For any facility or operations manager in Oakville, a malfunctioning commercial door isn’t just an inconvenience—it’s an operational bottleneck that can halt production, compromise security, and create serious safety risks. This guide is your definitive resource for navigating commercial garage door repairs oakville, providing the expert insights you need to manage unexpected door failures efficiently. You will learn how to identify early warning signs of a breakdown, understand the process for emergency repairs, recognize common issues like spring or opener malfunctions, and see how a proactive maintenance plan can prevent most problems before they start, ensuring your facility remains secure and productive.

Understanding the Impact of Commercial Door Failures

When a high-traffic loading dock door seizes up or a critical warehouse entry point fails, the consequences are immediate. Every minute of downtime translates into lost productivity, delayed shipments, and potential safety hazards for your team. Effectively managing these critical access points is essential for any Oakville industrial or commercial facility.

This guide is your operational playbook, designed for facility leaders who need clear, reliable information, not technical jargon. We will equip you with the knowledge to manage your building’s doors with confidence.

Here’s what you will learn:

- Spot Early Warning Signs: Learn to recognize the subtle signals a commercial door sends before a complete failure, allowing you to prevent a major breakdown.

- Handle Emergency Repairs: Understand what to expect from a 24/7 emergency service, from your initial call to the final repair sign-off.

- Identify Common Fixes: Gain a practical understanding of frequent issues, such as broken springs or motor malfunctions, to better anticipate maintenance needs.

- Implement Proactive Maintenance: Discover how a structured Planned Maintenance Program can eliminate the vast majority of emergencies, saving significant time and money.

By the end of this guide, you will be better prepared to handle any commercial door issue. Our goal is to be your respected partner in keeping your facility safe, secure, and productive. Whether you manage a single warehouse or multiple commercial properties, a solid understanding of commercial door repair is your best defense against operational disruption.

Meta Description:

Your expert guide to commercial garage door repairs in Oakville. Learn to spot failure signs, manage emergencies, and use preventive maintenance to eliminate downtime.

Image Alt Text:

A commercial warehouse with multiple large overhead garage doors, one of which is being serviced by a Wilcox Door Service technician in Oakville.

Spotting the Early Warning Signs of a Failing Commercial Door

In a busy Oakville facility, a commercial door rarely fails without warning. Catching these early signals is the key to preventing a complete operational shutdown. Think of your commercial door as a critical piece of machinery; it provides clues when something isn’t right. Ignoring an unusual noise or sluggish movement is like ignoring a check engine light—sooner or later, a minor issue will become a major breakdown, likely during your busiest shift.

The goal is to identify these red flags early and schedule professional garage door repairs in Oakville before a small problem becomes a costly crisis.

Audible Warning Signs: What to Listen For

Often, the first sign of trouble is a new sound during operation. Your team hears these doors open and close dozens of times a day, so any unusual noise should be investigated immediately.

Key sounds that indicate a problem:

- Grinding or Squealing: This typically points to a lack of lubrication or debris in the tracks. It could also mean the rollers—the small wheels that guide the door—are worn out and scraping against the metal tracks instead of rolling smoothly.

- Loud Banging or Popping: A loud bang is a serious red flag. This sound almost always signifies a broken torsion spring. The torsion spring is a large, powerful spring that does the heavy lifting, and without it, the door becomes inoperable and extremely dangerous.

- Excessive Rattling or Clanking: While some operational noise is normal, excessive rattling often indicates loose hardware. Bolts and hinges can loosen over time and require tightening before they fail completely.

“A change in sound is the number one symptom we hear about from facility managers. A door that was once quiet but is now loud and abrasive is telling you it’s under stress. Addressing it at this stage is almost always faster and more affordable than waiting for a complete failure.”

Visual and Operational Red Flags

Beyond strange noises, visual inspections and observing the door’s behaviour are powerful diagnostic tools. Encourage your staff to report these signs immediately.

Common visual and operational warnings include:

- Jerky or Slow Movement: A door that shudders, hesitates, or moves slower than usual may have a problem with its opener, springs, or track alignment. This puts excessive strain on the motor and can lead to premature failure.

- Visible Damage: Look for frayed cables, bent tracks, or rust on springs and panels. Frayed cables are a significant safety hazard as they are under extreme tension and can snap without warning.

- Door Imbalance: A properly balanced door should stay in place when opened halfway (with the opener disengaged). If the door slams shut or flies open, the springs are no longer correctly counterbalancing its weight and require immediate professional adjustment.

For example, at a busy logistics facility in Oakville, a forklift might accidentally strike a door track. While it may seem like a minor dent, this damage can misalign the entire system, causing rollers to pop out and the door to jam, halting all loading and unloading activities for that bay.

By training your team to listen for strange sounds and look for these visual cues, you can catch problems early. This proactive approach allows you to schedule a service inspection on your terms, rather than dealing with an emergency that dictates them for you.

What to Expect from an Emergency Commercial Door Repair Service

When a critical loading dock door fails at midnight or a warehouse bay door jams during a storm, every minute of downtime impacts your bottom line. An emergency is a direct threat to your facility’s security, safety, and productivity. Understanding what a top-tier emergency garage door repairs Oakville service provides is key to turning a crisis into a controlled, quickly resolved problem.

A true 24/7/365 response means having a dedicated team ready to act with the urgency your business demands. A skilled technician serves as an emergency responder for your facility: they arrive quickly, diagnose the problem accurately, secure the situation, and implement a lasting fix to restore your operations.

The Emergency Response Process from Start to Finish

From the moment you call, a structured, professional process should begin. A reliable partner ensures the entire experience is defined by clarity and efficiency.

Here’s what that process looks like:

- Immediate Dispatch: Your call is answered by a person, not a machine, who gathers essential details and dispatches a certified technician.

- Technician Arrival and Site Assessment: A fully equipped service vehicle arrives. The technician’s first priority is to secure the site, assess immediate safety hazards, and make the area safe for your staff.

- Transparent Diagnostics: The technician identifies the root cause of the failure, explains the problem in simple terms, outlines the necessary repairs, and provides a clear, upfront quote before work begins.

- On-the-Spot Repair: With service trucks stocked with common parts like springs, cables, and operator components, technicians can often complete the repair in a single visit, minimizing operational disruption.

What Sets a Premier Service Apart

Not all emergency services are equal. The difference between a temporary fix and a reliable, long-term solution lies in the provider’s expertise and commitment to quality.

True emergency service is more than just speed; it’s about delivering precision under pressure. It’s the confidence of knowing that a certified expert is en route who has the tools, the parts, and the knowledge to solve your problem correctly the first time.

Key differentiators include:

- Certified and Trained Technicians: Union-certified and factory-trained technicians possess a deep understanding of complex commercial and industrial door systems.

- Fully Stocked Service Vehicles: Well-prepared trucks eliminate delays, ensuring repairs are completed efficiently.

- Commitment to Safety: Technicians follow strict safety protocols, including lockout/tagout procedures, to protect everyone on site.

- Clear Communication: You are kept informed throughout the process, from the technician’s ETA to the final checks post-repair.

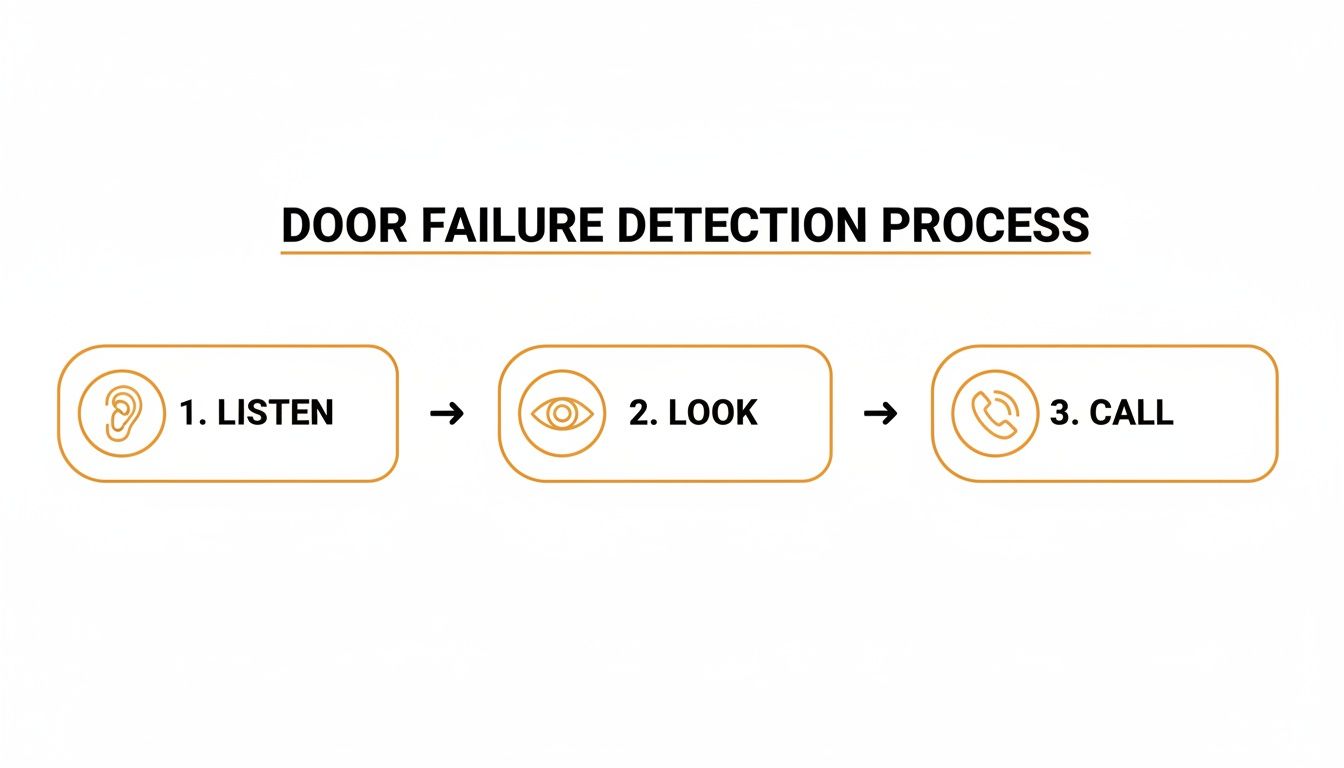

This simple troubleshooting flow helps your team quickly identify when it’s time to bring in a professional.

Teaching your on-site staff to listen, look, and then call ensures that problems are reported quickly, allowing an emergency response team to address the issue before it worsens. For a more detailed look at handling these situations, you can learn more about what to do in our guide on emergency garage door repair. Having a reliable partner like Wilcox Door Service means you have a team that embodies these principles, offering a respected partnership and dependable service when you need it most.

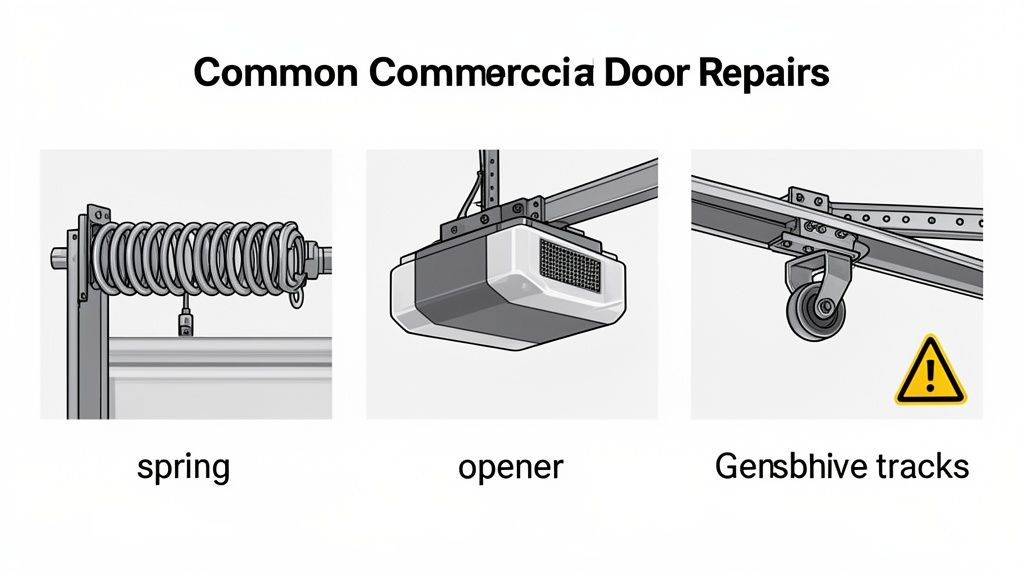

Common Commercial Door Failures and Repair Solutions

Understanding the most common points of failure in heavy-duty commercial doors helps you spot trouble early and communicate effectively with your service team. While these systems seem complex, most breakdowns trace back to a few key components that bear the brunt of daily operations.

Let’s break down the top repair scenarios we encounter, focusing on the workhorses of your door system—the springs, the opener, and the tracks—and explain in simple terms how they fail and what it takes to fix them.

Broken Spring and Cable Replacement

The large torsion springs are the muscles of your commercial door system. They are wound under immense tension to counterbalance the door’s weight, allowing the opener to lift hundreds of pounds of steel. Their lifespan is measured in cycles (one open and one close action). For a busy loading dock, this can mean thousands of cycles per month, leading to metal fatigue.

When a spring breaks, it typically does so with a loud bang, leaving the door as dead weight and halting operations instantly. This is not a DIY repair; it is a hazardous task requiring a professional. A technician will:

- Secure the Door: First, they will secure the door to prevent it from falling.

- Release Tension: Any remaining tension in the spring system is carefully released.

- Replace Components: The broken spring is replaced with a new, high-cycle spring rated for your door’s specific weight, size, and usage.

- Tension and Balance: The new spring is wound to the precise tension required, and the door’s balance is tested to ensure smooth operation and reduced strain on the motor.

A perfectly balanced door should hover in place when opened halfway (with the opener disconnected). This balance is non-negotiable—it drastically reduces strain on the motor and is the single biggest factor in extending the life of the entire system.

Opener and Operator Malfunctions

If the springs are the muscles, the commercial door operator (or opener) is the brain. This powerful motor and its sensitive electronics control the door’s movement and safety features. In industrial settings, these units are exposed to dust, moisture, and power fluctuations.

Common operator problems include:

- Logic Board Failure: The internal circuit board can fail due to a power surge or age, causing erratic behaviour or a complete lack of response.

- Motor Burnout: An unbalanced door forces the motor to work harder, causing it to overheat and fail prematurely.

- Worn Gears and Sprockets: The mechanical parts that drive the door wear down over time, resulting in grinding noises and eventual failure.

Technicians diagnose both electrical and mechanical systems to pinpoint the failure and replace the specific faulty component, whether it’s the logic board or the entire motor.

Track and Roller Damage

The tracks guide the door, and the rollers allow it to move smoothly. In a busy Oakville warehouse, it’s common for a forklift or pallet jack to strike a door track. Even a minor impact can bend the track, jamming the door or, in a worst-case scenario, causing it to come off its tracks—a major safety hazard. Rollers also wear out, creating loud, grating noises and stressing the opener.

A technician will assess the damage. A minor bend may be repairable, but significant damage requires replacing the track section to ensure safe operation. Worn-out rollers are swapped for new, heavy-duty ones designed for high-cycle commercial environments.

Breakdown of Common Commercial Door Repairs

Here is a quick overview of the most frequent repairs, their industrial causes, and what to expect.

| Repair Type | Common Industrial Causes | Signs of Failure | Repair Complexity |

|---|---|---|---|

| Spring & Cable Replacement | High cycle counts, metal fatigue, corrosion from moisture. | Loud bang, door won’t open or is extremely heavy, visible gap in the spring. | High – Requires specialized tools and training due to extreme tension. |

| Opener & Operator Repair | Power surges, lifting an unbalanced door, worn internal gears, environmental dust/moisture. | Door is unresponsive, moves erratically, or makes humming/grinding noises. | Moderate to High – Involves diagnosing both electrical and mechanical systems. |

| Track & Roller Damage | Forklift or equipment impact, lack of lubrication, rust, normal wear and tear. | Door is jammed, moves unevenly (shudders), or has come off its tracks. | Low to Moderate – Minor bends can be straightened; major damage requires track replacement. |

Acting quickly on these issues prevents small problems from escalating. For expert diagnostics and reliable service, contact Wilcox Door Service to schedule an inspection.

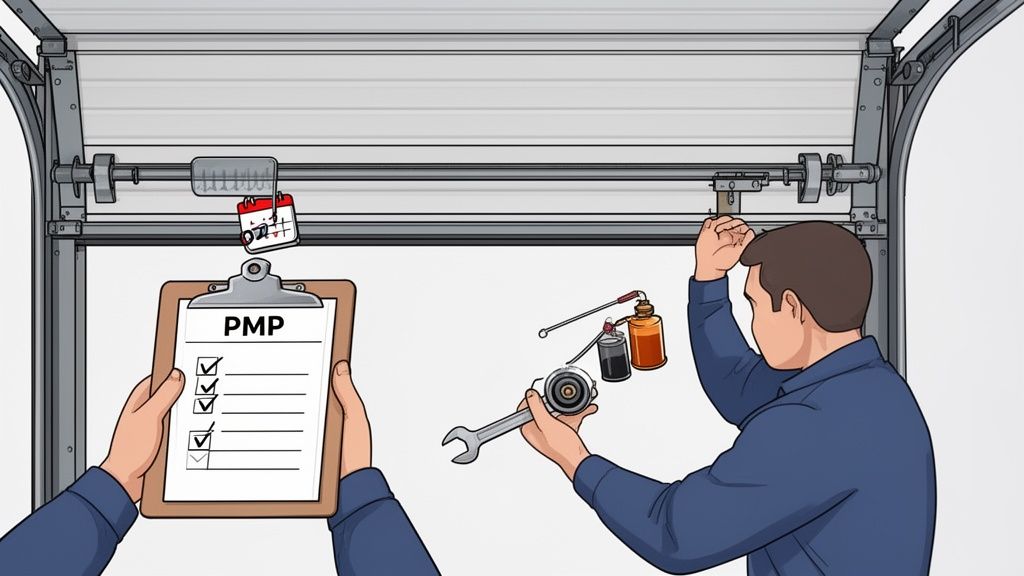

Shifting from Reactive Repairs to Proactive Maintenance

The most effective way to handle garage door repairs in Oakville is to prevent them from happening. For any facility manager, shifting from a reactive “fire-fighting” approach to a proactive maintenance strategy is the single best way to reduce costs, eliminate downtime, and ensure smooth operations. A Planned Maintenance Program (PMP) acts as a regular health check-up for your facility’s hardest-working assets, catching minor issues before they become major failures.

This is a strategic business decision. An unexpected door failure can halt operations, create costly delays, and pose serious safety risks. Investing in scheduled upkeep is an investment in operational reliability.

What a Comprehensive PMP Includes

A robust Planned Maintenance Program is a detailed, systematic process performed by a certified technician to keep your door systems in peak condition.

A typical PMP visit includes:

- Thorough Lubrication: All moving parts—rollers, hinges, bearings, and springs—are lubricated to reduce friction and prevent premature wear.

- Component Inspection and Adjustment: Technicians inspect critical parts like cables for fraying, rollers for wear, and tracks for damage, making on-the-spot adjustments.

- Balance and Tension Checks: The technician ensures the door is perfectly balanced to prevent excessive strain on the opener.

- Safety Feature Testing: Essential safety mechanisms like photo-eyes and reversing edges are tested to confirm they function correctly and meet all safety standards.

- Fire Door Drop Testing: For facilities with fire-rated doors, this mandatory annual test ensures the door will close automatically in an emergency, a critical part of your building’s life safety system.

The Real-World Impact of Proactive Maintenance

The value of a PMP is best illustrated with a real-world example. An Oakville logistics company was experiencing frequent loading dock door failures, leading to costly emergency calls and significant downtime. After implementing a Wilcox PMP, their situation transformed.

Over the next year, the company saw a 90% reduction in emergency repair calls and experienced zero operational downtime from door failures during their peak season. This small, predictable investment in maintenance delivered a massive return by ensuring their shipping and receiving operations flowed uninterrupted.

Proactive maintenance dramatically extends the life of your commercial doors. This approach is a best practice in other commercial sectors as well, such as the strategies found in commercial roof maintenance programs that protect assets. The principle is the same: consistent care protects your investment and prevents expensive emergencies. This aligns with our guide on the importance of maintenance on your garage door.

Ultimately, a PMP is more than a service—it’s a partnership in reliability. To see how a customized maintenance plan could benefit your Oakville facility, contact Wilcox Door Service for a complimentary assessment.

Choosing Your Trusted Partner for Oakville Commercial Door Services

When it comes to commercial garage door repairs in Oakville, selecting the right service provider is as critical as the repair itself. When a door fails, you are placing your facility’s safety, security, and operational continuity in their hands.

Your choice of partner determines whether you receive a lasting solution or a temporary patch destined to fail again. You need a team that understands the pressures facility managers face, communicates clearly, and has the experience to solve the problem correctly the first time.

The Wilcox Standard: Respected Partners, Reliable Service

For over a century, Wilcox Door Service has been that trusted partner for businesses in Oakville and beyond. Our approach is built on a simple promise: Respected Partners, Reliable Service. This isn’t just a tagline; it’s the standard we uphold on every job.

We deliver on this commitment through several key pillars:

- 24/7/365 Emergency Response: We operate a true, around-the-clock service. When you call, we dispatch a certified technician immediately to minimize downtime and secure your facility.

- Union-Certified Expertise: Our technicians are career professionals who undergo continuous, rigorous training. Their union certification guarantees a high level of skill and safety awareness.

- Deep Local Knowledge: We understand Oakville’s specific building codes and industrial requirements, ensuring every job is compliant and completed to the highest standard.

When you work with an established industry leader, you’re getting more than just a repair service. You get the peace of mind that comes from knowing the critical access points to your facility are managed by experts who are dedicated to keeping your business running smoothly and safely.

Beyond the Repair: A Commitment to Your Operations

Selecting a service provider should involve vetting their reputation, response time, and qualifications, much like the best practices for finding electric gate repair services. The principles of verifying credentials and seeking proven reliability are universal.

At Wilcox, we focus on providing long-term value that supports your operational goals. We don’t just fix what’s broken; we identify underlying causes to prevent future failures. This proactive approach helps you maximize the life of your equipment and lower your total cost of ownership, transforming a vendor transaction into a true partnership.

From emergency repairs to our comprehensive Planned Maintenance Programs, our mission is to keep your Oakville facility secure, efficient, and fully operational.

Your Questions Answered: Commercial Door Repair in Oakville

When your facility’s doors are down, you need answers fast. Here are some of the most common questions we get from facility managers across Oakville about commercial door repairs.

What’s a Realistic Emergency Response Time?

For a genuine 24/7 emergency service, a technician should be dispatched immediately after your call. In most cases around Oakville, our team can be on-site within a few hours, depending on traffic and call volume. Our first priority is always to secure your facility, then diagnose the problem to get you operational again.

How Long Do Commercial Door Parts Actually Last?

Lifespan depends heavily on usage. A high-cycle torsion spring at a busy distribution centre might last only a few years, while the same spring on a rarely used door could last over a decade.

Here are some general estimates:

- Torsion Springs: Rated for a specific number of cycles, typically from 10,000 to 100,000. A high-traffic door can exceed 10,000 cycles in under a year.

- Rollers: Standard steel rollers generally require replacement every 3-5 years. Upgrading to nylon rollers provides a longer and quieter service life.

- Openers: A well-maintained commercial operator can easily last 10-15 years. However, an operator constantly lifting an unbalanced door will have a significantly shorter lifespan.

What’s the Real Difference Between Commercial and Residential Doors?

While they both open and close, the similarities end there. Commercial systems are engineered for durability and high-frequency use in demanding environments.

Commercial doors are engineered for performance and endurance, not just access. They use heavier gauge steel, more robust hardware, and powerful operators designed to withstand the demanding environment of an industrial or commercial setting.

They also incorporate specialized features not found on residential doors, such as high-speed operators, advanced safety edges, and components designed to meet fire code regulations. Using the correct, commercial-grade parts for garage door repairs in Oakville is essential for safety and long-term reliability.

For a partner that understands the unique demands of your commercial facility, trust Wilcox Door Service Inc. to deliver reliable service and expert solutions. Contact us today to schedule a service or learn more about our maintenance programs.