This guide delivers everything facility managers and building owners need to know about fire window shutters. You will learn what these systems are, how to decode complex fire ratings and building codes, the different types available, and the critical importance of proper installation and mandatory annual testing. We’ll break down technical concepts into simple, practical terms, empowering you to make informed decisions that enhance your building’s safety and ensure compliance.

Understanding Fire Window Shutters and Their Purpose

alt=A roller fire window shutter containing a blaze in a commercial building.

Imagine a fire starts in your facility’s kitchen or workshop. Before it can spread, a heavy-duty steel barrier automatically drops, sealing off the window or service counter. That’s the life-saving function of a fire window shutter—an essential safety system designed to contain fire and smoke, protecting people and property.

Think of these shutters as a key component of your building’s passive fire protection strategy. This term simply means they are designed to contain a fire after it has started, rather than actively putting it out. Their primary job is to compartmentalize a fire, slowing its spread and buying crucial time for evacuation and for first responders to arrive.

The Core Function of Fire Shutters

At their core, fire window shutters are robust physical barriers designed to cover window openings automatically when a fire is detected. Unlike standard security shutters, they are constructed from fire-resistant materials, typically steel, and engineered to close without human intervention in an emergency.

Their most important function is to maintain the integrity of a fire-rated wall. Think of a fire-rated wall as a dam designed to hold back a fire. An unprotected window in that wall is like a hole in the dam. A fire shutter acts as the automatic plug, sealing that hole to ensure the entire wall performs as a single, solid barrier.

This compartmentalization is vital for several reasons:

- Protects Escape Routes: By keeping hallways and stairwells clear of smoke and flames, shutters give occupants the time needed to evacuate safely.

- Prevents Property Damage: Containing a fire to its room of origin dramatically reduces damage to inventory, equipment, and the building structure itself.

- Supports Firefighter Safety: A contained fire is a more predictable fire, making the situation safer and more manageable for emergency response teams.

Passive Protection in a Broader Safety Plan

Fire shutters are a form of passive fire protection, meaning they work to contain a fire rather than extinguish it. This makes them a perfect partner for your active fire protection systems, which are designed to suppress the flames directly.

A complete fire safety strategy includes both. While active systems like sprinklers and fire suppressant dispersing devices fight the fire, passive systems like fire window shutters contain it. For any facility manager, a robust plan layers these defenses to create maximum protection for your people and your operations.

Decoding Fire Ratings and Code Compliance

Navigating fire safety regulations can feel overwhelming, with technical jargon and acronyms at every turn. Let’s simplify it. Understanding what fire ratings mean is essential for ensuring your building is not only safe but also legally compliant.

When you see a fire window shutter with a rating like “90-minute” or “3-hour,” that’s a certification. It tells you precisely how long that shutter has been tested and proven to resist fire and intense heat, preventing them from passing through the opening.

Your fire-rated walls and the shutters within them must work together as a single system. A shutter with a lower rating than the wall it’s in creates a weak link, undermining the entire purpose of the fire-rated barrier. For example, a shutter rated for 45 minutes installed in a 2-hour rated wall would fail long before the wall does, allowing the fire to spread.

Understanding Fire Resistance Ratings

A fire-resistance rating ensures every component in a building’s safety system is synchronized. A shutter’s rating must be appropriate for the wall it’s installed in. For example, a 3-hour rated firewall, often used to separate high-risk areas like a loading dock from the main warehouse, requires a shutter that can also withstand fire for a comparable duration.

To choose the right product, it’s helpful to understand the rating system itself. Our comprehensive guide to fire door ratings explores these principles in greater detail, covering the standards that apply to all types of fire-rated openings.

Key Standards and Canadian Codes

Compliance is not optional—it’s the law. Two of the most important standards to know are:

- NFPA 80: This standard from the National Fire Protection Association is the essential guide for the installation, inspection, testing, and maintenance of all fire-rated doors and shutters in North America.

- National Building Code of Canada (NBC): This is the legal framework that all commercial and industrial buildings in Canada must adhere to.

The NBC is particularly stringent. It mandates that fire-rated openings, including fire window shutters, must match the fire-resistance of the surrounding wall. For instance, a wall with a 2-hour rating typically requires window shutters with at least a 90-minute fire rating to ensure containment.

Key Takeaway: Correctly matching shutter ratings to wall ratings isn’t just about passing an inspection. It’s about creating a cohesive safety system that will perform reliably in an emergency to protect lives and assets.

As “Respected Partners, Reliable Service,” our mission is to help you navigate the complexities of these regulations with confidence.

Exploring Types of Fire Shutters and Materials

Not all fire shutters are the same. Choosing the right design and material for your facility depends on both your safety requirements and your day-to-day operational needs. An informed choice ensures your investment provides effective, long-lasting protection.

The most common and reliable design in the industry is the rolling steel fire shutter (also known as a coiling fire shutter). It functions like an automated, armored curtain that remains coiled in a compact housing above a window or service counter, completely out of sight during normal operations. When a fire alarm is triggered, the shutter automatically descends to create a solid wall of fire-resistant steel.

This design is popular for its durability and space-saving efficiency, making it ideal for busy commercial environments like warehouses, distribution centers, and manufacturing plants. For example, at a busy parts counter in a factory, a rolling shutter provides certified fire protection without obstructing the workflow.

Steel vs. Insulated Shutters

While standard galvanized or stainless steel provides excellent fire containment, some applications require additional performance. This is where insulated fire window shutters come in. These shutters feature a core of mineral wool or another fire-retardant material sandwiched between steel slats.

This layered construction offers key advantages beyond fire resistance. To help you select the right material for each opening, here’s a quick comparison:

Fire Shutter Material Comparison

| Material | Key Benefit | Typical Application | Insulation Value |

|---|---|---|---|

| Galvanized Steel | Cost-effective and durable fire protection | Warehouses, parking garages, manufacturing plants | Low |

| Stainless Steel | Corrosion resistance and aesthetic appeal | Kitchens, labs, food processing, corrosive environments | Low |

| Insulated Steel | Fire safety plus thermal and sound control | Cafeterias, climate-controlled areas, office pass-throughs | High |

This construction offers several key benefits:

- Thermal Control: They create a thermal break, helping maintain stable indoor temperatures and improving energy efficiency. This is particularly valuable at a loading dock connected to a climate-controlled warehouse.

- Sound Dampening: The insulated core reduces noise transmission, making them perfect for locations like school cafeterias, laboratories, or office windows overlooking a loud production floor.

When you choose an insulated model, you’re not just installing a life-safety device; you’re also upgrading your building’s overall performance with added thermal and acoustic control.

The decision between standard steel and insulated shutters depends on the location. For a warehouse window facing a parking lot, standard steel is likely sufficient. However, for a pass-through window between a hot commercial kitchen and a customer-facing service area, an insulated shutter offers critical fire safety plus valuable heat and noise containment.

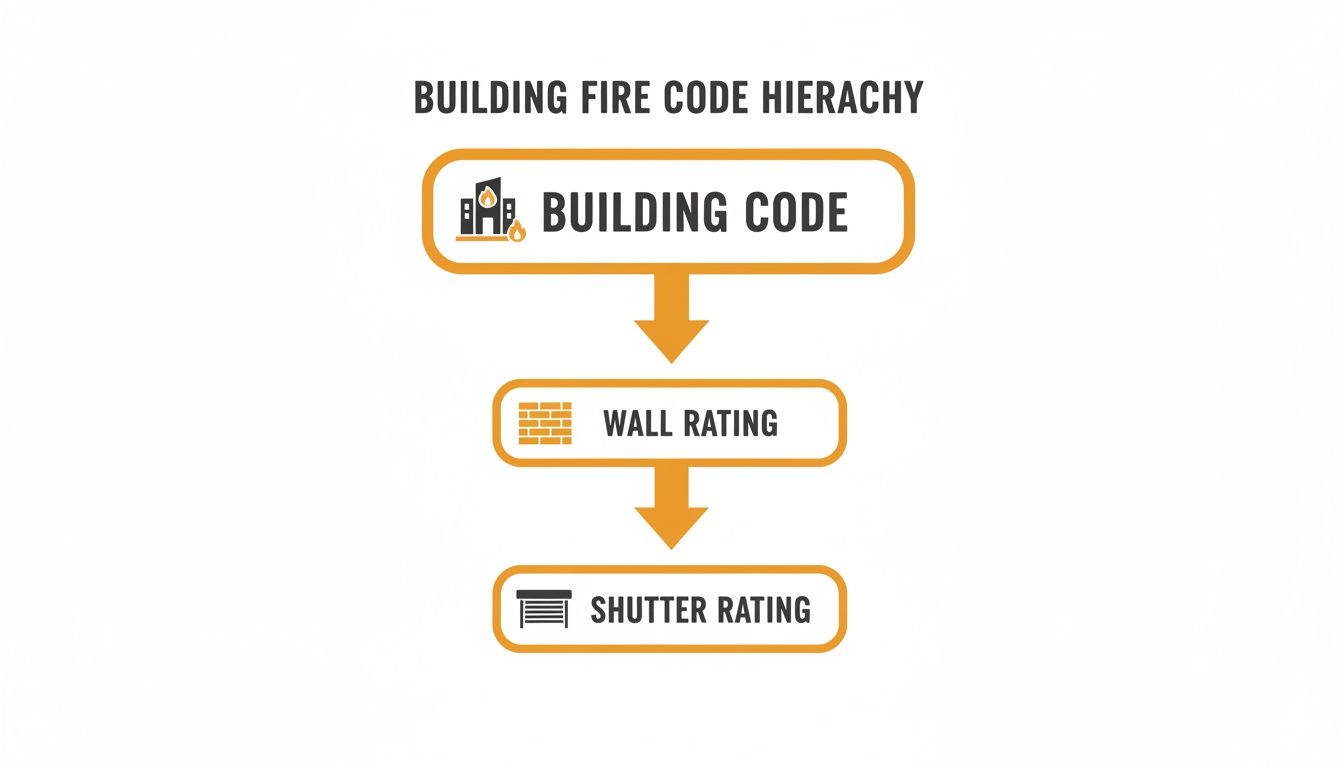

This flowchart illustrates how fire codes determine shutter requirements. The building code dictates the wall’s rating, which in turn specifies the necessary rating for the shutter itself.

alt=Flowchart showing Building Code determines Wall Rating, which determines Fire Window Shutter Rating.

This hierarchy shows that a fire window shutter is never a standalone product; its specifications are directly linked to the wall it protects. As “Respected Partners, Reliable Service,” Wilcox Door Service can guide you in selecting the ideal material and design for every opening in your facility.

How Installation and Alarm Integration Work

A high-quality fire shutter is only effective if installed correctly. For life-safety equipment like fire window shutters, professional installation by certified technicians is non-negotiable. This is the only way to ensure every component—from the guide rails to the release mechanism—is perfectly aligned, tested, and compliant with building codes.

Improper installation can lead to a catastrophic failure. If the guide rails are misaligned or the release mechanism is faulty, the shutter may jam during deployment, rendering it useless. Proper installation guarantees a smooth descent and a complete, tight seal when it matters most.

Understanding Shutter Activation Systems

A fire shutter’s true value lies in its ability to close automatically upon detecting a fire. This is managed by one of two main systems. The right choice depends on your facility’s specific needs and existing safety infrastructure.

The two primary activation methods are:

- Fusible Links: This is a traditional, standalone method. A fusible link is a small, heat-sensitive device that holds the shutter open. When the ambient temperature reaches a set point (typically around 74°C / 165°F), the link melts and breaks, releasing the shutter to close by gravity. It’s a simple, reliable mechanical solution.

- Electromechanical Systems: This is the modern, integrated approach. The shutter is connected directly to your building’s fire alarm panel and held open by an electromagnet. When a smoke detector or manual pull station is activated, the alarm panel cuts power to the magnet, instantly releasing the shutter.

The Power of Fire Alarm Integration

While fusible links are effective, they are reactive—they only trigger when a fire has grown large enough to generate significant heat near the opening. Integrating your fire window shutters with the building’s alarm system creates a proactive, unified defense.

When a smoke detector is activated anywhere in the designated zone, the alarm panel commands the shutter to close immediately, often long before flames reach the window. This rapid deployment contains smoke and toxic gases, protects escape routes, and minimizes property damage. It transforms your shutters from standalone devices into an intelligent, coordinated safety network. The same principles of reliability and integration that power a modern automatic door operator are essential here.

Key Insight: Integrating fire shutters with your alarm system ensures the earliest possible response. Containment begins at the first sign of smoke, not just when flames arrive, maximizing safety for occupants and first responders.

As “Respected Partners, Reliable Service,” Wilcox ensures every installation is performed to the highest industry standards, with seamless alarm integration you can count on.

Mastering Maintenance and Annual Drop Tests

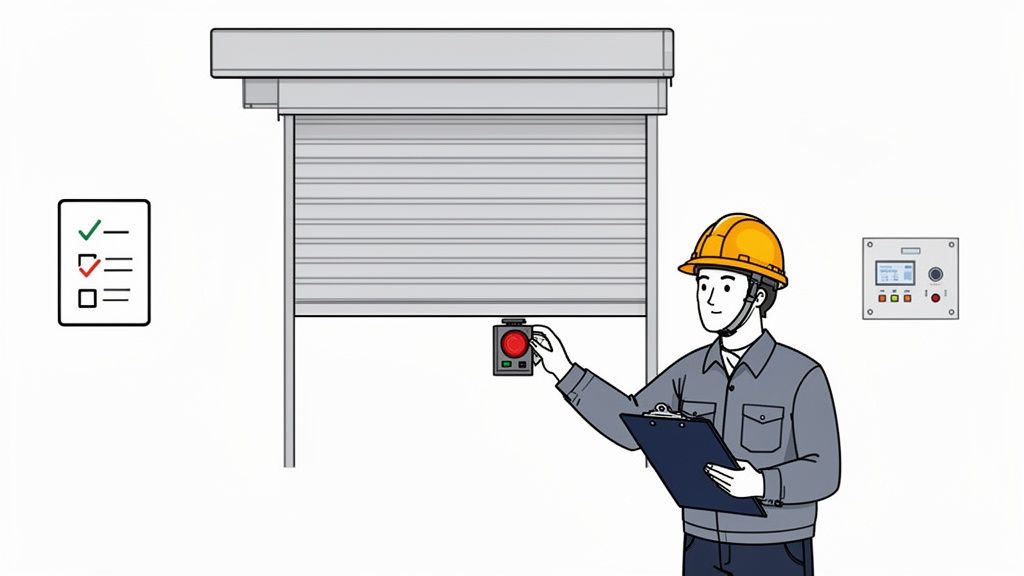

alt=Certified technician performing an annual drop test on a fire window shutter for compliance.

A fire window shutter is a critical safety device, but it’s only reliable if it’s in perfect working condition. A shutter that hasn’t been properly maintained and tested is a significant liability.

The cornerstone of fire shutter maintenance is the mandatory annual drop test, a strict requirement under NFPA 80 standards. This is not a best practice; it is a legally required procedure that must be performed and documented by a certified professional to maintain compliance. A proactive maintenance schedule ensures your fire window shutters are always ready to perform their life-saving function.

The Critical Role of the Annual Drop Test

A drop test is a controlled, real-world simulation of an emergency. A certified technician triggers the shutter’s release mechanism to verify that it closes completely and correctly under its own power. This test confirms that every component, from the release mechanism to the guide rails, is functioning as designed.

Think of it as a fire drill for your equipment. An untested shutter is an unknown risk. The drop test identifies hidden issues—like worn cables, sluggish operation, or misaligned tracks—that could cause a failure during an actual fire. For a deeper look at this process, our experts explain what’s involved in professional fire door drop testing.

Your Routine Visual Inspection Checklist

While the annual drop test must be performed by a certified professional, facility managers should conduct regular visual inspections to catch minor issues before they become major problems.

Use this simple checklist during your routine facility walk-throughs:

- Check for Obstructions: Ensure the shutter’s path is completely clear of equipment, storage boxes, or any other debris. A small object can prevent the shutter from forming a complete seal.

- Inspect Guide Rails: Look for any dents, damage, or buildup of grime in the tracks that could impede the shutter’s descent.

- Examine the Shutter Curtain: Visually inspect the steel slats for signs of damage, corrosion, or warping.

- Look for Damaged Components: Check visible cables, springs, and other hardware for obvious signs of wear and tear.

Important Reminder: These visual checks are a crucial part of preventative maintenance but do not replace the official, documented annual drop test performed by a certified technician.

As “Respected Partners, Reliable Service,” Wilcox Door Service provides the expert testing and maintenance required to keep your fire shutters compliant and ready.

Choosing the Right Fire Shutters for Your Building

Selecting the right fire window shutters involves balancing safety regulations, operational needs, and budget. A methodical approach ensures your investment will effectively protect your people and property for years to come.

The first and most critical step is to determine the required fire-resistance rating. This is dictated by the fire rating of the wall where the shutter will be installed. For example, a 2-hour rated wall, common in commercial buildings, generally requires a shutter with at least a 90-minute rating to maintain the barrier’s integrity and comply with the National Building Code of Canada.

Key Decision Factors for Your Facility

Once the required fire rating is established, consider the practical aspects of the installation. A thorough site assessment is key.

- Measure and Verify: Obtain precise measurements of the opening’s width and height. Crucially, confirm there is adequate headroom and side room to accommodate the shutter’s coil housing and guide rails without creating an obstruction.

- Choose Your Activation System: Decide how the shutter will be triggered. A standalone fusible link system is a simple, effective option. For a faster, more proactive response, an electromechanical release integrated with your building’s fire alarm system is the superior choice, as it activates on smoke detection.

- Balance Cost and Long-Term Value: While upfront cost is a consideration, prioritize durability and compliance. A properly specified and professionally installed shutter may have a higher initial cost but will minimize future maintenance issues and provide reliable protection, delivering greater long-term value.

A well-chosen fire shutter is more than just equipment; it’s a long-term investment in safety and peace of mind. Prioritizing correct specifications and professional installation guarantees compliance and reliability.

By carefully considering these factors, you can make an informed decision that enhances both the safety and efficiency of your facility. As “Respected Partners, Reliable Service,” Wilcox Door Service provides expert guidance at every stage, from site assessment and selection to installation and ongoing 24/7 emergency service.

Your Fire Window Shutter Questions, Answered

When it comes to the details of fire window shutters, facility managers often have a few key questions. Here are clear, practical answers to the most common inquiries.

How Often Do My Fire Shutters Need to Be Tested?

According to NFPA 80 standards, every fire window shutter must undergo a professional “drop test” at least once per year. This is a mandatory, documented procedure performed by a certified technician to verify that the automatic closing system functions correctly. This annual test is essential for ensuring both safety and legal compliance.

Can Fire Shutters Be Hooked Up to Our Fire Alarm?

Yes, absolutely. In fact, it is the recommended method for modern facilities. Fire shutters can be integrated directly with a building’s central fire alarm system using electromechanical release devices. When a connected smoke or heat detector is triggered, the alarm panel sends a signal to release the shutter instantly, providing a much faster response than a traditional heat-activated fusible link.

What Happens if Something Is Blocking a Fire Shutter?

An obstruction in a shutter’s path is a critical safety failure. If a box, cart, or piece of equipment prevents the shutter from closing completely, it leaves a gap for fire and smoke to penetrate, defeating its entire purpose. This is why regular housekeeping and visual inspections to keep paths clear are vital. The professional annual drop test is also designed to confirm a full, unobstructed closure.

Your facility’s safety is our top priority. As “Respected Partners, Reliable Service,” Wilcox Door Service provides expert installation, maintenance, and 24/7 support for all your fire protection needs. Contact us today for a comprehensive quote or to schedule your next inspection.