This guide offers a clear, practical overview of steel fire rated doors for Canadian facility managers. You will learn what these essential safety systems are, how to decode their fire ratings, and how to choose the right door for your specific industry—from warehouses to hospitals. We'll also cover the non-negotiable requirements for professional installation, maintenance, and navigating Canadian fire codes to ensure your facility is both safe and compliant.

The Essential Role of Steel Fire Rated Doors in Facility Safety

Alt text: A grey steel fire rated door assembly with a 90-minute fire resistance rating label, symbolizing facility safety and compliance.

In any commercial or industrial facility, steel fire rated doors are the unsung heroes of fire protection. While a standard door simply provides access, a fire-rated door is an engineered safety system designed to create a fire-resistant barrier. Its main job is a strategy known as compartmentalization.

In simple terms, compartmentalization means dividing your facility into smaller, sealed sections. Think of it like a submarine with multiple watertight compartments; if one area floods, the hatches are sealed to save the entire vessel. In a fire, these doors automatically seal off the affected "compartment," which helps starve the fire of oxygen and stops it from spreading rampantly through the building.

This containment strategy buys precious, life-saving time. It allows personnel to evacuate safely and gives emergency responders a crucial window to arrive and manage the situation. The entire purpose of a fire-rated door is to maintain the integrity of a fire-rated wall wherever there's an opening for people or equipment to pass through.

To put it simply, here are the fundamentals you need to know.

Quick Look at Steel Fire Rated Door Fundamentals

| Concept | Simple Explanation | Why It Matters for Your Facility |

|---|---|---|

| Compartmentalization | Dividing a building into smaller, fire-resistant sections using fire-rated walls and doors. | It contains a fire to its point of origin, preventing it from spreading and causing catastrophic damage. A practical example is a fire door separating a warehouse from the main office block. |

| Passive Fire Protection | Building components (like fire doors and walls) that help contain a fire without any active intervention. | Unlike sprinklers (active protection), these systems work automatically to limit fire spread, providing a fundamental layer of safety. |

| Fire Resistance Rating | The amount of time (e.g., 20, 45, 60, 90 minutes) a door assembly can withstand a fire test. | The rating must match the wall's rating to ensure the entire barrier works as intended during an emergency. |

| Complete Assembly | The door, frame, hardware (hinges, latches), and seals must all be fire-rated and work together. | A fire-rated door is only as strong as its weakest link. If one component fails, the entire barrier can fail. |

Understanding these basics is the first step toward creating a truly resilient and safe facility, not just a compliant one.

Why Steel Construction is Critical

Steel is the material of choice for these doors for a few key reasons: its incredible strength, durability, and high melting point. When exposed to extreme heat, other materials can warp, burn through, or completely fail. A properly constructed steel door, on the other hand, maintains its shape and structural integrity, ensuring the fire barrier stays intact when it matters most.

This toughness is especially important in demanding environments like loading docks, warehouses, or manufacturing plants, where doors must also stand up to the daily grind of impacts from carts, equipment, and heavy foot traffic.

The market reflects a growing reliance on these robust safety measures. In Canada, demand for fire doors is on the rise as safety regulations become more stringent. It's estimated that over 90% of commercial buildings now have at least one fire-rated door to comply with the National Building Code of Canada (NBC), a measure that can slash the risk of fire spread by up to 70%. You can discover more about the Canadian fire door market trends to see what's driving this growth.

Core Functions of a Fire-Rated Door System

A steel fire-rated door is much more than just a slab of metal; it’s a complete, engineered system where every component has a critical job. This system, often called an "assembly," includes:

- The Door and Frame: The core components, built and tested to resist fire for a certified amount of time.

- Hardware: Every piece, from the hinges and latches to the closing devices, must also be fire-rated to ensure it won't fail under intense heat.

- Seals: These often include intumescent strips, which look like simple weatherstripping but expand dramatically when heated, sealing the gaps around the door to block toxic smoke and gases from passing through.

Getting a handle on these components is the first step toward ensuring your facility isn't just compliant, but genuinely protected. As "Respected Partners, Reliable Service," we at Wilcox Door Service believe that an informed facility manager is the best defense against risk. For more on this, explore our insights on choosing the right hollow metal doors for your specific operational needs.

Decoding Fire Ratings and Testing Standards

Fire ratings on steel fire rated doors can seem technical, but they're your most direct guarantee of safety and compliance. These ratings aren’t arbitrary numbers; they are a certified promise of how a door will perform under the most intense conditions. Understanding them is the first step in properly protecting your facility.

Simply put, a fire rating tells you exactly how long a door assembly is built to withstand fire and smoke. So, when you see a door labelled as "90-minute rated," it means it has undergone rigorous testing to prove it can hold back flames and contain extreme heat for at least an hour and a half, maintaining the integrity of the fire barrier.

This whole idea is the foundation of compartmentalization, the strategy of dividing a building into fire-contained zones. As a real-world example, consider the door between an underground parking garage and a building's main lobby. That door is a critical fire barrier, designed to stop a vehicle fire from spreading into occupied spaces.

Understanding Fire Resistance Ratings

That containment buys you precious time—time for people to evacuate safely and for first responders to arrive and take control. The specific rating you'll need depends entirely on the fire resistance of the wall it’s being installed in. For the barrier to work, the door’s rating has to complement the wall's rating.

You'll commonly see these fire ratings on door labels:

- 20-Minute Rating: Often found on doors in corridors or separating an office from a main facility area.

- 45-Minute Rating: Typically required for room partitions and certain corridor separations.

- 60-Minute (1-Hour) Rating: Common for protecting openings in fire barriers that separate different occupancies inside a building.

- 90-Minute (1.5-Hour) Rating: Frequently used for stairwell doors and openings in walls that divide major building areas.

- 3-Hour (180-Minute) Rating: The highest rating, reserved for openings in critical fire walls that divide a building into completely separate fire areas.

A fire door isn’t just a slab of steel; it's an engineered system. Every single component—the door, frame, latch, and hinges—is tested together. If even one piece of hardware isn't rated correctly, the fire resistance of the entire assembly is compromised. This is why professional specification and installation are absolutely non-negotiable.

The Role of Canadian Testing Standards

For a steel fire rated door to earn its label here in Canada, it has to survive brutal testing protocols set by accredited organizations. These tests aren't theoretical; they simulate real-world fire scenarios, subjecting the door assembly to temperatures that can climb past 1,000°C.

The main standards bodies you'll run into are:

- Underwriters Laboratories of Canada (ULC): This is the key certification body in Canada. A ULC label is your guarantee that the door has met the tough requirements of standards like ULC-S104, the "Standard Method for Fire Tests of Door Assemblies."

- National Building Code of Canada (NBC): This code lays out the minimum requirements for where fire-rated doors are needed and what their ratings must be, all based on the building's use and construction. It directly references standards like ULC-S104 to ensure everything lines up.

For facilities like warehouses and hospitals, these standards are everything. In fact, steel doors providing 1-hour protection (EI 60 ratings) are especially critical in many commercial settings, a segment projected to capture 31.2% of global revenue share by 2025. You can discover more insights about the fire door market and how it's shaping facility planning.

By understanding what these labels and ratings really mean, you can look at your own facility with confidence. Decoding these standards turns a simple door label into a clear, powerful indicator of your facility's resilience, ensuring you are both prepared and compliant.

Choosing the Right Steel Fire Door for Your Application

Picking the right steel fire-rated doors isn't a one-size-fits-all decision. The demands of a bustling airport terminal are a world away from a sterile pharmaceutical lab, and the fire doors in each space need to reflect those unique realities. Making the right choice ensures you’re not just compliant, but that your doors also support operational efficiency and long-term durability.

A common misstep is focusing on the fire rating alone while forgetting about the door's daily job. For example, a heavy-duty rolling steel fire door is perfect for a high-traffic loading dock where durability is paramount. However, it would be completely out of place in a hospital corridor where quiet, easy access for staff and patients is the priority.

The key is to strike a balance between life-safety requirements and the facility's day-to-day rhythm. This means looking beyond the rating to consider factors like traffic type (people versus forklifts), frequency of use, environmental conditions, and integration with building systems like access control.

Tailoring Doors to Specific Industries

Every industry presents different challenges. A door that thrives in one environment might fail prematurely in another. Understanding these specific demands is the first step in specifying a door that will last.

Here's a look at how different industries stack up:

- Manufacturing and Warehouses: Durability is king. Doors here must withstand impacts from forklifts, pallet jacks, and heavy carts. Heavy-duty, insulated hollow metal doors or tough rolling steel doors are ideal. Their solid construction resists the dents and dings that could compromise a fire-rated assembly.

- Healthcare Facilities: Hygiene and accessibility are non-negotiable. Doors need smooth, non-porous surfaces that are easy to clean and sanitize. They must also integrate with access control systems and often require hands-free or automatic operators to accommodate staff, patients, and rolling medical equipment.

- Airports and Transit Hubs: These facilities see a relentless flow of people, so doors must be built for high-cycle operation. The operators and hardware have to be exceptionally durable. On top of that, security is a major concern, meaning fire doors must integrate seamlessly with complex security systems without compromising their core life-safety function.

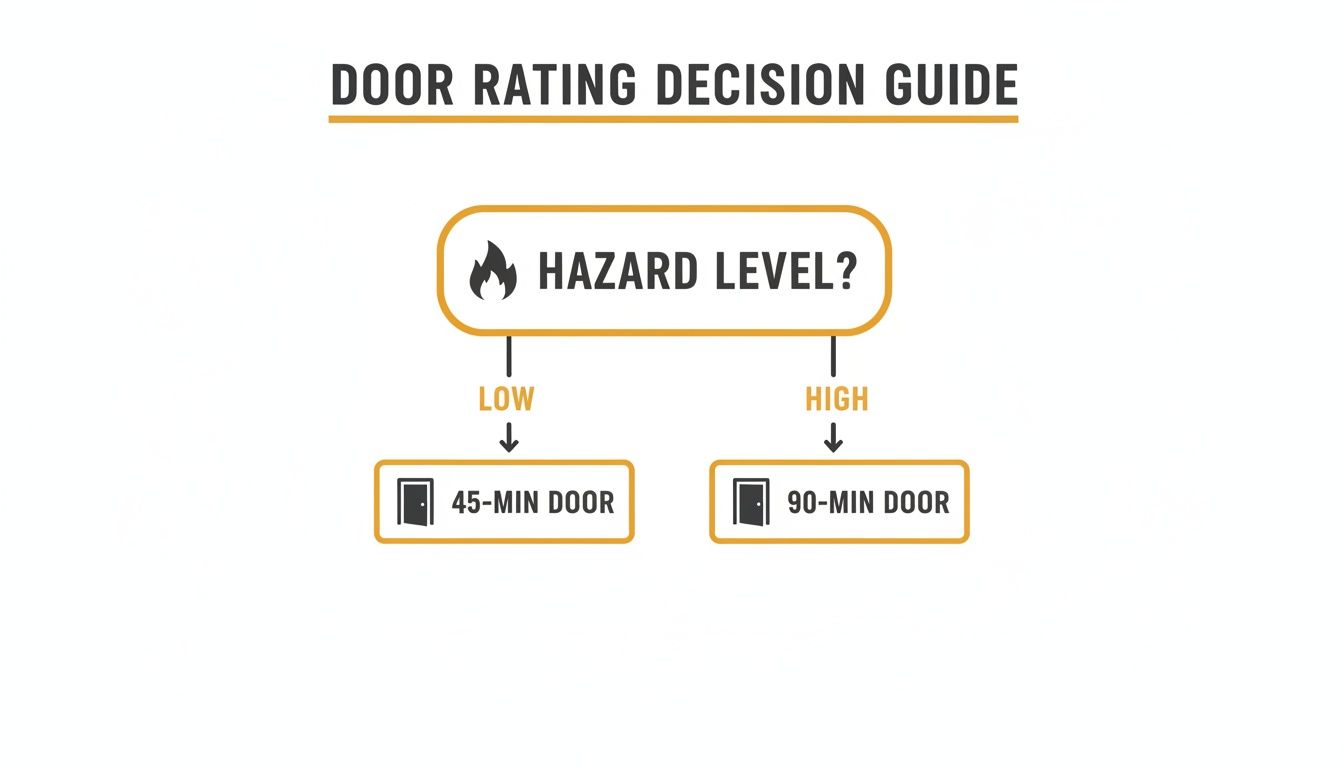

This simple flowchart can help visualize the initial decision-making process, starting with the hazard level of the area you're protecting.

Alt text: A decision guide flowchart for choosing a steel fire rated door, starting with assessing the facility’s hazard level to determine the correct rating.

This guide simplifies a critical first step: matching the door's fire resistance directly to the level of risk in that specific part of your building.

Application-Based Steel Fire Door Selection Guide

To make the selection process clearer, this table breaks down the best choices for different environments. This guide helps connect a facility’s function to the fire door features that will serve it best.

| Facility Type | Common Door Type | Recommended Fire Rating | Key Considerations |

|---|---|---|---|

| Warehouses & Manufacturing | Heavy-Duty Hollow Metal, Rolling Steel | 90-minute to 3-hour | High impact resistance, durability for high-cycle use, ability to withstand abuse. |

| Healthcare Facilities | Flush Hollow Metal, Stainless Steel | 20-minute to 90-minute | Hygienic surfaces, integration with access control, hands-free/automatic operation. |

| Airports & Transit Hubs | High-Cycle Hollow Metal, Rolling Steel | 45-minute to 3-hour | Extreme durability for constant use, security integration, noise reduction. |

| Office Buildings | Standard Hollow Metal, Wood-Grain Steel | 20-minute to 45-minute | Aesthetics, sound control (STC ratings), integration with building security. |

| Educational Institutions | Abuse-Resistant Hollow Metal | 20-minute to 90-minute (stairwells) | Vandalism resistance, hardware durability, compliance with accessibility codes. |

This table provides a solid starting point, but always remember that a site-specific assessment is crucial for confirming the exact requirements based on building codes and your unique operational needs.

Matching Ratings to Real-World Scenarios

Knowing where different fire ratings fit can make a huge difference, not just for safety but for your budget too. A higher rating isn't automatically better if it's not what the code demands for a specific location.

Think about an electrical room. It houses critical infrastructure and poses a high fire risk. Protecting that opening with a 90-minute or 3-hour rated steel door is essential to contain a potential fire and prevent it from spreading throughout the building.

In contrast, a standard office corridor separating administrative areas might only need a 20-minute rated door. This rating provides enough protection to slow down smoke and flames, giving occupants time to evacuate safely, but without the higher cost and heavier build of a 3-hour door. It's this kind of strategic approach that ensures you're investing wisely.

Expert Insight: Always remember the door rating is tied to the wall's rating. You can't just stick a 45-minute door in a 2-hour fire wall and call it a day. The entire assembly—the wall, frame, door, and hardware—has to work as a complete system to create an effective fire barrier.

It's no accident that these doors are so common. In fact, an estimated 90% of commercial buildings in North America, including Canada, have at least one fire-rated door, with steel being the material of choice. This highlights steel's indispensable role in sectors like warehousing and manufacturing, which are projected to make up 42.3% of the fire doors market in 2024, driven by the need for robust compartmentalization.

Ultimately, choosing the right steel fire-rated door is a strategic decision that protects your assets and, most importantly, your people. By taking the time to carefully consider the specific application, you ensure your investment delivers reliable performance and unwavering safety for years to come.

Installation and Maintenance for Lasting Compliance

A steel fire-rated door is a highly engineered safety system, but all that engineering means nothing without proper installation and diligent maintenance. You can have the highest-rated door on the market, but if it’s installed incorrectly, its certification is instantly void. This puts your facility, your assets, and your people at severe risk. Professional installation isn't just a good idea—it's an absolute must for real fire safety and code compliance.

Likewise, Canadian fire codes mandate ongoing maintenance for a reason. A door that works perfectly on day one might not perform a year later without proper care. Think of it this way: the annual inspection and drop test is a mandatory "fire drill" for your door. It’s a planned event designed to guarantee it will perform flawlessly during an unplanned emergency.

Alt text: A certified technician conducting a professional inspection on a steel fire rated door frame to ensure code compliance and safety.

Why Professional Installation is Non-Negotiable

Installing a fire-rated door assembly is a job of precision, governed by strict standards like NFPA 80. Unlike a standard door, every single component—from the frame and hinges to the latching hardware and seals—must be installed exactly according to the manufacturer’s specifications and code. A certified technician knows they aren't just hanging a door; they're creating a complete, sealed barrier.

Even small installation mistakes can lead to catastrophic failure. Common ones include:

- Improper Gapping: The clearance between the door and the frame is precisely defined, usually around 1/8th of an inch. If the gaps are too large, smoke and flames can get through. Too small, and the door can bind when heated by a fire, preventing it from latching shut.

- Using Non-Compliant Hardware: Every piece of hardware—hinges, closers, locks—must also be fire-rated and listed for use with that specific door assembly. Swapping in a standard hinge or lock completely compromises the entire system.

- Incorrect Frame Anchoring: The frame must be anchored securely to the surrounding wall. A poorly anchored frame can pull away under the intense pressure of a fire, creating a massive weak spot in your fire barrier.

These seemingly minor errors render the door’s fire rating invalid, turning a critical safety investment into a major liability. It's why our team at Wilcox Door Service believes expert installation is the foundation of lasting compliance.

The Critical Annual Drop Test

For rolling and sliding steel fire-rated doors, the annual drop test is the single most important piece of maintenance you can perform. This test is a mandatory requirement under the National Fire Code of Canada and NFPA 80. It’s the only way to verify that the door's automatic closing mechanism works correctly and that the door will close fully under its own power when triggered by a fire alarm or a heat-activated fusible link.

The process simulates an emergency activation to ensure:

- The door comes down smoothly at a controlled, safe speed.

- It achieves a complete and secure closure with no obstructions.

- All related activation systems, like fusible links and smoke detectors, are in good working order.

Having a documented drop test is your proof of compliance for the local Authority Having Jurisdiction (AHJ) or fire marshal. It demonstrates due diligence and confirms your fire protection systems are ready when you need them most.

A Practical Maintenance Checklist for Your Team

While a certified professional needs to handle the annual drop test, your in-house team can perform regular visual inspections to catch problems early. A proactive approach is the best way to maintain safety between professional service visits.

Here is a simple checklist for monthly visual checks:

- Check the Label: Ensure the fire rating label (e.g., ULC) is visible, legible, and hasn't been painted over or damaged.

- Inspect for Damage: Look for any dents, bent sections, or holes in the door or frame that could compromise its integrity.

- Verify Full Closure: Open the door completely and let it go. Does it close and latch entirely on its own, without sticking or binding?

- Examine Hardware: Check that all hinges, handles, and closing devices are present, secure, and in good shape.

- Clear the Area: Make sure nothing is blocking the door's path, like equipment or pallets, that would prevent it from closing.

By making these simple checks part of your routine facility walkthroughs, you can identify potential problems before they become serious safety risks. This proactive mindset is the core of an effective Planned Maintenance Program, keeping you compliant, safe, and always audit-ready.

Ultimately, the integrity of your steel fire-rated doors depends on a partnership between expert technicians and diligent facility staff. To ensure your doors meet all code requirements and are ready to protect your facility, contact Wilcox Door Service today to schedule a professional inspection or drop test.

Navigating Canadian Codes and Total Cost of Ownership

For any facility manager in Canada, staying on the right side of fire codes isn't just a good idea—it's a core responsibility. When it comes to steel fire rated doors, the two key documents you need to know are the National Building Code (NBC) and the National Fire Code (NFC). Think of them as the rulebook for life safety in your building. They aren't just suggestions; they are the law.

- The NBC primarily dictates where fire-rated doors are required. It specifies the fire-resistance rating any door must have based on its location in a fire separation wall.

- The NFC, on the other hand, deals with ongoing care. It governs the inspection, testing, and maintenance of these doors after they're installed to ensure they remain functional over their lifespan.

Beyond Compliance: The Total Cost of Ownership

Meeting code is the baseline, but smart facility management looks at the bigger picture: the total cost of ownership (TCO). A high-quality steel fire-rated door might seem like a bigger investment upfront, but its long-term value is in a completely different league.

This value comes from several key areas:

- Exceptional Durability and Longevity: Steel doors are tough. With proper upkeep, they can provide reliable service for 20 to 30 years or more, easily outlasting less robust options and pushing replacement costs far into the future.

- Reduced Maintenance and Repair Costs: Their inherent strength means they stand up to wear and tear, from accidental forklift bumps at a loading dock to the daily grind of cart traffic in a busy corridor. This translates directly to fewer service calls and smaller repair bills.

- Lower Insurance Premiums: Insurance companies recognize facilities with solid, well-maintained fire protection systems. Having properly certified and regularly inspected fire doors can signal a lower risk profile, potentially leading to better insurance rates.

Simply put, buying a quality steel door isn’t just an expense; it's an investment in the long-term health and resilience of your facility.

Calculating the True Value of a Steel Fire-Rated Door

The real math behind TCO goes beyond the initial purchase price. It’s also about risk. A non-compliant or malfunctioning fire door exposes your facility to massive liabilities.

The true cost of a door isn't just its price tag. It's the cost of failure. A properly specified and maintained steel fire-rated door protects against catastrophic fire spread, prevents costly non-compliance fines from the Authority Having Jurisdiction (AHJ), and, most importantly, safeguards your people.

Managing these long-term expenses is a critical skill for any facility leader. By prioritizing durability and proactive maintenance, you can dramatically improve your financial outcomes. To get a better handle on this strategy, you can explore our guide on reducing the total cost of ownership for your facility's most important assets.

Just as you need to understand fire door rules, it’s also important to be aware of local regulations for other safety systems. For example, learning the specifics of smoke alarm compliance regulations shows how different, yet equally critical, safety components are governed.

Ultimately, choosing high-quality steel fire-rated doors and committing to their maintenance shifts your approach from reactive to proactive. This mindset doesn't just keep you compliant with Canadian codes; it builds a safer, more predictable, and cost-effective operational environment for years to come.

Partnering with an Expert for Fire Door Solutions

Keeping your facility’s steel fire-rated doors compliant and functional is an ongoing mission, not a one-time task. True safety requires a solid plan that covers everything from initial specification to long-term maintenance. Partnering with a specialist like Wilcox Door Service removes the guesswork, ensuring every detail is handled by a professional.

It all starts with a proper consultation. An expert will help you select the right doors for each unique application in your building, carefully balancing code requirements with your operational workflow. This is key to avoiding costly mistakes, like overspending on a door for a low-risk area or—much worse—installing an under-rated door where it’s meant to contain a serious fire hazard.

The Value of Certified Installation and Maintenance

Once you’ve chosen the right product, installation by certified technicians who live and breathe the fire code is non-negotiable. These professionals understand the precise tolerances and specific hardware required for a fire-rated assembly. They ensure your investment performs as designed and its certification is valid from day one.

After installation, a comprehensive Planned Maintenance Program is what guarantees long-term compliance and reliability. This isn't just about fixing things when they break; it's a proactive strategy that includes:

- Scheduled Inspections: Regular, documented check-ups to spot wear and tear long before it becomes a safety hazard.

- Annual Drop Tests: A mandatory requirement for rolling and sliding fire doors, these tests confirm that automatic closing systems will work flawlessly in an emergency.

- Detailed Record-Keeping: Professional documentation that keeps you ready for any audit by the local Authority Having Jurisdiction (AHJ).

This is where our promise of being “Respected Partners, Reliable Service” truly shines. We take on the complexities of fire door management so you can stay focused on running your business.

An effective fire door strategy is a continuous cycle of specification, installation, inspection, and maintenance. If any one of these stages is neglected, the entire system is compromised. You're left exposed to unnecessary risk and potential fines for non-compliance. A dedicated partner ensures that cycle is never broken.

Your Partner in Emergency and Upgrade Planning

Even with the best maintenance plan, unexpected issues can arise. A door gets hit by a forklift or a mechanism suddenly fails. That's when having 24/7 emergency repair services on speed dial is essential to minimize downtime and keep your environment safe. An expert partner can dispatch union-certified technicians to your site quickly to resolve the problem and restore your facility’s protection.

Looking ahead, a long-term partner also helps you plan for the future. As building codes evolve and your facility’s needs change, we can help you map out a phased approach to retrofitting older doors, ensuring your facility remains protected, compliant, and efficient for years to come.

Protect your people and property by ensuring your fire doors meet all safety standards. Contact Wilcox Door Service today to schedule an inspection or request a consultation.

Your Top Questions About Steel Fire Rated Doors

When it comes to facility safety, fire-rated doors are a critical piece of the puzzle. To help you sort through the essentials, we’ve put together answers to some of the most common questions facility managers ask us about steel fire rated doors. These insights are designed to give you clear, practical information to support your compliance and protection decisions.

How Often Should Steel Fire Rated Doors Be Inspected?

According to the National Fire Code of Canada and the NFPA 80 standard, every fire door assembly in your facility must be professionally inspected and tested at least once a year. For any rolling or sliding fire doors, this includes a mandatory annual “drop test” to verify they close automatically as designed.

Keeping detailed, consistent records of these inspections isn't just good practice—it's essential. This documentation is your proof of due diligence for fire marshals and ensures your facility is always audit-ready.

Can I Paint or Modify a Steel Fire Rated Door?

Any modifications to a fire-rated assembly—the door, frame, or hardware—must be handled by certified professionals to maintain its integrity. While you can paint the door, you cannot apply paint so thick that it interferes with proper closure and latching.

The most important rule? The official certification label (e.g., from ULC) must always be visible and legible. Drilling new holes, adding non-rated hardware, or making any unapproved alterations will instantly void the door's safety certification and put your facility at risk.

What Is the Difference Between a Fire Door and a Fire Exit?

It's easy to confuse these terms, and sometimes a single door serves both functions. However, they have distinct primary goals.

- A Fire Door is designed for compartmentalization. Its main job is to contain a fire and block smoke from spreading for a specific amount of time, buying precious minutes for evacuation and emergency response.

- A Fire Exit is a designated part of an egress route. It is engineered to allow people to exit a building quickly and safely during an emergency.

While many fire exit doors (like those in stairwells) are also fire-rated, their primary role is providing a clear path out. This is why they often feature specific hardware, such as panic bars, which are not required on every type of fire door.

Your facility's safety and compliance are too important to leave to chance. At Wilcox Door Service, our union-certified technicians provide expert installation, inspection, and maintenance for all types of steel fire rated doors. As "Respected Partners, Reliable Service," we ensure your facility is always protected and audit-ready.

Ensure your fire doors meet all Canadian safety standards. Contact us today to schedule a professional inspection or drop test.