Choosing the right security for your facility can feel complex, but magnetic locks for doors offer a powerful, reliable, and surprisingly simple solution for commercial and industrial properties. Unlike traditional locks with moving parts that can wear out, these devices—often called maglocks—use the force of an electromagnet to secure an entry point with incredible strength. This guide will walk you through everything a facility manager, contractor, or property owner needs to know, from the basic science to practical installation and code compliance.

In this article, you will learn:

- The core principles of how magnetic locks work.

- The critical difference between fail-safe and fail-secure systems for life safety.

- How to decode technical terms like "holding force" to choose the right lock.

- The importance of professional installation and integration with access control systems like keypads and card readers.

- How to ensure your system complies with Canadian fire codes and egress regulations.

alt="A magnetic lock for doors installed on a double glass entrance with a keypad for secure access control."

How Magnetic Locks Create a Secure Bond

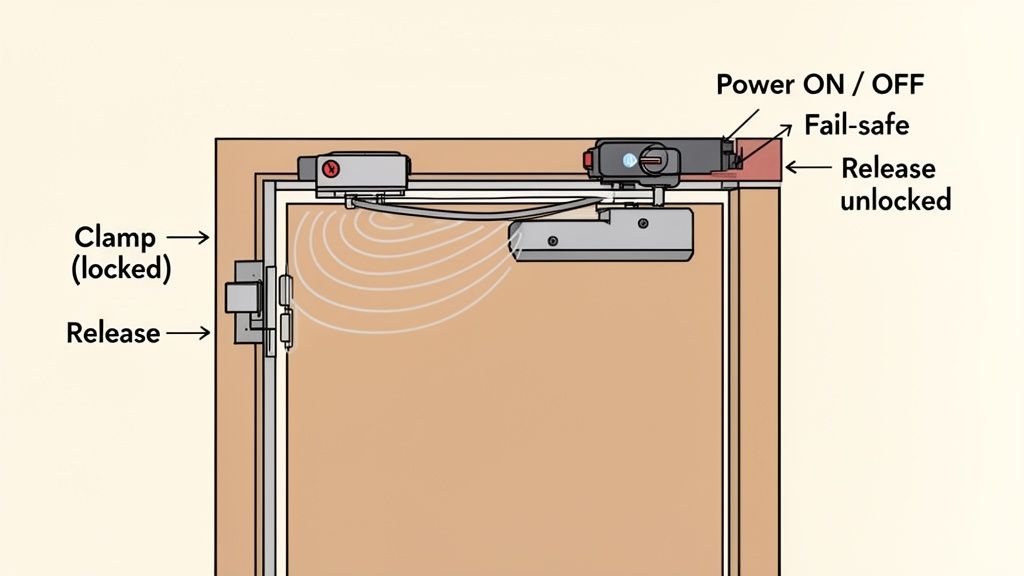

At its heart, a magnetic lock is a brilliantly simple yet incredibly powerful device. Think of it as a super-strong magnet you can switch on and off instantly. The system consists of two main components: an electromagnet mounted on the door frame and a steel armature plate fixed to the door.

When an electrical current is supplied, the electromagnet creates a powerful magnetic field that pulls the armature plate tight, locking the door with immense force. To unlock it, the power is simply cut. The magnetic field disappears, and the door is released. This elegant design has no moving parts to wear out or jam, making electromagnetic door locks exceptionally durable and reliable.

alt="Diagram showing the components of an electromagnetic door lock, including the electromagnet and armature plate."

This reliance on electricity leads to its most important safety feature. Because the lock needs power to stay locked, it is inherently "fail-safe." In simple terms, if the building loses power, the lock automatically unlocks. This is a non-negotiable requirement for emergency exits, ensuring people can always evacuate safely during a fire or other crisis.

Two Primary Designs for Commercial Doors

When you explore magnetic locks, you’ll find they come in two main types, each suited for different applications and aesthetic needs.

- Surface-Mounted Maglocks: This is the workhorse of the magnetic lock world. The electromagnet is mounted directly onto the surface of the door frame, making it visible. It’s the standard choice for most commercial and industrial doors, such as those on loading docks or server rooms, due to its rugged strength and straightforward installation.

- Shear Maglocks: For applications where aesthetics are as important as security, the shear lock is the perfect solution. This type is mortised (recessed) into the door and frame, making it completely hidden when closed. It works by resisting a shearing or sliding force, delivering a clean look popular in modern offices.

A properly implemented magnetic lock system does more than just secure a door; it enhances operational efficiency, ensures compliance with building codes, and protects your most valuable assets. As your respected partners, Wilcox Door Service brings reliable service and expertise to every project.

The demand for these reliable security devices is climbing fast. Canada's magnetic door lock market is seeing major growth, as part of a North American market that holds 34% of the global share. That means significant investment in the region, with commercial use booming due to security needs in retail, hospitality, and industrial sites like the ones Wilcox Door Service supports. You can review the full market research about Canada's segmented growth to see how it's shaping facility security.

Decoding Key Technical Specifications

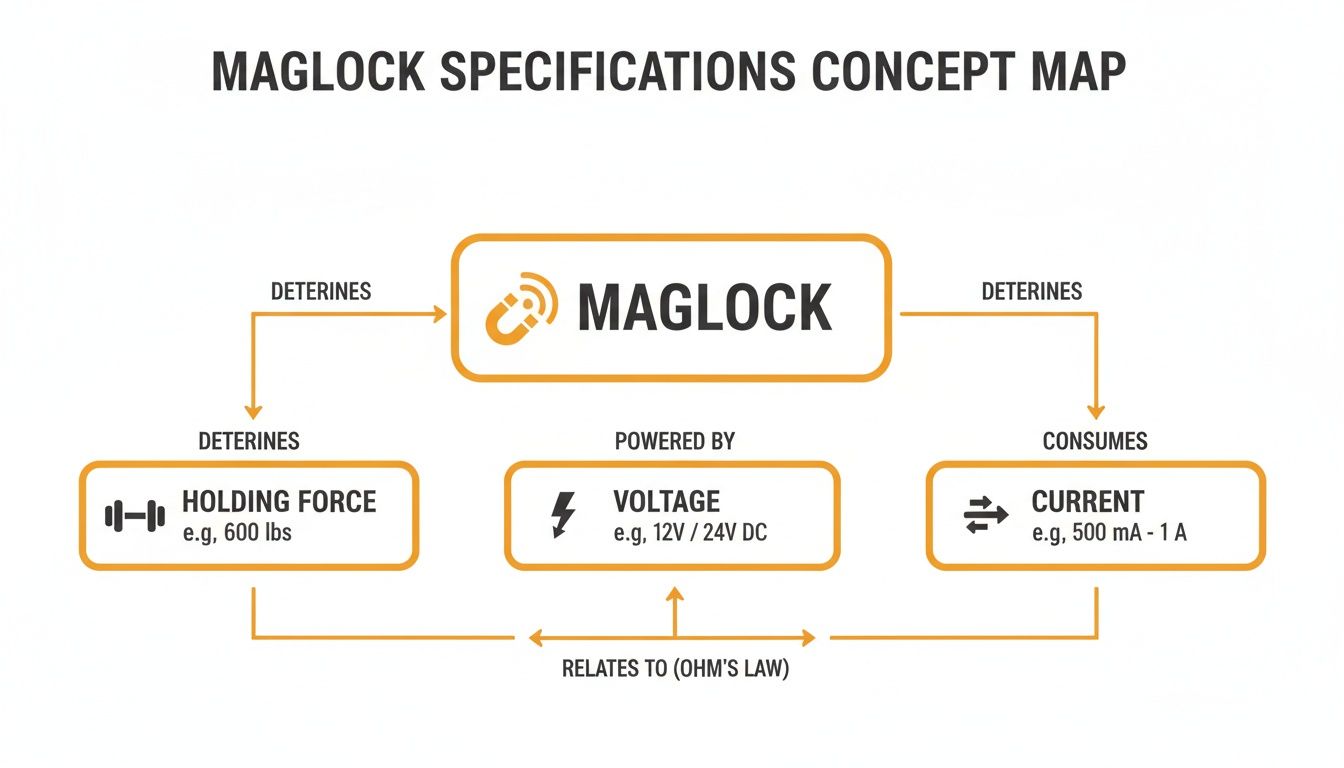

Choosing the right magnetic lock isn't guesswork. It's about understanding what a few key numbers on the spec sheet mean for your building's security. Let’s translate the technical jargon into practical knowledge you can use.

The most important specification is holding force. Simply put, this measures how much direct pulling force the lock can withstand before it breaks open. Measured in pounds (lbs) or kilograms (kg), it is a direct indicator of the lock's strength. A bigger number means a stronger lock.

Matching Holding Force to Your Door

Not every door needs a fortress-grade lock. The key is to match the lock’s strength to the door’s function and security risk. This ensures critical entry points are secure without overspending on unnecessary hardware.

For example, a heavy exterior steel door on a warehouse loading dock is a prime target for a brute-force attack. That door requires a high holding force—typically 1,200 lbs (around 544 kg) or more—to be an effective deterrent. In contrast, an interior office door can be perfectly secured with a lighter-duty maglock.

A common mistake is thinking every door needs maximum security. A 600 lb lock is often the perfect fit for low-risk interior doors, while a 1,200 lb lock is the standard for protecting high-value areas like server rooms or pharmaceutical storage.

Matching Holding Force to Your Door Application

This table provides a starting point for pairing the right maglock strength with your specific commercial doors.

| Door Type / Application | Typical Environment | Recommended Holding Force (lbs) | Key Consideration |

|---|---|---|---|

| Interior Office Door | Low-security, controlled access | 300 – 600 lbs | Balancing security with cost for a large number of doors. |

| Server Room or IT Closet | High-security, critical assets | 1,200 lbs | Protecting sensitive data and equipment from unauthorized access. |

| Main Entrance (Glass/Aluminum) | Medium-security, high traffic | 600 – 1,200 lbs | Must be strong enough to deter entry but integrates with access control for frequent use. |

| Warehouse or Loading Dock Door | High-security, perimeter access | 1,200 – 1,800 lbs | Provides robust defence against brute force entry attempts on heavy-duty doors. |

Understanding the Electrical Requirements

Beyond physical strength, maglocks have specific power needs. Understanding these is crucial for proper performance. The two main electrical specs are voltage and current.

-

Voltage (V): This is the electrical "pressure" that powers the electromagnet. Most maglocks are dual-voltage, designed to run on either 12V DC or 24V DC (Direct Current). Running locks at 24V DC is often better for long wire runs, as it helps prevent voltage drop, ensuring the lock receives consistent power and achieves its full holding force.

-

Current (A): This measures how much power the lock consumes, measured in Amperes (A) or milliamperes (mA). Knowing the current draw is critical for ensuring your power supply can handle the load. For example, if you have ten 600 lb locks that each draw 500mA (0.5A) at 12V, your power supply must deliver at least 5A (10 locks x 0.5A).

For more context on how security hardware fits into the bigger picture, our guide on fire door ratings is a great resource.

Installation and Access Control Integration

A high-quality magnetic lock provides the muscle, but its true value comes from a professional installation and smart integration with your building's access control system. Proper mounting is what allows the lock to achieve its full holding force, while correct wiring transforms it into an intelligent security tool.

The process requires precision, an understanding of different door types, and the right hardware to create a perfectly flush connection between the electromagnet and the armature plate.

Mounting Magnetic Locks Correctly With Brackets

Commercial doors come in many shapes and sizes, and their installations must be just as varied. Specialized brackets are essential for a secure fit on doors that swing in or out, and those made of wood, hollow metal, or framed glass.

- L-Brackets: Used for out-swinging doors, an L-bracket provides a perpendicular mounting surface for the electromagnet on the door frame header.

- Z-Brackets: Used with an L-bracket for in-swinging doors, the "Z" shape positions the armature plate perfectly to meet the magnet.

- U-Brackets: Designed for frameless glass doors, a U-bracket clamps onto the glass without drilling, providing a solid anchor for the armature plate.

Using the wrong bracket—or no bracket at all—leads to poor alignment. This creates a gap between the magnet and plate, which drastically reduces holding force and compromises your security.

alt="Concept map for magnetic locks for doors, showing how voltage and current affect holding force."

Integrating With Your Access Control System

The true power of magnetic locks for doors is unlocked when wired into an access control panel. This integration allows the lock to work with other devices to manage who enters, when, and how they exit.

A typical integrated setup includes:

- The Power Supply: Provides low-voltage DC power (12V or 24V) to keep the electromagnet energized.

- The Access Control Reader: A card reader, keypad, or biometric scanner that sends a signal to the control panel when an authorized credential is presented.

- The Control Panel: The system's brain. It validates the credential and momentarily cuts power to the magnetic lock, allowing entry.

- Request-to-Exit (REX) Devices: Buttons or motion sensors inside the door that signal the control panel to release the lock for safe egress.

Imagine a loading dock door at a distribution centre. Its maglock is tied into the security panel to log every entry, restrict access after hours, and automatically unlock the second a fire alarm is triggered. That's the power of a fully integrated system.

The same principles of access control apply to other entry points, like automatic gates for driveways. This concept is also at the core of how an automatic door operator works, linking door activation with crucial safety protocols. Ultimately, a professional installation ensures every component is wired for dependable, safe operation, which is a cornerstone of our reliable service promise.

Navigating Canadian Fire Codes and Egress Rules

When securing commercial doors, compliance with the National Building Code of Canada (NBC) and provincial fire codes is non-negotiable. For magnetic locks for doors, these regulations are all about life safety—ensuring everyone can exit your building quickly and safely in an emergency.

An improperly installed magnetic lock can turn from a security asset into a dangerous liability during a fire. This is why professional installation is not just recommended, but essential.

The Fail-Safe Mandate for Egress Doors

The number one rule for maglocks on any emergency exit path is the fail-safe requirement. As explained earlier, a fail-safe lock unlocks when it loses power. For most egress doors, this is a mandatory function that ensures exits remain usable during a power outage.

Consider a fire alarm in an office building. The fire alarm control panel (FACP) must instantly cut power to all magnetic locks on designated emergency exits. This immediate release allows for a smooth evacuation—a core principle of Canadian building codes.

Any delay in that process could have devastating consequences. That's why directly integrating the magnetic lock system with the building's fire alarm panel isn't just best practice—it's a life-saving function required by law.

Key Code Requirements for Magnetic Lock Installations

Beyond the fail-safe principle, the NBC specifies how electromagnetic door locks must function on egress routes to ensure unlocking is intuitive and immediate.

Key compliance points include:

- A Clear Unlocking Device: An obvious push-button, touch sensor, or panic bar must be located near the door. It must be clearly marked and instantly cut power to the maglock, overriding the access control system.

- Independent Operation: This request-to-exit device must work independently from the main access control reader. No one should need a key card or code to get out in an emergency.

- Fire Alarm Integration: The lock must be wired to release automatically when the building's fire alarm system is activated.

Strict building codes, enforced by bodies like the National Building Code of Canada (NBC), require fail-safe electromagnetic locks for fire-rated doors and emergency exits. In Ontario alone, over 15,000 commercial buildings retrofitted mag locks to comply with updated NBC Section 3.4 on egress doors, which led to a 28% reduction in unauthorized access incidents, according to provincial safety reports.

Before any installation, it’s vital to consult local authorities and review resources for understanding general building codes and regulations. You can also learn more from our guide on how fire door ratings impact overall compliance.

Maintaining Your Magnetic Locks for Long-Term Reliability

Even the most durable hardware needs routine care. Think of your magnetic locks for doors like any other critical equipment in your facility—they need regular attention to deliver the reliable security you depend on. A simple maintenance plan is your best defense against unexpected failures.

Proactive checks are straightforward and essential for preserving the lock's core function: a perfect, uninterrupted bond between the magnet and the armature plate. This prevents minor issues from becoming major security headaches.

Your Practical Maintenance Checklist

Regular inspections can catch potential problems early. A consistent schedule is a key benefit we also cover in our guide to planned garage door maintenance programs.

Incorporate these steps into your facility’s routine checks:

- Clean Contact Surfaces: Gently wipe the electromagnet face and armature plate surface with a soft, non-abrasive cloth. Dust, grime, or rust can create a gap that weakens the lock's holding force.

- Check for Secure Mounting: Firmly wiggle the magnet and plate. Are they solidly attached? Loose hardware is a common cause of buzzing sounds and weakened security.

- Verify Electrical Connections: Inspect all wiring for corrosion, frayed wires, or loose terminals that could interrupt power flow.

- Test the Power Supply: Occasionally, use a multimeter to check the voltage at the lock. It should be a steady, correct level (usually 12V or 24V DC).

Troubleshooting Common Maglock Issues

When a maglock acts up, the issue is usually related to power, alignment, or a physical obstruction. Here’s a quick guide to fixing common problems.

A buzzing sound from a maglock is almost always a red flag. It usually means the magnet and armature plate aren't making full, solid contact. This creates vibrations as the magnetic field tries to bridge the gap.

Here’s how to tackle the most frequent issues:

-

Issue: The Lock is Buzzing or Humming

- Probable Cause: This signals a poor connection, often due to bad alignment, a loose armature plate, or debris on the contact surfaces.

- Solution: First, clean both surfaces. Next, check that the armature plate has a tiny bit of "float" to align perfectly with the magnet. Finally, verify the lock is receiving the correct voltage.

-

Issue: The Door Fails to Lock

- Probable Cause: This is almost always a power problem, such as a complete power loss, a cut wire, or an issue with the access control system.

- Solution: Use a multimeter to confirm power is reaching the lock. Trace the wiring for damage and ensure the access control panel is functioning correctly.

For tricky electrical problems or physical repairs, it’s best to rely on the certified technicians at Wilcox Door Service to provide the "Respected Partners, Reliable Service" you can count on.

Frequently Asked Questions About Magnetic Locks

As experts in commercial and industrial door solutions, we often receive questions about maglocks. Here are straightforward answers to some of the most common inquiries.

Are Magnetic Locks More Secure Than Traditional Locks?

They offer a different, often stronger, type of security. A quality maglock with a 1,200 lb holding force is significantly more resistant to brute force than a standard mechanical lock because there are no moving parts to pick or break.

However, the key difference is how they behave without power. A standard maglock is "fail-safe" (unlocks when power is cut), while an electric strike is typically "fail-secure" (stays locked). The best choice depends on the door's purpose. For an emergency exit, a fail-safe maglock is required by code. For a high-value server room, a fail-secure option or a maglock with a battery backup is the more secure solution.

What Happens to a Magnetic Lock During a Power Outage?

A standard magnetic lock unlocks instantly when power is cut. This is a critical safety feature known as a fail-safe mechanism, mandated by fire codes for emergency exits to ensure escape is always possible.

For high-security areas that must remain locked, such as a data centre, the system should be connected to an Uninterruptible Power Supply (UPS) or a battery backup. This keeps the door secure during an outage while still integrating with the fire alarm system for code compliance.

How Much Maintenance Do Magnetic Locks Require?

Magnetic locks are incredibly durable due to their lack of moving parts, but they aren't completely maintenance-free. Simple routine tasks go a long way.

The single most important maintenance task is regularly wiping down the surfaces of the magnet and armature plate. Dust or grime can create a barrier that weakens the magnetic bond and reduces holding force.

It’s also wise to periodically check that all mounting hardware is tight and electrical connections are secure. Including your maglocks in a planned maintenance program is the best way to ensure they function perfectly day in and day out.

Can Magnetic Locks Be Installed on Any Type of Door?

Yes, for the most part. Their versatility is a major advantage. Maglocks can be fitted to nearly any commercial door, including hollow metal, solid wood, and framed glass. The key to a solid installation is using the right mounting hardware.

A range of specialized brackets—L-brackets, Z-brackets, and U-brackets for glass doors—are designed for different door frames and swing directions. A professional installer will select the exact bracket kit needed for a perfect, secure fit, ensuring maximum holding force.

Your facility's security and code compliance are too important to leave to chance. As your Wilcox Door Service Inc. partners, we bring the expertise needed to design, install, and maintain the right magnetic lock solutions for your property.