Choosing a new commercial door can be a complex decision. In this guide, you’ll get a clear, expert breakdown of the fibreglass vs steel doors debate, helping you understand which material is the right investment for your facility. We will cover the critical differences in durability, energy efficiency, long-term costs, and suitability for specific industries like manufacturing, logistics, and food processing. By the end, you'll be equipped to select a door that enhances your security, efficiency, and operational uptime.

Fibreglass vs. Steel: Choosing the Right Commercial Door

For any facility manager in Canada, selecting a new commercial or industrial door is a significant decision. It's a choice that directly impacts your security, operational efficiency, and long-term energy and maintenance budgets. The two primary contenders, fibreglass and steel, each offer a unique set of strengths tailored for different environments. Understanding these differences is key to making a smart, lasting investment.

This guide moves beyond simple specifications to provide a real-world analysis of how each material performs under pressure. We’ll explore everything from durability at a busy loading dock to thermal performance inside a climate-controlled food processing plant, giving you the practical insights needed to choose wisely.

What We'll Be Comparing

To provide a clear picture, we will compare the materials across the factors that matter most to your operations:

- Core Strength and Durability: How each material handles daily abuse, from accidental impacts to general wear and tear.

- Thermal Performance: A practical look at insulation ratings (R-values) and what they mean for your facility's energy bills.

- Maintenance and Lifecycle Costs: Uncovering the true cost of ownership long after the initial installation.

- Industry-Specific Use Cases: Real-world recommendations for manufacturing, logistics, food processing, and more.

Here’s a quick snapshot of the core differences between these two workhorse door materials.

| Attribute | Fibreglass Doors | Steel Doors |

|---|---|---|

| Primary Advantage | Insulation & Corrosion Resistance | Strength & Security |

| Impact Resistance | Resists dents but can crack under heavy force | Dents with heavy impact but rarely breaks |

| Best For | Food processing, labs, coastal areas, public entrances | Warehouses, manufacturing, high-security zones |

| Maintenance | Very low; needs minimal upkeep | Low; requires paint touch-ups to prevent rust if scratched |

By the end of this guide, you’ll have a solid framework for navigating the fibreglass vs steel doors dilemma. As your "Respected Partners, Reliable Service," our goal is to help you select a door that perfectly aligns with your facility's operational demands and long-term goals.

Core Strength and Durability Showdown

In a high-traffic commercial setting, door durability isn't just a feature—it's essential for operational uptime. When you compare fibreglass vs steel doors, their core strength and ability to handle daily wear and tear represent one of the most significant differences for facility managers. This choice directly impacts long-term maintenance costs and, more importantly, workplace safety.

Alt text: A side-by-side comparison of fibreglass vs steel doors, with a hammer icon over the steel door for durability and a snowflake icon over the fibreglass door for insulation.

Let's break down how each material performs under pressure, from an accidental forklift bump at a busy loading dock to the harsh reality of a Canadian winter. Understanding these real-world differences ensures your door becomes a lasting asset, not a recurring operational headache.

Steel Doors: Unmatched Impact Resistance

For environments where collisions are a matter of "when," not "if," steel is the undisputed champion. There's a reason it's the standard for demanding applications like warehouses, manufacturing plants, and distribution centres—its raw strength is simply hard to beat.

A steel door can withstand significant impacts from forklifts, pallet jacks, and heavy equipment. While a severe blow might leave a dent, it's far less likely to cause a catastrophic failure that compromises security or shuts down a critical access point. This resilience is a key reason why commercial steel doors are a top choice and have dominated the market for decades.

Fibreglass Doors: A Different Kind of Durability

Fibreglass doors bring a different kind of resilience to the table. Their composite skin is highly resistant to the dings and dents from minor impacts, like rolling carts or hand tools, and it won't scratch as easily as a painted steel surface. This makes fibreglass a fantastic option for high-traffic pedestrian doorways where maintaining a clean, professional appearance is important.

However, fibreglass has its limits, especially under severe force or in extreme cold. A direct, heavy blow can cause the skin to crack or puncture, which is often a more complex and costly repair than hammering out a dent in a steel panel.

Expert Insight: In the extreme cold of a Canadian winter, where temperatures can plummet below -30°C, fibreglass can become more brittle. This increases its susceptibility to cracking on impact—a critical factor for any exterior-facing door in colder regions.

Head-to-Head Durability Comparison

To truly see the difference, let’s review a few common scenarios.

Scenario 1: Loading Dock Collision

A forklift grazes the door. The steel door receives a dent but remains fully functional and secure. The fibreglass door, however, might suffer a deep crack, requiring an immediate panel replacement to maintain security and climate control.Scenario 2: High-Traffic Corridor

Carts and equipment constantly bump the door. Here, the fibreglass door shines, resisting minor dents and scratches and keeping its appearance longer. The painted steel door will likely show scuffs and require periodic touch-ups to prevent rust.Scenario 3: Extreme Weather Exposure

During a harsh winter, an exterior steel door maintains its structural integrity without issue. A fibreglass door in the same conditions could become brittle, making it more vulnerable to shattering from an accidental impact.

Ultimately, the right choice comes down to the specific risks your facility faces every day. For raw, brute-force durability, steel is still king. But for environments where minor dents, scratches, and corrosion are the bigger enemies, fibreglass presents a compelling alternative.

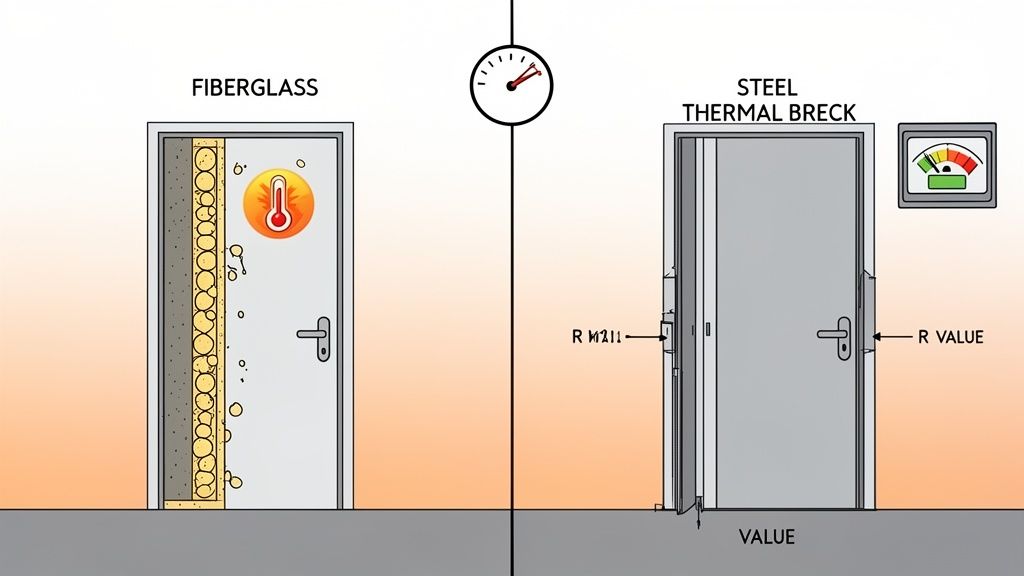

Analyzing Thermal Performance and Energy Efficiency

Your commercial doors are a critical part of your building’s envelope—the barrier separating your controlled indoor environment from the Canadian climate. In the fibreglass vs steel doors debate, thermal performance isn't just a technical specification; it's a factor that directly impacts your monthly utility bills. Understanding how each material insulates can be the difference between an efficient building and one that constantly leaks energy.

Alt text: A commercial door with a thermometer icon, illustrating the importance of thermal performance and energy efficiency for steel and fibreglass doors.

Let's break down the metrics that truly matter for energy efficiency and see how these two materials stack up in commercial and industrial settings.

Understanding R-Value and Thermal Breaks

Before comparing, let's clarify two key terms. The primary measure of insulation is the R-value, which indicates how well a material resists heat flow. It's simple: a higher R-value means better insulation and less energy loss.

Another key term is a thermal break. This is simply a piece of low-conductivity material placed within a door's structure to stop heat or cold from transferring through the metal parts. It acts as a roadblock for temperature, preventing the exterior cold from creating a "bridge" to the interior face, which causes condensation and energy loss.

Fibreglass: The Natural Insulator

By its nature, fibreglass is a better insulator than steel. The composite material itself does not conduct temperature easily. When combined with a thick, insulated polyurethane foam core, fibreglass doors achieve impressive natural R-values.

This inherent quality makes fibreglass an outstanding choice for any environment where strict temperature control is essential.

- Food Processing and Storage: In facilities like cold storage warehouses or refrigerated production areas, a fibreglass door helps maintain consistent temperatures, preventing product spoilage and reducing the load on refrigeration systems.

- Pharmaceutical and Lab Environments: For clean rooms and laboratories, stable temperatures are often critical for sensitive work. Fibreglass provides a reliable thermal barrier.

Steel: Engineered for Efficiency

While steel is a natural conductor of temperature, modern insulated steel doors are engineered to overcome this. These are not hollow sheets of metal; they are packed with high-density polyurethane foam cores that deliver excellent R-values, sometimes reaching R-17 or higher in premium models.

What truly allows steel doors to compete is the use of effective thermal breaks. By interrupting the path of thermal transfer, these doors prevent condensation and frost buildup—a common problem in Canada's cold climate. This is crucial for preventing moisture damage and potential mould growth. At Wilcox, we’ve seen advanced insulated steel doors cut energy loss by 15-25% compared to older models. For more on this, check out the case for insulated overhead doors in our detailed article.

Quick Comparison: Thermal Performance

Here’s a side-by-side comparison of key thermal attributes:

| Attribute | Fibreglass Doors | Steel Doors |

|---|---|---|

| Natural Insulation | Excellent; material is a poor conductor of heat. | Poor; material is a natural conductor of heat. |

| Core Insulation | High-density foam core standard. | High-density foam core in insulated models. |

| Achievable R-Value | Often high in standard models (e.g., R-12 to R-20+). | Can achieve high R-values (R-17+) with premium insulation. |

| Thermal Breaks | Less critical due to material properties. | Essential for high performance; prevents thermal bridging. |

| Condensation Control | Naturally resistant to condensation. | Relies on thermal breaks to prevent condensation and frost. |

| Best For | Extreme temperature control (cold storage, labs). | General-purpose use where high R-value is needed with durability. |

The verdict on thermal performance is nuanced. While fibreglass has a natural edge, a well-engineered, thermally broken steel door offers fantastic energy efficiency, making it a powerful contender for almost any application.

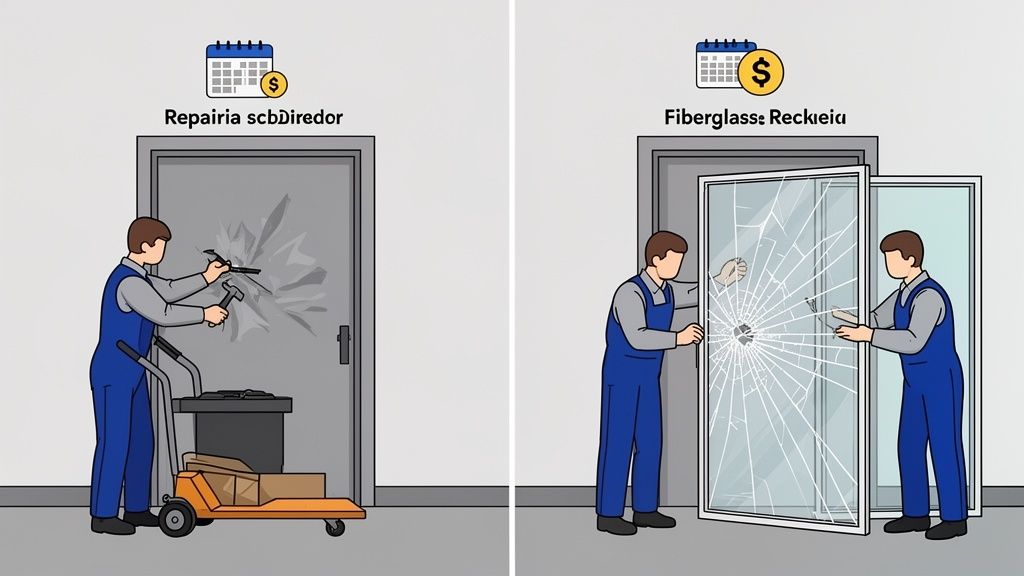

Comparing Maintenance, Repairability, and Lifecycle Costs

When considering fibreglass vs. steel doors, the initial purchase price is only the beginning. The true value—or hidden cost—is revealed over years of daily use, factoring in everything from routine upkeep to repairs from an unexpected forklift impact. To make a smart investment, you must consider the total cost of ownership.

Alt text: A maintenance expert inspecting a commercial steel door, highlighting the lifecycle costs and repairability in the fibreglass vs steel doors comparison.

Let's move past the sticker price and explore how each material performs financially over its service life.

Routine Upkeep and Maintenance Demands

The day-to-day care for fibreglass and steel doors highlights their fundamental differences.

Fibreglass doors are the champions of low-maintenance operation. Their composite skin is built to resist common issues like rust, corrosion, and moisture damage.

- Minimal Cleaning: A simple wash with mild soap and water is typically all that’s needed.

- No Painting Required: The colour is integrated into the material, so you avoid the time and expense of periodic painting.

Steel doors are also low-maintenance but have one key vulnerability: rust. The protective paint or galvanized coating is their only line of defence.

- Surface Inspections: It’s crucial to regularly check for scratches or dents that break the surface.

- Prompt Touch-ups: Any breach in the protective layer must be cleaned and repainted immediately to prevent corrosion. For a related perspective on material longevity, this metal vs. shingle roof comparison offers useful insights.

The Critical Factor of Repairability

This is where long-term cost differences truly emerge. A door's repairability can mean the difference between a quick fix and a major capital expense.

Here, steel doors have a clear advantage. If a forklift dents a steel door panel, a skilled technician can often pound out the dent and repaint it on-site. The process is cost-effective and, more importantly, fast, minimizing operational disruption.

Key Takeaway: The ability to repair a dented steel door rather than replacing the entire section significantly reduces lifecycle costs and prevents minor accidents from disrupting your operations.

Fibreglass, on the other hand, is less forgiving. While it resists minor bumps, a serious impact will cause it to crack or puncture. This type of damage cannot be repaired to restore the door's original strength and integrity. In almost all cases, a cracked fibreglass panel requires a full section replacement, which costs more and often involves longer lead times.

Total Lifecycle Cost and ROI

To get the full picture, you must look beyond the initial purchase and factor in all maintenance and potential repair costs over a 20- to 30-year lifespan.

- Steel Doors: The upfront cost is generally lower. While they require diligent paint touch-ups if scratched, their superior repairability often results in a lower total lifecycle cost, especially in busy environments where impacts are likely.

- Fibreglass Doors: The initial investment is usually higher. Routine maintenance is practically zero, but the high cost of replacing a single damaged panel can erase those savings, particularly in high-traffic industrial settings.

Your operating environment is the deciding factor. For a busy warehouse, steel's rugged and repairable nature often makes it the smarter long-term financial bet. To better understand the financial side, review the factors that influence the cost to replace a commercial door.

Choosing the Right Door for Your Industry

The "best" commercial door does not exist—only the right door for the job. In the fibreglass vs. steel doors debate, the answer almost always depends on the specific demands of your industry. A door perfect for a food processing plant could be destroyed in a week at a high-volume distribution centre.

Making the right choice from the start ensures you get the performance, compliance, and longevity you paid for. Let’s break down our recommendations for key Canadian industries.

Manufacturing and Logistics: High-Impact Environments

In a manufacturing plant, warehouse, or logistics hub, the environment is defined by constant motion. Forklifts, pallet jacks, and heavy machinery mean door impacts are an inevitability. In this setting, steel is the undisputed workhorse.

Steel's greatest advantage is its raw structural strength and impact resistance. When a forklift hits a steel door, it typically leaves a dent that our technicians can often repair quickly, minimizing downtime. A cracked fibreglass door, however, usually requires a full panel replacement and a longer service interruption. Additionally, steel doors are widely available with high fire ratings, making it easier to meet National Building Code of Canada requirements.

Food Processing and Pharmaceuticals: Hygiene-Critical Zones

In industries like food processing, beverage production, and pharmaceuticals, the priorities are entirely different: hygiene, corrosion resistance, and moisture control. This is where fibreglass doors truly excel.

The non-porous, smooth surface of a fibreglass door is easy to clean and sanitize, a major benefit for facilities meeting Canadian Food Inspection Agency (CFIA) standards. Unlike steel, fibreglass will never rust or corrode, even after daily high-pressure washdowns with harsh chemicals.

Industry Insight: In a wet processing environment like a dairy or seafood plant, a painted steel door with even a minor scratch can become a breeding ground for bacteria as rust forms. Fibreglass eliminates this risk entirely, protecting product integrity and simplifying compliance.

The natural insulating properties of fibreglass also make it the ideal choice for climate-controlled areas like coolers and freezers. Explore our range of specialized commercial doors designed for these demanding environments.

Commercial and Public-Facing Properties

For commercial buildings, retail centres, and condominiums, the choice is more nuanced, balancing aesthetics, security, and daily use.

- Public Entrances: Where curb appeal matters, fibreglass offers more design flexibility. It can be moulded with textures like wood grain for an inviting look without the upkeep of real wood.

- Service and Utility Areas: For back-of-house service doors, utility closets, or parking garages, security and durability are paramount. Steel is the clear winner here, offering superior resistance to forced entry and vandalism.

A smart property manager might specify a beautiful fibreglass door for the front lobby and a tough steel door for the underground loading bay. Our team provides complete maintenance and repair services for all door types, and our 24/7 emergency services are always ready to respond to urgent issues.

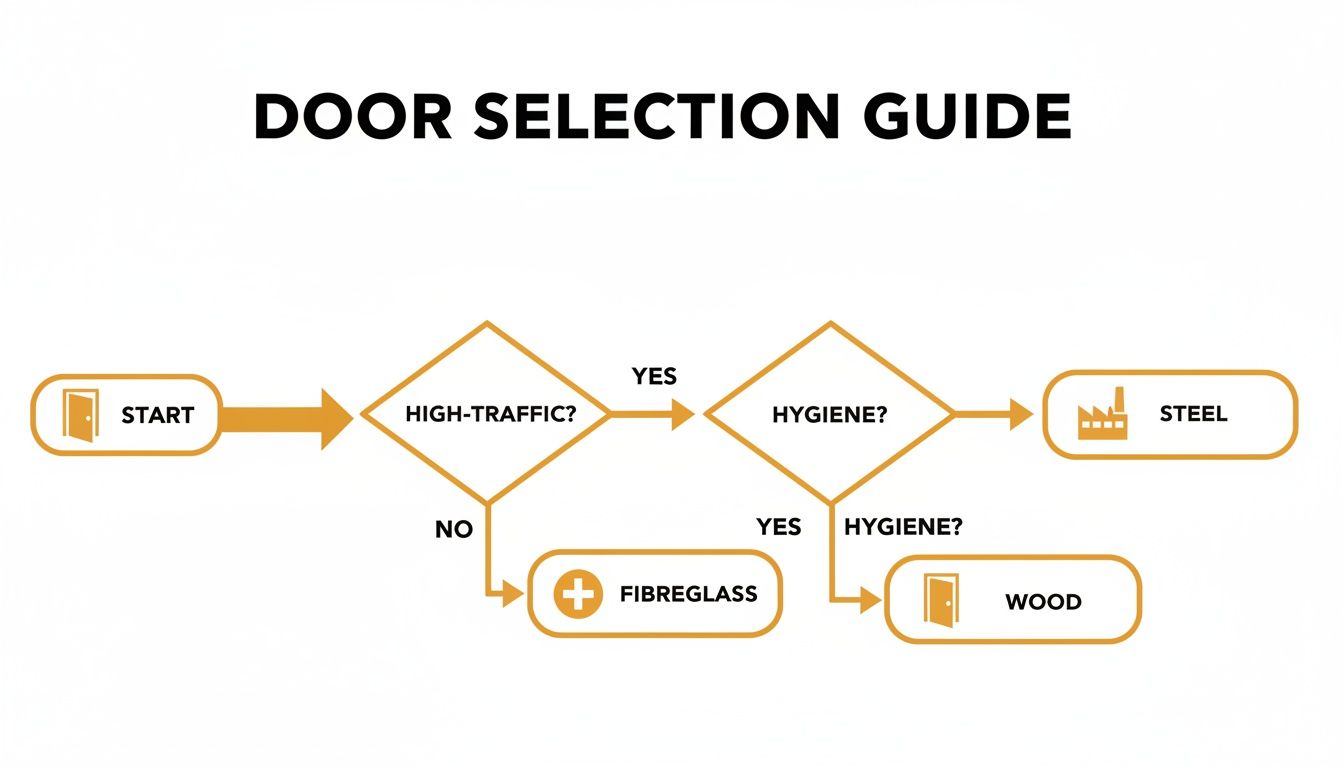

Making the Final Decision for Your Facility

We've covered the core differences in the fibreglass vs steel doors debate. Now, the final decision rests on your facility's unique operational reality. It's not about finding a single "better" door; it's about matching the material to your daily demands.

To help, we've created a practical checklist to guide your decision-making process.

Your Facility Decision Checklist

Answer these questions to identify the most logical and cost-effective choice for your facility.

- What is your biggest operational risk? If the primary threat is heavy impacts from forklifts or equipment, steel’s superior durability and straightforward repairability make it the clear winner.

- Are hygiene and corrosion top priorities? For environments with constant moisture, chemical washdowns, or strict sanitation rules (e.g., food processing), fibreglass is the superior choice due to its rust-proof, non-porous surface.

- How important is energy efficiency? For climate-controlled facilities like cold storage or labs, fibreglass’s natural insulating properties give it an edge. However, modern insulated steel doors can also deliver excellent R-values.

- What level of security is non-negotiable? For exterior service entrances or high-value storage areas, steel provides unmatched resistance to forced entry and remains the default for security-first applications.

- What is your long-term maintenance capacity? Steel doors require prompt attention to scratches to prevent rust. Fibreglass is virtually maintenance-free. Be realistic about your team's ability to handle proactive upkeep.

This decision tree helps visualize the thought process, guiding you from your primary need to the right material.

Alt text: An infographic decision tree guiding users in the fibreglass vs steel doors choice, based on needs like high-traffic durability and hygiene standards.

As you can see, the path splits clearly: high-impact industrial settings favour steel, while specialized, hygiene-critical environments benefit most from fibreglass.

Final Takeaway

Choose steel for its raw durability and security in tough, high-traffic industrial zones. Opt for fibreglass when top-tier insulation, corrosion resistance, and low maintenance are the most important factors.

Making the right choice from the start ensures your facility’s access points are secure, efficient, and built to last. Contact Wilcox Door Service today for an expert assessment and quote.

Frequently Asked Questions

Here are straight answers to the most common queries we hear when our partners are weighing fibreglass vs steel doors.

Which Door Is More Secure, Fibreglass or Steel?

When it comes to pure security, steel is the undisputed winner. The sheer density and strength of steel make it incredibly resistant to forced entry. It's tough to break through a steel door, which is why it remains the top choice for any exterior application where security is a priority, such as utility rooms, service entrances, or main warehouse access points.

Are Steel Doors Better in Canadian Winters?

This is an excellent question. While fibreglass is a fantastic natural insulator, it can become brittle in deep-freeze conditions and more prone to cracking from a sudden impact.

Modern insulated steel doors, however, are engineered for the cold. They are built with high-density polyurethane cores and designed with thermal breaks—barriers that stop cold transfer—to provide excellent energy efficiency without sacrificing structural strength. This makes them a highly reliable choice for Canadian winters.

Real-World Application: At a busy loading dock in Edmonton on a -35°C morning, an accidental bump from a forklift would likely only dent a steel door. In the same situation, a fibreglass door faces a much higher risk of cracking open, instantly compromising your building's security and climate control.

Can a Dented Steel Door Be Repaired?

Yes, and this is one of steel's biggest long-term advantages. In most cases, a qualified technician can repair minor to moderate dents on a steel door panel. This is a significant difference from fibreglass, where a crack or deep gouge almost always requires replacing the entire panel.

The repairability of steel directly lowers its total lifecycle cost and, more importantly, minimizes operational downtime. Our expert maintenance and repair services can get your bay back up and running much faster than waiting for a new panel.

Which Door Offers More Design Options?

For aesthetic flexibility, fibreglass generally has the edge. The composite material can be moulded into different textures, including a convincing wood-grain appearance. Fibreglass doors also come in a wider variety of styles and factory-finished colours, making them a strong contender for public-facing entrances or areas where appearance matters. Steel is all about function, typically offering a smooth, industrial finish that prioritizes performance.

Making the right choice ensures your facility is safe, efficient, and prepared for the future. As your respected partners in reliable service, Wilcox Door Service is here to help you find the perfect solution.