire halls, or retail storefronts, aluminum and glass doors offer a clean, professional aesthetic. They bring in natural light and create a more open, inviting feel. While they aren’t as resistant to heavy impacts as their steel counterparts, modern aluminum doors are surprisingly durable. They’re lightweight, naturally corrosion-resistant, and can be fitted with various types of glazing, including insulated or reinforced security glass, making them a versatile choice for any public-facing part of your building.

Commercial Entry Door Material Comparison

| Material | Key Benefits | Best For | Considerations |

|---|---|---|---|

| Hollow Metal | Extreme durability, high security, fire-rated options, low maintenance | Warehouses, manufacturing plants, distribution centres, utility rooms | Can be heavy; prone to rust if coating is damaged |

| Insulated Steel | Excellent thermal performance (high R-value), energy savings, durability | Climate-controlled facilities, cold storage, heated workshops, exterior walls | Dents can be difficult to repair; higher upfront cost |

| Aluminum & Glass | Modern aesthetics, allows natural light, corrosion-resistant | Retail storefronts, auto dealerships, fire stations, office entryways | Less impact-resistant than steel; lower security unless specified |

Choosing the right material is about balancing your daily operational demands with your long-term goals for security, energy efficiency, and maintenance.

A Custom Solution: The Integrated Man Door

So, what do you do when there’s no wall space for a separate pedestrian door next to your main bay? The answer is a clever piece of engineering: an integrated pass-through door. You might also hear it called a “man door,” and it’s built directly into a larger sectional overhead door.

This is a highly specialized, custom application designed specifically for commercial use. It allows people to walk in and out without having to open the entire overhead door, which is a massive win for both efficiency and energy conservation. Imagine a maintenance technician in a busy logistics hub needing to quickly grab a tool from a bay—they can slip through the man door instead of opening a 14-foot high door and letting all the heated air escape.

Of course, safety is paramount. A properly installed integrated door includes essential safety interlocks. These mechanisms physically prevent the overhead door operator from running while the man door is open, which stops catastrophic damage to the door panel and, more importantly, keeps your employees safe. By understanding these different options, you can move beyond just filling an opening and choose an entry door that actively boosts your facility’s security, efficiency, and ultimately, your bottom line.

Integrating Modern Security and Access Control

Your facility’s entry doors are more than just a way in and out; they’re the first line of defence protecting your people, products, and property. This section will demystify how to turn these standard access points into intelligent security assets. We’ll break down modern access control systems and the essential hardware you need, showing you how a complete approach creates a secure, efficient, and compliant environment.

Alt text: A secure commercial entry door for a garage, featuring a panic bar and biometric access control keypad, demonstrating modern security integration.

Beyond the Basic Lock and Key

In a commercial setting, traditional keys are a security headache. They get lost, stolen, or copied, creating vulnerabilities that are almost impossible to track. Modern access control systems are like a digital keychain, giving you total command over who can enter specific areas and when. Instead of a physical key, employees use a credential to get in. This flips security from a reactive problem into a proactive strategy, letting you manage access rights instantly from one central system. These systems are incredibly flexible, scaling to fit the unique security needs of any facility, whether it’s a small workshop or a massive distribution centre.

Types of Access Control for Pedestrian Doors

Integrating access control with your entry doors for garage bays means picking the right tech for your operation. Every method offers a different balance of security, convenience, and cost.

- Keypad Entry: This is access control in its simplest form, requiring just a numeric code. It’s a budget-friendly choice for low-security areas, but since the code can be shared, it offers very little tracking.

- Card/Fob Readers: Employees get a programmed card or key fob. This is a popular option because you can grant or revoke access instantly and it creates a digital log of every entry attempt.

- Biometric Scanners: For high-security environments, biometric systems use unique physical traits like fingerprints or facial recognition. This provides the highest level of certainty that the person entering is exactly who they claim to be.

Consider a pharmaceutical warehouse as a practical example. They could use card readers on their loading bay man doors. This creates a verifiable, time-stamped log of all personnel movement—something that’s absolutely critical for maintaining a secure chain of custody for valuable products.

Essential Security Hardware

An access control system is only as strong as the physical hardware bolted to the door. These components all work together to make sure your entry points are both secure and safe for daily use.

A truly secure entry point is a complete system. Advanced electronics must be paired with robust, reliable mechanical hardware to create a door that protects your facility against unauthorized access while ensuring safe egress for your team during an emergency.

Here are the critical hardware elements you need to consider:

- Heavy-Duty Locks and Strikes: Commercial doors need locks built to handle serious force and constant use. An electric strike, controlled by the access system, is the component that releases the latch when someone presents a valid credential.

- Panic Bars (Exit Devices): This hardware is a non-negotiable life-safety requirement for many exit doors. It allows anyone to get out quickly in an emergency just by pushing the bar, even if the door is locked from the outside.

- Automated Door Closers: These hydraulic devices make sure the door closes and latches securely after every use, preventing it from being propped or accidentally left open. This is crucial for maintaining both security and climate control.

A cohesive security plan pulls all these digital and physical components together seamlessly. To ensure your advanced access control systems are professionally installed and maintained, you might consider partnering with a reliable security system supplier. Proper integration is what unlocks the full potential of your facility’s security.

Navigating Safety Compliance and Fire Protection

Meeting safety and fire codes isn’t just about ticking a box; it’s a fundamental part of protecting your people, your inventory, and your entire facility. When it comes to entry doors for garage bays, safety takes on a new level of importance, especially with fire protection. This is where specialized fire-rated doors enter the picture.

Think of a fire-rated door less like a standard door and more like an engineered life-safety system. Its primary job is to act as a powerful barrier, containing fire and smoke during an emergency to buy precious time for everyone to evacuate safely.

Understanding Fire Ratings and Canadian Codes

In Canada, regulations like the National Building Code (NBC) dictate exactly where fire-rated doors are needed. While you don’t need to be a code expert, as a facility manager, you do need to grasp the basics. A fire rating simply tells you how long a complete door assembly—the door, frame, and hardware working together—can withstand a fire.

Common ratings you’ll encounter include:

- 20-Minute Rating: Often found in doors between offices and corridors.

- 45/60-Minute Rating: Typically required for separations between different zones or areas of a building.

- 90-Minute Rating: Used for critical fire separation walls, like those in stairwells.

- 3-Hour Rating: Reserved for walls separating major sections of a building or high-hazard areas.

The most important thing to remember is that the entire assembly must be certified. You can’t just stick a fire-rated door in a non-rated frame and call it a day. It’s a complete system, and every component has to work in harmony. To get a better handle on what these ratings mean for your building, you can learn more about door fire ratings in our detailed guide.

The Importance of Fire Door Drop Testing

So, you have the right systems in place. But how do you know they’ll actually work when an emergency hits? The answer is a mandatory procedure called fire door drop testing. This isn’t just a good idea; for any rolling or sliding fire doors, it’s a required annual “fire drill” for the door itself.

A fire door drop test is a functional check to verify that a fire door will close automatically and completely under simulated fire conditions. This certified test ensures all components—from the release mechanism to the closing speed—are functioning flawlessly, confirming the door is ready to perform its life-saving duty.

During the test, a certified technician manually triggers the door’s automatic closing device. They watch to make sure it closes smoothly, at the proper speed, and forms a complete seal without any obstructions. A failed drop test is a major compliance issue that leaves your facility and its occupants dangerously exposed.

Mitigating Risk with Certified Inspections

Regular, certified inspections are your best tool for maintaining compliance and minimizing liability. Imagine a multi-tenant commercial property with shared loading dock areas. If a fire breaks out, the fire-rated pedestrian doors separating different tenant spaces are the first line of defence. An uninspected, malfunctioning door could lead to catastrophic property loss and put lives at risk.

As a trusted partner with a legacy of providing reliable service, we’ve seen firsthand how absolutely critical these tests are. Partnering with certified technicians for these inspections isn’t just about following the rules; it’s about demonstrating due diligence and actively protecting your most valuable assets: your people and your business.

Boosting Energy Efficiency with Smart Door Choices

In Canada’s demanding climate, every unsealed gap or uninsulated surface in your facility is a drain on your operational budget. The right entry doors for garage bays are more than just access points; they’re powerful tools for energy conservation. Choosing a door with the right features can dramatically reduce heating and cooling costs, directly impacting your bottom line.

This section will walk you through how to make smart, energy-efficient choices for your pedestrian doors. We’ll break down key concepts like R-value and show how a complete sealing system works together to create a formidable barrier against the elements.

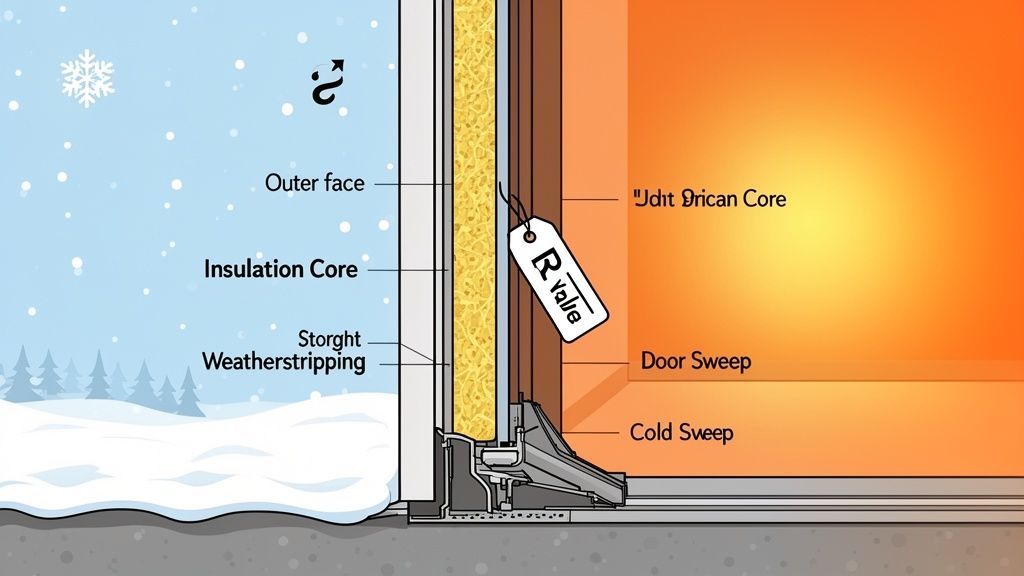

Alt text: Cross-section of an insulated entry door for a garage showing weatherstripping and high R-value core for superior energy efficiency.

Decoding R-Value: The Winter Coat for Your Building

When we talk about insulated doors, you’ll hear the term R-value a lot. Think of it as a simple rating for a door’s ability to resist heat flow, much like the rating on a high-performance winter coat. The higher the R-value, the better the door is at stopping heat from passing through.

In a practical sense, a door with a high R-value keeps your heated air inside during the winter and your cooled air inside during the summer. This thermal separation is achieved by injecting a dense polyurethane foam core between the door’s steel panels, creating an effective thermal break. For facilities looking to minimize energy use, selecting a door with the highest possible R-value is a smart investment that pays for itself over time.

The Power of a Complete Sealing System

An insulated door panel is only one piece of the energy efficiency puzzle. Air infiltration—those sneaky drafts seeping in around the edges of the door—can undermine even the best insulation. That’s where a complete sealing system comes in, creating a truly airtight barrier.

This system is a team effort, with several key components working in unison:

- Weatherstripping: This flexible seal runs along the sides and top of the door frame. When the door closes, it compresses to block air from whistling through the gap.

- Door Sweeps: Attached to the bottom of the door, sweeps create a tight seal against the threshold, preventing drafts from sneaking in underneath.

- Threshold Seals: This component is installed on the floor directly under the door. It gives the door sweep a solid, raised surface to press against, ensuring a reliable seal every time.

When properly installed and maintained, these elements form a continuous barrier that significantly cuts down on energy loss.

Real-World Impact: A Cold-Storage Case Study

The benefits of a well-insulated and sealed pedestrian door become crystal clear in demanding environments. Take a cold-storage facility in Alberta, for example. Here, maintaining a consistent internal temperature isn’t just about efficiency—it’s essential for product integrity.

By installing high R-value man doors equipped with robust, commercial-grade weatherstripping and sweeps, the facility can dramatically cut the energy consumption of its refrigeration systems. Every time an employee uses the pedestrian door instead of the main overhead bay, the facility prevents a massive influx of warm air. This reduces the load on the cooling equipment and, ultimately, lowers electricity bills.

This practical application shows how a seemingly minor detail like a pedestrian door can deliver a major impact on operational costs. It’s a strategic upgrade that strengthens your building’s thermal envelope and contributes to a more sustainable and cost-effective operation.

As respected partners in facility management, we help you identify these opportunities for improvement. Choosing the right entry doors is an investment in long-term efficiency and reliability.

Protecting Your Investment with Planned Maintenance

Your investment in high-quality entry doors for garage bays really pays off when they deliver reliable performance year after year. But just like any critical piece of equipment in your facility, these doors need regular service to sidestep unexpected failures and costly downtime. A proactive approach is always the smartest move.

Think of it this way: you wouldn’t run a delivery vehicle for years without changing the oil or checking the brakes. Your pedestrian doors deserve the same attention. They’re constantly in use, and their components are subject to wear and tear that can compromise safety, security, and energy efficiency if left to chance.

What a Professional Maintenance Plan Covers

A proper planned maintenance program is much more than a quick look-over. It’s a systematic inspection and service designed to catch small issues before they snowball into major headaches. As your service partner, we look at the entire door assembly, top to bottom.

A typical inspection from a certified technician includes:

- Hardware Functionality: Checking and adjusting closers, hinges, locks, and panic bars to make sure everything operates smoothly and securely.

- Seal Integrity: Inspecting all weatherstripping, sweeps, and thresholds for wear or damage that could be leaking energy.

- Frame and Alignment: Ensuring the door is properly aligned within its frame to prevent it from binding or failing to latch correctly.

- Access Control Systems: Testing keypads, card readers, and electric strikes to confirm they are working exactly as they should.

This detailed process ensures every component is doing its job, preserving the door’s safety features and operational reliability.

Maximizing Your Return on Investment

The ROI of well-maintained doors goes way beyond just avoiding emergency repair bills. Proactive care ensures your doors last longer, operate safely, and keep their energy-saving performance year after year. The return on investment for upgrading entry doors for garages can be significant, with some replacements yielding a high ROI according to industry data like the Cost vs. Value report.

A practical example is a manufacturing facility that relies on climate control. By ensuring their insulated pass-through doors and dock seals are properly maintained, they can prevent energy loss that directly impacts heating costs. Over the long term, this proactive maintenance extends the life of the asset and prevents the operational disruption of an unexpected door failure.

Regular maintenance isn’t an expense; it’s a strategic investment in uptime, safety, and efficiency. By identifying and addressing wear and tear early, you protect your initial investment and ensure your facility runs smoothly without interruption.

This proactive stance is at the heart of our “Respected Partners, Reliable Service” promise. We’re dedicated to making sure your critical access points remain dependable assets, not potential liabilities.

Protect your assets and prevent costly downtime. Schedule a professional maintenance inspection with Wilcox Door Service today.

We Get These Questions All The Time

When you’re dealing with the nuts and bolts of commercial entry doors for garage bays, a lot of questions can pop up. It’s completely normal. As specialists who live and breathe this stuff, we’ve heard just about everything. Here are a few of the most common things facility managers ask us, along with some straight-up answers.

Can a Pedestrian Door Really Be Installed Into an Existing Sectional Overhead Door?

Yes, absolutely. It’s a practical and common solution for commercial settings, often called a pass-through or ‘man door.’ In many cases, it can be retrofitted into an existing sectional door.

The process involves installing a specialized, fully-framed pedestrian door kit directly into the overhead door panels. This is an expert-level task, as the priority is ensuring the structural integrity of the larger door isn’t compromised. Most critically, the installation must include safety interlocks—a mechanism that prevents the overhead door from operating while the man door is in use. This is a crucial step to prevent serious damage and ensure personnel safety.

What Is the Difference Between a Fire-Rated Door and a Standard Hollow Metal Door?

They might look similar, but their construction and purpose are worlds apart. A standard hollow metal door is a workhorse, designed for security and durability in high-traffic areas. A fire-rated door, however, is an engineered life-safety device, specifically built and certified to hold back fire and smoke for a set period, like 45 or 90 minutes.

A fire-rated door isn’t just a slab of metal; it contains a special fire-resistant core and must be installed as a complete, tested assembly—including the frame and all hardware—to be compliant. Swapping in a non-rated door where a fire-rated one is required by code is a major safety violation that puts both people and your property at serious risk.

How Often Should Our Commercial Pedestrian Doors Be Inspected?

The frequency of inspection depends on the door’s usage and function. For doors in high-traffic areas or critical fire-rated exits, an annual inspection by a certified technician is the industry best practice. In many cases, it’s a legal requirement under standards like NFPA 80 to ensure these life-safety systems are ready to perform when needed. For doors with less traffic, regular in-house checks may suffice. However, a proactive annual maintenance program is the smartest way to catch small issues—like worn seals, failing closers, or misaligned latches—before they turn into security problems or expensive emergency repairs.

Your facility’s doors are critical assets that demand reliable service. At Wilcox Door Service, we provide expert installation, planned maintenance, and 24/7 emergency support to keep your operations running smoothly.

Protect your investment and ensure compliance. Contact us today for a professional door and dock equipment inspection.