Choosing the right loading dock repair company is a critical decision that directly impacts your facility’s safety, operational uptime, and the overall efficiency of your supply chain. It’s not about finding a quick fix for a single breakdown; it's about building a partnership with a reliable team that can prevent problems before they start.

In this guide, you will learn how to evaluate a company's technical expertise, verify their safety record, and understand the difference between a reactive vendor and a proactive maintenance partner. We’ll provide practical, real-world examples to help you select a team that ensures your operations run smoothly and safely.

Your Loading Dock Is An Ecosystem, Not Just Equipment

Think of your loading dock as more than just a door and a ramp. It's a complex ecosystem where your entire operation connects with the outside world. This system includes several key components working together: the dock leveler, vehicle restraint, dock seal, and the overhead door itself.

When a single component fails—a stuck leveler, a malfunctioning vehicle restraint, or a torn dock seal—the entire flow of goods can grind to a halt. The consequences ripple through your business, causing shipping delays, missed deadlines, and frustrated partners. Finding the right repair company means finding a team that understands this interconnectedness. As respected partners in the industry, we know that reliable service means looking at the whole system, not just the broken part.

Alt text: A split image showing a truck waiting at a closed loading dock versus a truck actively being loaded at a functional loading dock, representing downtime versus uptime for loading dock repair companies.

For example, a major distribution centre in Mississauga learned this lesson the hard way during their peak holiday season. A hydraulic leak in their main dock leveler seemed like a simple problem. But the first company they called sent a junior technician who didn't have the experience to spot the real issue: an underlying electrical fault that was overworking the hydraulic pump. The result? Two days of crippling downtime during their most profitable quarter.

The True Cost of Downtime

When a dock goes down, the repair bill is often the least of your worries. The real pain comes from a cascade of hidden expenses:

- Lost Productivity: Your team is on the clock but can't move products.

- Detention Fees: Trucks and drivers are stuck waiting, racking up extra charges from logistics partners.

- Supply Chain Disruption: Your delays become your partners' problems, impacting production schedules and retail availability down the line.

- Reputation Damage: Consistently failing to meet shipping deadlines erodes the trust you've built with customers and suppliers.

A single hour of downtime can cost a facility thousands. The right repair partner understands this urgency. They act less like a mechanic and more like a critical part of your operational continuity team, always seeing the bigger picture.

From Reactive Fixes to Proactive Partnerships

The best loading dock repair companies do more than fix what's broken; they help you shift from a reactive to a proactive mindset. Instead of waiting for the next breakdown, a true partner works with you to prevent them from happening in the first place.

They effectively become an extension of your team, offering insights and recommendations that improve the long-term reliability and safety of your operations. This relationship is built on trust, transparency, and the shared goal of keeping your business moving. To see what that commitment looks like from the inside, this service department spotlight on Wilcox Door Service offers valuable context.

Vetting Technical Skills Beyond a Simple Checklist

A service call for a "broken loading dock" is too vague to be useful. Is it a hydraulic leak in the leveler? A bad sensor in the truck restraint? A tear in a dock seal? The best loading dock repair companies dispatch technicians who see your entire loading dock as one interconnected system, not just a collection of parts.

Gauging that level of expertise means you need to dig deeper than a simple checklist. You need to ask sharp questions that reveal a company's technical depth. This is how you separate genuine problem-solvers from part-swappers. A technician who understands how an unbalanced overhead door is straining its motor is infinitely more valuable than one who just replaces the motor without finding the root cause. That deeper insight is what stops recurring problems and saves you from costly, needless repairs.

Alt text: A professional technician from a loading dock repair company performing diagnostic maintenance on a loading dock leveler with specialized tools.

Let's break down the key equipment at your dock and the specific questions you should ask to vet a potential service partner’s expertise.

Evaluating Dock Leveler Expertise

The dock leveler is the bridge between your facility and the trailer, and it's often the most mechanically complex piece of equipment. They come in two main types: mechanical (spring-powered) and hydraulic (fluid-powered), each with unique failure points.

A competent technician must be a hybrid mechanic and electrician, comfortable diagnosing a faulty hydraulic solenoid and safely tensioning a massive mainspring on a mechanical unit.

- Common Failure Points: Worn-out springs and hold-downs in mechanical levelers; hydraulic fluid leaks, motor failures, and control box issues in hydraulic models.

- Insightful Questions to Ask:

- "Can your technicians troubleshoot both electrical control boxes and hydraulic pump systems on the first service call?"

- "Walk me through your process for safely releasing the tension on a mechanical leveler's mainspring during a repair."

- "What diagnostic tools do your teams carry to pinpoint intermittent electrical faults versus hydraulic pressure loss?"

Assessing Knowledge of Vehicle Restraints

A vehicle restraint (or truck lock) is a non-negotiable safety device. It physically locks a trailer to the dock to prevent "trailer creep"—a dangerous situation where the trailer gradually inches away from the dock during loading. Modern restraints are often integrated with the leveler and overhead door controls for safe, sequential operation.

A provider must understand not just the restraint itself, but how it "talks" to the rest of the system.

A technician who can't diagnose a communication fault between the restraint's control panel and the dock door's operator can leave your bay inoperable and unsafe. True expertise means seeing the full electrical and mechanical picture.

Verifying Competency with Dock Seals and Shelters

Dock seals and shelters are your first line of defense for climate control, pest prevention, and energy efficiency. An improperly installed or poorly repaired seal can cost you thousands in heating or cooling losses over time.

Real expertise here is about knowing the right materials for the job (like high-wear fabrics for busy docks), proper installation techniques, and how to repair damage without compromising the unit's integrity.

- Common Failure Points: Rips from trailer impacts, compression foam that has lost its shape, and worn-out wear pleats.

- Insightful Questions to Ask:

- "How do you determine the correct projection and size of a dock seal for our specific trailer types and dock height?"

- "What is your approach to repairing a major tear versus recommending a full replacement to guarantee long-term energy savings?"

Understanding High-Performance Commercial Doors

The loading dock doors are the gatekeepers to your facility. From standard sectional doors to high-speed fabric models, each has unique repair needs. A broken torsion spring on a sectional door is a world away from a faulty sensor on a high-speed roll-up door. A versatile repair partner should be cross-trained on different models. For example, a deep understanding of critical safety procedures like fire door testing and maintenance is a strong indicator of a company’s commitment to safety and compliance.

Putting It All Together: A Technical Capability Checklist

An organized checklist helps you make an apples-to-apples comparison of potential loading dock repair companies based on the skills that matter to your operation.

Technical Capability Checklist for Repair Partners

| Equipment Type | Key Repair Competencies to Verify | Questions to Ask Potential Vendors |

|---|---|---|

| Dock Levelers | Hydraulic and mechanical system diagnosis; electrical troubleshooting; welding and fabrication for structural repairs. | "Are your technicians certified to perform on-site welding for leveler deck repairs?" |

| Vehicle Restraints | Experience with integrated control systems; knowledge of both mechanical and powered restraint mechanisms. | "Describe your process for integrating a modern restraint system with our existing dock levelers and doors." |

| Dock Seals/Shelters | Understanding of material types, proper installation for effective sealing, and repair techniques for different fabrics. | "How do you assess a seal for energy loss, and what are your recommendations for improving it?" |

| Commercial Doors | Expertise with torsion springs, operators, track alignment, and sensors for various door types (sectional, rolling, high-speed). | "What is your typical inventory of common door parts, like springs and rollers, on your service vehicles?" |

By asking these targeted questions, you push past generic "we fix loading docks" claims to get real proof of a company's expertise. To see how these pieces come together in the real world, check out our projects and case studies for valuable insights.

Understanding Safety Certifications and Compliance

At a busy loading dock, safety is a non-negotiable requirement. When you partner with a loading dock repair company, you are entrusting them with the well-being of your team and the integrity of your facility.

This is where certifications and a documented commitment to compliance separate the true professionals. These credentials are proof that a company invests in ongoing training, follows strict safety protocols, and can protect you from significant liability. A technician's qualifications directly reflect their employer's commitment to being a reliable partner.

Alt text: An image representing safety compliance for loading dock repair companies, featuring a hard hat, checklist, and fire door icon to highlight workplace safety.

Why Certifications Matter More Than You Think

A certification signifies that a technician has undergone rigorous, standardized training. This is critical at the loading dock, an area where 25% of all industrial accidents occur. High worker turnover and the constant pressure of busy operations only increase this risk. Having certified professionals perform proactive maintenance can slash unplanned downtime by up to 50%, boosting both productivity and safety.

Here are key credentials to look for:

- Union Certification: This is a strong indicator of a well-trained, professional workforce. It means technicians have completed extensive apprenticeship programs covering electrical systems, mechanical repairs, and job site safety protocols.

- Manufacturer-Specific Training: Certifications from equipment manufacturers confirm that technicians are experts on your specific models. They know the common failure points and use the correct OEM parts for repairs.

- Workplace Safety Certifications: Credentials related to fall protection, confined space entry, and electrical safety show a company’s commitment to protecting their employees—and yours—on your property.

The Critical Role of Fire Door Compliance

One of the most critical areas of compliance is fire door maintenance. A rolling fire door is a life-saving device designed to automatically close during a fire to prevent its spread. For it to work, it must be regularly inspected, tested, and maintained by a certified professional.

A certified fire door drop test is a documented procedure where a technician ensures the door closes correctly at the proper speed when triggered. Failing to perform and document this annual test is not just a safety risk—it can lead to massive fines, voided insurance claims, and catastrophic liability.

A warehouse in the Greater Toronto Area once failed a fire marshal inspection because they couldn't produce records of their fire door tests. The repair company they used wasn't certified for this specific work, leaving the facility non-compliant. The cost of the emergency certification and fines far exceeded what a proper planned maintenance program would have cost.

Verifying a Company's Safety Program

How do you confirm a potential partner walks the talk on safety? Ask direct questions and request documentation.

A reputable company should be able to provide clear answers to these questions:

- Can you provide documentation of your corporate safety program? Look for established policies on personal protective equipment (PPE) and job site hazard analysis.

- Are your technicians certified for fire door drop testing? Ask to see proof. A simple "yes" isn’t enough when compliance is on the line.

- What is your procedure for ensuring site safety before work begins? A professional team will always start with a safety briefing and secure the work area. Understanding these fundamentals is key, which is why we’ve detailed essential practices in our guide to Lock Out/Tag Out safety.

Choosing a partner with a robust, verifiable commitment to safety is a strategic decision. It protects your employees, shields your business from liability, and ensures work is performed to the highest standard. It is the cornerstone of a reliable service partnership.

Comparing Emergency Response with Proactive Maintenance

When a loading dock goes down, every minute of stalled operations translates into lost revenue. In those moments, all that matters is how fast a qualified technician can get on-site.

However, relying only on emergency repairs is a reactive and costly strategy. The alternative is a proactive approach centered on a Planned Maintenance Program (PMP). This shifts the focus from fixing what’s broken to preventing it from breaking in the first place. This commitment to being respected partners who provide reliable service is what sets exceptional companies apart.

Let's break down the two strategies to see how proactive maintenance delivers a greater return on investment through less downtime, better safety, and a longer life for your equipment.

The Reality of Emergency Repairs

A true 24/7 emergency service commitment means having the capacity to dispatch a fully-equipped service vehicle and a certified technician to your facility within a 2-4 hour window.

This rapid response is critical for stopping the immediate financial bleed from a shutdown. However, emergency calls are always more expensive due to overtime labour and urgent parts sourcing. More importantly, they don’t address the root cause of the failure, leaving you vulnerable to the next breakdown.

The Business Case for Proactive Maintenance

A well-structured Planned Maintenance Program is your best defense against unexpected failures. It involves regularly scheduled inspections, adjustments, lubrication, and minor repairs by a qualified technician who knows your specific equipment.

The benefits go far beyond just avoiding breakdowns:

- Reduced Downtime: Catching wear and tear before it leads to catastrophic failure can prevent the vast majority of surprise shutdowns.

- Longer Equipment Life: Regular lubrication and adjustments reduce stress on critical components like motors and pumps, significantly extending their operational lifespan.

- Improved Safety: Proactive checks ensure safety features like vehicle restraints and fire doors are always working correctly, protecting your team and keeping you compliant.

- Predictable Budgeting: A PMP allows you to budget for maintenance as a predictable operational expense instead of facing large, unexpected repair bills.

The total cost of ownership for a facility running reactively is almost always higher than for one with a PMP. The savings from preventing just one major failure can often pay for the entire annual cost of the maintenance program.

Key Elements of a Valuable PMP

Not all maintenance programs are equal. A valuable PMP from a respected partner should include:

- Detailed Inspection Checklists: A comprehensive checklist for each piece of equipment ensures nothing is overlooked.

- Transparent Reporting: After each visit, you should receive a detailed report outlining the work performed, the condition of your equipment, and any recommendations.

- Priority Service: PMP customers often get priority scheduling for emergency calls.

- Expert Technicians: The program should be carried out by union-certified technicians trained to service a wide range of equipment.

The logistics and e-commerce boom in Canada has made this proactive approach more critical than ever. The North American market, valued at USD 244.88 million, is projected to grow, and in this competitive environment, companies that use planned maintenance can cut unplanned repairs by up to 50%.

The principles behind proactive care are universal. You can find helpful insights into preventive and corrective maintenance strategies from other technical fields that parallel the approaches for loading docks. The same logic applies to other critical access points; for example, a structured approach to maintenance on commercial garage doors is just as important. Ultimately, choosing proactive maintenance is a choice for long-term reliability over short-term fixes.

Making Your Final Decision with a Practical Vetting Guide

You have a shortlist of potential loading dock repair companies. Now it's time to find a true partner, not just another vendor. This isn't about price comparison; it's about understanding their problem-solving culture, how they react under pressure, and whether they are committed to a long-term relationship.

This final stage is where you review their Service Level Agreements (SLAs), confirm their insurance, and ask tough questions that go beyond a simple "yes" or "no." A company’s ability to clearly walk you through their processes reveals their professionalism and commitment.

Decoding Service Contracts and SLAs

A Service Level Agreement (SLA) is the rulebook for your partnership. It sets clear expectations for everything from response times to reporting. Don't just skim it—read every line.

Look for crystal-clear definitions. For example, what does "emergency response time" really mean? Does the clock start when you hang up the phone or when a technician is dispatched? A well-crafted SLA is specific and leaves no room for misunderstandings during a crisis.

A good SLA is a mutual promise. It guarantees you a certain level of service and protects the provider by defining the scope of work. If a company is hesitant to provide a detailed SLA, that’s a major red flag.

Verifying Insurance and Parts Inventory

Before any technician steps into your facility, you must verify the company's insurance and liability coverage. Ask for their certificate of insurance and ensure the coverage limits are high enough for your operation. This simple step protects your business from significant liability if an accident occurs.

Equally important is their parts inventory. A service vehicle stocked with common parts means a higher chance of a first-call fix. A company with a deep inventory of OEM (Original Equipment Manufacturer) parts for equipment like dock levelers and restraints is better prepared to solve your problem without delay.

The growth of Canada's logistics sector drives this point home. As a key part of the North American loading dock equipment market, which reached USD 244.88 million in sales, the demands of e-commerce and manufacturing require repair partners with significant inventory and expertise. You can find more insights on the loading dock equipment market on cognitivemarketresearch.com.

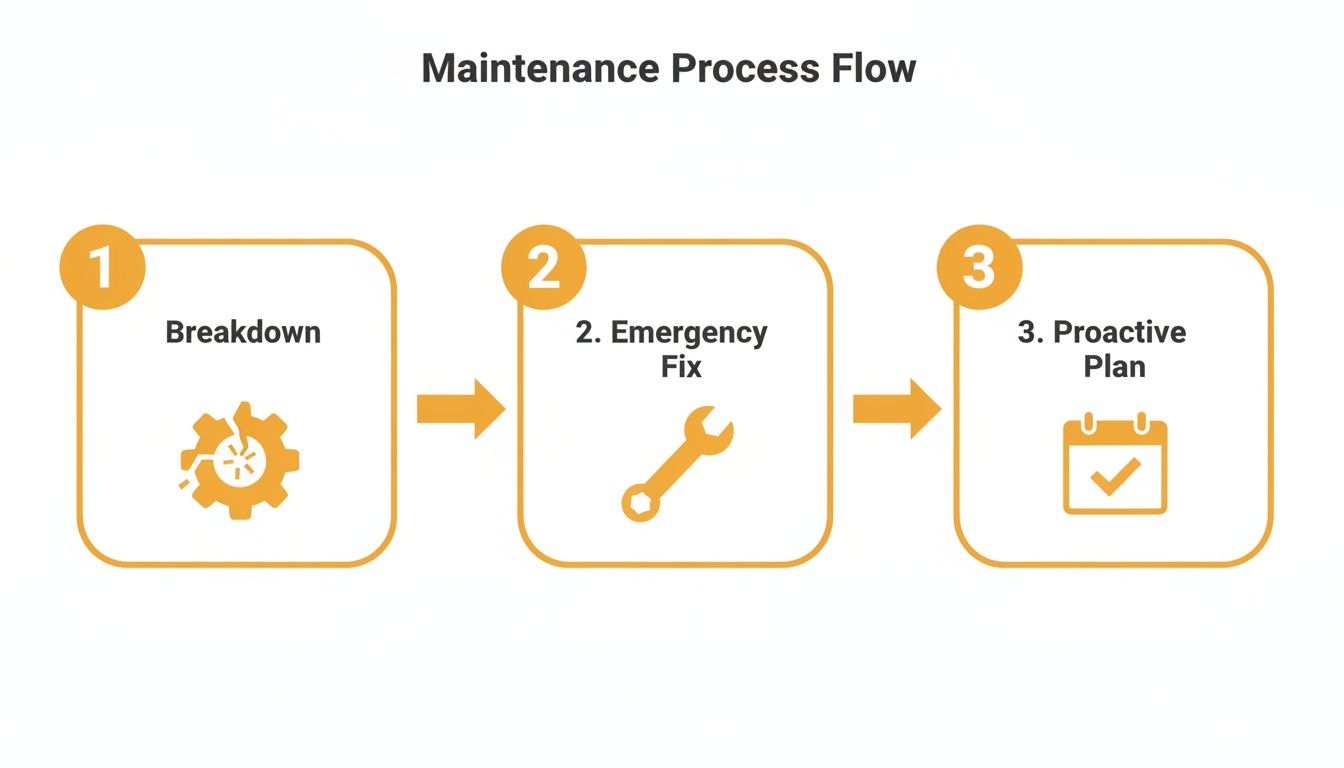

This flow chart shows the ideal maintenance journey, moving from crisis mode to a stable, proactive strategy.

Alt text: A flowchart showing the transition from reactive breakdown and emergency fix to a proactive planned maintenance strategy, a service offered by top loading dock repair companies.

Moving from emergency fixes to a proactive plan is how a true partner helps you escape the expensive cycle of reacting to breakdowns.

Insightful Questions for Your Final Interview

It’s time to talk to your final candidates. These questions are designed to get past the sales pitch and see how they solve problems.

-

Problem-Solving & Experience:

- "Walk me through a time you helped a client solve a recurring equipment issue. What was the root cause, and how did you fix it permanently?"

- "How do your technicians handle a repair when the necessary part isn't on their truck? What is your process?"

-

Communication & Transparency:

- "What is your standard procedure for keeping us informed during a complex, multi-day repair?"

- "How do you document the work your team performs, and what kind of reports can we expect after a service call?"

-

Partnership Potential:

- "Beyond fixing what's broken, what advice can you offer to help us make our loading docks safer and more efficient?"

- "How do you keep your technicians trained on new equipment and evolving safety standards?"

Choosing the right partner is the most important step. Once you've found a company that aligns with your values, the best way to start the relationship is with a comprehensive facility assessment. Contact Wilcox Door Service today to schedule a site evaluation and begin building a proactive maintenance strategy together.

Your Top Questions About Choosing a Loading Dock Partner

Choosing the right company for your loading dock repairs is a major decision, and it’s smart to have questions about cost, parts, and long-term value. Here are straightforward answers to common questions from facility managers.

How Much Should I Budget for a Planned Maintenance Program?

The honest answer is: it depends. The right budget hinges on the number of dock positions, the age and condition of your equipment, and your operational intensity. A reputable service provider should offer a no-cost site assessment to provide a precise quote tailored to your facility.

However, a good rule of thumb is that the annual cost of a solid maintenance program is typically a fraction of what you'd pay for a single emergency call-out and the associated downtime.

An effective maintenance program is an investment, not an expense. It often pays for itself by preventing just one or two major equipment failures, making it one of the best cost-control tools available.

What Is the Difference Between OEM and Aftermarket Parts?

This is a critical point that directly impacts the safety and lifespan of your equipment.

- OEM (Original Equipment Manufacturer) parts are made by the same company that built your equipment. They guarantee a perfect fit, intended performance, and adherence to original safety standards.

- Aftermarket parts are made by third-party companies. While they might seem cheaper, their quality can be inconsistent, potentially compromising the durability and safe operation of your systems.

For critical safety components like the locking mechanisms in your vehicle restraints or the mainsprings in a leveler, we always recommend sticking with OEM parts. It's the only way to ensure maximum reliability and keep manufacturer warranties intact.

Can One Company Service My Mix of Old and New Equipment?

Absolutely. In fact, finding a company that can handle a diverse portfolio of equipment should be a non-negotiable. The best providers have technicians with extensive cross-brand training and a wide network for sourcing parts, whether for an old mechanical system or the latest hydraulic equipment.

Companies with a long history often possess invaluable "tribal knowledge" for servicing older equipment while also being certified on the newest technologies. This gives you a single, reliable partner for your entire facility, simplifying maintenance and ensuring consistent, high-quality service on everything from your docks to your commercial doors.

Your loading docks are the heart of your operation. Choosing the right partner to keep them running is one of the most important decisions you'll make. If you’re ready to shift from reactive fixes to a proactive strategy that boosts safety and reduces downtime, the team at Wilcox Door Service Inc. is here to help. As respected partners providing reliable service, we are committed to your success.